21 Sep MgO Board Use For Fire Resistant Interior Wall Panels

Table of Contents

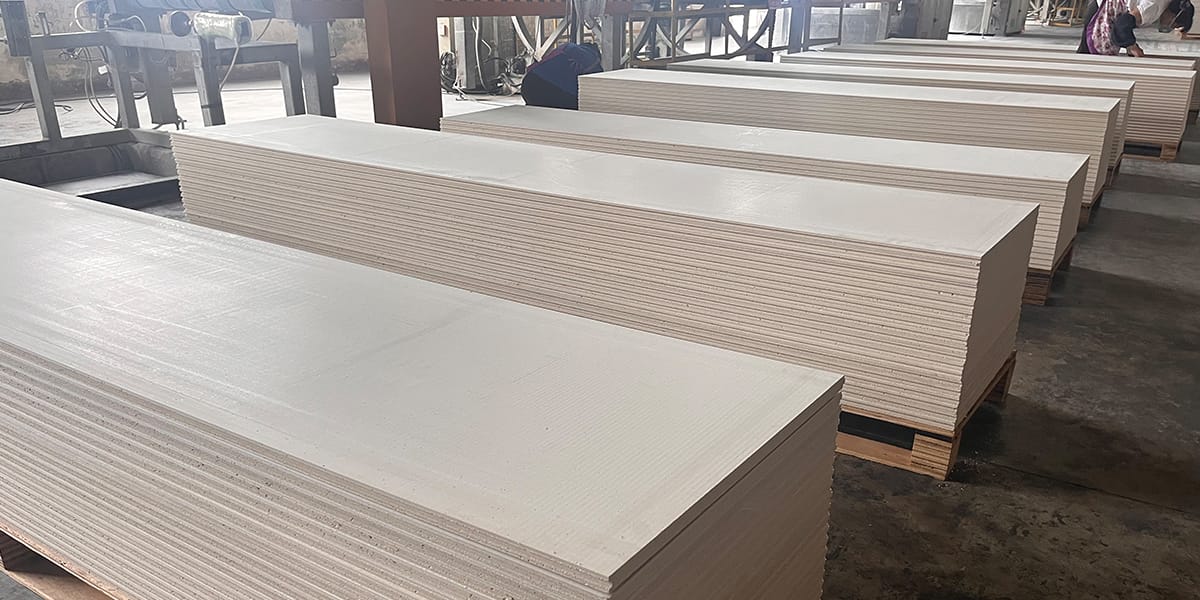

If you want the best fire safety, MgO boards are a good choice for inside wall panels. Architects and builders select materials that slow down flames, smoke, and harmful gases. MgO boards are special because they are fire resistant and do not burn. They remain strong when wet and also prevent mold and pests.

MgO boards help buildings comply with strict regulations. They provide a sense of security in homes, schools, and hospitals.

Unique Feature | Benefit |

|---|---|

Fire Resistant | Does not burn, high fire ratings up to 4 hours |

Moisture Resistance | No water gets in, stays strong when it is wet |

Eco-Friendly | Made from natural materials, no harmful chemicals |

Key Takeaways

MgO boards stop fire and do not burn. They protect for up to 4 hours.

These boards do not get damaged by water or mold. They work well in wet places like bathrooms and kitchens.

MgO boards are good for the environment. They use natural materials and do not let out bad chemicals.

Using MgO boards makes buildings safer. People have more time to get out if there is a fire.

MgO boards are easy to take care of. They stay strong for a long time and help you spend less on fixing things.

Effectiveness

Fire Resistant Performance

You want wall panels that stand up to fire and keep your building safe. MgO boards do not burn, even when exposed to very high temperatures. These panels stay strong up to 780°C (1436°F), which means they will not fail quickly during a fire. Most MgO boards pass strict tests like ASTM E136, which checks if materials can handle heat up to 750°C.

MgO boards earn top marks for fire resistant performance. They receive a Class A rating and withstand temperatures up to 1472°F (800°C).

Here is a table that shows how MgO boards compare to other wall panel materials in fire tests:

Board Type | Flame Spread Index (FSI) | EN 13501-1 Rating | Additional Fire Performance Details |

|---|---|---|---|

Magnesium Sulfate (MgO) | 0 to 25 | A1 (Non-combustible) | Handles heat up to 1200°C; ASTM E84 FSI 0; Smoke Developed Index low; Passes ASTM E136 non-combustibility test |

Gypsum Boards | Moderate (varies by type) | Class A to C | Fire resistance up to 4 hours (Type X, Type C); Moderate flame spread; ASTM E84 tested but lower than MgO boards |

Cement Boards | Lower fire resistance | Lower than MgO | Less effective fire resistance compared to MgO boards |

MgO boards also maintain their shape and strength during a fire. You will notice little warping or discoloration. They produce very little smoke, which helps keep people safe.

Limiting Fire Spread

You need wall panels that stop fire from moving from room to room. MgO boards do this better than most other materials. They do not burn and block flames, so fire cannot travel easily through them.

MgO boards are non-combustible and can handle extreme heat without losing strength.

Gypsum boards may lose their fire resistant qualities when exposed to high heat.

MgO boards keep their structure at temperatures over 1,000°F for more than two hours.

MgO boards have earned independent fire ratings. Many panels achieve 1 to 4-hour fire resistance in tests like ASTM E119. This means you get more time to escape or for firefighters to respond.

Board Type | Fire Resistance Rating Achieved | Relevant Standards and Notes |

|---|---|---|

Magnesium Sulfate Board | 1 to 4 hours | Tested under ASTM E119; Class A fire rating under ASTM E84; certified under EN ISO 1716 and EN 13501 |

Magnesium Oxide Board | 30 minutes | Full-scale fire tests on light gauge steel frame walls; failure due to board cracking or joint opening |

Tip: When you choose MgO boards for your interior walls, you help slow down the spread of fire and protect everyone inside.

What Is MgO Board

Composition

Composition

MgO board means magnesium oxide board. This material uses minerals from nature and special extras to make a strong panel. The main part is magnesium oxide. It comes from the ground and makes the board tough and fire resistant. Makers add other things to improve the board for building use.

Magnesium Oxide (MgO) is the base. It gives fire resistance and strength.

Magnesium Chloride (MgCl₂) is a binder. It holds the board together and keeps it solid.

Glass fibers make the board stronger. They help stop cracks.

Silica and clay help the board handle heat. They make it resist flames better.

Water mixes all the parts. It helps form a thick, solid panel.

This board does not burn. It stays strong in heat and keeps out water. The mix of minerals and fibers helps MgO boards work well inside buildings.

Note: MgO boards do not have harmful chemicals. You can use them in homes, schools, and hospitals safely.

Comparison to Other Panels

If you look at MgO boards and other wall panels, you see big differences in fire safety. Here is a table to show you:

Board Type | Fire Resistance Properties |

|---|---|

MgO Board | Great fire resistance, does not burn, handles high heat for fire-rated jobs. |

Gypsum Board | Some fire resistance, but not as good. Needs more layers for better ratings. |

Cement Board | Good fire resistance, but may need coatings. Not as safe as MgO for fire. |

Fiber Cement | Does not burn, but often needs coatings for best fire safety. |

MgO boards are special because they do not burn and can take heat up to 1200°C. Even in a fire, they keep their shape and do not make much smoke or bad fumes. Gypsum and cement boards may need extra layers or treatments to get close to MgO’s fire rating. MgO boards pass tough tests like ASTM E119 and EN 13501-1. This makes them a top pick for fire safety.

Tip: If you want the best safety for your building, MgO boards give better fire resistance than most other wall panels.

Fire Resistant Properties

Fire Resistant Ratings

MgO boards get high fire safety ratings. Trusted groups test these panels. They check how well MgO boards stand up to fire and heat.

Standard | Rating | Description |

|---|---|---|

EN 13501-1 | Shows MgO boards do not help fires grow. | |

BS 476 Part 4 | N/A | Proves MgO boards do not burn. |

UL Two-Hour Fire Rating | 2 hours | MgO boards stay strong for two hours in fire. |

MgO boards pass tough tests like ASTM E136 and CAN/ULC S114. These tests show MgO boards do not burn or spread flames. MgO boards do not make harmful gases when they get hot.

MgO boards get the top fire rating of A1 under the Chinese GB 8624 standard. This matches the EN 13501-1 rating in Europe. Some MgO boards can stop fire for 90 minutes or even 4 hours, depending on the type.

Here are some certifications MgO boards meet:

Certification | What It Tests | Fire Rating Type |

|---|---|---|

EN 13501-1 | Noncombustible | |

CAN/ULC S114 | Fire performance | Noncombustible |

ASTM E136 | Noncombustibility | Noncombustible |

ASTM E84 | Fire spread | Class A, B, C |

You can trust these ratings when you pick MgO boards for walls.

Real-World Use

MgO boards work well in real fires. Builders use them in places where fire safety is important. You see MgO boards in homes, schools, hospitals, and busy offices. These buildings need strong walls to protect people.

Residential buildings

Educational institutions (schools and universities)

Hospitals and busy workplaces

MgO boards do not burn. They help stop fire from spreading. They stay strong in high heat. This gives people more time to get out if there is a fire. MgO boards do not make dangerous smoke or gases.

Material | Heat Resistance | Duration in Fire | Non-combustibility | Environmental Safety |

|---|---|---|---|---|

MgO Boards | 4 hours | A1 non-combustible | No harmful gases | |

Plywood/OSB | Weakens quickly | Less than 1 hour | Combustible | Releases harmful gases |

In 2014, a hotel in Los Angeles had a big fire during construction. Workers used MgO boards for walls and ceilings. After the fire, the boards kept their shape. They stopped flames from moving to other parts of the building. Firefighters said MgO panels helped slow the fire and protected the building.

MgO boards give real protection in emergencies. They help keep people safe and calm.

Additional Benefits

Durability

Durability

You want wall panels that last a long time. MgO boards are strong and do not need many repairs. These panels resist water, bugs, and fire. They stay in good shape for many years. You do not have to use extra chemicals or coatings. This saves you time and money. MgO boards keep their shape. They do not bend or get smaller. Your walls look nice and stay tough.

You should check your walls sometimes for cracks or damage. MgO boards do not need much care most of the time.

Maintenance Aspect | Description |

|---|---|

Durability | Stays strong against water, bugs, and fire for many years. |

Low Maintenance | No need for extra coatings or chemicals. |

Mold and Mildew Resistance | Less cleaning needed, better air inside. |

Dimensional Stability | No bending or shrinking, keeps its shape. |

Regular Inspection | Look for cracks or mold to keep walls good. |

Moisture and Mold Resistance

Mold is a problem in wet places like bathrooms. MgO boards help stop this problem. They do not soak up water. They never swell or bend. In tests, over 1,000 MgO boards stayed dry and strong for more than two years. You can use them in wet rooms.

MgO boards stop mold from growing, even in damp rooms.

The high alkalinity of MgO makes it hard for mold to live.

You get a safer and healthier place to live or work.

Property | MgO Boards | Drywall | Cement Boards | Plywood/OSB |

|---|---|---|---|---|

Fully waterproof; does not soak up water or swell | Soaks up water easily, bends and swells | Resists water, but can still soak up some | Soaks up water fast, bends and swells | |

Prevention of Mold, Mildew, and Water Seepage | Stops mold and mildew because of high alkalinity | Gets mold and mildew in wet places | Resists mold but not fully safe | Gets mold and mildew in damp places |

Eco-Friendly Features

You want to help the planet. MgO boards are good for the environment. They do not let out bad chemicals into the air. You can use them in hospitals, schools, and homes safely. MgO boards help keep rooms at a steady temperature. They also make less dust when you fix them.

Certification | Description |

|---|---|

CE | Meets European safety rules |

ISO | Follows world safety and quality rules |

INTERTEK | Shows product safety and quality |

MgO boards make less pollution when made. They release only 70 kg of CO2 per ton, much less than cement. When you finish using them, you can recycle MgO boards. Workers collect, clean, and grind them to make new boards. This helps cut down on waste and keeps the planet clean.

If you pick MgO boards, you help make homes healthier and the world greener. 🌱

MgO boards are a great pick for fire resistant walls. They give strong safety, last a long time, and are good for the earth. The table below explains why builders like MgO boards:

Feature | Why It Matters |

|---|---|

Made from non-flammable materials | Makes buildings safer and helps the environment |

High fire resistance and non-combustibility | Good for homes, schools, and businesses |

Better protection against fire hazards | Helps keep people and things safe |

You might pay more at first or find it harder to install. But the safety and how well they work make MgO boards a smart choice for your next job.

FAQ

What makes MgO boards better than drywall for fire resistance?

MgO boards do not burn. You get more time to escape during a fire. Drywall can break down faster in high heat. MgO boards also make less smoke and keep their shape.

Can you use MgO boards in bathrooms or kitchens?

Yes, you can use MgO boards in wet areas. They do not soak up water or swell. You will not see mold or mildew grow on them. This keeps your bathroom or kitchen safer and cleaner.

Are MgO boards safe for people with allergies?

You can trust MgO boards for healthy air. They do not release harmful chemicals or dust. People with allergies or asthma can breathe easier in rooms with MgO walls.

How do you install MgO boards?

You can cut MgO boards with standard tools. Use screws or nails to attach them to wall studs. Always follow the manufacturer’s instructions for best results.

Composition

Composition Durability

Durability