31 Oct Fiber Cement Board VS MgO Board On Fire Protection

Table of Contents

You want your building to be safe from fire. MgO boards protect better against fire than fiber cement board. Fire safety is important because it saves lives and keeps things safe. Here is an easy comparison:

Material | Fire Resistance Rating | Notes on Fire Resistance |

|---|---|---|

Magnesium Oxide (MgO) Board | Works better against fire than other boards, even fiber cement | |

Fiber Cement Board | Moderate | Stops fire, but not as well as MgO |

Key Takeaways

MgO boards protect better against fire. They can resist flames for up to 2 hours. This makes them good for places with high fire risk.

Fiber Cement Board does not burn. It may need extra coatings to be as fire-resistant as MgO boards.

Both boards follow fire safety rules. MgO boards usually get higher fire ratings in tests.

MgO boards last longer and do not make toxic smoke. This helps keep people safer during a fire.

MgO boards cost more at first. They save money later because they last longer and need less fixing.

Fiber Cement Board Overview

Fire Resistance

You might wonder how Fiber Cement Board helps stop fire. This board does not burn like wood. Wood catches fire fast and burns quickly. Fiber Cement Board will not catch fire. It can take high heat and still keep its shape. Even if there are flames, it does not break down. Gypsum board can slow fire, but it may fail in a fire. Fiber Cement Board stays strong and helps block fire from moving.

The reason it works well is because of what it is made of. Here are the main parts:

Component | Role in Fire Resistance |

|---|---|

Cement | Holds everything together and makes the board strong. It also helps stop fire, especially with Portland cement. |

Cellulose Fibers | Makes the board stronger and more flexible. This helps stop cracks when it gets hot. |

Silica | Fills in spaces to make the board dense and strong. It also helps the board keep its shape and not bend. |

These parts work together to make a strong board. The board does not burn, bend, or crack easily when it gets hot.

Tip: If you want a wall that can handle fire, Fiber Cement Board is better than wood or gypsum board.

Fire Ratings

You should look at fire ratings before picking a building material. Fiber Cement Board gets high scores for fire safety. International rules show how well it works:

Standard | Description |

|---|---|

EN 13501-1 | This test checks how building materials react to fire. (Clause-8.3) A2: Good fire behavior s1: Low smoke d0: No flaming drops |

ASTM E-84 – Flame spread index is 0 and smoke is 5.

NFPA 285 – No flames go up 10 feet or sideways 5 feet.

Class A fire ratings mean Fiber Cement Board has a flame spread rating from zero to 25. This is the best score for fire safety. You can trust this board to help keep your building safe.

MgO Board Overview

Fire Resistance

Fire Resistance

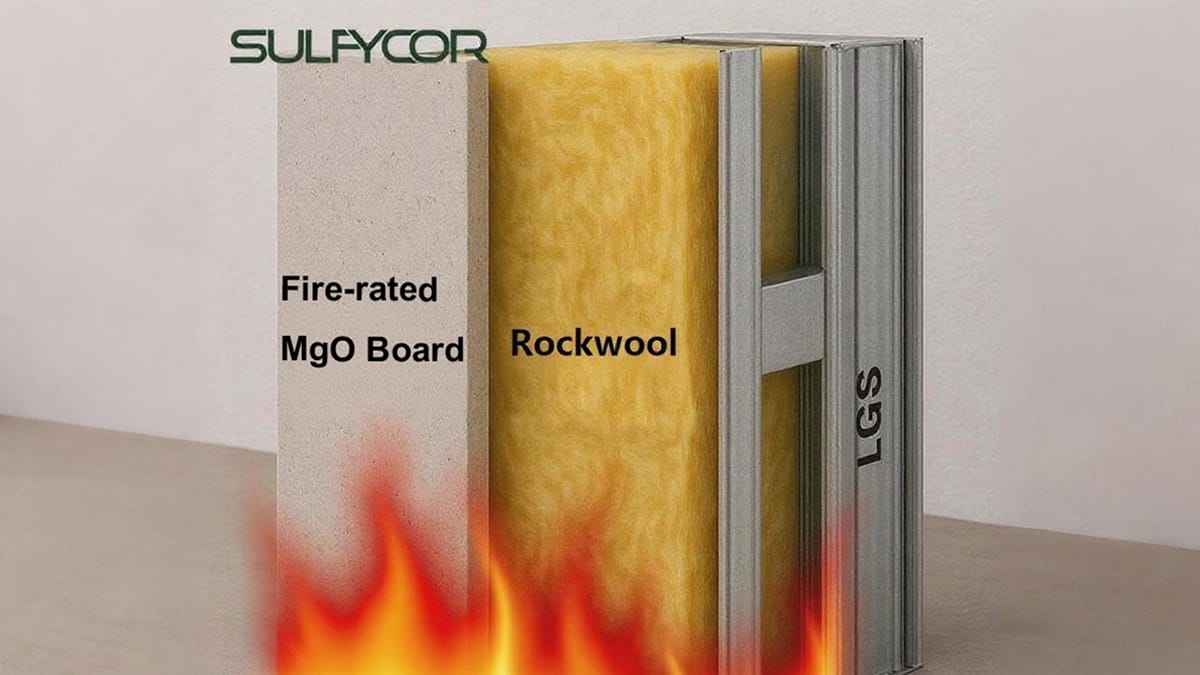

You want a board that does not burn in fire. Magnesium oxide (MgO) boards protect buildings from fire. These boards stay strong even in very high heat. You can count on MgO boards to keep their shape during a fire.

A great thing about magnesium oxide (MgO) boards is their strong fire resistance. They are non-combustible, so they do not catch fire. Builders like MgO boards for places that need good fire safety.

MgO boards use special ingredients to block fire. Here is what helps them work well:

Ingredient | How It Helps With Fire Protection |

|---|---|

Magnesium Oxide | Main part, does not burn, makes fire resistance better |

Magnesium Chloride | Helps the board stay strong and resist fire |

Perlite | Gives insulation and helps stop fire |

Fiberglass Mesh | Makes the board tough and safe from fire |

MgO boards give extra safety because they do not make toxic smoke. Tests show MgO boards stay strong in very hot fires. Fiber cement boards also stop fire, but sometimes need extra coatings. MgO boards do not need these coatings.

Fire Ratings

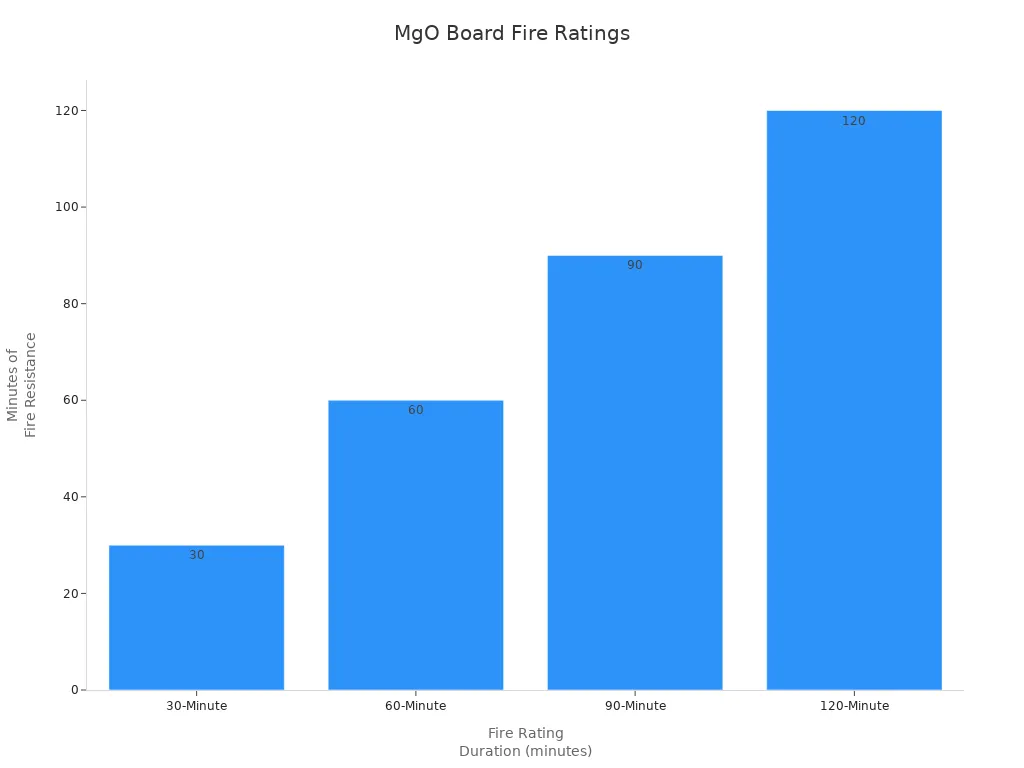

You should check fire ratings before picking a board. MgO boards get high scores from tests. These ratings show how long the boards last in fire:

Fire Rating | What It Means |

|---|---|

30-Minute | Stops fire for 30 minutes before breaking. Used in small buildings or inside walls with low fire risk. |

60-Minute | Stays strong for 1 hour in fire. Used in homes and offices, giving time to get out. |

90-Minute | Good for places needing more fire safety, like stairs, halls, and some ceilings. |

120-Minute | Lasts 2 hours in fire, best for risky places like hospitals, labs, factories, and tall buildings. |

You will see MgO boards tested by different rules in many countries:

EN 13501 (Europe): Checks how materials act in fire. A1 or A2 means they do not burn.

ASTM E119 (United States): Tests fire resistance for 1, 2, or 4 hours.

BS 476 (United Kingdom): Looks at fire resistance for strength, insulation, and load.

MgO boards help you feel safe. You know your building will be protected from fire.

Fire Protection Comparison

Test Results

You want to know how these boards perform in fire tests. MgO boards usually get higher fire ratings than Fiber Cement Board. You can see this in the way they handle heat and flames. MgO boards resist temperatures up to 1200°C. Fiber Cement Board does not reach this level. Here is a table that shows the difference:

Board Type | Temperature Resistance | Fire Rating |

|---|---|---|

MgO Boards | Up to 1200°C | Higher than fiber cement |

Fiber Cement Boards | Lower than MgO boards | Generally lower |

MgO boards do not burn or help fire spread. They do not produce toxic smoke. They keep their strength during a fire. Fiber Cement Board also resists fire, but it may need extra coatings to improve its performance. You can trust MgO boards to protect your building better in fire tests.

Real-World Performance

You want to know how these boards work in real fires. MgO boards show strong results in homes, offices, and factories. They do not burn or release harmful smoke. You can use them in places where fire safety matters most. Here are some examples:

Product Name | Fire Resistance Rating | Key Applications |

|---|---|---|

DragonBoard | Up to 2 hours | Fire-rated subfloor assemblies, wall sheathing, shaft walls, mezzanines, modular buildings |

Suparna MgO Board | Class A (EN 13501-1) | Internal partition walls, subflooring, modular panels, fire-rated ceilings, doors |

MgO Boards | Up to 4 hours | High-risk areas in residential and commercial buildings |

MgO boards do not burn or help fire spread.

They do not produce toxic smoke.

They maintain their strength during a fire.

Fiber Cement Board works well in many buildings, but it may not perform as well in severe fire scenarios. Sometimes, you need extra coatings or treatments to make it safer. MgO boards do not need these extras. You get better fire protection with MgO boards in real-world situations.

Durability

You want your building materials to last. MgO boards stay strong even after a fire. They do not crack or lose shape. You can use them in places with high fire risk. Fiber Cement Board is also durable, but it may not handle extreme heat as well as MgO boards. In some cases, Fiber Cement Board needs extra coatings to keep its fire resistance.

MgO boards outperform Fiber Cement Board in fire resistance.

Fiber Cement Board may require additional coatings or treatments to enhance fire resistance compared to MgO boards.

Note: If you need the best fire protection, MgO boards give you higher ratings, better performance under extreme conditions, and more durability.

Building Code Compliance

Standards

It is important to know what standards your building materials meet. Fire protection rules help you pick safe boards for your project. MgO boards and fiber cement boards both meet big international standards. These rules show how each board works during a fire.

Here is a table that compares the standards for both materials:

Material | Standards Met | |

|---|---|---|

MgO Boards | Naturally non-combustible, keeps strength under extreme heat, does not release toxic smoke | ASTM E136, EN 13501-1 |

Fiber Cement Boards | Non-combustible, may need extra coatings for best results | Fire-rated assemblies |

MgO boards pass ASTM E136 and EN 13501-1. These rules test how materials act in fire and heat. You can trust MgO boards to stay strong and safe. Fiber cement boards also pass fire-rated assembly rules. Sometimes, you need to add coatings for the best fire protection.

Tip: Always check if your board meets local and international fire safety rules before you start building.

Approved Uses

You want to use the right board for each part of your building. Both MgO boards and fiber cement boards have approved uses in fire-rated buildings. You see these boards in many places because they help keep people safe.

Here is a table that shows common uses:

Application Type | Common Uses in Fire-Rated Construction |

|---|---|

Interior Applications | Wall and ceiling panels replace gypsum drywall. You find them in schools, hospitals, and offices. |

| Fire-rated assemblies use these boards in walls and floors to meet fire codes. |

Specialized and Niche Uses | Structural Insulated Panels (SIPs) use these boards as skins. This gives fire resistance and energy efficiency. |

You can put MgO boards and fiber cement boards in walls, ceilings, and floors. Builders use them where fire safety is very important. You also see these boards in structural insulated panels. These panels help save energy and protect against fire.

Note: Always follow local building codes and manufacturer rules when you pick and install fire-rated boards.

Installation And Cost

Installation Factors

Installation Factors

You want your project to go well. Both MgO boards and fiber cement boards need careful work when you put them in. MgO boards are good at stopping fire and water, but they can be tricky if you have not used them before.

If you are new to MgO sheathing, you might need some training.

You have to use the right fasteners and sealing to get the best fire safety.

You should finish the boards the way experts suggest to keep them strong.

Sometimes, it is hard to find good MgO boards or enough for big jobs.

Many builders know how to use fiber cement boards. You can cut and shape them with special saw blades or scoring tools. You need to measure and mark carefully so you do not waste material. Both MgO and fiber cement boards need screws or nails that do not rust. You should use fiberglass mesh tape and joint compound to stop cracks.

Tip: Always wear safety gear when you cut or sand these boards. Keep them flat and dry so they do not get damaged by water.

Cost Differences

You want to know how much money you will spend. MgO boards cost more at first than fiber cement boards. But MgO boards last longer and do not need as much fixing, so you may save money later.

Board Type | Upfront Cost | Long-term Cost Considerations |

|---|---|---|

MgO Boards | Higher | You pay less for labor, install them faster, and do not need as many repairs. They are strong and resist fire, water, and mold, so you save money over time. |

Fiber Cement Boards | Lower | They are heavy, so you pay more for labor. You might need extra protection in wet or fire-prone places, which can cost more later. |

You might pay less for fiber cement boards at first, but you could spend more on work and repairs. MgO boards help you save money over time because they fight fire, water, and mold better.

Note: If you want the best fire safety and strength, MgO boards are worth the higher starting price.

Choosing The Right Board

Key Differences

You want to choose the safest board for fire. MgO boards and Fiber Cement Board are not the same. They have some big differences. You can see these in the table below:

Feature | MgO Boards | Fiber Cement Board |

|---|---|---|

Fire Resistance | Very strong fire resistance | Good fire resistance, but it depends on the type |

Combustibility | Will not burn or catch fire | Will not burn, but might crack if hot |

Fire Rating | Usually lower fire ratings | |

Smoke Emission | Makes little or no smoke | Sometimes makes smoke |

Moisture Resistance | Works in damp places, but not as good | |

Ideal Applications | Best for strong, fire-safe walls | Good for normal building, not for high fire risk |

Here are some main things to remember:

MgO boards are called A1 non-combustible. You can use them where fire risk is high. They do not make toxic smoke.

Fiber Cement Board gives good fire safety. It might crack if it gets too hot or need extra help to work better.

MgO boards are good in wet places. You can count on them to stay safe and strong.

Fiber Cement Board is okay with some water. It might not last long in very wet spots.

Note: MgO boards are best for fire-safe walls, room dividers, and floors. Fiber Cement Board is good for normal building and places with less fire danger.

You want the best fire protection for your building. MgO boards give you higher fire resistance and better safety than fiber cement boards. See the difference:

Material | |

|---|---|

MgO Board | Highly fire-resistant, 1–2 hours |

Fiber Cement Board | Good, but lower than MgO |

MgO boards also resist water, mold, and pests. They cost more at first, but you save money over time because they last longer. Always check your local codes and talk to a building expert before you choose.

FAQ

What makes MgO boards better for fire protection?

MgO boards do not burn. You can trust them to stay strong in high heat. They do not release toxic smoke. You get better fire ratings with MgO boards than with fiber cement boards.

Can you use MgO boards outside?

Yes, you can use MgO boards outside. They resist water, mold, and fire. You should follow the manufacturer’s instructions for best results.

Are fiber cement boards safe for homes?

Yes, fiber cement boards are safe. They do not catch fire easily. You can use them in walls and ceilings. They help slow down fire spread in your home.

Is it hard to install MgO boards?

You may need some training to install MgO boards. Use the right tools and fasteners. Always follow the manufacturer’s guide. Wear safety gear to protect yourself.

Do MgO boards cost more than fiber cement boards?

Yes, MgO boards usually cost more at first. You may save money over time because they last longer and need fewer repairs.

Fire Resistance

Fire Resistance Installation Factors

Installation Factors