03 Aug Top Floor Sheathing Options for Modern Construction in 2025

Table of Contents

When you look at new buildings in 2025, you will see builders use materials like plywood, OSB, engineered wood panels, MgO board, particle board, concrete panels, and some new popular choices for floor sheathing. OSB is the most common choice because it is cheap, strong, and works in many buildings. Choosing the right floor sheathing can help your floors last longer and stop expensive repairs. Think about what your project needs, like moisture resistance, your budget, and the kind of flooring you want on top, before you choose.

Key Takeaways

Floor sheathing makes a strong, flat base for your floors. It helps spread weight so the floor does not sag or bounce.

Pick floor sheathing by looking at strength, water resistance, price, and how it affects the environment. This helps you choose what fits your project best.

OSB is a common and cheap choice. It works well inside but needs to stay dry to last longer.

Plywood is strong and has a smooth top. It is good for heavy things and for tile or wood floors.

In wet places or where there is fire risk, MgO board and concrete panels work very well. They are tough and last long, but they cost more.

Floor Sheathing Overview

Definition

You might wonder what floor sheathing actually is. In construction, floor sheathing is the layer that sits right on top of the floor joists. It creates a flat, stable surface for your finished flooring, like hardwood, carpet, or tile. This layer does more than just give you something to walk on. It spreads out the weight from furniture, people, and appliances so your floor does not sag or shift over time. Builders often use materials like plywood or tongue-and-groove OSB because they are strong and resist moisture. When you see workers laying down big panels before any flooring goes in, that is the floor sheathing going into place.

Tip: Floor sheathing is usually the first layer installed in a new building. It gives workers a safe, sturdy platform to move around on during construction.

Role in Construction

Floor sheathing plays a huge part in making your home or building safe and sturdy. It acts as the backbone for your floors, holding up everything above it. When you walk across a room, the sheathing spreads your weight across the joists below. This helps prevent weak spots or bouncy areas in your floor. Good floor sheathing also helps protect your home from moisture and even boosts energy efficiency by sealing gaps.

You will find that floor sheathing works together with wall and roof sheathing to make the whole building stronger. It helps your house stand up to wind, heavy loads, and even earthquakes. By choosing the right material, you make sure your floors stay flat, strong, and safe for years to come.

Choosing Floor Sheathing

When you choose floor sheathing, you should think about a few main things. These things can change how your floor feels, how long it lasts, and how much money you spend. Let’s look at what is most important.

Structural Strength

Your floor should feel strong when you walk on it. Strong sheathing stops floors from sagging or bouncing. OSB panels are strong and dependable. They work for new buildings and for fixing old ones. If your building is big or holds heavy things, make sure your sheathing has the right strength ratings.

OSB and plywood both give good support for floors, walls, and roofs.

Tongue-and-groove panels help stop squeaks and spaces.

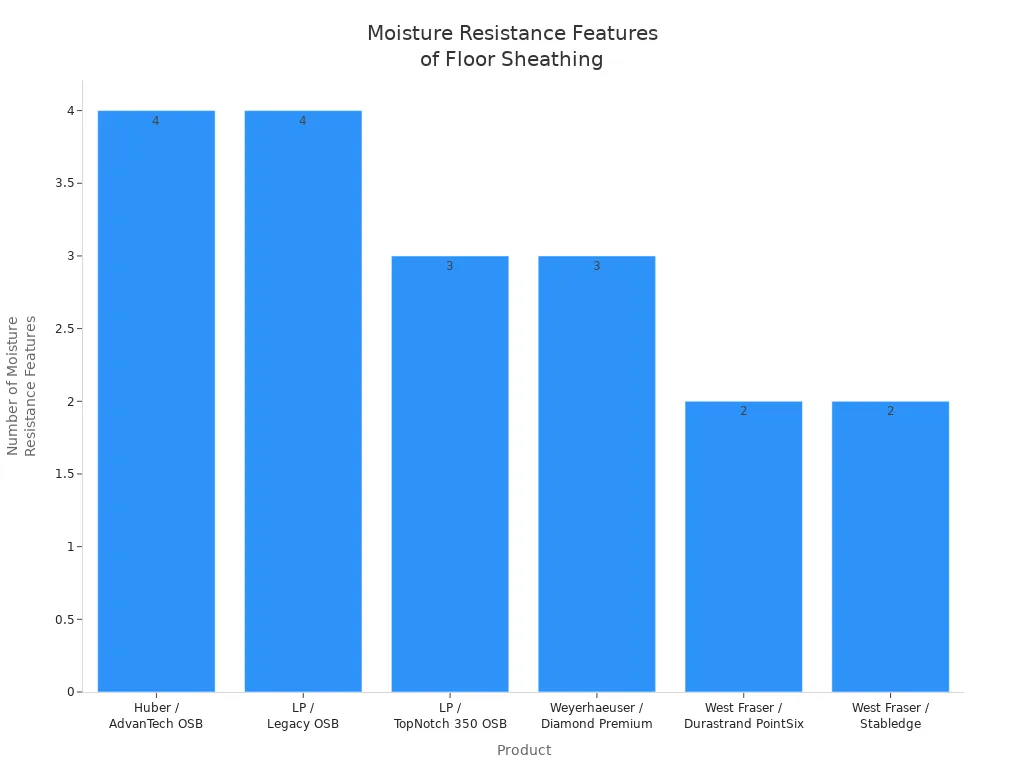

Moisture Resistance

Floors can get wet from spills, leaks, or even air moisture. Some sheathing does better with water than others. Makers add special resins, wax, and coatings to help panels fight water. Pick products with good warranties and certifications.

Manufacturer / Product | Moisture Resistance Features | Warranty / Guarantee Details |

|---|---|---|

Huber / AdvanTech OSB | Extra resin, coated strands, water-resistant finish | 500-day guarantee against edge swelling |

LP / Legacy OSB | Gorilla Glue tech, rain channels, self-spacing edges | Focuses on durability and moisture resistance |

Weyerhaeuser / Diamond Premium | Drain grooves, tongue-and-groove edges | Limited lifetime warranty, 500-day no-sand guarantee |

West Fraser / Durastrand PointSix | Tapered edges for swelling, many thickness choices | 50-year limited warranty, no-sand guarantee |

Tip: Always look for APA certification and a strong warranty if you want the best water protection.

Cost Factors

Your budget is important. OSB is the cheapest choice for most jobs. Plywood costs more but lasts longer. Some top choices like Advantech or MgO board cost even more but have extra good points.

Plywood: Costs 60% more than OSB

MgO board and Advantech: Cost more, best for wet or fire-risk places

Environmental Impact

If you care about the earth, you have choices. Pick FSC-certified or reused wood to help forests. Some panels use crop leftovers or farm waste, which lowers carbon footprint and can sometimes be composted. Timber sheathing cuts carbon early and can be used again, while steel is easier to recycle later.

Note: Using screws or nails instead of glue makes recycling easier when your floor is old.

Plywood

Features

You will notice that plywood stands out because of its unique construction. Manufacturers layer thin sheets of wood, called veneers, in a cross-grain pattern. This design makes plywood strong and helps it resist warping or shrinking. You can find plywood in different thicknesses and strengths, so it fits many building needs. Most plywood panels have tongue-and-groove edges, which help you create a smooth, squeak-free floor. The surface feels smooth, so you can stain, paint, or finish it easily. If you need extra moisture protection, marine plywood works well in damp or outdoor spaces. Softwood plywood is a popular, budget-friendly choice for most homes. Plywood is also lighter than solid wood, so you can carry and install it without much trouble. Many brands use renewable woods like pine or fir, making plywood a sustainable option.

Pros and Cons

Disadvantages of Plywood | |

|---|---|

Strong and durable, resists warping and splitting | Costs more than OSB, raising project expenses |

Holds nails and screws well | Can have knots or voids that weaken it |

Lighter weight, easy to handle and install | May delaminate or warp if it stays wet too long |

Smooth surface for finishing or tile | Needs replacement sooner than some natural materials |

Tip: Plywood dries faster than OSB if it gets wet, but you should still keep it dry for best results.

Best Uses

You will see plywood used in many types of construction. Builders often pick it for subfloors in homes and commercial buildings because it stays strong under heavy loads. Plywood works well for walls, roofs, and even beams. If you want a sturdy base for tile or hardwood, plywood is a smart choice. For big projects outside, structural plywood gives you the strength you need. CDX plywood is a favorite for subfloors because it handles moisture better than some other types.

Installation

Choose panels that meet APA standards for strength and stiffness.

Pick the right thickness for your joist spacing—thicker panels for wider gaps.

Glue and nail the panels to the floor framing. Use the right fasteners to stop squeaks.

Place the smooth side up and run the grain across the joists.

Leave a small gap (about 1/32 inch) between panels for expansion.

Start fastening at the edges and make sure nails or screws sit just below the surface.

Fill any gaps or rough spots before you add your finished flooring.

Remember to let the plywood adjust to your room’s temperature and moisture before you install it. This helps prevent future problems.

OSB (Oriented Strand Board)

Features

You might notice OSB panels look different from plywood. Manufacturers make OSB by pressing together long, thin wood strands in layers. They glue these strands in different directions, which gives the panel strength and keeps it from warping. OSB panels have no big gaps or knots, so you get a smooth, even surface every time. The panels are strong along their length, which helps them hold up heavy loads. OSB is water-resistant, but not waterproof. You need to seal the edges or use a moisture barrier if you expect a lot of water. Most OSB panels come in large sizes, so you can cover more space with fewer seams.

OSB panels have a uniform thickness and density.

The panels resist bending and breaking.

Manufacturers treat OSB with special chemicals to stop mold and bugs.

Tip: OSB is made from small trees and wood chips, so it is a smart choice if you want to use fewer natural resources.

Pros and Cons

Pros | Cons |

|---|---|

Can swell or warp if it gets too wet | |

Cheaper than plywood | Needs careful storage to stay flat |

Good for the environment | Edges may need sealing |

Fewer knots or voids | Heavier than plywood |

Helps block sound | Needs the right fasteners and spacing |

You get a tough, budget-friendly panel with OSB, but you must protect it from water and follow the right steps during installation.

Best Uses

You will see OSB used in many homes and buildings as a subfloor. It works well under carpet, hardwood, or laminate. Builders like OSB because it comes in big sheets, which means fewer seams and faster work. OSB is a great pick for new houses, remodels, and even workshops. Tongue-and-groove OSB panels help stop squeaks and gaps. You should use OSB inside, not outside or in places that get wet a lot.

Note: OSB is best as a base layer, not as the finished floor you walk on.

Installation

Leave a 1/8-inch gap between each panel to let them expand if they get damp.

Use both glue and nails or screws to keep the floor strong and quiet.

Put glue on the joists in a zigzag pattern and add some in the tongue-and-groove joints.

Nail or screw the edges every 6 inches and the middle every 12 inches.

Make sure the panels sit flat and the fasteners are just below the surface.

Keep heavy carts or tools off the new subfloor until you finish the top flooring.

Check that the floor is clean, flat, and has no loose nails before you add carpet or wood.

Always follow the manufacturer’s instructions for the best results and a long-lasting floor.

Engineered Wood Panels

Features

When you look at engineered wood panels, you see a product built for strength and stability. Manufacturers make these panels by pressing wood strands or thin wood layers together with strong adhesives. They arrange the layers in different directions, which helps the panel stay flat and resist warping. You often find tongue-and-groove edges on premium panels, making installation easier and helping the floor feel solid. Most panels have a rough surface because they focus on strength, not looks. You will notice that these panels come in different thicknesses and sizes, so you can pick what fits your project best. Some panels even have special stops built in to allow for expansion when the weather changes.

Tip: Always leave a small gap between panels. This helps the wood expand and contract without causing problems.

Pros and Cons

Here’s a quick look at what you get with engineered wood panels:

Aspect | Benefits | Drawbacks |

|---|---|---|

Load-bearing capacity | Strong enough for heavy furniture and lots of foot traffic | N/A |

Dimensional stability | Stays flat and strong in all directions | N/A |

Moisture resistance | Premium panels handle moisture well if installed with gaps | Can swell if you skip the gaps |

Sustainability | Uses small trees and wood waste, saving big trees | N/A |

Resistance to warping | Less likely to split or bend than regular wood | N/A |

Cost | N/A | Costs more than regular lumber |

Aesthetic appeal | N/A | Not as pretty as solid wood |

Installation notes | Needs gaps for expansion | Bad installation can cause swelling |

Best Uses

You can use engineered wood panels in many types of buildings. They work great for subfloors in homes, offices, and stores. If you have a high-traffic area, these panels hold up well. Builders like them for big projects because they are strong, light, and easy to install. You might also see them in places where moisture or pests are a problem, since they resist both. Cross-laminated timber panels are even used for floors, walls, and roofs in some modern buildings.

Subfloors in houses and apartments

Commercial buildings with lots of people

Large structures that need strong, stable floors

Projects where moisture or pests are a concern

Installation

You can install engineered wood panels without much trouble if you follow a few steps:

Pick the right thickness for your joist spacing.

Lay the panels with the rough side up for better grip.

Leave a small gap (about 1/8 inch) between each panel for expansion.

Use glue and nails or screws to attach the panels to the joists.

Stagger the joints so they do not line up in a straight row.

Check that all fasteners sit just below the surface.

Clean up any glue that squeezes out before it dries.

Note: If you skip the expansion gaps, your floor might swell or buckle later.

Mgo Board

Features

Features

MgO board, or magnesium oxide board, brings a lot to the table when you want a tough and safe floor. You get a material that stands up to fire, water, and mold. Here’s what makes MgO board special:

Handles fire like a champ—doesn’t burn, melt, or give off smoke.

Stays strong and stable, even in wet places like bathrooms or basements.

Offers high strength, so it works well under heavy furniture or lots of foot traffic.

Made from non-toxic, recyclable materials, so it’s better for the planet.

Easy to cut, drill, and shape with simple tools.

Helps keep your home quiet and warm with good sound and heat insulation.

Works well in tough spots like commercial kitchens, tunnels, or coastal homes.

Tip: If you need a floor that can handle water leaks or fire risks, MgO board is a smart pick.

Pros and Cons

Let’s break down the main upsides and downsides of MgO board:

Pros | Cons |

|---|---|

Costs more than regular boards | |

Stops water and mold—great for damp areas | Heavier, so it takes more effort to move |

Super strong and resists dents or cracks | Needs skilled workers for best results |

Eco-friendly and safe for your family |

|

Good insulation for sound and heat |

|

You might pay more at first, but MgO board lasts longer and needs less fixing over time.

Best Uses

You can use MgO board in lots of places. It shines as a subfloor or underlayment, giving a solid base for tile, hardwood, or laminate. Builders trust it in homes, schools, hospitals, and even parking garages. It’s perfect for:

Wet rooms like bathrooms, kitchens, and laundry areas

High-traffic spots that need extra strength

Buildings where fire safety matters most

Projects that want eco-friendly materials

MgO board also helps stop mold and fungus, so your floors stay healthy.

Installation

You’ll find MgO board easy to work with if you follow a few steps:

Measure and cut the boards to fit your space.

Lay the boards flat on the joists, leaving a small gap for movement.

Use screws to fasten the boards down—space them about every 8 inches.

Seal the joints with a waterproof tape or sealant if you expect a lot of moisture.

Clean up dust before you add your finished flooring.

Note: MgO boards are heavier than plywood, so you might need help lifting them into place.

Particle Board

Features

You can find particle board in lots of homes. It gives a flat, smooth surface for floors. Makers use wood scraps and grind them into small pieces. They dry the pieces and mix them with resin. Then, they press the mix into panels using heat. The middle has bigger wood bits, and the top has smaller ones. This makes the board strong and even all over. Some boards have special resins that help them fight water. You might see particle board with a coating or laminate like melamine. This makes it tougher and better looking. Sometimes, makers add things to stop fire, mold, or bugs. Particle board comes in many thicknesses and strengths. You can pick the one that works for your job.

Made from leftover wood and resin

Flat and smooth, so it is easy to finish

Can have a coating or laminate for more strength

Comes in many thicknesses and strengths

Can have extras to fight water, fire, or bugs

Tip: Check if your particle board can handle water if you want to use it in damp rooms.

Pros and Cons

Here is what you get with particle board:

Aspect | Advantages | Disadvantages |

|---|---|---|

Cost | Costs much less than plywood or solid wood. Good for big or small jobs. | N/A |

Surface Quality | Flat and smooth, great for under floors. Glue sticks well. Works for tile, wood, or linoleum. | N/A |

Variety | Comes in many sizes and thicknesses. You can use it for lots of things. | N/A |

Environmental | Uses leftover wood, so it helps cut waste. Some types have no formaldehyde, so they are safer. | N/A |

Moisture Sensitivity | N/A | Soaks up water and can swell or break. Needs a barrier if used for floors. |

Note: Particle board is best for dry rooms. Water can make it swell or fall apart.

Best Uses

You can use particle board under many kinds of finished floors. It works under carpet, tile, or laminate. Builders use it in bedrooms, living rooms, or offices where it stays dry. You also see it in shelves or furniture because it is easy to cut. If you want a cheap, smooth subfloor, particle board is a good pick.

Under carpet, tile, or laminate

Subfloors in dry rooms

Shelves and furniture

Temporary or low-use floors

If you use it in kitchens or bathrooms, add a barrier to keep out water.

Installation

It is easy to put in particle board if you follow these steps. First, measure and cut the boards to fit your space. Lay them flat on the joists or over another floor. Leave a small gap between each board so they can expand. Use nails or screws every 6 to 8 inches on the edges and every 12 inches in the middle. If you use it under another floor, sweep away dust before you finish. Always seal the edges or use a barrier if water might be a problem.

Pro tip: Wear a mask when you cut particle board. The dust can bother your nose and throat.

Concrete Panels

Features

You might think concrete panels sound heavy and hard to work with, but modern panels are much easier to handle than you expect. Many builders use STRUCTO-CRETE® Brand Structural Panels because they bring a lot of benefits to your project. Here’s what you get:

Noncombustible panels that meet strict fire safety standards (ASTM E136)

Mold-, moisture-, and termite-resistant, so you don’t have to worry about pests or water damage

Panels stay flat and stable, so you won’t see buckling or warping like with wood

Fire-rated assemblies for 1, 2, or even 3 hours, which helps keep your building safe

Lighter than traditional concrete, making them easier to move and install

You can cut and fasten them with regular tools—no special equipment needed

No curing time, so you can keep your project moving fast

High compressive and flexural strength, which means you can use them in taller buildings

Made in the USA with both domestic and imported materials

Tip: Concrete panels support many types of finished floors. For most finishes, use an engineered underlayment, except when you install carpet and pad.

Pros and Cons

Pros | Cons |

|---|---|

Excellent fire resistance | Heavier than wood panels |

Resists mold, moisture, and termites | Costs more than OSB or plywood |

No curing time needed | Needs underlayment for some floor finishes |

Stays flat and stable | May require extra help for lifting |

You get a tough, safe, and long-lasting floor base, but you might spend more money and need extra hands for installation.

Best Uses

You can use concrete panels in places where safety and strength matter most. They work well in apartments, hotels, schools, and hospitals. Builders pick them for high-rise buildings and places with strict fire codes. If you want a floor that stands up to water, pests, and heavy loads, concrete panels are a smart choice. They also shine in basements, garages, and commercial kitchens.

Installation

You will find concrete panels easy to install if you follow a few steps:

Measure and cut the panels with a circular saw.

Lay the panels flat on the joists, leaving a small gap for movement.

Fasten the panels with screws—no glue or adhesive needed.

Use an engineered underlayment for most finished floors, except carpet and pad.

Start other trades right away since you don’t need to wait for curing.

Note: Concrete panels are lighter than poured concrete, but you may still need help to lift them safely.

Trending Floor Sheathing Materials 2025

Composite Panels

You might notice more builders using composite panels in 2025. These panels mix different materials, like wood fibers, plastics, and sometimes even recycled glass. This blend gives you a strong, stable base that resists bending and breaking. Many composite panels have a sandwich structure. That means you get a tough outer layer and a lightweight core inside. Some panels use fiberglass mesh to stop cracks and boost strength. Others add expanded polystyrene (EPS) to make the panels lighter. You can carry and install them with less effort. Composite panels work well in modular and prefab buildings because they are easy to cut and fit. You also get good sound and heat insulation, which helps keep your home quiet and comfortable.

Eco-Friendly Options

If you care about the planet, you have more choices than ever. Eco-friendly sheathing uses recycled wood, crop waste, or even bamboo. Some panels skip harmful chemicals, so you get better indoor air quality. Magnesium oxide (MgO) boards stand out here. They do not give off VOCs and help lower your building’s carbon footprint. MgO boards also last a long time and protect against mold and water. Check out this quick comparison:

Feature | Magnesium Oxide (MgO) Board | Traditional Gypsum Board |

|---|---|---|

Fire Resistance | Excellent | Moderate |

Water Resistance | High | Low |

Durability | Superior | Lower |

MgO boards now make up almost half of the lightweight panel market. Builders like them for their safety, strength, and green benefits.

🌱 Tip: Look for FSC-certified wood or panels made with renewable resources if you want to build green.

Smart Sheathing

Smart sheathing brings technology to your floors. Some new panels have built-in sensors that track moisture or temperature. You get alerts if there is a leak or if the floor gets too cold. Other smart panels use special coatings that fight bacteria or mold. Some even help control humidity in your home. These features keep your floors safe and healthy. You can connect some smart panels to your phone or home system. That way, you always know what is happening under your feet.

🏠 Note: Smart sheathing is still new, but it is growing fast. You might see more of these panels in homes and offices soon.

Floor Sheathing Comparison

Performance Table

You might want to know how each material compares. This table shows the main features for each one. It helps you see which is best for your needs.

Material | Strength | Moisture Resistance | Fire Resistance | Eco-Friendly | Ease of Install |

|---|---|---|---|---|---|

Plywood | High | Moderate | Low | Good | Easy |

OSB | High | Moderate | Low | Good | Easy |

Engineered Wood | High | Moderate | Low | Good | Easy |

MgO Board | High | High | Very High | Excellent | Moderate |

Particle Board | Low | Low | Low | Good | Easy |

Concrete Panel | Very High | Very High | Very High | Moderate | Moderate |

Composite Panel | High | High | Moderate | Excellent | Easy |

Tip: For the best fire or water safety, pick MgO board or concrete panels.

Cost Comparison

You might wonder which material costs the least. Here is a simple list to help you compare prices:

OSB: Cheapest for most homes

Plywood: About 60% more than OSB

Engineered Wood: A bit more than plywood

MgO Board: Costs more, but lasts longer

Particle Board: Least expensive, but not for wet places

Concrete Panel: Most costly, but very strong

Composite Panel: Price is between OSB and MgO board

Note: Spending more at first can save you money on repairs later.

Suitability by Project

You should choose the right floor sheathing for your job. Here is a quick guide to help you decide:

Homes and apartments: OSB, plywood, or engineered wood are good picks.

Wet areas (bathrooms, basements): MgO board or concrete panels work best.

High-rise or commercial buildings: Concrete panels or MgO board give strength and safety.

Eco-friendly builds: Pick MgO board or composite panels.

Budget projects: OSB or particle board save money. Only use particle board in dry rooms.

🛠️ Always pick what fits your needs. Think about water, fire, and your budget before you choose.

When you choose floor sheathing, you should think about your project, the weather, and how much money you have. These things are important for picking the right material:

Why It Matters | |

|---|---|

Moisture Resistance | Needed for wet rooms like bathrooms |

Durability | Good for busy areas with lots of foot traffic |

Fire Resistance | Important for safety in any building |

Environmental Impact | Helps if you want a green home |

Cost | Keeps your project on budget |

If you do not know what to pick, ask a builder for help. You can also look at guides or talk to someone at the hardware store for advice.

FAQ

What is the best floor sheathing for wet areas?

You should pick MgO board or concrete panels for wet spaces. These materials resist water and mold. They work great in bathrooms, basements, and laundry rooms.

Can I install floor sheathing by myself?

You can install some types, like OSB or plywood, if you have basic tools. Heavy panels, like concrete or MgO, may need extra help. Always follow safety tips.

How do I know what thickness to use?

Check your floor joist spacing. Most homes use 3/4-inch panels for 16-inch joist spacing. If your joists are farther apart, use thicker panels. Ask a pro if you are not sure.

Is eco-friendly floor sheathing strong enough?

Yes! Many green options, like MgO board or composite panels, offer great strength. You get a tough floor and help the planet at the same time.

Do I need to leave gaps between panels?

Yes, you should leave small gaps—usually 1/8 inch—between panels. This lets the material expand and keeps your floor from buckling.

Features

Features