28 Jul Top 8 Materials for Subfloor Insulation in 2025

Table of Contents

Here are the top 8 materials for subfloor insulation in 2025:

Spray foam

Rigid foam board

Mineral wool

Fiberglass batt

mgo board subfloor

Cork panels

Reflective foil

Cellulose insulation

When you pick insulation, check the R-value and cost. Also, think about how easy it is to install. Look at how long it lasts and if it resists water. See if it is good for the environment. Subfloor insulation keeps your home warmer. It lowers your energy bills. It also helps keep your floors dry. A new study says ground floor insulation can cut heating use by up to 10%. Good floor insulation helps stop mold. It keeps pests out. It also makes the air inside better.

Key Takeaways

Pick subfloor insulation by looking at R-value, price, how easy it is to put in, if it keeps out water, and if it is good for the environment.

Closed-cell spray foam gives the best insulation and keeps out water well, but it costs more and must be put in by a pro.

Rigid foam boards are strong and insulate well, and they are easier for people to install themselves than spray foam.

Mineral wool and cork panels help stop fires and block noise, and they are good for the planet, but they work best in dry places.

Fiberglass and cellulose insulation do not cost much and are easy to put in yourself, but they work best in dry spots and need you to watch out for water.

Insulation Factors

You want your house to stay comfy all year. Picking the right subfloor insulation helps with this. Let’s look at what you should check in 2025.

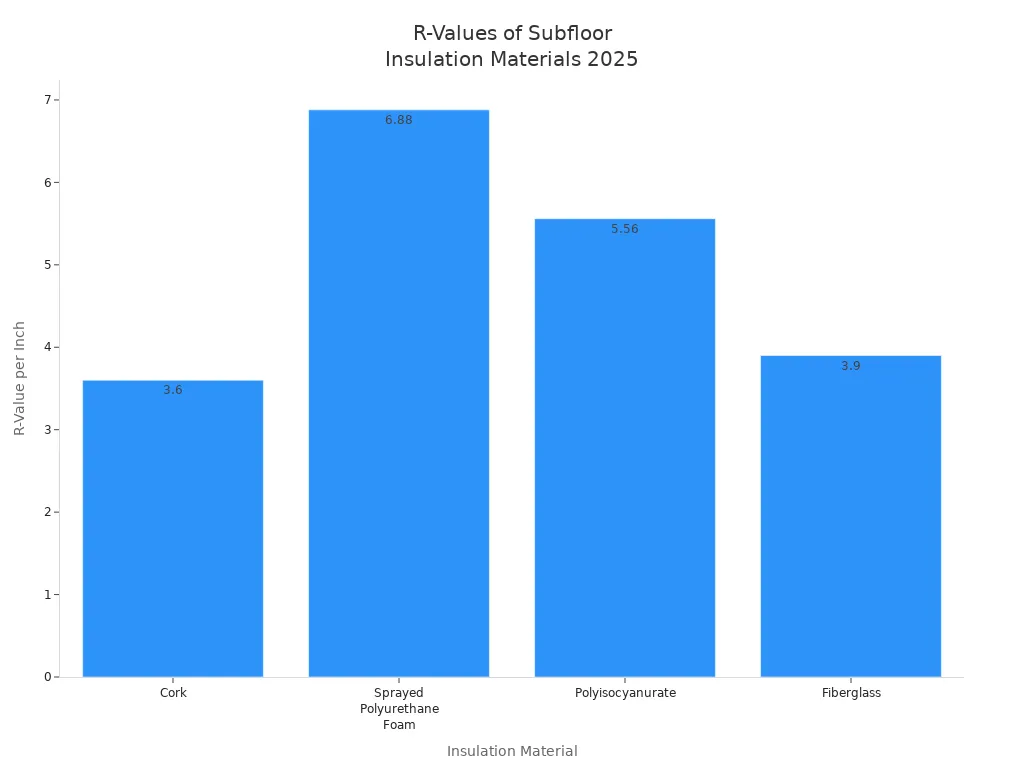

R-Value

R-value shows how well insulation keeps heat inside. A higher r-value means better insulation. You want a strong r-value to keep floors warm. This also helps save energy. Here is a table with r-values for common insulation:

Insulation Material | Typical R-Value (per inch) |

|---|---|

Cork | |

Sprayed Polyurethane Foam | 6.88 |

Polyisocyanurate | 5.56 |

Fiberglass | 3.90 |

Cost

You want to save money now and later. Some insulation costs more at first. But it can lower your energy bills over time. Here is a table with average costs for subfloor insulation in 2025:

Subfloor Insulation Material | Average Cost Range (per Sq. Ft.) |

|---|---|

Plywood | |

DRIcore® | $2.50 to $9 |

Amdry | $3 to $10 |

Barricade | $2 to $10 |

Warmboard | Around $7 |

OSB | $2.50 to $4.50 |

Concrete slab | Around $6 |

Installation

You want the job to be easy. Some insulation needs special tools or skills. Problems can happen with uneven floors or moisture. Using the wrong material can also cause trouble. Always measure well and follow the steps. Seal any gaps and use vapor barriers if needed. Good installation makes your home warmer and saves energy.

Moisture Resistance

Water can damage insulation and cause mold. Some materials, like mgo board and closed-cell spray foam, block water well. Rigid foam boards like XPS and Polyiso are also good in wet places. Fiberglass and mineral wool do not work as well with water. Use them only in dry spots.

Eco-Friendliness

If you care about nature, pick eco-friendly insulation. Cellulose, cork, and sheep’s wool are great choices. These come from recycled or natural things. They are better for the earth. They also help save energy and keep your home healthy.

Tip: Always make sure your insulation follows local building rules. It should also work with smart home tech for energy checks.

Spray Foam Insulation

Types

When you look at spray foam insulation for subfloors, you will find two main types: open-cell and closed-cell polyurethane. Open-cell foam is light and expands a lot. It fills gaps and helps with sound reduction. However, it has a lower r-value and does not block moisture well. Closed-cell polyurethane foam is much denser. It creates a strong air and vapor barrier. This type of foam works best in places where you need moisture resistance, like crawl spaces or high-humidity areas. Most experts recommend closed-cell polyurethane insulation for subfloors because it keeps water out and adds strength.

Open-cell polyurethane foam: light, flexible, not good for damp spots.

Closed-cell polyurethane foam: dense, blocks air and water, adds support.

Performance

You want insulation that keeps your floors warm and dry. Closed-cell spray foam insulation stands out for its high r-value, usually between R-6 and R-7 per inch. This means you get great insulation performance in a thin layer. The foam seals every crack, so you do not get drafts or cold spots. It also keeps moisture from getting into your subfloor, which helps prevent mold and wood rot. If you want the best thermal barrier, closed-cell polyurethane insulation is hard to beat.

Cost

Spray foam insulation costs more than other options. For closed-cell polyurethane foam, you can expect to pay $2.00 to $5.00 per square foot. The total price depends on how big your space is and how easy it is to reach. DIY kits cost less, but you might not get the same results as a pro.

Insulation Type | Cost per Sq. Ft. |

|---|---|

Closed-cell polyurethane foam | $2.00 – $5.00 |

Installation

Installing spray foam insulation takes skill. You need special tools and safety gear. Most people hire a professional for this job. The foam expands fast and sticks to everything. It fills every gap and makes a tight seal. If you do not install it right, you could trap moisture or cause off-gassing. Always check your subfloor for leaks or damage before you start.

Tip: Let a pro handle spray foam insulation for your subfloor. You will get better results and avoid costly mistakes.

Pros & Cons

Here is a quick look at the good and bad sides of spray foam insulation:

Pros:

High r-value for great energy savings

Cons:

Hard to remove if you need repairs

Needs expert installation

Can trap moisture if not installed right

Spray foam insulation, especially closed-cell polyurethane, gives you top-notch protection for your subfloor. Just make sure you weigh the cost and hire a skilled installer.

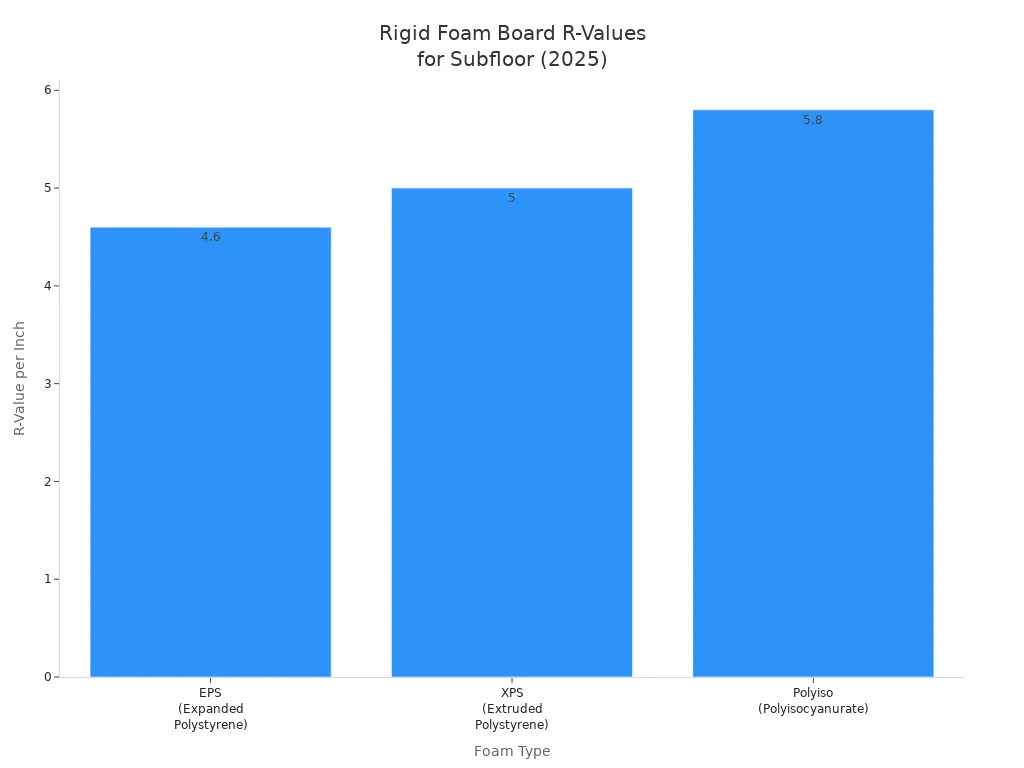

Rigid Foam Board

Types

There are three main kinds of rigid foam insulation for subfloors. These are expanded polystyrene (EPS), extruded polystyrene (XPS), and polyisocyanurate. EPS is the cheapest and works in many places. But it can be too soft for some floors. XPS is stronger and denser than EPS. People use XPS a lot in basements and places that need more support. Polyisocyanurate insulation gives the highest r-value per inch. It often has a foil face that reflects heat. You can put these foam boards under plywood or concrete subfloors.

EPS: low cost, can be used in many ways, but is softer

XPS: strong, keeps out water, good for basements

Polyisocyanurate: best r-value, needs a vapor barrier

Performance

Rigid foam insulation is known for being strong and keeping heat in. Polyisocyanurate insulation has an r-value between 5.6 and 7.0 per inch. But it can lose some power when it gets cold. XPS keeps a steady r-value of about 5 per inch. It is the strongest and can hold heavy things well. EPS has an r-value of about 4 per inch. Its strength depends on how dense it is. All three types keep out water. But XPS and polyisocyanurate insulation work best in wet places.

Cost

You probably want to know how much rigid foam insulation costs. Polystyrene insulation, which is EPS and XPS, is the least expensive. The price is from $0.25 to $0.70 for each board foot. Polyisocyanurate insulation costs a little more, from $0.40 to $0.75 per board foot. If you pay someone to install it, the total price is $1.20 to $3.70 per square foot. Rigid foam insulation costs more than fiberglass batts. But it is cheaper than spray foam.

Material Type | Cost per Board Foot (Material Only) | Installed Cost per Square Foot |

|---|---|---|

Polystyrene (XPS/EPS) | $0.25 – $0.70 | $1.20 – $3.70 |

Polyisocyanurate | $0.40 – $0.75 | $1.20 – $3.70 |

Installation

You can put in rigid foam insulation by yourself if you have simple tools. Cut the foam boards so they fit tight between the floor joists. Or lay them flat under plywood or concrete. Seal the seams with tape or spray foam to stop air leaks. Always use a vapor barrier with polyisocyanurate insulation to keep out water. If you use polystyrene insulation, make sure it is strong enough for your floor. Rigid foam insulation is easy to move and cut. But you should cover it with plywood or OSB to keep pests away.

Tip: Check for water leaks before you put in rigid foam insulation. Fix any leaks first so you do not get mold.

Pros & Cons

Here are some good and bad things about rigid foam insulation:

Pros:

High r-value, especially with polyisocyanurate insulation

Strong and can hold up heavy floors

Keeps out water well

Easy to cut and put in place

Can go under plywood and concrete

Cons:

Polyisocyanurate insulation can lose r-value when it is cold

Needs extra cover to keep pests out

EPS might be too soft for some floors

Costs more than fiberglass batts

Rigid foam insulation, especially polyisocyanurate insulation, is a great pick for subfloors in 2025. You get strong boards, good r-value, and protection from water. Just make sure you pick the right foam for your floor and weather.

Mineral Wool

Types

There are two main kinds of mineral wool insulation for subfloors. One is stone wool, which is made from volcanic rock. The other is slag wool, made from recycled steel slag. Both types work well for timber floors and between joists. You can buy mineral wool as batts or loose-fill. Batts fit tightly between floor joists, so there are fewer gaps. Loose-fill is good for odd spaces or around pipes.

Performance

Mineral wool insulation is great at stopping fire and blocking sound. It can handle heat over 2,000℉, so it helps slow down fire. This keeps your home safer. The R-value is about 4.3 per inch, so your floors stay warm. This also helps lower your energy bills. If mineral wool gets wet, it still works and dries fast. It blocks noise, so you hear less from above. Mineral wool also stops mold, rot, and pests. It is a smart choice for dry or ventilated subfloors.

Here is a table with its main features:

Performance Characteristic | Description |

|---|---|

Fire Resistance | Handles heat over 2,000℉, slows fire, adds safety. |

Energy Efficiency | R-value is about 4.3 per inch, works even when wet. |

Moisture Resistance | Keeps out water, stops mold, dries fast. |

Soundproofing | Blocks noise, makes rooms quieter. |

Sustainability | Made from recycled stuff, can be recycled again. |

Flexibility & Durability | Fits tricky spots, strong under weight. |

Cost

Mineral wool insulation costs a bit more than fiberglass. It is about $0.62 per square foot. Fiberglass costs around $0.50 per square foot. You pay more at first, but you save money later. This is because your energy bills go down and you need fewer repairs.

Installation

You can put in mineral wool insulation yourself. Wear gloves and a long-sleeve shirt because the fibers can itch. Batts are stiff and stay in place between joists. You do not need extra fasteners. Use a serrated knife or saw to cut mineral wool, especially around pipes or wires. Always measure well and fill every gap for best results. Mineral wool works well in dry or ventilated subfloors.

Tip: Wear a dust mask and goggles when you use mineral wool insulation. This keeps you safe and comfortable while you work.

Pros & Cons

Here is a quick list to help you decide if mineral wool insulation is right for your subfloor:

Pros:

Great fire resistance for more safety

Good at blocking sound and keeping heat in

Eco-friendly and made from recycled materials

Cons:

Costs more than fiberglass insulation

Can itch your skin—wear protective gear

Heavier and harder to cut around things

If you want insulation that keeps your home safe, quiet, and saves energy, mineral wool is a good choice for dry or ventilated subfloors.

Fiberglass Batt

Types

Fiberglass batt insulation is easy to spot. It comes in big, soft rolls or panels. These fit between your floor joists. Some batts have a vapor barrier, and some do not. Faced batts help stop moisture from getting in. Most people use regular batts for subfloors. They are simple to cut and put in place.

Performance

Fiberglass batt insulation keeps your floors warm. Its R-value per inch is between R-3.1 and R-3.4. Most floor jobs use batts that are 5 ¾” to 9 ½” thick. This gives you a total R-value from R-19 to R-30. That meets most building rules for floors in 2025.

Parameter | Value/Range |

|---|---|

R-value per inch (fiberglass batt) | R-3.1 to R-3.4 |

Typical thickness for floor insulation (subfloor) | 5 ¾” to 9 ½” |

Recommended R-value for floor insulation (subfloor) | R-19 to R-30 |

Fiberglass does not stop air as well as spray foam. You may need to seal cracks before you add insulation. If fiberglass gets wet, it does not work as well. It is best for dry places.

Cost

Fiberglass batt insulation is not expensive. It is one of the cheapest ways to insulate your floor. The cost to put fiberglass batts under your floor is about $2.03 to $3.37 per square foot in 2025. This price covers both the material and labor if you hire someone. You can save money by doing it yourself.

Installation

It is easy to install fiberglass batt insulation. Cut the batts to fit between the joists. Push them into place. Wear gloves, a mask, and long sleeves. Fiberglass can bother your skin and lungs. Make sure there are no gaps in the insulation. If you use faced batts, put the vapor barrier on the warm side. Fiberglass works well in dry basements or crawl spaces. Do not use it in wet areas because it can hold water.

Tip: Check for leaks or water before you put in fiberglass. Dry floors help your insulation last longer.

Pros & Cons

Here are some good and bad things about fiberglass batt insulation for subfloors:

Pros | Cons |

|---|---|

Costs less than most other insulation | Can hold dust, allergens, and moisture, which can cause mold |

Fits standard joist and stud spaces | Can release tiny bits that bother your breathing |

Good for DIY if you have some skill | Can make your skin itch or rash if you touch it |

Does not burn and is eco-friendly | Can sag or fall down over time |

| Lets air move, which can make floors cold and bills higher |

Fiberglass batt insulation is a good pick if you want cheap, easy floor insulation for dry spots. Keep it dry and use a vapor barrier if you need to. If you need better moisture protection, try another insulation type.

mgo Board Subfloor

What Is It

What Is It

You might hear people talk about mgo board when they want strong, safe subfloor insulation. Mgo board stands for magnesium oxide board. Manufacturers make these boards from magnesium oxide, magnesium chloride, perlite, wood fiber, vermiculite, and glass mesh. This mix gives you a board that is tough, fire-resistant, and moisture-resistant. You can use mgo boards in homes, basements, and even busy commercial spaces. They do not swell or warp when wet, so you can trust them in bathrooms, kitchens, or anywhere that gets damp. These boards also help keep your indoor air clean because they do not give off harmful chemicals or support mold growth.

Performance

Mgo board insulation stands out for its safety and strength. It can handle heat up to 1200°F without burning or making toxic fumes. You get peace of mind knowing your floors are safer from fire. These boards resist water and mold, so you do not have to worry about swelling or pests. They also give you good thermal insulation and soundproofing, making your home quieter and more comfortable. The boards stay strong under heavy foot traffic and do not break down like wood panels. You can cut and shape them with regular tools, which makes them easy to fit in any space.

Cost

You will pay more for mgo board insulation than for plywood or OSB. Here is a quick look at how the costs compare:

Material | Average Cost per Sq. Ft. | Key Features |

|---|---|---|

OSB | $0.50 – $1.00 | Cheapest, basic subfloor use |

Plywood | $0.80 – $1.60 | Stronger than OSB |

mgo Board | Fire/moisture resistant, durable |

The higher price comes from the extra benefits you get—better fire safety, moisture resistance, and a longer lifespan. Over time, you may save money on repairs and energy bills because these boards last longer and help with insulation.

Installation

You can install mgo board insulation with standard tools. The boards are lighter than cement boards, so you can move them easily. Cut them to size, lay them flat, and fasten them to your subfloor frame. Always let the boards adjust to your room’s temperature before you install them. This helps prevent cracks later. You do not need special skills, but you should follow the manufacturer’s instructions for the best results. Once installed, these boards need little upkeep because they resist mold and moisture.

Tip: Store mgo boards flat and dry before installation. This keeps them in top shape for your project.

Pros & Cons

Here’s a quick list to help you decide if mgo board insulation is right for you:

Pros:

Excellent fire resistance for safer homes

Resists water, mold, and pests

Durable and strong under heavy use

Eco-friendly and made from non-toxic materials

Easy to cut and install with regular tools

Good thermal and sound insulation

Cons:

Quality can vary between brands

Needs proper storage and acclimation before use

Not fully waterproof—long-term soaking can cause damage

Mgo board insulation is becoming more popular in 2025 because it gives you a safer, longer-lasting, and greener subfloor. If you want peace of mind and less maintenance, these boards are worth considering.

Cork Panels

Types

You have a few great choices when it comes to cork panels for floor insulation. Most cork panels come from renewable cork oak bark. Manufacturers press and steam-heat cork granules to make semi-rigid or rigid boards. These panels do not use adhesives, so you get a natural and toxin-free insulation option. You can find cork underlayment panels in different thicknesses, from 1/8 inch up to 12 inches. Some panels even have tongue-and-groove edges for a snug fit. If you want extra features, look for Eco Cork Foam underlayment. This combines cork with foam and a vapor barrier, giving you a waterproof and sound-absorbing layer for your subfloor.

Performance

Cork panels give you solid thermal insulation. They keep your floors warmer and help lower your energy bills. The R-value for cork panels usually falls between 3.6 and 4 per inch. Cork keeps its insulation power for at least 50 years. Even if the panels get a little wet, they still work well because moisture only stays on the surface. Cork also absorbs sound, so your home feels quieter. If you want a comfortable and peaceful space, cork floor insulation is a smart pick.

Did you know? Cork insulation can cut energy use by up to 29% compared to regular brick walls. It also helps lower CO2 emissions, making your home greener.

Cost

Cork panels cost more than fiberglass but less than spray foam. You might pay between $1.50 and $3.00 per square foot, depending on thickness and brand. While the upfront price is higher, you save money over time because cork lasts so long and helps reduce heating and cooling costs.

Installation

You can install cork panels yourself if you like DIY projects. Cut the panels to fit your subfloor, then lay them flat. Some panels have tongue-and-groove edges, which makes them easy to snap together. Always let the panels adjust to your room’s temperature before you start. For best results, follow the manufacturer’s instructions and use a vapor barrier if needed.

Pros & Cons

Here’s a quick look at the ups and downs of cork floor insulation:

Pros | Cons |

|---|---|

Renewable and eco-friendly | Higher upfront cost |

Great sound and thermal insulation | Can dent under heavy furniture |

Naturally resists mold and pests | Limited color choices |

Long-lasting (50+ years) | Needs careful installation for best results |

Cork panels give you a sustainable, comfortable, and quiet home. If you want floor insulation that is good for the planet and your family, cork is a top choice.

Reflective Foil

Types

You have a few choices when it comes to reflective foil for subfloor insulation. The most popular option is multi-foil. Multi-foil insulation uses several layers of foil and wadding. Some types have bubble wrap or foam between the foil sheets. You can find multi-foil in rolls or panels. Some brands add a vapor barrier to help block moisture. Multi-foil insulation works well as a stand-alone layer or with other insulation types.

Performance

Multi-foil insulation reflects heat back into your home. This keeps your floors warmer in winter and cooler in summer. You get the best results in climates with big temperature swings. Multi-foil insulation does not absorb water, so it helps stop mold and rot. It also blocks drafts and dust. You can use multi-foil as a main insulation or as a booster with other materials. Many people add multi-foil insulation under wood or laminate floors for extra comfort.

Note: Multi-foil insulation works best when you leave a small air gap on at least one side. This helps the foil reflect heat better.

Cost

Multi-foil insulation costs more than fiberglass but less than spray foam. You might pay $1.50 to $3.00 per square foot. The price depends on the number of layers and the brand. You save money over time because multi-foil insulation helps lower your energy bills. You also spend less on repairs since it resists moisture.

Installation

You can install multi-foil insulation yourself. Cut the rolls or panels to fit your subfloor. Staple or tape the multi-foil in place. Make sure you seal the seams to stop air leaks. Always follow the instructions from the manufacturer. If you use multi-foil insulation with other materials, put the foil layer facing the air gap. This gives you the best performance.

Pros & Cons

Here are some things to think about with multi-foil insulation:

Pros:

Reflects heat and keeps floors comfy

Blocks moisture, mold, and drafts

Lightweight and easy to install

Works as a main or extra insulation layer

Cons:

Needs an air gap for best results

Not as thick as some other insulation types

May not meet code alone in very cold places

Multi-foil insulation gives you a flexible and easy way to boost your subfloor insulation. You get comfort, energy savings, and less worry about moisture.

Cellulose Insulation

Types

You have a few choices when it comes to cellulose insulation for your subfloor. The most common type is loose-fill cellulose. This type uses recycled paper, usually newsprint, treated with safe chemicals to resist fire and pests. You might also see dense-pack cellulose, which installers blow into tight spaces for better coverage. Both types work well in dry subfloor areas. If you want an eco-friendly option, cellulose insulation stands out because it uses up to 85% recycled content.

Performance

Cellulose insulation does a great job keeping your floors warm. It has an R-value of about 3.2 to 3.8 per inch. This means you get solid thermal protection. Cellulose fills gaps and covers odd shapes, so you do not get cold spots. It also helps block sound, making your home quieter. You should only use cellulose in dry subfloor spaces. If it gets wet, it can lose its power and may take a long time to dry.

Tip: Cellulose insulation works best in dry, enclosed subfloors. Always check for leaks before you install it.

Cost

You will like the price of cellulose insulation. It usually costs $0.60 to $2.30 per square foot, including installation. This makes it one of the most affordable insulation choices for subfloors. You save money up front and on your energy bills over time.

Installation

You can install cellulose insulation yourself if you rent a blower. Most people hire a pro for the best results. The installer blows cellulose into the subfloor cavity, filling every gap. Make sure the area stays dry. Always wear a mask and goggles to protect yourself from dust.

Pros & Cons

Here’s a quick look at the good and bad sides of cellulose insulation:

Pros | Cons |

|---|---|

Made from recycled paper | Not good for wet areas |

Great at filling gaps | Can settle over time |

Blocks sound well | Needs a vapor barrier in some cases |

Low cost | Needs pro installation for best results |

If you want eco-friendly insulation for a dry subfloor, cellulose insulation is a smart pick. It keeps your home warm, quiet, and green.

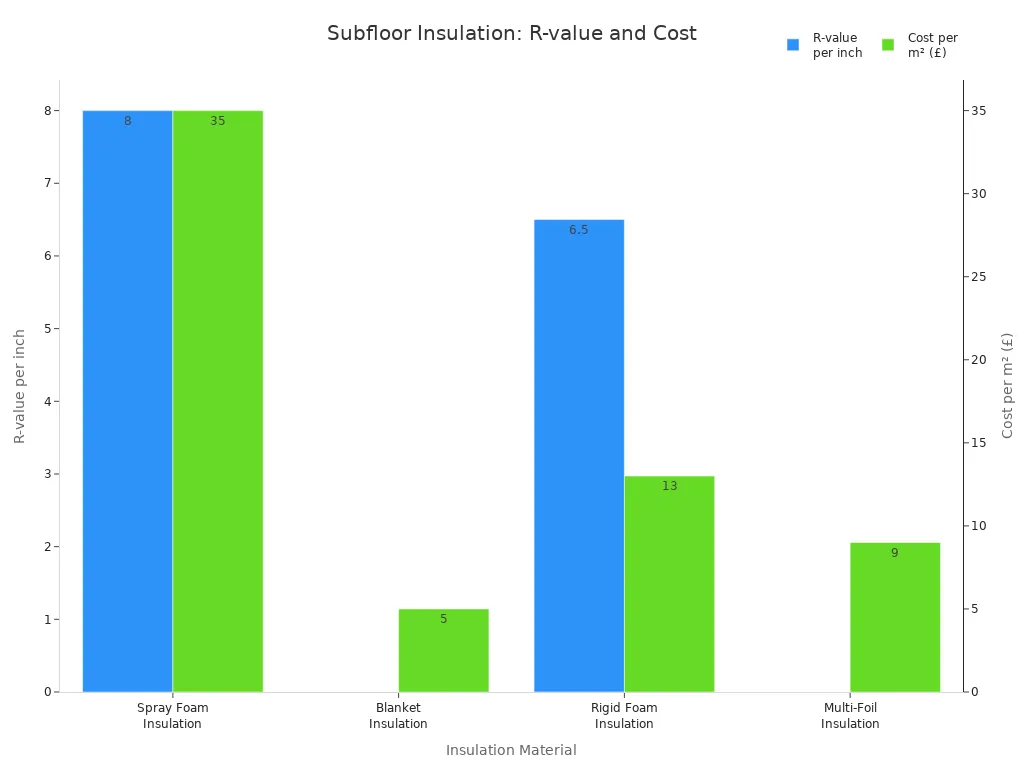

Comparison

It helps to compare insulation choices for your subfloor. This way, you can see which one fits your needs best. Here is a simple guide to help you pick the right insulation materials.

R-Value

R-value shows how well insulation keeps heat inside. A higher number means better at stopping heat loss. Closed-cell spray foam insulation and polyurethane foam have the highest numbers. They save the most energy. Rigid foam insulation, like polyisocyanurate, also works very well. Cork and mineral wool are good choices too. Fiberglass and cellulose have lower r-values but still help. Reflective foil does not trap heat. It bounces heat back instead.

Insulation Material | Typical R-Value (per inch) |

|---|---|

Spray Foam Insulation | Up to R-8 (closed-cell) |

Rigid Foam Insulation | EPS ~R-4, XPS ~R-5, Polyiso ~R-6.5 |

Mineral Wool | ~R-4.3 |

Fiberglass Batt | R-3.1 to R-3.4 |

~R-1.2 to R-1.5 | |

Cork Panels | ~R-3.6 |

Reflective Foil | Reflective barrier |

Cellulose Insulation | R-3.2 to R-3.8 |

Cost

You want insulation that does not cost too much. It should also help you save on energy bills. Spray foam insulation and polyurethane foam cost the most at first. But they lower your bills the most. Rigid foam insulation and polystyrene are cheaper and still work well. Cork, mineral wool, and cellulose insulation cost a medium amount. Fiberglass is the cheapest, but it may not last as long. Reflective foil is also low-cost and easy to add on top.

Insulation Material | Cost per Sq. Ft. (USD) |

|---|---|

Spray Foam Insulation | $2.00 – $5.00 |

Rigid Foam Insulation | $1.20 – $3.70 |

Mineral Wool | $0.62 |

Fiberglass Batt | $2.03 – $3.37 |

mgo Board Subfloor | $1.50 – $3.00 |

Cork Panels | $1.50 – $3.00 |

Reflective Foil | $1.50 – $3.00 |

Cellulose Insulation | $0.60 – $2.30 |

Installation

Some insulation is easy for you to put in yourself. Fiberglass, cellulose, cork, and rigid foam insulation are good for DIY if you follow safety steps. Spray foam insulation and polyurethane foam need a pro because they use special tools. mgo board subfloor and polystyrene panels are easy to cut and fit. Always check the instructions before you start. Reflective foil is light and quick to install. It is great if you want to add more insulation.

Tip: Always wear gloves, a mask, and goggles when working with insulation. This keeps you safe and comfortable.

Best Use

Pick the insulation that matches your space. Here is a quick list to help you choose:

Spray foam insulation / Polyurethane foam: Best for crawl spaces, wet spots, and saving the most energy.

Rigid foam insulation / Polystyrene: Good for basements, under concrete, or where you need strong support.

Mineral wool: Great for fire safety and blocking sound in dry floors.

Fiberglass batt: Works well in dry, easy-to-reach places and for quick DIY jobs.

mgo board subfloor: Pick this for fire safety and moisture control in kitchens or bathrooms.

Cork panels: Choose cork for green comfort and quiet floors.

Reflective foil: Use as an extra layer in hot or cold places, especially with an air gap.

Cellulose insulation: Best for dry, closed subfloors if you want eco-friendly insulation.

There are many insulation choices. Think about your budget, your space, and how much energy you want to save. The right insulation materials make your home warmer, safer, and more comfortable.

Subfloor insulation in 2025 helps you save money, stay warm, and keep your home dry. Each material has its own perks. Spray foam and rigid foam work best for tough jobs. Mineral wool and mgo board give you safety and strength. Cork and cellulose are great if you want eco-friendly options. Fiberglass and foil cost less and are easy to install.

Tip: Think about your budget, climate, and skill level. If you feel unsure, talk to a pro or get a quote before you start.

FAQ

What is the best insulation for a damp crawl space?

Closed-cell spray foam works best for damp crawl spaces. It blocks water and keeps your floors dry. You get strong insulation and fewer worries about mold.

Can I install subfloor insulation myself?

Yes, you can install many types yourself. Fiberglass batts, rigid foam boards, and cork panels are DIY-friendly. Always wear gloves and a mask. If you use spray foam, hire a pro.

How do I know if my subfloor needs insulation?

Feel your floors. If they feel cold or drafty, you probably need insulation. High energy bills or moldy smells also mean you should check your subfloor.

Does subfloor insulation help with noise?

Yes! Mineral wool and cork panels block sound very well. You will notice quieter rooms and less noise from footsteps or voices above.

What Is It

What Is It