25 Aug How To Maintain Fire Resistance Of Magnesium Wall Board After Cutting

Table of Contents

- 1 Key Takeaways

- 2 Cutting and Preparation

- 3 Edge Sealing Methods

- 4 Maintaining Fire Resistance

- 5 Mistakes to Avoid

- 6 FAQ

- 6.1 How soon should you seal cut edges after cutting magnesium wall boards?

- 6.2 Can you use regular caulk or paint on magnesium wall boards?

- 6.3 What happens if you skip edge sealing?

- 6.4 How do you check if your wall still has fire resistance?

- 6.5 Do you need special tools to cut magnesium wall boards?

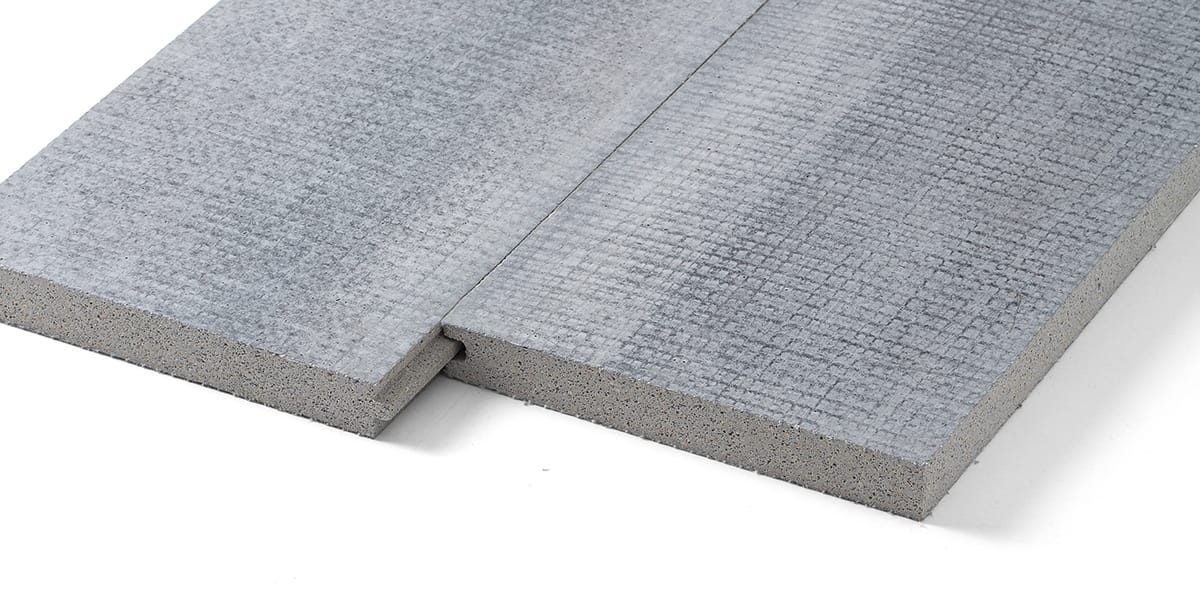

You must protect the cut edges of magnesium wall boards. This helps keep their fire resistance strong. Water can harm these boards fast after cutting. Safety reports say water causes chemical breakdown. This makes the boards weak and less able to stop fire. Always use tools made for magnesium wall boards. Use materials made for magnesium wall boards too. If you make mistakes or use wrong products, water can get in. Water can cause mold, corrosion, and board failure. Many building codes say you must seal joints. You must use fireproof materials at seams.

Key Takeaways

Always seal the cut edges right away. This keeps water out and helps fire resistance stay strong.

Use the correct tools like carbide-tipped saws and utility knives. These tools make clean cuts and do not hurt the board.

Clean and smooth the edges before you seal them. This helps the sealer stick better. It also protects the board from water and fire.

Put fire-resistant caulk on all joints and seams. This stops fire, smoke, and water from getting into the wall.

Check your boards often for cracks, wet spots, or rusted fasteners. Fix any problems fast to keep fire resistance strong.

Cutting and Preparation

Tools for Clean Cuts

You need the right tools to cut magnesium wall boards. Using the correct tools helps you keep the board strong and safe. If you use the wrong tool, you can damage the board and lower its fire resistance.

Use a utility knife with a straightedge to score the board deeply. Do not cut all the way through at once.

Snap the board along the scored line for a clean break.

For bigger cuts, use a circular saw with a fine-tooth carbide blade made for cement boards.

For round or odd shapes, try a Roto Zip or Dremel with a carbide-tipped bit.

Always wear safety glasses, dust masks, and gloves.

Work in a space with good airflow to avoid breathing in dust.

Smooth any rough edges with a sanding block.

Tip: Reinforce corners with adhesives after cutting. This helps prevent cracks and keeps the board strong.

Edge Cleaning

After you cut the board, you must clean the edges. Clean edges help sealers stick better and protect the board from water and fire.

Sand the cut edges with 120, then 180, and finally 220 grit sandpaper. This makes the edge smooth.

Draw a pencil line on the edge. Sand until the line disappears. This helps you sand evenly.

Wipe the edge clean and check for rough spots.

Lightly spray water on the edge and let it dry.

Sand again with fine sandpaper to remove any raised fibers.

Clean and smooth edges help you keep the fire resistance of the board. Always prepare the edges before you seal them.

Edge Sealing Methods

Edge Sealer Application

Edge Sealer Application

You need to seal the cut edges of magnesium wall boards right after you finish cutting and cleaning. High-quality edge sealers or primers made for MgO boards work best. These products protect the exposed edges from water and keep the board strong against fire.

Choose a sealer or primer that matches the brand of your magnesium wall board.

Use a small brush or roller to apply the sealer. Cover the entire edge with a thin, even layer.

Let the sealer dry fully before you move the board or install it.

Check the label for drying times and safety tips.

Note: If you skip sealing, water can get into the board. Over time, this causes cracks, warping, and weak spots. Damaged boards lose their fire resistance and may need repairs sooner.

Here are some problems that happen when you do not seal the edges properly:

Moisture gets inside the board.

Cracks and bends form over time.

Fasteners start to rust and break.

The board becomes weaker and may not stop fire as well.

You might need to fix or replace the board much sooner.

You keep the board strong and safe when you seal the edges the right way.

Fire-Resistant Caulk

You must seal all joints and seams with fire-resistant caulk. This step blocks fire and smoke from moving through gaps. Caulk also keeps water out, which helps the board last longer.

Pick a caulk that says “fire-resistant” on the label. Make sure it works with magnesium wall boards.

Cut the tip of the caulk tube at an angle. Use a caulk gun to fill every joint and seam.

Smooth the caulk with a wet finger or a caulk tool. Make sure there are no gaps or holes.

Let the caulk dry before you paint or cover the wall.

Tip: Keep the boards dry before and after sealing. Wet boards do not hold sealers or caulk well. Store boards off the ground and away from rain or leaks.

You can see how magnesium wall boards compare to gypsum boards in the table below. Proper sealing helps magnesium boards keep their fire resistance even after cutting.

Criteria | Magnesium Sulfate Boards (MgO) | Gypsum Boards |

|---|---|---|

Fire Resistance Rating | Rated A1 Non-Combustible; withstands up to 1200°C; maintains strength during fire exposure including after cutting and sealing with proper installation | Fire-resistant up to 1 hour; softens under heat; lower endurance |

Flame Spread | Low flame spread, slows fire movement | Moderate flame spread, fire spreads more |

Heat Resistance | High; stays strong in extreme heat | Medium; weakens with prolonged heat exposure |

Smoke and Toxic Gas Emissions | Low emissions; little smoke, no toxic gases | Moderate emissions; releases non-toxic gases |

Fire Endurance | Very high; some designs maintain integrity during 2-hour fire tests (e.g., UL G575) | Limited; protects 30-60 minutes |

Installation Considerations | Requires cutting with carbide-tipped saws and sealing edges with fireproof caulking to maintain fire safety | Easier to cut and install; fire-rated types require specific layering |

You protect your building and keep people safe when you seal edges and joints the right way. Always follow the instructions for sealers and caulk. Check your boards often for signs of water or damage. Good sealing keeps fire resistance strong for years.

Maintaining Fire Resistance

Joint Compounds and Tapes

Joint Compounds and Tapes

You need to use the right joint compounds and tapes to keep the fire resistance of magnesium wall boards strong. When you finish cutting and sealing, fill the seams and joints with flexible fillers. For most rooms, you can use gypsum-based fillers with polymer additives like KNAUF FUGENFULLER or SEMIN SE-78. In humid places, pick polymer-cement fillers such as Snezhka’s ACRYL-PUTZ FD12. If your space has big changes in temperature or humidity, elastic putties like Fibrelastic work best.

Fill gaps with Manus-Bond 75-AM for extra flexibility.

Embed 6-inch fiberglass tape into a joint compound like RapidSet “Wunderfixx.”

Feather the compound 12-18 inches past the seam. Sand it lightly while damp for a smooth finish.

Apply a final coat with a high-quality compound such as Murco Wall M-100. Feather it out wider for better coverage.

Keep the room at a steady temperature and humidity during finishing. This helps prevent cracks.

Tip: Always sand, prime, and paint the joints after finishing. This protects the seams and keeps the fire resistance strong.

Fire Resistance Checks

You must inspect your magnesium wall boards often to make sure they stay fire-resistant. Look for signs of moisture, damage, or cracks. If you see rust on fasteners or gaps in seams, fix them right away. Overtightening screws can crush or crack the board. This weakens the holding power and lowers fire resistance. Tighten screws only until they sit flush with the surface. Use corrosion-resistant fasteners to stop rust and keep the board strong.

Check seams and joints for cracks or gaps.

Look for moisture stains or soft spots.

Make sure screws are flush and not breaking the surface.

Replace any rusted or damaged fasteners.

Note: Magnesium chloride moisture can cause corrosion in metal fasteners. This weakens the attachment and can lead to loss of fire resistance over time.

Regular checks and careful installation help you keep your magnesium wall boards safe and fire-resistant for years.

Mistakes to Avoid

Wrong Materials

You can lose fire resistance if you use the wrong products on magnesium wall boards. Many people make mistakes by choosing sealants or caulks that are not rated for fire protection. Some use regular paint or joint compound that does not block moisture. These errors can let water get inside the board and weaken it. Always check the label before you buy any product. Look for words like “fire-resistant” or “compatible with MgO boards.” If you skip this step, you risk damaging the board and making your wall unsafe.

Here are common mistakes with materials:

Using non-rated sealants or caulks

Skipping edge sealing or using incomplete coverage

Applying regular paint instead of fire-resistant coatings

Choosing joint compounds that do not protect against moisture

Tip: Store magnesium oxide boards in a dry, flat area on raised supports. This keeps them safe from water before you install them.

Poor Installation

Poor installation can ruin the fire resistance of your wall. If you do not clean and seal the edges after cutting, water can get in and cause cracks. Overtightening screws can crush the board and make it weak. You should always sand rough edges and reinforce corners with construction adhesive. This helps prevent micro-cracking and keeps the board strong.

Follow these steps to avoid installation mistakes:

Acclimate boards in the room for at least 48 hours before you install them.

Sand and clean all cut edges before sealing.

Use fire-resistant caulk at every joint and seam.

Tighten screws only until they sit flush with the surface.

Inspect joints and seams often for gaps or damage.

Finish and seal the boards fully to block moisture.

If you expose magnesium wall boards to water or skip sealing, you risk mold, warping, and loss of fire resistance. Always finish the job with care and check your work.

Mistake | Risk to Fire Resistance | How to Prevent |

|---|---|---|

Wrong sealant | Weakens board | Use fire-rated products |

Skipped edge prep | Lets water in | Sand and seal all edges |

Overtightened screws | Cracks board | Tighten screws just flush |

Incomplete coverage | Reduces protection | Seal every joint and seam |

You can keep magnesium wall boards safe by doing a few things. Always seal the cut edges right after cutting. Use only fire-rated products for sealing and filling seams. Check your work often to make sure everything is sealed well. Groups like ASTM and ULC have rules for fire resistance. These rules help you know if your boards are safe.

Certification Body / Standard | Purpose / What It Tests | Fire Resistance Aspect |

|---|---|---|

Checks if materials will not burn | Noncombustibility | |

ASTM E84 | Measures how fast fire spreads on surfaces | Class A, B, C fire ratings |

EN 13501-1 | Sorts fire behavior into classes | Class A1 noncombustible |

CAN/ULC S114, ULC S135 | Tests how well walls resist fire | Fire-rated walls |

To get the best results, do these things:

Use polyurea or epoxy seam fillers for joints.

Pick fasteners that do not rust.

Let boards sit in the room before installing.

Cut boards with carbide-tipped tools.

Check your boards often and use the right products. If you are not sure, ask the board maker or a building expert for help.

FAQ

How soon should you seal cut edges after cutting magnesium wall boards?

You should seal the cut edges right after cutting and cleaning. This step keeps water out and helps the board stay fire-resistant. Do not wait, as moisture can weaken the board quickly.

Can you use regular caulk or paint on magnesium wall boards?

No, you should not use regular caulk or paint. Always choose fire-resistant products made for magnesium wall boards. These products protect against fire and moisture. Regular products may fail and reduce safety.

What happens if you skip edge sealing?

If you skip edge sealing, water can enter the board. This causes cracks, warping, and loss of fire resistance. You may need to replace the board much sooner.

How do you check if your wall still has fire resistance?

Inspect seams and joints for cracks or gaps.

Look for moisture stains or soft spots.

Make sure screws sit flush and do not break the surface.

Replace any rusted fasteners.

Do you need special tools to cut magnesium wall boards?

Yes, you need sharp utility knives or carbide-tipped saw blades. These tools make clean cuts and help keep the board strong. Using the wrong tools can damage the board and lower its fire resistance.

Edge Sealer Application

Edge Sealer Application Joint Compounds and Tapes

Joint Compounds and Tapes