20 Aug Magnesium Wall Board Smoke Density During Combustion

Table of Contents

Magnesium oxide boards make very little smoke when they burn. The ASTM E84 test proves this. Low smoke helps people see better in a fire. People can find exit signs and escape paths more easily. Magnesium wall boards stop fire and do not make harmful gases. This makes them good for fire safety. Using these boards keeps people safer. It lowers health risks and helps people get out safely.

Aspect | Impact on Fire Safety |

|---|---|

Smoke Density | Helps people see and leave safely |

Toxic Gas Emission | Makes breathing safer during a fire |

Fire Resistance | Stops fire from spreading and causing harm |

Key Takeaways

Magnesium oxide wall boards make very little smoke when burning. They also make few toxic gases. This helps people see and breathe better during fires.

These boards have the best fire resistance ratings (Class A1). They can handle high heat for 1 to 4 hours. This keeps walls strong and slows down fire spread.

Special flame retardants and minerals are inside the boards. These release water vapor that cools fires. They also lower smoke, making things safer for people and firefighters.

Boards must be installed the right way. They need to stay dry. This keeps their fire protection working. It also stops smoke or fire from getting through cracks.

Magnesium oxide boards work better than gypsum and cement boards. They last longer and keep air cleaner. This makes them a smart choice for safer buildings.

Smoke Density

ASTM E84 Test Results

The ASTM E84 test checks how building materials act in fire. It looks at flame spread index and smoke developed index. Magnesium oxide boards do very well in this test. In the test, workers put the boards in a Steiner Tunnel. They blow air over the boards and light them with a strong burner. The flame spread index for these boards is between 0 and 25. This means fire moves slowly or not at all on the board. The smoke developed index is usually between 0 and 450. Many boards even get a 0/0 rating. This shows almost no smoke comes out when they burn.

Magnesium oxide boards have minerals and special flame retardants. These help the boards not burn easily and make less smoke. The boards do not melt or make thick smoke. They let out water vapor instead. This cools the fire and makes even less smoke. Because of low flame spread and smoke, these boards get a Class A fire rating. This is the best rating for fire resistance and low smoke. It makes them great for fire-safe walls and building parts.

Test Criteria | Magnesium Oxide Boards | Gypsum Boards |

|---|---|---|

Flame Spread Index | 0 to 25 | Higher values |

Smoke Developed Index | 0 to 450 (often 0/0) | Higher smoke levels |

Fire Resistance Rating | Class A (A1) | Class A to C |

What Low Smoke Density Means

Low smoke density can help save lives in a fire. When magnesium oxide boards burn, they make very little smoke. This keeps the air clear and helps people see better. People can find exits and escape faster and safer. Firefighters can also see better and help people more quickly.

Magnesium oxide boards use special flame retardants and smoke control. These stop toxic gases and thick smoke from coming out. The boards do not add to smoke breathing dangers. This is important because smoke breathing hurts many people in fires. The boards help keep the air safe and stop panic.

Note: Low smoke density and a low smoke developed index mean magnesium oxide boards do not add to fire dangers. They help people leave safely and protect them from smoke problems.

Magnesium oxide boards do not burn and do not make toxic smoke.

The boards get the best fire rating (Class A1) and a top smoke safety level (AQ1).

Special flame retardants and smoke control keep smoke low and clear.

Less smoke helps people and firefighters see and stay safe.

These features lower toxic risks and help with fire safety.

Using special flame retardants and smoke control in magnesium oxide boards keeps smoke very low, even in big fires. This makes them a smart choice for buildings that need good fire safety.

Fire Resistant Performance

Fire Resistance Ratings

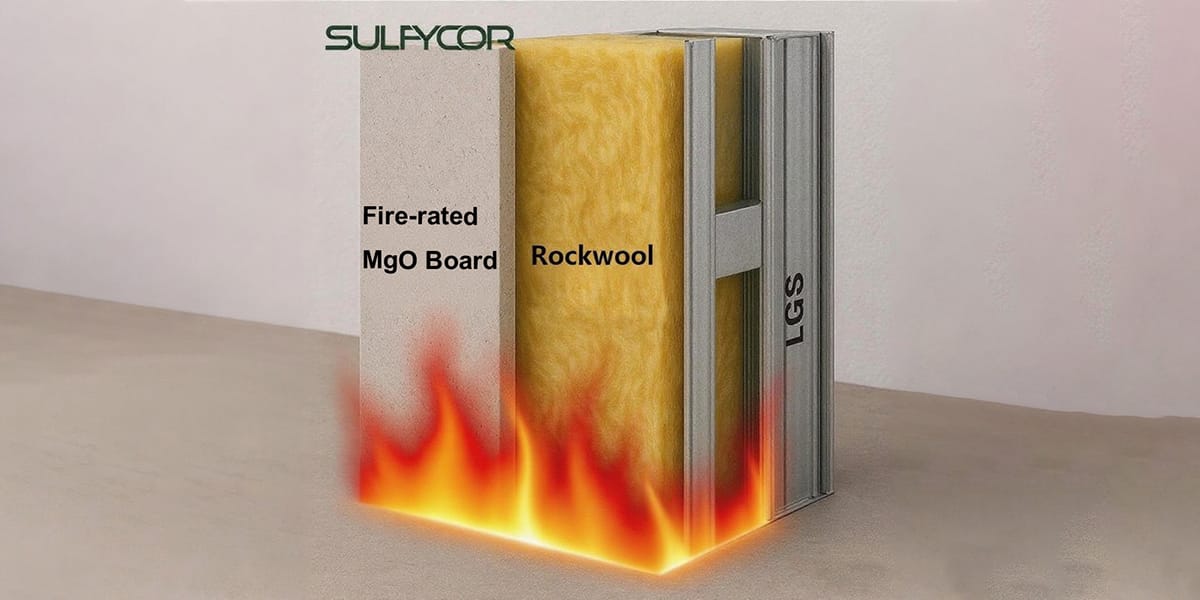

Magnesium wall boards are very good at stopping fire in buildings. They are made mostly of magnesium oxide, which is strong and does not burn. When there is a fire, magnesium hydroxide forms and lets out water vapor. This water vapor cools the board and slows down the fire. Because of this, the boards stay strong even when it gets very hot.

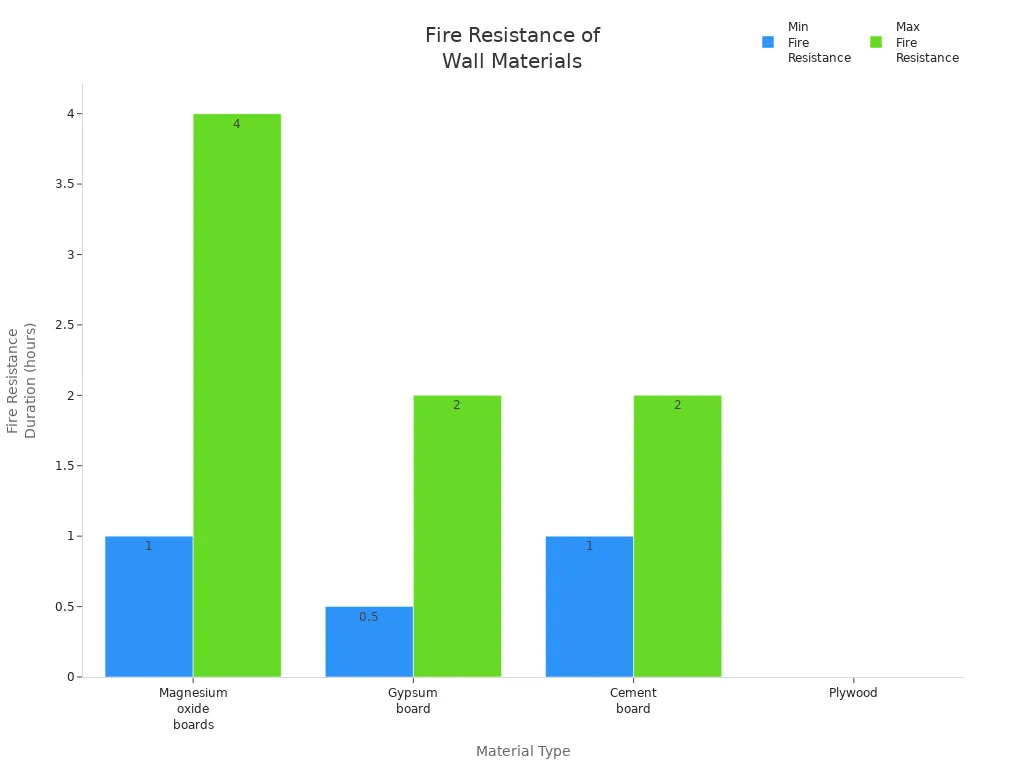

Building codes around the world say magnesium wall boards are fire resistant. They pass tough tests like ASTM E136, ASTM E84, EN 13501-1, and Canadian codes. These tests check how fast flames move, how much smoke and toxic gas come out, and how long the boards last in fire. Magnesium wall boards usually get a Class A or A1 rating. This means they do not burn and stop fire well. Most boards can last 1 to 2 hours in fire for walls, floors, and ceilings. Some types can handle heat up to 1200°C without burning or changing shape.

Standard / Code | Description | Fire Resistance Rating / Classification |

|---|---|---|

ASTM E136 | Noncombustibility test | Noncombustible |

ASTM E84 | Surface flame spread | Class A rating |

EN 13501-1 | European fire classification | Class A1 (noncombustible) |

CAN/ULC S114, S135 | Canadian fire resistance standards | Suitable for fire-rated walls, exteriors |

Magnesium wall boards use special flame retardants that do not have halogen. These help stop fire from starting and spreading. The boards also have glass fibers, silica, and clay. These make the boards strong and help them stand up to heat. The way the boards are made packs these materials tightly together. This makes the boards tough and helps them last longer in fire.

There are different types of magnesium wall boards for different jobs. G Grade is for inside, E Grade is for outside, NC Grade is for Canada, S Grade is for building support, and FR Grade gives extra fire protection. Builders pick the right type for each job.

Magnesium wall boards are trusted for fire safety. Their minerals and special flame retardants make them a top pick for buildings that need to stop fire.

No Toxic Gas Emission

Magnesium wall boards keep people safe from toxic gas during fire. Gypsum boards can let out bad gases when they burn, but magnesium wall boards do not. Their design and halogen-free flame retardants keep the air clean when there is a fire.

Magnesium hydroxide helps lower smoke and toxic gas. When fire hits the board, magnesium hydroxide lets out water vapor. This cools the fire and stops bad gases from forming. This keeps the air safe for people and firefighters. The boards also stop mold, mildew, and moisture, which helps keep the air healthy inside.

Magnesium wall boards do not give off VOCs.

They do not burn or break down in high heat.

Halogen-free flame retardants stop toxic gases from coming out.

Great fire resistance lowers health risks in a fire.

Magnesium hydroxide and other retardants work together to keep air safe.

People are safer because magnesium wall boards stop fire and toxic gas. The boards last in fire and keep the air clean. Their strong build and halogen-free flame retardants make them safer than other boards.

Picking magnesium wall boards with halogen-free flame retardants makes buildings safer. Their fire resistance and clean air set a high standard for fire safety today.

Fire Safety and Protection

Impact on Evacuation

Impact on Evacuation

Magnesium wall boards help keep people safe in fires. They do not burn or make toxic smoke. This keeps escape paths clear and easy to breathe. People can see exit signs and find their way out. The boards make almost no smoke, so the air stays clear. This helps people and firefighters move fast and safely.

Walls made with magnesium wall boards slow down fire. They also block heat and stay strong when it gets hot. This lowers the chance of walls falling down. People get more time to leave before the fire spreads. Fire barriers made from these boards meet strict safety rules like ASTM E119 and EN 13501-1. These rules make sure the boards last in strong fires.

Fire-resistant wallboards, like magnesium oxide, help buildings follow safety codes. They give people more time to get out and keep escape paths safe.

Magnesium wall boards are used in hospitals, schools, and stores. Builders trust these boards to protect people and property during fires.

Air Quality and Visibility

Magnesium wall boards make less smoke and no toxic gas. This keeps the air clean during a fire. Clear air helps people see and breathe better. It also stops panic and confusion. Walls made with these boards stop smoke from filling halls and stairs. This keeps escape paths easy to see.

Material Type | Fire Resistance Duration | Combustibility | Smoke/Toxic Fume Emission |

|---|---|---|---|

Magnesium oxide boards | Non-combustible | None | |

Gypsum board | 0.5 to 2 hours | Combustible | Low |

Cement board | 1 to 2 hours | Non-combustible | None |

Plywood | 0 hours | Combustible | Yes |

Magnesium wall boards meet top fire safety standards. They have an A1 fire rating and can handle heat over 750°C for more than 30 minutes. They do not lose strength in fire. These features make them great for fire walls, doors, and partitions. Builders use them in stairs, public places, and risky areas to keep everyone safe.

Material Comparison

MgO vs. Gypsum Board

Magnesium oxide boards and gypsum boards are both used to protect buildings. But they act very differently in a fire. MgO boards have minerals that do not burn or make smoke. They stay strong even when it gets as hot as 1200°F. This helps them work better in fires. Gypsum boards slow down fire at first because water inside turns to steam. When the water is gone, the board gets weak and soft, usually above 150°C. Gypsum boards can last about 110 minutes before they start to break down. Both boards follow fire safety rules, but MgO boards last longer and work better in big fires.

Material Type | Fire Resistance Mechanism | Key Test Standards | Performance Highlights |

|---|---|---|---|

Gypsum Board | Water in core slows fire, weakens after water loss | ASTM E119, ASTM E84 | Protects up to 110 minutes; weakens above 150-190°C |

Magnesium Board | Non-combustible minerals, maintains strength at high heat | ASTM E119, ASTM E136, EN 13501-1, BS 476 | Withstands up to 1200°F (650°C); retains shape and strength |

MgO boards get an A1 fire rating, which is the best. They do not make bad fumes, so the air stays safe in a fire. Gypsum boards work for normal fires but do not last as long as MgO boards in very hot fires.

MgO vs. Cement Board

MgO boards and cement boards both stop fire, but they are not the same. MgO boards stay strong and do not break in high heat. They do not make toxic smoke and keep their shape in a fire. Cement boards also stop fire but can crack or break when it gets too hot. MgO boards are lighter, so they are easier to put up and save work time. They also do not get moldy or rot, which is good in wet places.

Magnesium Oxide (MgO) Board | Fiber Cement Board | |

|---|---|---|

Fire Resistance | Superior, higher fire ratings | Fire-resistant, lower ratings |

Moisture Resistance | Highly water-resistant, resists mold and rot | Moisture-resistant, can absorb water over time |

Weight | Lightweight, easy to install | Heavier, more effort to install |

Durability | Impact-resistant, weatherproof | Strong, more brittle |

Environmental Impact | Eco-friendly, natural materials | Less eco-friendly, energy-intensive production |

Cost | Higher initial cost, lower lifetime cost | Lower material cost, higher labor cost |

Installation | Easy to cut and install | Needs special tools, more labor |

Health and Safety | No toxic dust or fumes | May release silica dust |

MgO boards may cost more at first, but they save money later. Builders can use thinner boards and need less support. They also spend less on throwing away old boards. MgO boards last longer and need less fixing because they are tough and fire safe. Cement boards cost less to buy but need more work and can make dust that is not safe to breathe.

Tip: MgO boards are better for fire safety, are easier to put up, and save money over time. This makes them a smart pick for new buildings.

Factors Affecting Smoke Density

Board Composition

What is inside magnesium wall boards changes how much smoke they make in a fire. Magnesium hydroxide is very important. When fire hits it, magnesium hydroxide turns into magnesium oxide and water vapor. This helps cool the board and makes less smoke. Boards with magnesium hydroxide make much less smoke than boards with other things. For example, boards with magnesium hydroxide can make only 0.012 m²/s of smoke at their highest. Boards with aluminum hypophosphite can make up to 0.025 m²/s.

Fire-retardant additives also change how much smoke comes out. Halogen-free flame retardants, like phosphorus-based ones, help make a strong char layer in a fire. This char layer has special chemical groups that trap smoke and stop it from getting out. Glass fiber mesh, perlite, and other fillers help the board fight fire and lower smoke even more. Hydrated minerals in magnesium oxychloride and magnesium oxysulfate cements let out water when hot. This helps stop fire and smoke too. How the board is made, and what is put in it, changes how well it stops fire and smoke.

Boards with magnesium hydroxide and halogen-free flame retardants work best for stopping smoke and keeping people safe.

Installation and Environment

Putting up magnesium wall boards the right way is very important. If workers do not follow the rules, the boards can crack or open at the joints in a fire. This lets fire and smoke get through faster. How the joints are made, how the boards are fastened, and what is inside the wall all matter for fire safety.

The environment also matters. If the boards get wet, they can shrink, bend, or crack. Wetness can also rust metal fasteners and help mold grow. These problems make the wall weaker and lower its fire resistance. If the board gets weak, more smoke can come through during a fire.

Workers should use the right joint treatments and fasteners.

Boards need to stay dry before and after they are put up.

Checking the walls often helps keep them safe from fire.

A wall system that is put up well, with halogen-free flame retardants and good fire additives, gives strong fire protection and keeps smoke low. This helps people get out safely and keeps the air cleaner during a fire.

Magnesium oxide wall boards make little smoke and stop fire well. They also protect buildings from fire for a long time. Builders and architects like these boards because they last up to 4 hours in fire. They do not let out bad fumes and stay strong even when wet.

These boards help build green buildings and follow tough fire rules.

They have the right safety labels and pass ASTM and UL tests.

When picking wall boards for fire safety, experts should check:

National rules and what fire safety is needed.

Trusted tests for fire, flame spread, and smoke danger.

Building rules for putting up boards and sealing joints.

Green building rules for the environment.

Picking magnesium oxide boards makes fire safety better and keeps people safe for a long time in every building.

FAQ

What is the smoke developed index for magnesium wall boards?

The smoke developed index for magnesium wall boards is usually between 0 and 450. Many boards get a 0/0 score in ASTM E84 tests. This shows they make almost no smoke when burning.

Do magnesium wall boards release toxic gases in a fire?

Magnesium wall boards do not let out toxic gases during a fire. Their minerals and halogen-free flame retardants keep the air safe for people and firefighters.

How long can magnesium wall boards resist fire?

Most magnesium wall boards can resist fire for 1 to 4 hours. The exact time depends on the board type and how it is put up. Builders should look at product details for the right rating.

Where are magnesium wall boards commonly used for fire safety?

Builders put magnesium wall boards in hospitals, schools, stairwells, fire-rated walls, and doors. These boards help protect people and property in places that need strong fire safety.

Impact on Evacuation

Impact on Evacuation