06 Sep What Makes MgO Boards Different From Regular Drywall

Table of Contents

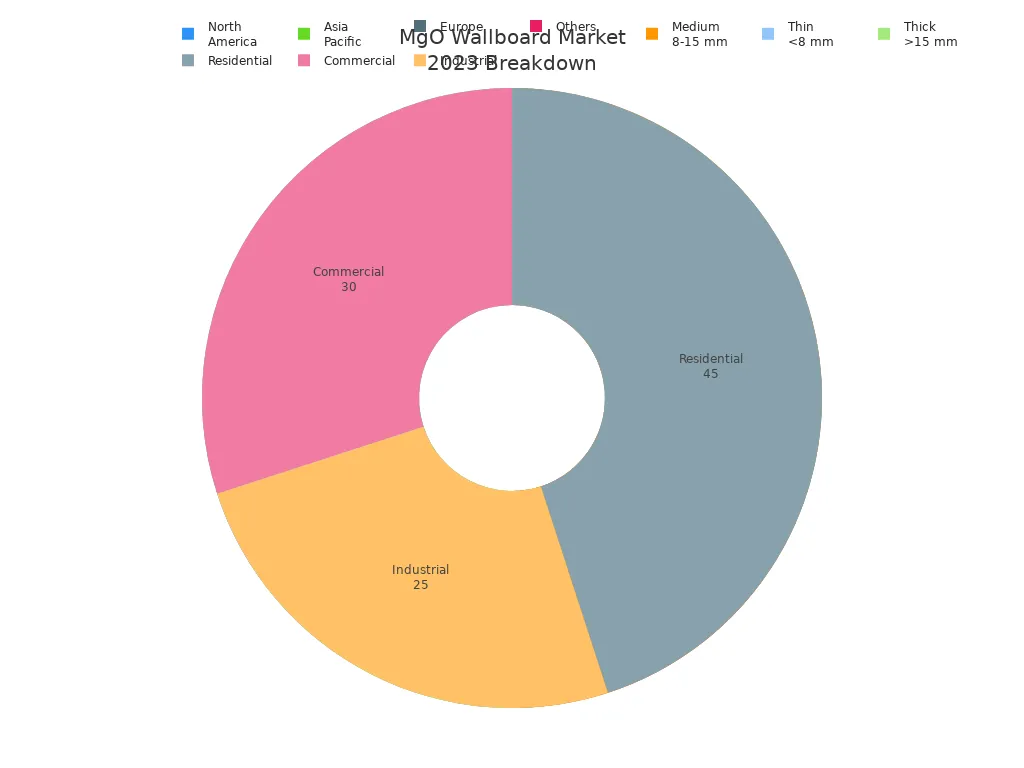

You may see that mgo boards and drywall do the same job, but they work in different ways. Most builders pick drywall because it is cheaper and simpler to put up. In North America, only 28% of architects use mgo wallboards, but 89% choose drywall. Mgo is better at stopping fire and mold, but it costs more and needs special skills to install. This makes it less popular. As more people want green buildings, more projects now look at mgo, especially in Asia-Pacific and North America.

Key Takeaways

MGO boards stop fire, water, and mold better than drywall. This makes them great for wet or fire-risk places.

MGO boards last longer and are tough. They do not break easily. This means fewer repairs and saves money later, even if they cost more at first.

MGO boards use natural minerals and are good for the earth. They do not let out bad chemicals like some drywall does.

Drywall costs less and is simple to put in. But it works best only in dry and quiet indoor rooms.

Picking MGO boards makes buildings safer and stronger. It also helps the planet, especially in wet, busy, or fire-risk areas.

Composition

MGO Boards

Mgo boards are made with minerals and special extras. The main part is magnesium oxide, which comes from rocks. Makers mix magnesium oxide with magnesium chloride or magnesium sulfate. This makes a strong binder. Perlite, a volcanic glass, is added to make the board lighter. It also helps keep heat out. Fiberglass mesh goes inside to stop cracks and bending. Chemical reactions during making help the board fight fire and water. The surface stays cool when heated because magnesium hydroxide lets out water vapor. This mix makes mgo boards tough, fire-resistant, and able to block moisture.

Mgo boards do not have harmful things like formaldehyde, asbestos, or volatile organic compounds.

The board’s makeup stops mold from growing because mold cannot eat it.

Mgo boards soak up very little water, so they do not swell or break in wet places.

Regular Drywall

Drywall, also called gypsum board, is made differently. The middle of drywall is gypsum, a soft mineral. Both sides are covered with heavy paper. The front paper is smooth for painting. The back paper holds the core together. Some drywall has extras like fiberglass or water-resistant chemicals. These make it stronger or better for bathrooms. Drywall is easy to cut and put up. But the paper can let mold grow, and the gypsum core soaks up water fast. This makes drywall not good for wet places.

Gypsum board has water in its mineral part, which helps slow fire.

The paper gives drywall its shape but can get moldy if wet.

Extras in some gypsum boards help with water, but most drywall still gets weak with water.

Key Differences

Aspect | Gypsum Board Composition & Properties | |

|---|---|---|

Core Material | Magnesium oxide, reinforced with fibers | Gypsum core with paper layers |

Moisture Resistance | Superior; resists moisture, mold, and deterioration | Vulnerable to moisture damage and mold |

Fire Resistance | High fire resistance due to mineral composition | Good fire resistance but less than mgo |

Structural Strength | Enhanced by fiber reinforcement; more impact-resistant | Less durable and impact-resistant |

Weight & Density | Heavier and denser, contributing to durability | Lighter, easier to install |

Environmental Impact | Lower impact; recyclable and natural materials | Energy-intensive production; less commonly recycled |

Application Suitability | Ideal for humid, fire-prone, and high-traffic areas | Common for general interior walls and ceilings |

Tip: If you want a wall that fights water, mold, and fire, mgo boards protect better than regular drywall. Gypsum board works well for most dry indoor spaces, but mgo board is best for tough places.

Fire Resistance

MGO Boards Fire Safety

You get outstanding fire protection when you use mgo board in your building. Mgo boards have an A1 non-combustible rating under EN 13501-1, which is the highest class for fire safety. These boards do not burn, melt, or give off toxic gases, even at very high temperatures. In laboratory tests, mgo board keeps its shape and strength up to 1200°C. You can trust mgo to slow down flames and stop smoke from spreading. Many building codes, like ASTM E136 and BS 476 Part 4, recognize mgo boards as non-combustible. You can use them for walls, ceilings, floors, and partitions where fire safety matters most.

Property | MgO Board | Gypsum Board | Cement Board |

|---|---|---|---|

Fire Resistance Rating | A1 Non-Combustible (highest class) | Fire-resistant up to 1 hour | Fire-resistant up to 2 hours |

Combustibility | Non-combustible, does not burn | Combustible, softens at heat | Non-combustible |

Flame Spread | Low flame spread | Moderate flame spread | Low flame spread |

Heat Resistance | High, keeps integrity | Medium, degrades with heat | High, withstands high heat |

Smoke/Toxic Emissions | Minimal, no toxic gases | Moderate, non-toxic gases | Minimal, non-toxic gases |

Fire Endurance | 30-60 minutes | Up to 2 hours |

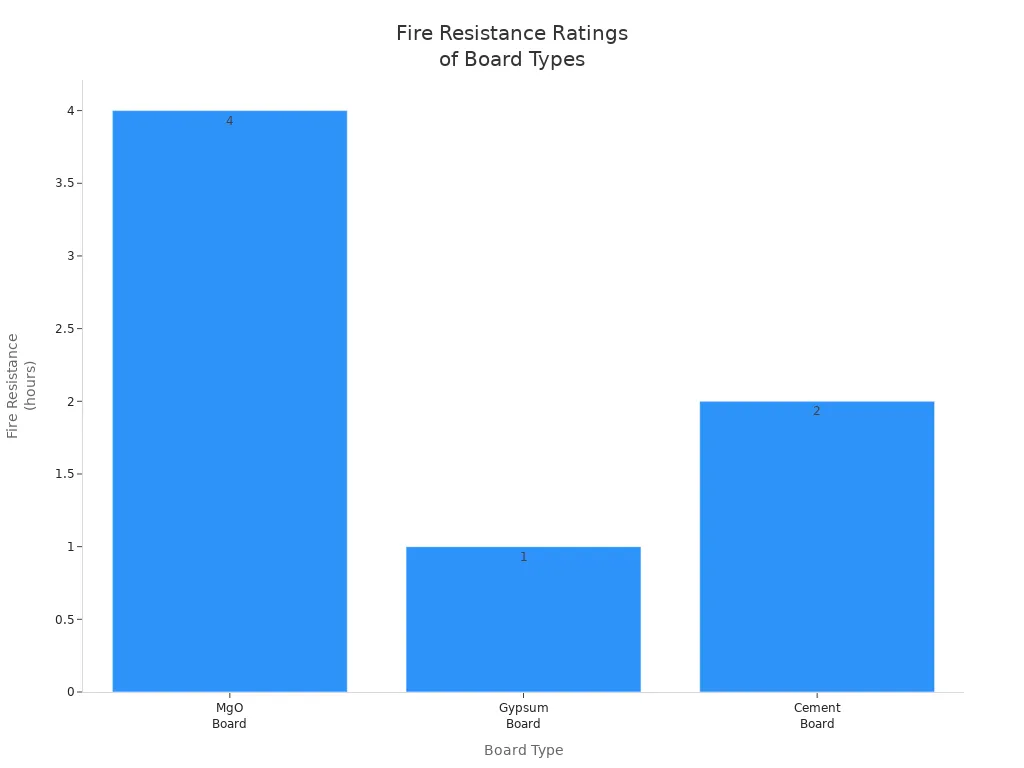

You can see how mgo boards compare in this chart:

Note: Mgo board meets strict fire safety standards like ASTM E119 and UL 263. It can protect your building for up to 4 hours during a fire.

Drywall Fire Safety

Drywall, also called gypsum board, gives you some fire protection because the gypsum core holds water. When fire hits, the water in the core slows down the flames for a short time. Regular gypsum board usually lasts up to 1 hour in fire tests like ASTM E119. Special fire-rated drywall, such as Type X or Type C, can last 1 to 2 hours or more. These types have extra materials like fiberglass to help them resist fire longer. Still, drywall softens and breaks down when exposed to high heat. The paper facing can catch fire, and the board may crack or fall apart.

Comparison

When you compare mgo and drywall, you see big differences in fire resistance properties. Mgo board stands out for high fire resistance. It does not burn, even at temperatures up to 800ºC (1472ºF), and keeps its strength for up to 4 hours. Gypsum board, on the other hand, usually fails after 30 to 60 minutes. Flames can spread faster on drywall, and it produces more smoke. Mgo boards meet the toughest fire safety codes and work well in places where you need the best fire protection. If you want to keep your building safe from fire, mgo is a much stronger choice than regular drywall.

Water and Moisture Resistance

MGO Boards Performance

Mgo boards are great at stopping water and moisture. They use minerals that do not soak up water. The surface stays dry, even in wet rooms like bathrooms or basements. You will not see swelling or warping. The board does not rot. It keeps its shape and strength, even when it is very humid or wet. Mgo boards made with magnesium sulfate work best in wet places. These boards do not let water in, so mold and mildew cannot grow. You can use mgo boards in kitchens, saunas, pool rooms, and other damp places.

Here is a table that shows how mgo boards do in wet places:

Aspect | MGO Boards with Magnesium Sulfate | MGO Boards with Magnesium Chloride | Gypsum Board | Plywood | Cement Board |

|---|---|---|---|---|---|

Water Resistance | High; not hygroscopic; no swelling or warping | Moderate; absorbs moisture; can cause condensation | Poor; swells and warps | Poor; swells and rots | High; moisture resistant |

Mold and Mildew Resistance | Excellent | Lower | Poor | Poor | Good |

Structural Integrity in Humid/Wet Conditions | Maintained | Can degrade | Compromised | Compromised | Maintained |

Suitability for High Humidity/Direct Water Exposure | Suitable | Risky | Not suitable | Not suitable | Suitable |

Tip: If you want walls to last in wet places, pick good sulfate-based mgo boards. These boards keep your building safe from water and mold.

Drywall Performance

Drywall does not do well with water. The gypsum core soaks up water fast. The paper on the outside is food for mold and mildew. If drywall gets wet, it swells and sags. It can even rot. You might see stains, soft spots, or holes. In humid places, water inside walls makes things worse. Mold grows quickly, and the board gets weak. Even moisture resistant drywall cannot handle lots of water or long-term dampness. You may need to replace wet drywall often, which costs more money.

Studies show drywall helps mold grow when it is wet. If the moisture goes above 18%, drywall can make mold grow in wood nearby. Mold like Stachybotrys chartarum grows well on wet drywall. Newer buildings with bad airflow trap water, so drywall fails even more.

Comparison

There are big differences between mgo board and drywall when it comes to water and moisture. Mgo boards stop water, mold, mildew, and rot. Their makeup does not let mold grow. You can use mgo boards in bathrooms, kitchens, basements, and outside walls. The board does not swell or break, even in wet places. Drywall, though, soaks up water and helps mold grow. The paper and gypsum get weak and rot when wet. Even moisture resistant drywall cannot beat mgo boards.

Here is a table that sums up the main features:

Feature | MGO Board | Gypsum Board (Regular Drywall) |

|---|---|---|

Water and Moisture Resistance | Highly resistant; does not swell, rot, or delaminate | Susceptible to water damage; swells, sags, and promotes mold growth |

Mold Resistance | Impervious to mold and mildew growth | Prone to mold growth when exposed to moisture |

Rot Resistance | Resistant to rot, maintaining durability | Vulnerable to rot under moist conditions |

Suitable Applications | Bathrooms, kitchens, basements, exterior use | Interior walls, not recommended for wet areas |

Mgo boards do not soak up water, so you do not need to worry about mold or mildew.

You can use mgo boards in places with lots of water or humidity.

Drywall works best in dry, indoor rooms. You should not use it in wet or humid places.

Note: Mgo boards only take in about 0.34% water, but gypsum board takes in almost 3%. This means mgo boards last longer and are safer in wet places.

Strength and Durability

Impact Resistance

Impact Resistance

You want your walls to stand up to daily bumps and knocks. Mgo board gives you much better impact resistance than regular drywall. When you use mgo in busy places like schools or hospitals, you notice fewer dents, cracks, and holes. Drywall often gets damaged by carts, doors, or even a hard kick. You may need to patch or replace drywall panels often. Mgo board, on the other hand, stays strong and keeps its shape. This makes it a smart choice for high-traffic areas where you need tough walls.

Note: Mgo board is tougher and more durable than drywall. You can trust it to handle heavy use without breaking or crumbling.

Here is a quick comparison:

Feature | MGO Board | Regular Drywall |

|---|---|---|

Impact Resistance | High | Low |

Damage from Bumps | Rare | Common |

Repairs Needed | Few | Frequent |

Longevity

You want your building materials to last a long time. Mgo board gives you that peace of mind. It does not absorb water, so it will not swell or rot in humid places. You do not have to worry about mold, mildew, or pests eating away at your walls. Mgo also stands up to fire and heavy loads. You spend less time and money on repairs because mgo board keeps its strength and durability year after year.

Mgo board resists moisture and mold, keeping its structure in wet rooms.

You do not need to replace it as often as drywall.

Mgo board is fire-resistant and pest-resistant, which means fewer problems over time.

You can use thinner boards without losing strength.

Drywall, in contrast, often needs repairs or replacement. It can get soft, crack, or grow mold if it gets wet. Over time, this means more work and higher costs for you. If you want a wall that lasts, mgo board is the better choice.

Environmental Impact

Magnesium Oxide Board Sustainability

When you pick magnesium oxide board, you help the earth. This board is made from minerals found in nature. These minerals often come from seawater or salty pools. Making this board uses less energy than other wall boards. This means fewer greenhouse gases go into the air. The board does not have bad chemicals like formaldehyde or asbestos. It will not let out toxic gases in your house. You can recycle the board or grind it up for soil. The board fights mold, mildew, and bugs, so it lasts longer and makes less trash. Many boards have safety and quality labels like CE, ISO, and INTERTEK. Some fire tests have the ILAC-MRA logo, which means labs around the world trust the results.

Material | |

|---|---|

Ordinary Silicate Cement | 740 |

Gypsum | 65 |

MgO Boards | 70 |

Making magnesium oxide board with natural gas gives off 18% less CO2 than using coal. The board also traps carbon dioxide as it dries, so it is even better for the planet.

Drywall Environmental Factors

Drywall is not as good for the environment. Making drywall uses a lot of energy and makes greenhouse gases. These gases can dirty the air and cause acid rain. Getting gypsum for drywall hurts the land and uses up resources. When you throw drywall away, it can leak chemicals into the ground and water. Some drywall has bad chemicals like lead or VOCs. These can hurt your health and the earth if not handled right. Recycling drywall helps, but most drywall goes to landfills and can pollute.

Making drywall pollutes the air and uses lots of energy.

Throwing it away can hurt soil and water.

Some drywall has toxic chemicals that can make indoor air bad.

Eco Comparison

Magnesium oxide board is a greener choice. It is safe, can be recycled, and is okay for landfills. You do not have to worry about bad chemicals or high disposal costs. The board lasts longer, so you do not need to replace it often. You can recycle scraps or use them to help plants. Drywall is not as green. It can pollute landfills and let out toxins. You must be careful with drywall to keep people safe.

Feature | Magnesium Oxide Board | Drywall |

|---|---|---|

Non-Toxic | Yes | Sometimes contains VOCs |

Recyclable | Yes | Limited |

Landfill Friendly | Yes | No |

Indoor Air Quality | Safe | Can release toxins |

Resource Use | Sustainable | Energy-intensive |

If you want to help the earth and stay healthy, magnesium oxide board is best. You cut down on pollution and waste, and your walls last longer and are safer.

Cost

MGO Boards Price

When you look at the price of mgo board, you see a higher upfront cost than many other wall materials. In the United States and Europe, you usually pay between $1.50 and $3.00 per square foot, depending on thickness and quality. Some brands, like MagPanel, offer sheets that cost about $0.93 to $2.16 per square foot, but most market reports show an average of $2.10 to $2.50 per square foot. The price can change based on several factors:

Thickness and size: Thicker and larger boards cost more.

Brand reputation: Well-known brands charge more for proven quality.

Location: Shipping and local supply affect the price.

Extra features: UV protection or decorative finishes add to the cost.

Bulk discounts: Buying more at once can lower the price.

You may also pay more for installation because mgo board is heavier and needs special tools.

Cost Factor | Impact on Price |

|---|---|

Thickness/Size | Higher thickness = higher price |

Brand | Trusted brands cost more |

Region | Shipping and supply affect cost |

Features | Extra treatments increase price |

Installation | Heavier boards raise labor costs |

Drywall Price

Drywall is usually less expensive than mgo board. Standard drywall sheets cost about $0.40 to $0.50 per square foot for materials. When you add labor, the total cost ranges from $1.50 to $3.00 per square foot in most areas. In big cities, you might pay up to $4.00 per square foot. The price depends on where you live, how complex your project is, and if you use special types like moisture-resistant drywall.

Standard drywall is easy to find and install.

Labor costs are lower because drywall is lighter and simpler to cut.

Prices go up in cities or for special finishes.

Value Comparison

You might wonder if the higher price of mgo board is worth it. While you pay more at first, you save money over time. Mgo board lasts much longer—about 25 to 50 years—while drywall often needs replacing after 10 to 15 years. Mgo board resists fire, water, and mold, so you spend less on repairs and maintenance. Drywall can get damaged by moisture or impact, leading to more frequent fixes. Most of your building’s lifetime costs come from repairs, not just the first installation. By choosing mgo board, you lower these long-term expenses and get better value for your money.

Tip: If you want a wall that lasts and needs fewer repairs, mgo board gives you better value over its lifetime than regular drywall.

Applications

MGO Boards Uses

MGO Boards Uses

Mgo boards can be used in many places. They are strong and last a long time. You can use them inside or outside buildings. Here are some ways people use mgo boards:

Wall panels for inside and outside walls. These panels protect against fire, water, and bugs.

Ceiling and floor layers that make floors stronger and keep out water and mold.

Fireproof doors and walls in places like hospitals, schools, and hotels.

Structural insulated panels (SIPs) that help stop fire, mold, and termites.

Roofing base that adds support and keeps roofs safe from fire.

Soundproof panels for studios, offices, and apartments.

Wet area lining for bathrooms, kitchens, laundry rooms, and basements.

Tile backboard that gives a strong, water-safe base in kitchens and bathrooms.

Furniture backing for cupboards and closets, making them stronger and stopping mold.

You can also find mgo boards in tough places like tunnels and busy kitchens. They are used in buildings near the ocean too. These boards meet strict rules like MOCA AC-386 and ASTM E119. You can trust them for fire safety and outside use.

Drywall Uses

Drywall is used in most homes and offices. Builders like it because it is easy to put up. It works well for many indoor jobs. Here are the main ways drywall is used:

Inside walls and ceilings in houses, apartments, and offices.

Walls that split big rooms into smaller ones.

Smooth surfaces for paint or wallpaper.

Soundproofing between rooms in apartments, schools, and offices.

Drywall is good for quick and cheap building. You can use it in most dry, indoor places. It is not good for wet or rough areas.

Suitability

Pick the right board for your project. The table below shows how mgo boards and drywall are different:

Feature | MGO Board | Drywall |

|---|---|---|

Excellent, does not swell or mold | Poor, absorbs water and molds | |

Impact Resistance | High, resists dents and cracks | Low, dents and cracks easily |

Fire Resistance | Top-rated, does not burn | Basic, weakens in high heat |

Best for Wet Areas | Yes (bathrooms, kitchens, basements) | No, unless specially treated |

Best for High-Traffic Areas | Yes (schools, hospitals, tunnels) | No, gets damaged easily |

Installation | Heavier, needs skilled labor | Lighter, easy to install |

Tip: Pick mgo boards for wet, busy, or fire-risk places. Use drywall for dry, calm rooms where you want fast and easy work.

You can pick from different wall materials. MGO boards are great for stopping fire and water. They are strong and good for the planet. Drywall costs less money and goes up faster. But drywall does not last long in hard places.

Feature | MGO Board | Drywall |

|---|---|---|

Excellent | Moderate | |

Moisture Resistance | High | Low |

Durability | Strong | Less durable |

Cost | Higher upfront | Lower upfront |

Installation | Skilled labor | Easy, quick |

Tip: Pick MGO boards for wet or busy rooms. They are best for places with fire risk. Drywall is good for dry and simple rooms. Always choose what fits your project and budget.

FAQ

What makes MGO boards better for wet areas?

You get strong protection from water with MGO boards. The board does not swell or rot. Mold cannot grow on it. You can use it in bathrooms, kitchens, and basements without worry.

Can you paint or finish MGO boards like drywall?

You can paint MGO boards. The surface holds paint well. You may need a primer for a smooth look. You can also use wallpaper or tiles on MGO boards.

Are MGO boards safe for indoor air quality?

You stay safe with MGO boards. The board does not release harmful chemicals. It does not contain formaldehyde or asbestos. You get clean air in your home or office.

Do MGO boards cost more to install than drywall?

You pay more for MGO boards at first. The board is heavier and needs skilled workers. Over time, you save money because repairs are rare and the board lasts longer.

Where should you use drywall instead of MGO boards?

You can use drywall in dry rooms like bedrooms and living rooms. Drywall works well for quick jobs. You save money when you do not need extra protection from water or fire.

Impact Resistance

Impact Resistance MGO Boards Uses

MGO Boards Uses