11 Feb Magnesium Sulfate Board vs Cement Board Which Is Best for Modern Construction

Table of Contents

If you’re wondering about magnesiu sulfate board vs. cement board, the best choice depends on your project’s needs. Builders consider factors like fire safety, moisture resistance, durability, cost, and sustainability. Check out the table below to see what experts prioritize:

Description | |

|---|---|

Sustainability | Eco-friendly options that benefit the environment. |

Durability | Boards that are long-lasting and resistant to damage. |

Cost-effectiveness | Materials that save money while maintaining performance. |

Technological advances | Innovative building materials that improve construction. |

When comparing magnesiu sulfate board vs. cement board, both options are known for their strength and safety. Some believe MgSO4 board isn’t suitable for wet environments, but high-quality MgSO4 board can handle moisture, while lower-quality boards may have problems. Make your decision based on reliable information, not just opinions. This guide is here to help you choose the right board for your next building project.

Key Takeaways

Magnesium sulfate board stops fire for up to four hours. It works well in places where fires can happen.

Magnesium sulfate board does not let water in. It keeps out mildew and stays strong. You do not need extra waterproofing.

Magnesium sulfate board costs more at first. But it saves money later because it lasts longer and needs less fixing.

Cement board is cheaper for tile underlayment in wet places. But you must add a waterproof layer for it to work best.

Pick magnesium sulfate board if you want something good for the planet. It works in many building jobs. Cement board is better for places like bathrooms and kitchens.

Head-to-Head Comparison: Fire Resistance

Magnesium Sulfate Board Fire Safety

You want your building to stay safe during a fire. Magnesium sulfate board, also called mgo board, gives you strong fire safety. This material does not burn. It does not add fuel to a fire. You can trust it in high-risk fire zones. Many builders choose mgo board because it meets strict fire safety standards.

Here is a table that shows how mgo board performs in fire tests:

Fire Rating | Standard | Description |

|---|---|---|

A1 | EN 13501-1 | Non-combustible, does not contribute to fire growth, and has less than 1% organic matter. |

A2 | EN 13501-1 | High fire resistance, does not burn or spread flames. |

Class A | ASTM E84, E136 | Highest fire rating classes, withstands temperatures up to 1200°C without losing strength. |

1-hour | ASTM E119 | Passes fire tests, maintaining integrity for at least 1 hour. |

2-hour | ASTM E119 | Passes fire tests, maintaining integrity for at least 2 hours. |

4-hour | ASTM E119 | Exceeds typical building code requirements, maintaining integrity for up to 4 hours. |

You see that mgo board can last up to four hours in a fire. It keeps its shape and strength. This makes it a top choice for fire safety in modern construction.

Cement Board Fire Safety

Cement board also offers fire safety, but there are key differences when you compare mgo panel vs cement panel. Cement board does not burn easily. It can slow down the spread of flames. Many people use cement board for walls and floors because it helps protect buildings from fire.

Here is a table that compares mgo board and cement board in fire resistance tests:

Material | Fire Resistance Rating | Notes on Fire Resistance |

|---|---|---|

Magnesium Oxide (MgO) Board | Up to 1-2 hours; rated noncombustible (ASTM E136 & E84) | Highly fire-resistant, superior to gypsum and fiber cement boards |

Fiber Cement Board | Fire-resistant but generally less than MgO boards | Moderate fire resistance |

You notice that cement board does not match the fire safety of mgo board. It still gives you good protection, but it does not last as long in extreme heat.

Safety Comparison

You need to know the key differences in fire safety between mgo panel vs cement panel. The main difference is how long each board can resist fire and keep its strength. Mgo board stands out because it does not burn and can last up to two hours or more in a fire. Cement board gives you fire resistance, but it usually lasts for a shorter time.

Here is a simple table to show the key differences:

Board Type | Fire Resistance Rating |

|---|---|

MgO Board | Very fire-resistant, doesn’t burn (1-2 hours) |

Fiber Cement Board | Fire-resistant, less than MgO boards |

Tip: If you build in high-risk fire zones, you should choose mgo board for the best fire safety. It gives you more time to react and protects your building better.

When you look at the head-to-head comparison, mgo panel vs cement panel shows clear key differences. Mgo board gives you higher fire safety, longer fire resistance, and better performance in tough conditions. Cement board still helps, but it does not match the fire safety of mgo board. You should always check your local building codes and choose the board that fits your needs.

Moisture Resistance: Magnesium Sulfate Board vs. Cement Board

MgO Board in Wet Areas

MgO Board in Wet Areas

You want strong water resistance when you build in places that get wet. Mgo board gives you this protection. You can use mgo board in bathrooms, kitchens, and laundry rooms. This board does not soak up water easily. It keeps its shape even when it gets wet. You do not see swelling or warping. Mgo board also stops mildew from growing. You do not smell musty odors. You do not see black spots on your walls. This makes mgo board a smart choice for wet area applications.

You can use mgo board for floors, ceilings, and walls. You do not need to worry about mildew or water damage. Many builders pick mgo board for pools, basements, and showers. You get a clean, safe space that lasts a long time.

Cement Board Water Protection

Cement board also gives you good water resistance. You can use cement board in high-humidity rooms. It does not break down when it gets wet. You see only small changes in size after soaking in water. The board swells less than 1.58% in thickness after 504 hours. The length changes less than 0.29% after 24 hours in water. This means cement board stays strong and flat.

You should know that cement board is not fully waterproof. You need to add a waterproofing layer for the best results. This layer keeps water out and stops mildew from growing. You do not want mildew in your home. It can cause health problems and bad smells. When you use cement board with a waterproofing layer, you get better water resistance and mildew control.

Here is a quick look at how cement board performs in wet spaces:

Feature | Cement Board Performance |

|---|---|

Water Absorption | Low, but not zero |

Swelling in Water | Less than 1.58% (thickness) |

Mildew Resistance | Good with waterproofing layer |

Best Use | Showers, kitchens, laundry rooms |

Best Choice for Moist Environments

You want to pick the right board for wet area applications. Both mgo board and cement board give you water resistance. Mgo board stands out because it does not need extra layers to stop mildew. You get strong mildew protection right away. Cement board works well, but you must add a waterproofing layer to get the best mildew control.

Here are some tips to help you choose:

Use mgo board if you want easy mildew control and strong water resistance.

Pick cement board if you plan to add a waterproofing layer and want a board that stays flat in water.

For pools, basements, and showers, mgo board gives you extra mildew protection.

For kitchens and laundry rooms, cement board works well with a waterproofing layer.

Note: Always check the quality of the board before you buy. High-quality mgo board and cement board give you better moisture resistance and mildew control.

You can trust both boards for construction in wet spaces. Mgo board gives you simple, strong mildew protection. Cement board gives you good water resistance with the right setup. You get a safe, long-lasting result with either choice.

Long-Term Durability and Strength

MgO Board Durability

You want your building to last for years. MgO board gives you impressive strength and durability. This material stands up to tough conditions. It keeps its shape in high humidity and does not swell or break down. Studies show that mgo board loses very little weight over time, which means it keeps its strength. You can see the results in the table below:

Study | Findings |

|---|---|

Bista and Tamrakar (2015) | Very little weight loss, proving strength |

Vázquez et al. (2016) | Less heat damage compared to granite |

Freire-Lista and Fort (2017) | Fewer cracks formed, showing long-lasting performance |

You can trust mgo board in wet places. Research shows it stays stable even after 840 days in 90% humidity at 30°C. It absorbs only 0.34% moisture, so you do not see swelling or damage. This makes mgo board a smart choice for areas that need strength and durability.

Cement Board Durability

Cement board also gives you long-term durability. You can use this material for more than 50 years if you install and care for it properly. Over a 10-year period, cement board keeps its structural integrity. You need to check for moisture, weather, and load. Regular inspections and protective coatings help cement board last longer. You get strong performance in many construction projects.

Impact Resistance

You want your walls to handle bumps and knocks. Both mgo board and cement board offer good impact resistance. The table below shows how each material performs:

Board Type | Average Impact Strength (KJ/m2) |

|---|---|

Magnesium Oxide | |

Cement Board | ≥3.5 |

Gypsum Board | ≤1 |

Mgo board gives you higher impact strength. Cement board also protects against damage, but mgo board stands out for strength and durability. You can count on both for safe, long-lasting walls.

Tip: Choose mgo board if you want the best mix of strength, durability, and impact resistance for your construction project.

Installation and Versatility

Ease of Installing MgO Board

Ease of Installing MgO Board

Mgo board is light and simple to move. You can cut it with regular tools. This helps you finish your work faster. You do not need special skills or big machines. One person can carry and install mgo board alone. This makes work easier for small teams. You can use mgo board for paint, tile, or wallpaper. It gives you smooth results with less work. Mgo board works for walls, ceilings, and outside surfaces.

Cement Board Installation

Cement board is heavier than mgo board. You may need more people to lift it. You also need special tools to cut cement board. This can slow down your work. Many people think cement board takes more time and effort to install. Here is a table that shows common problems with cement board:

Challenge Type | Description |

|---|---|

Weight | Cement board is much heavier, so it is hard to carry. |

Installation Difficulty | Needs special tools and skilled workers, making it harder than drywall. |

Labor Requirements | You may need to hire more workers because of the weight and difficulty. |

You should plan for these problems if you pick cement board. You may need extra money for more workers and tools.

Application Flexibility

You want building materials that work in many ways. Mgo board is more flexible than cement board. You can use mgo board in wet places, fire zones, and spots that need insulation. It works for inside and outside projects. Cement board is useful, but it is not as flexible as mgo board. Here is a table that compares how you can use each board:

Feature | Magnesium Sulfate Boards | Cement Boards |

|---|---|---|

Moisture Resistance | Excellent | Limited |

Fire Safety | Up to 4 hours | Not specified |

Installation Ease | Easy | More effort required |

Suitable for Wet Areas | Yes | No |

Insulation R-value | 0.20 to 0.40 per inch | 0.05 to 0.20 per inch |

You can see mgo board gives you more choices for your projects. You get better water resistance, stronger fire safety, and easier installation. Mgo board lets you use it for many needs. You can trust mgo board for homes and businesses.

Tip: Pick mgo board if you want easy installation and more ways to use it. You will save time and work on your building project.

Environmental Impact

Sustainability of MgO Board

You want to use building materials that are good for the planet. Mgo board is a smart choice because it uses natural things and makes less pollution. Making mgo board puts out much less CO2 than other boards. For every metric ton, magnesium oxide makes about 340 kg of CO2. Calcium oxide, which is in cement, makes 740 kg for each ton. This is a big difference, so picking mgo board helps the earth.

Mgo board can help you get green building points like LEED. You can recycle or use these boards again, so there is less trash. Mgo board lasts a long time, so you do not need to change it often. This saves materials and helps the planet. Mgo board does not have bad chemicals, so your indoor air is safer.

Mgo board makes less pollution and uses less energy to make.

These boards do not have asbestos or formaldehyde.

You can recycle or reuse mgo board, which is better for nature.

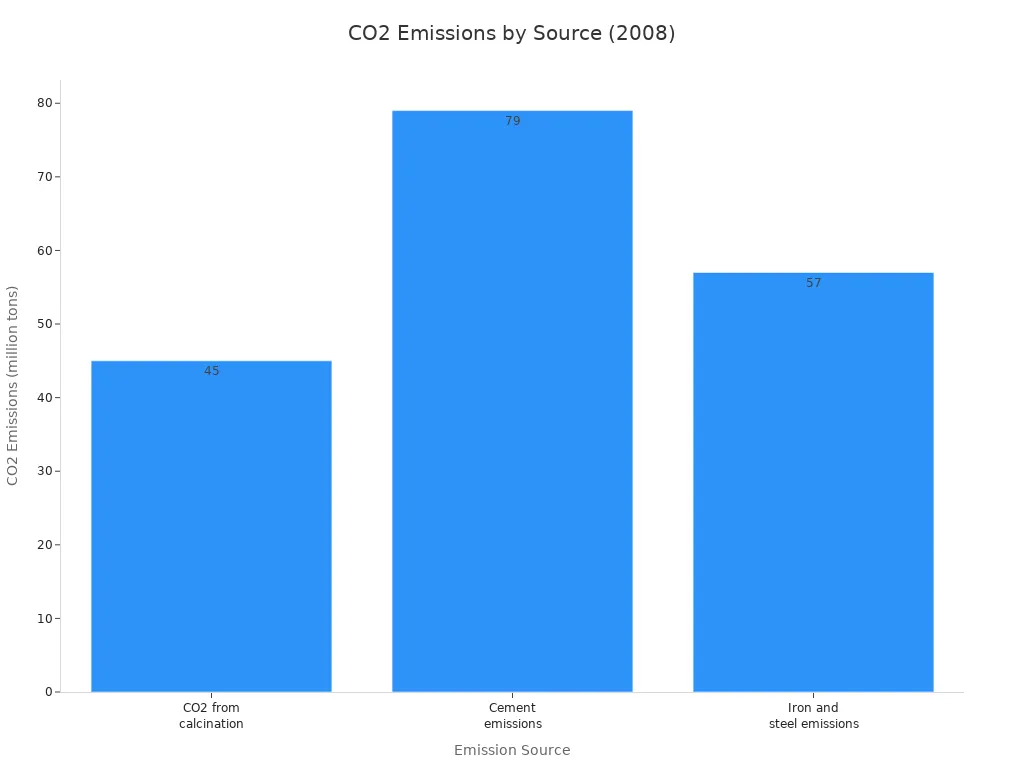

Sustainability of Cement Board

Cement board is not as good for the environment. Making cement board uses a lot of energy and makes more CO2. Most of the pollution comes from a step called calcination. This is when limestone turns into lime and carbon dioxide at very high heat. This step makes 60-65% of all the pollution from making cement board.

Here is a table that shows the facts:

Aspect | Value |

|---|---|

Global CO2 emissions from cement | 5% of anthropogenic emissions |

U.S. total CO2 emissions | 2% of total emissions |

CO2 from calcination (2008) | 45 million tons |

Cement emissions (2008) | 79 million tons |

Iron and steel emissions (2008) | 57 million tons |

You can see that making cement board adds a lot of pollution to the world. This means it is not as good for the environment.

Health and Safety

You want your building to be safe and healthy for everyone. Mgo board helps stop mold, so the air stays clean. These boards do not have bad chemicals, so you stay healthy. When you cut or drill mgo board or cement board, wear gloves, goggles, and a mask to keep dust away. Both boards do not burn easily, so they help keep you safe from fire. Check your boards often to find problems early.

Tip: Pick materials that are safe for you and the planet. Mgo board works well and is better for the environment.

Cost Comparison: Magnesium Sulfate Board vs. Cement Board

Initial Costs

You want to know how much you will spend at the start of your project. The upfront cost for magnesium sulfate boards is higher than cement boards. You pay more for MgO boards because they use advanced materials. Cement boards cost less, but you may not get the same benefits. Here is a simple table to help you with your cost analysis:

Board Type | |

|---|---|

MgO Board | $1.50 – $2.50 |

Cement Board | $0.50 – $1.00 |

You see that MgO boards cost more at first. This cost comparison helps you plan your budget for construction.

Maintenance and Value

You want your building to last without spending too much on repairs. Cement boards need more maintenance over time. You may need to fix cracks or replace damaged sections. These repairs add to your total cost. Magnesium sulfate boards are stronger and resist damage. You spend less on maintenance because these boards last longer. Over five years, you save money with MgO boards. This cost analysis shows that durability matters when you choose materials.

Tip: Choose materials that need less maintenance. You will save time and money in the long run.

Long-Term Savings

You want to get the best value for your investment. Magnesium sulfate boards give you long-term savings. You pay a higher upfront cost, but you spend less on repairs and replacements. Cement boards seem cheaper at first, but the extra maintenance increases your total cost. A smart cost analysis looks at both short-term and long-term expenses. MgO boards help you lower your overall cost for construction projects.

MgO boards offer better durability.

You save money on repairs.

Your building stays strong for many years.

This cost comparison shows that magnesium sulfate boards are a wise choice if you want to save money over time.

Application Scenarios

Best Uses for MgO Board

Best Uses for MgO Board

You can use magnesium sulfate boards in many types of projects. These boards work well in homes, offices, and factories. They give you strong fire safety and resist water. You can trust them in places that need extra protection. Here is a table that shows where you see MgO boards most often:

Construction Type | Description |

|---|---|

Used for affordable and green housing. | |

Commercial Construction | Chosen for offices, stores, and hotels that need fire safety and sustainability. |

Industrial Construction | Picked for factories and warehouses, especially in Asia Pacific and the Middle East. |

You can use MgO boards for walls, ceilings, and floors. They also work for exterior cladding and as a base for tiles. You get a board that fits many needs.

Best Uses for Cement Board

Cement boards help you in wet and busy areas. You see them in bathrooms, kitchens, and entryways. They give you a strong base for tiles and protect against water. Here is a table with common uses for cement boards:

Application Area | Specific Uses |

|---|---|

Bathrooms | Shower walls, bathtub surrounds, laundry rooms |

Kitchens | Backsplashes, countertop underlayment, wall panels |

Commercial Buildings | Wall cladding in offices and stores |

Entryways | Tile underlayment |

Wet Areas | Pool areas, wall panels in busy spaces |

You can count on cement boards for places that get wet or need extra strength. They last a long time when you install them the right way.

Choosing the Right Board

You want to pick the best board for your project. Think about fire safety, water resistance, weight, and how easy it is to install. The table below helps you compare the two options:

Factor | MgO Board | Cement Board |

|---|---|---|

Top fire safety, non-combustible, lasts 1-4 hours in fire | Good fire resistance, but may crack under heat | |

Water & Moisture Resistance | Does not swell or rot, stops mold | Water-resistant, but may need extra waterproofing |

Weight & Installation | Lighter, easy to cut and handle | Heavier, needs special tools |

Strength & Durability | Strong and tough, good for impact | Very strong, high impact resistance |

Flexibility | Can bend for curved surfaces | Very stiff, not for curves |

Environmental Impact | Green choice, less energy to make, no harmful chemicals | Uses more energy, can make dust when cut |

Tip: If you want a board that is light, safe, and good for the planet, choose MgO board. If you need a strong base for tiles in wet rooms, cement board is a solid pick.

You can match the right board to your needs by looking at your project’s goals and the space you want to build.

You have learned how magnesium sulfate board and cement board work in important ways. The table below shows what each board does well and where it is not as strong:

Feature | MgO Board | Cement Board |

|---|---|---|

Fire Resistance | Non-combustible, great for fire zones | Moderate, may need extra fireproofing |

Moisture Resistance | Stays stable in wet places | Good, but needs sealing |

Eco-Friendliness | Sustainable, low impact | Higher carbon footprint |

Durability | Lightweight, flexible, resists cracks | Strong, but heavier and can crack |

Installation | Easy to cut and install | Heavier, needs special tools |

Cost | Costs more at first, saves money later | Cheaper at first, costs more to maintain |

When you pick a board for your building job, think about these things:

Decide if you want the board for support or just for looks.

Make sure the board fits the area, like wet or dry spots.

Choose the style you want for your room.

Here is a simple guide to help you choose:

Recommendation | Choose MgO Board | Choose Cement Board |

|---|---|---|

Sustainability | Yes | No |

Longevity | Yes | No |

Water Resistance | Yes | No |

Budget | No | Yes |

Tile Underlayment | No | Yes |

Versatility | Yes | No |

Health & Safety | Yes | No |

Think about the good and bad points before you pick. If you want a board that is safe, strong, and helps the planet, magnesium sulfate board is usually the best choice for new buildings.

FAQ

What is the main difference between magnesium sulfate board and cement board?

You will notice that magnesium sulfate board is lighter and easier to cut. Cement board is heavier and needs special tools. Both boards work well, but you get more flexibility with magnesium sulfate board.

Can you use magnesium sulfate board outside?

Yes, you can use magnesium sulfate board for exterior walls. It resists water and fire. You should always check the product label to make sure it is rated for outdoor use.

Is cement board safe for wet areas like showers?

You can use cement board in showers and bathrooms. It resists water but needs a waterproofing layer for best results. This keeps your walls safe from mold and damage.

Which board is better for green construction?

You help the environment when you choose magnesium sulfate board. It uses less energy to make and creates less pollution. Cement board uses more energy and produces more carbon dioxide.

How do you cut and install these boards?

You can cut magnesium sulfate board with a regular saw. Cement board needs a carbide-tipped tool. Always wear gloves, goggles, and a mask to protect yourself from dust during installation.

MgO Board in Wet Areas

MgO Board in Wet Areas Ease of Installing MgO Board

Ease of Installing MgO Board Best Uses for MgO Board

Best Uses for MgO Board