30 Oct Fiber Cement Board Subfloor Vs MgO Board Subfloor

Table of Contents

If you want the best subfloor, MgO board often stands out. It handles fire better than fiber cement board and resists moisture well. You might pay more at first, but you save on repairs and upkeep later. MgO board is also more eco-friendly because it creates less carbon and you can recycle it. Fiber cement board needs special tools and dust control, which can slow down your project. Your choice should match your needs, budget, and the environment where you build.

Key Takeaways

MgO board is a great pick for subfloors in wet or fire-risk places. It is very good at stopping water and fire.

Fiber cement board costs less at first. But it might need more fixes and care later, especially if it gets wet.

Both boards can last many years if you put them in right and take care of them. But MgO board is worth more over time and needs less work.

Pick MgO board if you want to help the planet. It makes less carbon and you can recycle it, so it is better for the earth.

When you put it in, MgO board is simpler to cut and move. This saves time and work when compared to fiber cement board.

Material Overview

Fiber cement board

Fiber cement board is used in lots of homes and buildings. It is made from cement, sand, and cellulose fibers. These parts are pressed and cured to make flat, strong panels. The board can handle daily use and does not wear out fast. It can resist fire and some water, but it might soak up water after a while. When you use fiber cement board for a subfloor, it gives a solid base for tile or wood. Many builders pick it because it costs less at first and can hold heavy things. But if you put too much weight on it, it might crack. You need special tools to cut it, and the dust can be bad for you, so wear a mask.

Tip: Check the thickness and density before you buy fiber cement board. Thicker boards are stronger and more stable.

MgO board

MgO board is short for magnesium oxide board. It is made with different materials than fiber cement board. The main part is magnesium oxide, which comes from minerals with lots of magnesium. Other things like perlite, vermiculite, wood fibers, and fiberglass mesh make it stronger. Bonding agents such as magnesium sulfate or magnesium chloride help hold it all together.

Here is a quick look at the main raw materials:

Raw Material | Description |

|---|---|

Magnesium Oxide | The main part, comes from minerals with magnesium, gives strength and stability. |

Fillers | Perlite, vermiculite, wood fibers, and fiberglass mesh make the board better. |

Bonding Agents | Magnesium sulfate or magnesium chloride glue the materials together. |

To make MgO board, companies do these steps:

Measure the raw materials.

Mix them into a smooth paste.

Put the paste with fabric and fiberglass mesh in layers.

Heat and add moisture for the first curing step.

Take the boards out of the molds.

Let the boards cure at room temperature.

Dry the boards to get rid of water.

Cut the boards to the right size.

MgO board is strong and does not crack easily. It can resist fire and water very well. It can hold heavy things and lasts a long time. You might pay more for MgO board, but it needs less fixing and lasts longer.

MgO Boards | Fiber Cement Boards | |

|---|---|---|

Durability & Strength | Very strong, handles hits, holds heavy things | Strong but can crack if too much weight |

Fire Resistance | Great at stopping fire and heat | Fire-resistant but not as good as MgO |

Moisture Resistance | Stops mold and water damage well | Handles water but can soak it up |

Cost | Costs more at first but lasts longer | Cheaper at first but needs more repairs |

Durability

Impact strength

Impact strength

When you choose a subfloor, you want it to handle heavy loads and sudden impacts. MgO board stands out for its high impact strength. You can drop tools or move furniture across it, and it will not crack easily. This makes it a good choice for busy homes or places where people walk a lot. Fiber cement board also offers good strength, but it can crack if you put too much weight on it or if something heavy falls on it. Over time, repeated impacts may cause small chips or cracks in fiber cement board, especially if the subfloor does not have even support.

Longevity

You want your subfloor to last for many years with little trouble. Both MgO board and fiber cement board can last a long time, but they face different challenges. MgO board resists moisture, so it does not swell or warp when it gets wet. This helps it keep its shape and strength over time. Fiber cement board is generally more durable in dry conditions, but it can absorb water. When it gets wet, it may swell, and when it dries, it can shrink. This cycle can lead to cracks or even breaks.

Here are some common causes of warping, cracking, or breaking in subfloors:

Cause | Explanation |

|---|---|

Cracking can occur if the main structure does not meet design requirements, such as uneven foundations leading to distortion. | |

Moisture Absorption | Fiber cement boards absorb water, causing them to swell; when they dry, they shrink, which can lead to cracking. |

Joint Quality | The quality of the materials used in joints can affect whether the fiber cement board will crack. |

Installation Practices | Poor design and installation can lead to cracks in the joins of the fiber cement board. |

To keep your subfloor in good shape, you need to do some regular maintenance. Here are some tips:

Clean fiber cement board once a year to remove dirt and mold.

Repaint every 10 to 15 years to keep it looking good and protect it.

Check for cracks, gaps, or wear every year.

Replace caulking and seal any gaps to stop water from getting in.

MgO board needs less upkeep because it does not soak up water and does not crack as easily. You will spend less time and money fixing it over the years. Fiber cement board may need more care, especially in places with lots of moisture.

Note: If you install your subfloor well and keep up with maintenance, both types can last for decades. But MgO board gives you extra peace of mind in wet or high-traffic areas.

Moisture Resistance

Wet environments

When you build in a wet area, you want a subfloor that can handle water without problems. MgO board gives you excellent protection in places like pools, saunas, bathrooms, and kitchens. You can use it in flood-prone zones or anywhere with high humidity. MgO board does not absorb water, so it stays strong and does not warp or break. You do not need to worry about swelling or shrinking.

Fiber cement board also resists water, but it can soak up moisture if it stays wet for too long. This can cause the board to change shape or even crack. You may need to add coatings or sealants to keep fiber cement board safe in very damp areas. If you use fiber cement board in a bathroom or kitchen, it works well, but you should check it often for signs of water damage.

Here is a table that shows how both boards perform in wet conditions:

Material | Moisture Resistance Performance | Lifespan in Wet Conditions | Mold Resistance |

|---|---|---|---|

MgO Board | Excellent; stays strong in wet areas, ideal for pools and saunas | Over 30 years | Prevents mold and mildew growth |

Fiber Cement Board | Moderate; handles moisture but may deform if wet for too long | Varies | Better than regular cement, but may need coatings in damp areas |

Tip: If you live in a place with lots of rain or flooding, MgO board gives you better long-term protection.

Mold and mildew

You want your subfloor to stay clean and safe. Mold and mildew can grow in damp places and cause health problems. MgO board helps you avoid these issues. It is inorganic, so mold and mildew cannot grow inside it. The board creates an environment where mold cannot survive. Even in high-humidity rooms, MgO board keeps its shape and does not let mold take hold.

Fiber cement board has very little organic material, so it does not let mold grow inside. Sometimes, mold can appear on the surface if dirt and moisture collect. You can clean this with mild soap and water. If you use fiber cement board in a wet area, you may need to check and clean it more often.

Here are some key points about mold resistance:

MgO board does not absorb water, so it prevents mold from growing.

You can use MgO board in bathrooms, kitchens, and other humid places.

Fiber cement board stops mold from growing inside, but surface mold can appear if you do not clean it.

Both boards work better than drywall or plywood, which can soak up water and grow mold.

Note: Experts recommend MgO board for high-humidity areas because it controls moisture and stops mold before it starts.

If you want a subfloor that stays strong and clean in wet environments, MgO board is the best choice. Fiber cement board works well in most homes, but you may need to give it extra care in very damp places.

Fire Safety

Fire resistance

Fire resistance

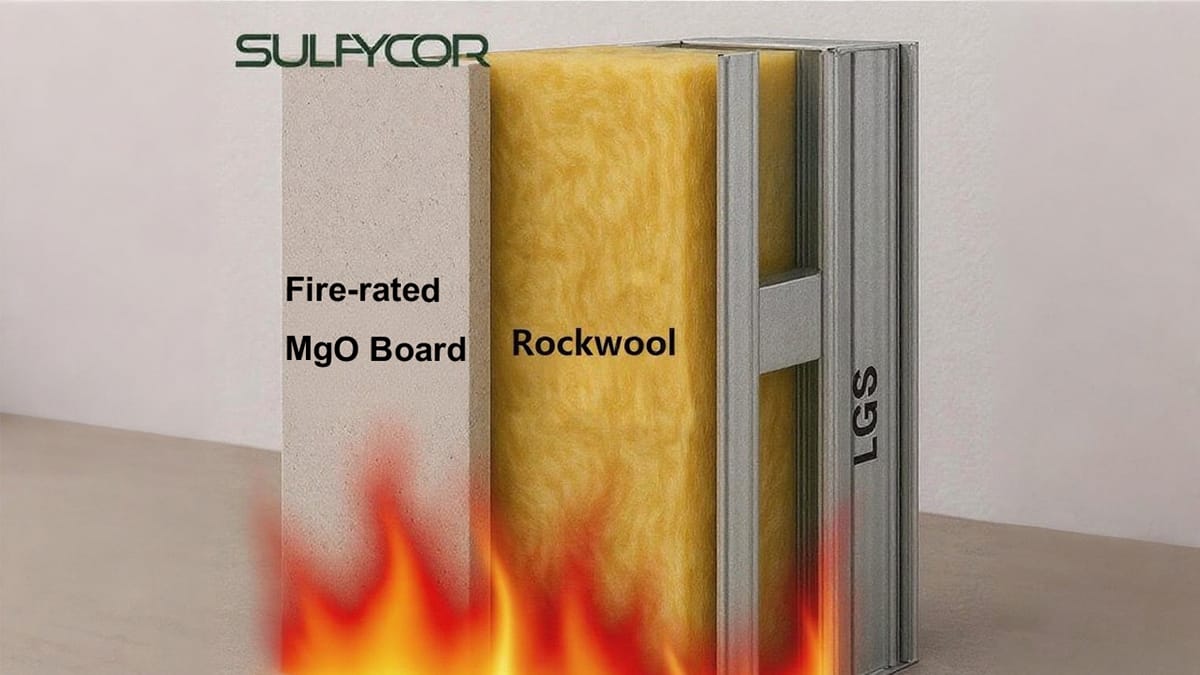

You want your subfloor to protect your home if a fire starts. Both fiber cement board and MgO board help slow down fire, but MgO board gives you even more safety. MgO board does not burn. It stands up to very high heat and keeps its shape. You can trust it in places where fire risk is high, like kitchens or factories.

MgO board passes tough fire tests. These include ASTM E119 and EN 13501-1. In these tests, MgO board earns top marks for stopping flames and smoke. It usually gets a Class A rating in ASTM E84, which means it spreads fire very slowly and makes little smoke. MgO board is also called non-combustible by EN 13501-1 and ASTM E136. This means it will not catch fire or help a fire grow.

Fiber cement board also resists fire. It does not burn easily and can slow down flames. Many fiber cement boards get good ratings in fire tests. Still, MgO board often performs better, especially in very hot fires or when you need the highest level of safety.

Tip: If you build in a place with strict fire codes or high fire risk, MgO board gives you extra peace of mind.

Key fire resistance points:

MgO board: Non-combustible, top ratings in fire tests, Class A fire rating.

Fiber cement board: Fire-resistant, but may not match MgO board in extreme conditions.

Certifications

You should always check for fire safety certifications before you choose a subfloor board. These certifications show that the board passed strict tests and meets building codes. Boards with Class A ratings work best in tall buildings, schools, or factories. Class B and C boards fit homes or places with lower fire risk.

Here is a table of common fire safety certifications:

Certification | What It Means |

|---|---|

CE | Meets health and safety rules in Europe |

ISO | Made by a company with strong quality controls |

INTERTEK | Tested for safety and performance |

ASTM E84 | Shows how fast fire and smoke spread |

EN 13501 | Rates fire performance in Europe |

UL 723 | Proves the board meets fire safety standards |

You should look for certifications like ASTM E136 and EN 13501-1. These show the board passed hard fire tests. When you see these marks, you know the board will help keep your building safe.

Class A: Best fire resistance, for high-risk buildings.

Class B and C: For lower-risk places.

Note: Always ask for proof of fire safety ratings before you buy. This helps you choose the safest option for your project.

Health and Safety

Indoor air quality

You want your home to have clean, safe air. The materials you choose for your subfloor can affect indoor air quality. MgO board stands out because it does not release harmful chemicals. It is formaldehyde-free and has almost zero volatile organic compound (VOC) emissions. This means you breathe easier and lower your risk of health problems.

Property | MgO Board Effect on Indoor Air Quality |

|---|---|

Formaldehyde Emissions | Formaldehyde-free and safe |

VOC Emissions | Near-zero VOC emissions |

Contribution to Air Quality | Better indoor air quality, reducing health risks |

Fiber cement board also keeps your air clean, but you need to watch out during installation. When you cut or sand fiber cement board, it can release fine dust. This dust may contain crystalline silica, which can harm your lungs if you breathe it in. Always use dust-reducing tools and work in a well-ventilated area. Wear a mask to protect yourself.

Tip: MgO board also helps prevent mold and mildew. This lowers the chance of allergies and keeps your home healthier.

Handling

You need to handle both MgO board and fiber cement board with care. When you cut, drill, or sand these boards, you create dust that can irritate your eyes, skin, and lungs. Protect yourself by following these safety steps:

Wear safety glasses or goggles to shield your eyes from flying debris.

Use a dust mask or respirator to avoid breathing in fine particles.

Put on protective gloves to prevent cuts or scrapes.

Work in a well-ventilated area or use a dust extraction system indoors.

Store MgO boards flat and on a stable surface to stop warping or tipping.

MgO board is made from non-toxic materials, so it is safer for you and your family. Fiber cement board needs more caution because of the silica dust. Always use the right gear and keep your workspace clean. This way, you protect your health while building a strong subfloor.

Environmental Impact

Sustainability

It is important to pick materials that are good for the earth. MgO board is a greener choice for your subfloor. Making MgO board uses less energy and water than fiber cement board. MgO boards are made from natural minerals and things you can recycle. When MgO boards cure, they even trap carbon dioxide. This helps lower pollution.

Fiber cement board needs cement, which takes a lot of energy to make. The cement industry makes about 5% of the world’s CO2 pollution. Getting limestone and clay from the ground also hurts nature. Fiber cement boards are heavy and hard to recycle. Most of the time, they end up in landfills.

Here is a table that compares both boards:

Aspect | Fiber Cement Board | MgO Board |

|---|---|---|

Carbon Footprint | High due to cement production | Low, captures CO2 during curing |

Resource Use | Mining for limestone, clay, and silica | Uses magnesite, less impact |

Recyclability | Difficult, often goes to landfill | Fully recyclable, little waste |

Toxicity | May contain harmful substances | Non-toxic, no asbestos or formaldehyde |

Tip: MgO board is better for the planet if you want an eco-friendly subfloor.

Disposal

When your subfloor gets old, you need to think about what happens next. MgO board is easier and safer to get rid of. You can take MgO boards from old buildings and clean off paint or coverings. Then, you can grind them into small pieces. Sieves or magnets help remove any leftover bits. You can mix the clean MgO pieces with new stuff to make new boards or other things.

Fiber cement boards are not easy to recycle. Most recycling places will not take them, so they go to landfills. They are heavy and may have harmful stuff inside, which makes throwing them away harder.

MgO boards: Simple to recycle, less trash, better for the earth.

Fiber cement boards: Hard to recycle, more landfill waste, worse for the environment.

Note: Picking MgO board helps you make less waste and keep the earth cleaner.

Cost

Upfront cost

When you plan your project, you want to know how much you will spend at the start. Fiber cement board usually costs less than MgO board. You can see the price difference in the table below:

You pay less for fiber cement board at first. This makes it a popular choice if you have a tight budget or need to cover a large area. MgO board costs more per square foot or meter. The higher price comes from its special materials and extra benefits, like better moisture and fire resistance.

Tip: If you only look at the upfront cost, fiber cement board helps you save money right away.

Long-term value

You should also think about how much you will spend over the years. MgO board gives you more value in the long run. It lasts longer and needs less fixing. You do not have to worry about mold, water damage, or fire as much. This means you save money on repairs and replacements.

Here are some reasons why MgO board offers better long-term value:

MgO board rarely needs to be replaced, even in wet or humid places.

You spend less on maintenance because it resists mold and moisture.

The board keeps its strength and shape for many years.

You avoid extra costs from fire or water damage.

Fiber cement board may cost less at first, but you might pay more later. It can crack or soak up water if not sealed well. You may need to fix or replace it sooner, especially in damp areas.

Note: If you want to save money over time, MgO board is a smart investment. You pay more at the start, but you spend less on upkeep and repairs.

Installation

Tools and skills

Tools and skills

You need certain tools and skills to put in subfloor boards. MgO board is easier to cut and install than fiber cement board. You can cut MgO boards with a carbide tipped scoring knife. Fiber cement boards need special shears for neat cuts. Both boards need dust-reducing saws to keep the area clean. Use corrosion-resistant screws to hold the boards down. Adhesive helps stick the boards to the floor. Seam filler makes the joints smooth. Underlayment gives your subfloor a steady base.

Here is a table that lists the main tools and materials:

Tool/Material | Purpose |

|---|---|

Carbide Tipped Scoring Knife | Cutting MgO boards |

Dust Reducing Circular Saw | Reducing dust while cutting |

Fiber Cement Shears | Precise cuts for fiber cement board |

Corrosion-Resistant Screws | Holding boards securely |

Adhesive | Attaching boards to surfaces |

Polyurea or Modified Epoxy Seam Filler | Filling gaps for smooth joints |

Underlayment | Providing a stable base |

Wear safety glasses, a dust mask, and gloves. These keep your eyes, lungs, and hands safe while you work.

MgO boards are lighter than fiber cement boards. You can carry and install them faster. Fiber cement boards are heavier and break more easily. You need more time and effort to put them in.

MgO boards help you finish faster and save on labor.

Fiber cement boards need special tools and more skill.

Challenges

You might run into some problems when installing these boards. MgO boards can soak up water if they are not high quality. This can make them hold more water. Sometimes, salts inside the board move to the top. This is called weeping and can change how your floor looks. Too much water can also make metal screws and studs rust. Pick good MgO boards and use screws that do not rust.

Fiber cement boards break more easily. They can crack if you do not handle them right. You need special tools to cut them. The dust from cutting can hurt your lungs. Always wear a mask and work where air moves well.

Both boards need good quality control. Some companies do not follow strict rules. This can make boards that do not work well. Buy from trusted brands and check for safety marks.

Challenge | Description |

|---|---|

MgO panels can absorb more moisture, increasing water content. | |

Weeping | Salts may migrate to the surface, causing weeping in lower quality panels. |

Corrosion of Metal Components | High moisture can cause screws and studs to rust. |

Quality Control Issues | Inconsistent manufacturing can lead to performance risks. |

Tip: Pick high-quality boards and use the right tools. This helps you avoid problems and build a strong subfloor.

Best Uses

Fiber cement board applications

Fiber cement board applications

Fiber cement board works in many places. It is good for regular floors and mezzanine floors. You see it in busy spots because it can take a lot of weight. Builders use it in places like hospitals, hotels, and malls. The board does not break when people walk or move heavy things on it.

Here is a table that shows where fiber cement board works best:

Use Case | Description | Suitability |

|---|---|---|

Traditional Floors | Used in homes and offices for strong flooring | High pressure areas |

Mezzanine Floors | Serves as finished floor over a framework | Industrial spaces |

High-Traffic Areas | Handles lots of foot traffic and heavy loads | Commercial buildings |

You can also use fiber cement board for walls and ceilings. It is good for sandwich floors in factories too. Many builders choose it for places that need tough floors.

Tip: If you need a subfloor for busy or work areas, fiber cement board gives you strength and lasts a long time.

MgO board applications

MgO board gives you more ways to use it for subfloors. You can put it under laminate, tile, or wood floors. The board is strong and does not bend or rip. It gives a steady base for homes and businesses.

Here is a table that shows why MgO board is helpful:

Property | Benefit |

|---|---|

Material Strength | Handles heavy loads and impacts |

Dimensional Stability | Stays flat and does not warp |

Compatibility | Works with many flooring types |

Compressive Strength | Lasts long as an underlayment |

MgO board helps you save on insulation costs. It stops fires and keeps the air inside clean. You can put it in fast, so your job goes quicker. The board is better for the earth, so it is a greener pick.

Use MgO board in wet rooms, kitchens, and bathrooms.

Pick it for places with strict fire rules.

Choose it for homes and businesses that need clean air and strong floors.

Note: MgO board is a good choice if you want something strong, safe, and easy to put in.

You want a subfloor that matches your needs. MgO board works best in wet or fire-prone areas. Fiber cement board fits regular floors and tight budgets. Experts say MgO board is lighter and better for the environment. Fiber cement board is heavy and needs more care. See the table below for a quick guide:

Feature | Fiber Cement Board | MgO Board |

|---|---|---|

Fire Resistance | High | Non-combustible |

Moisture | Moderate | Impervious |

Weight | Heavy | Lighter |

Eco Impact | Moderate | Low |

Tip: Think about your climate, budget, and long-term plans before you choose.

FAQ

What is the main difference between fiber cement board and MgO board?

Fiber cement board uses cement, sand, and cellulose fibers. MgO board uses magnesium oxide and mineral fillers. MgO board resists water and fire better. Fiber cement board costs less at first but may need more care.

Can you install MgO board and fiber cement board in bathrooms?

Yes, you can use both in bathrooms. MgO board works best in wet areas because it does not absorb water. Fiber cement board needs extra sealing to prevent moisture damage.

Is MgO board safe for indoor air quality?

MgO board does not release harmful chemicals. It is formaldehyde-free and has almost zero VOCs. You get cleaner indoor air and fewer health risks.

Which board is easier to cut and install?

You can cut MgO board with a scoring knife or saw. It is lighter and easier to handle. Fiber cement board needs special shears and creates more dust. Always wear safety gear.

Impact strength

Impact strength Fire resistance

Fire resistance Tools and skills

Tools and skills Fiber cement board applications

Fiber cement board applications