10 Aug How Cement Board and Gypsum Board Differ in Construction

Table of Contents

You will see big differences between cement board and gypsum board when you build something. Cement board is stronger and does not get damaged by water easily. This makes it good for wet places or outside. Gypsum board is lighter and easier to put up. You can finish work faster and spend less money with it. Each board has good and bad points:

Material | Advantages | Disadvantages |

|---|---|---|

Cement Board | Strong, water-resistant, fireproof, stable | Heavy, costly, difficult to cut and install |

Gypsum Board | Lightweight, inexpensive, easy to install | Less durable, susceptible to water damage |

You should know these differences. They change how long your project lasts, how safe it is, and how much it costs.

Key Takeaways

Cement board is very strong. It does not get damaged by water. It does not burn easily. This makes it good for wet places like bathrooms. It also works well for outside walls.

Gypsum board is light and simple to put up. It does not cost a lot of money. It works best in dry rooms like bedrooms and offices.

Cement board lasts a long time. It does not get damaged easily. But it costs more money. It is also harder to put up than gypsum board.

Gypsum board has a smooth surface. You can paint it or put wallpaper on it. Cement board needs tile or stucco on top.

You should pick the right board for your project. Think about water, strength, price, and how it looks. This helps you get the best results.

Cement Board

Composition

Cement board is made from a mix of tough stuff. It has cement, synthetic fiber, paper pulp, water, and pigments. Making cement board takes many steps.

Workers collect things like limestone, clay, shales, and silica.

The powder gets heated in a kiln to make clinker. Then it cools and gets ground up with other things.

To make the board, cement is mixed with water, paper pulp, and synthetic fibers.

This mix becomes thin panels. The panels are pressed and dried to take out water.

After curing, the panels are cut and finished for use.

This way, cement board becomes strong. It does not get ruined by water or fire.

Uses

Cement board can be used in many places in a building. It works inside and outside. Here are some ways people use it:

Roofs and outside walls

Under tiles in bathrooms and kitchens

Walls and ceilings that split rooms

Areas that need to stop fire or handle water, like offices, hospitals, and warehouses

Prefab buildings and green projects

Tip: Cement board is great for wet places and spots that need to be strong.

Pros and Cons

It is good to know the main good and bad things about cement board.

Pros | Cons |

|---|---|

Very strong and hard to break | |

Does not let water or mold in | Costs more than gypsum board |

Stops fire and heat | Hard to cut and put in place |

Not many design choices |

Cement board is safe and lasts a long time. But you might need help to put it in.

Gypsum Board

Composition

Gypsum board is made mostly from gypsum. This can be natural or synthetic. Workers crush and grind the gypsum into powder. They heat the powder to take out water. This makes plaster of Paris. Then, they mix the plaster with water and other things. These things include starch, glass fiber, and foaming agents. The mix turns into a thick paste called slurry. Workers pour the slurry between two strong paper sheets. Machines press and shape the sheets into long boards. The boards go through dryers to lose extra water. Machines cut the boards to the right size. They also finish the edges. The table below shows the main steps for making gypsum board:

Process Step / Equipment | Description |

|---|---|

Crushing | Gypsum ore is crushed into smaller pieces for processing. |

Grinding Mill | Crushed gypsum is ground into fine powder. |

Calcination | Gypsum is heated to remove water, producing plaster of Paris. |

Mixing Equipment | Calcined gypsum is mixed with water and additives to form slurry. |

Forming Machines | Shape gypsum slurry into sheets between paper liners. |

Dryer | Removes moisture from formed gypsum boards. |

Trimmer and Cutter | Cuts dried boards to required sizes. |

Edge Finishers | Finish edges of gypsum boards. |

Uses

Gypsum board is used in many buildings. Builders use it for inside walls and ceilings. You can find it in homes, offices, and schools. It is good for making partitions between rooms. It can be a base for tiles made of ceramic, plastic, or metal. It helps protect beams and columns from fire. People use it in elevator shafts and other closed spaces. It is also used for outside soffits and some metal buildings. Gypsum board helps block sound and slow down fire. Many commercial buildings use it for easy walls that are simple to change. It does not need much care.

Tip: Gypsum board works best in dry, indoor places. It is good when you want fast work and a smooth look.

Pros and Cons

It is important to know the good and bad things about gypsum board. The table below can help you choose:

Disadvantages | |

|---|---|

Easy to put up and finish, so you save time and work | Not good for wet places; it soaks up water |

Cheap and easy to find | Can get dents, holes, and other damage |

Stops fire because of water in gypsum | Not very strong; needs support from frames |

Good at blocking sound and keeping heat in | Hard to fix; broken boards often need to be replaced |

You can paint, wallpaper, or texture it for different looks | Not very tough and not good for places with lots of hits |

Good for the environment; uses recycled stuff and less energy | Dust from putting it up can be bad for your health |

Gypsum board gives a smooth, clean wall for most inside jobs. You get quick results and save money. But you must keep it dry and safe from hard hits.

Comparison

Durability

Durability

When you choose a wall or ceiling material, you want it to last. Cement board and gypsum board both offer good durability, but they perform differently in real life. Cement board stands up well in tough environments. It resists cracking, breaking, and damage from impacts. Gypsum board can also last a long time, especially if you use reinforced types and keep them dry. Field tests show that gypsum board can stay strong for years without cracks if you install and maintain it well. However, if you expose gypsum board to water or heavy use, it may lose strength faster than cement board.

Application | Typical Lifespan (years) |

|---|---|

Exterior Cladding | |

Interior Walls | 40–60 |

Ceilings | 35–55 |

Flooring Substrates | 25–40 |

Roof Underlayment | 20–35 |

Note: Proper installation and regular care help both materials last longer.

Moisture Resistance

Moisture can ruin many building materials. Cement board is waterproof and keeps its strength even after long water exposure. It blocks mold and mildew, making it perfect for showers, bathrooms, and other wet places. Gypsum board, even with special coatings, only resists moisture for a short time. It absorbs water more easily and loses strength after repeated wetting and drying. Some types, like Gold Bond® XP®, have less than 5% water absorption and high mold resistance, but they still do not match cement board in wet areas.

Cement board:

Waterproof and fire-resistant

Maintains strength after water exposure

Industry’s lowest water absorption and highest mold resistance

Gypsum board:

Moisture-resistant, not waterproof

Water absorption less than 5% for special types

High mold resistance, but not as strong as cement board

Fire Resistance

Fire safety is important in any building. Cement board does not burn and keeps its shape under high heat. It slows down fire and meets strict fire safety rules. Its thick, cement-based structure blocks flames and heat. Gypsum board also protects against fire, especially Type X and Type C boards. These types have special additives that help them last longer in a fire. In some tests, gypsum board gives better fire resistance than fiber cement board, especially in wall systems made with steel frames. Both materials help protect your building, but the best choice depends on your needs and local codes.

Installation

You want a material that is easy to install. Gypsum board is light and simple to cut, carry, and screw into place. Most builders know how to work with it, so you save time and money. Cement board is heavier and harder to cut. It needs special tools and more effort to move and install. However, new cement board stucco systems can cut installation time in half compared to traditional stucco. You can install cement board in any weather, which helps on busy job sites.

Common installation challenges include:

For gypsum board:

Sagging if you use too few screws

Gaps around outlets if not measured right

Visible seams if not finished well

For cement board:

Heavy panels are hard to move

Needs special tools for cutting

More labor required for proper installation

Cost

Cost matters for any project. Gypsum board is cheaper to buy and install. You pay about $0.30 to $0.70 per square foot for the material, and $1.50 to $2.50 per square foot installed. Cement board costs more, usually $1.50 to $3.50 per square foot for the material, with higher labor costs because it is heavier and harder to work with. Even though cement board costs more at first, it can save you money over time because it needs less repair and lasts longer in tough conditions.

Board Type | Material Cost per Sq.Ft. | Installed Cost per Sq.Ft. (Material + Labor) | Notes on Labor and Installation |

|---|---|---|---|

Gypsum Board | $0.30 – $0.70 | $1.50 – $2.50 | Light, easy to install, lower labor costs |

Cement Board | $1.50 – $3.50 | Higher than gypsum board | Heavier, more complex installation, higher labor costs |

Tip: Cement board may cost more at first, but it can save you money on repairs and replacements.

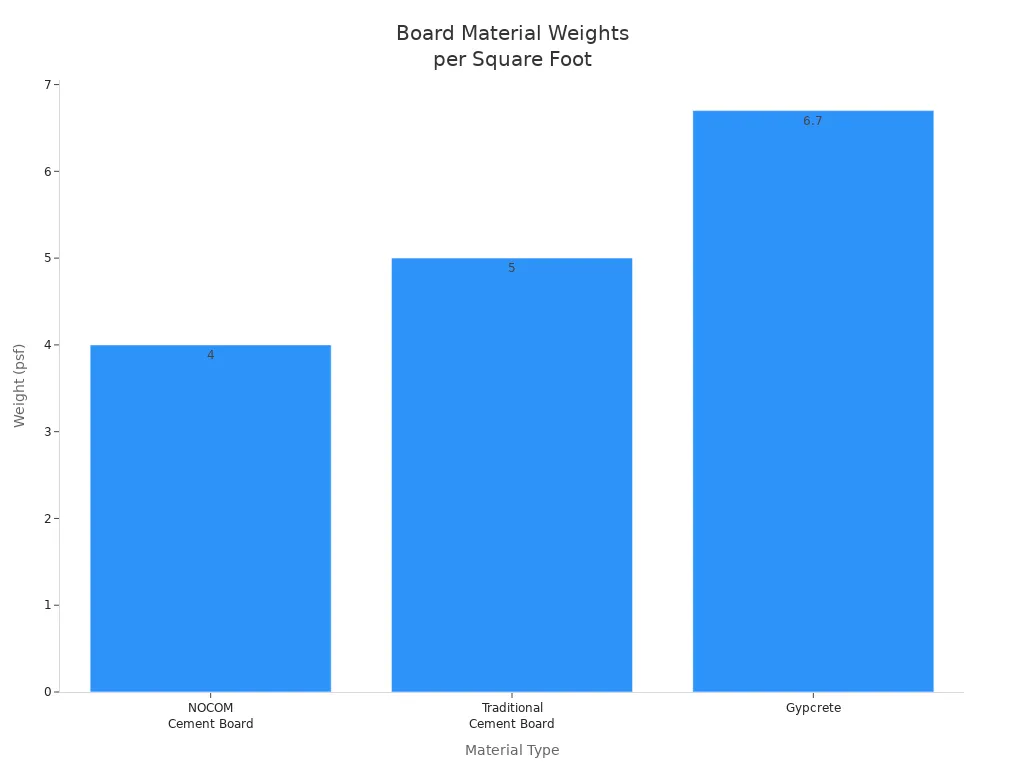

Weight

Weight affects how easy it is to move and install a board. Cement board is much heavier than gypsum board. For example, a 3/4″ cement board weighs about 4 pounds per square foot, while gypsum board is lighter. Heavy boards need more workers and stronger framing. Lighter gypsum boards are easier to carry, cut, and install, which speeds up construction and lowers transportation costs.

Cement board: Heavier, harder to move, needs more support

Gypsum board: Lighter, easier to handle, faster to install

Appearance

You want your walls and ceilings to look good. Gypsum board gives you a smooth, clean surface. You can paint, wallpaper, or texture it in many ways. There are five levels of finish, from no finish (Level 0) to a perfect, smooth surface (Level 5). You treat the joints with tape and joint compound for a seamless look. Cement board does not offer as many finish options. It is usually covered with tile, stucco, or another surface. You do not use cement board for a finished wall unless you plan to cover it.

Best Applications

Choosing the right board depends on where you use it:

Use cement board for:

Wet areas like showers, bathrooms, and kitchens

Exterior walls, siding, and places exposed to weather

Floors under tile and areas that need extra strength

Use gypsum board for:

Dry, indoor spaces like bedrooms, offices, and living rooms

Ceilings and partitions that do not get wet

Projects where you want a smooth, finished look quickly and at a lower cost

Remember: Pick cement board for strength and moisture resistance. Choose gypsum board for easy, fast, and affordable interior walls.

Choosing the Right Board

For Wet Areas

You need a board that stands up to water in places like bathrooms, kitchens, and laundry rooms. Cement board works best here because it does not soak up water or swell. It keeps mold and mildew away, so your walls stay strong and safe. Some special gypsum boards, like ToughRock Mold-Guard, resist mold and moisture better than regular types. These boards work well in high-humidity spots if you keep them dry and install them right. For the toughest wet areas, you should pick cement board or other water-resistant panels like MGO or PVC.

Tip: Always use cement board behind tiles in showers or tubs to prevent water damage.

For Interiors

For most inside walls and ceilings, you want a board that is easy to handle and gives a smooth finish. Gypsum board is lightweight and simple to cut, so you can install it quickly. It also costs less and works well for bedrooms, living rooms, and offices. You can paint, wallpaper, or texture it for many looks. If you need more strength or sound control, you can use thicker gypsum boards or fiber cement boards. The table below shows how different boards compare for interior use:

Board Type | Durability | Finish Quality | Best Use |

|---|---|---|---|

Gypsum Board | Good (dry areas) | Smooth, easy to paint | Walls, ceilings |

Fiber Cement | Very high | Smooth, strong | High-traffic interiors |

MGO Board | High | Modern, smooth | Humid interiors |

Note: Choose gypsum board for most dry rooms. Use fiber cement or MGO boards if you need extra strength or moisture resistance.

For Exteriors

Outside walls face rain, wind, and sun. You need a board that can handle weather and stay strong. Cement board is a top choice for exterior walls, siding, and places that get wet. It resists water, fire, and bugs. Some special gypsum boards, like Type X or Type C, work for exterior soffits and meet fire codes. These boards can handle some moisture but do not last as long as cement board in harsh weather. Always check local building codes before you choose.

Use cement board for:

Siding and exterior walls

Areas with lots of rain or snow

Fire safety zones

Use exterior-rated gypsum board for:

Soffits and covered outdoor ceilings

Places with less direct water

Remember: Pick the board that matches your project’s needs for water, strength, and safety.

You can look at this table to see how gypsum board and cement board are different:

Attribute | Gypsum Board | Cement Board |

|---|---|---|

Durability | Less durable | Strong and impact resistant |

Moisture Resistance | Prone to water damage | Highly moisture and mold resistant |

Fire Resistance | Excellent | |

Installation | Easy and lightweight | Heavy and harder to install |

Cost | More affordable | More expensive |

Best Use | Dry interiors | Wet areas, tile backing, exteriors |

When you pick a board, think about these things. Cement board is best for places with water or fire danger. Gypsum board works well in dry rooms that are safe. You should also think about how much it costs, how strong it is, and how hard it is to put in. You get the best results when you use the right board for your job. Gypsum board is good for dry, finished walls. Cement board is better for wet or rough places because it lasts longer and protects more.

FAQ

What is the main difference between cement board and gypsum board?

Cement board is strong and resists water. You can use it in wet or outdoor areas. Gypsum board is lighter and easier to install. You should use it for dry, indoor spaces.

Can you paint or finish cement board like gypsum board?

You cannot paint cement board directly for a smooth look. You usually cover it with tile, stucco, or another finish. Gypsum board gives you a smooth surface for paint, wallpaper, or texture.

Is gypsum board safe to use in bathrooms?

You should avoid regular gypsum board in bathrooms. It absorbs water and can get damaged. For better results, use cement board or a special moisture-resistant gypsum board in wet areas.

Which board is better for soundproofing?

Gypsum board blocks sound well in most rooms. You can use thicker or double layers for more sound control. Cement board is dense but does not block sound as well as special soundproof gypsum boards.

How do you cut cement board and gypsum board?

You can cut gypsum board with a utility knife. Cement board needs a saw with a carbide blade or special scoring tools. Always wear a mask and goggles to protect yourself from dust.

Durability

Durability