26 Jan Magnesium Sulfate Subfloor or Fiber Cement Subfloor Which Is the Better Choice for 2025

Table of Contents

If you want the best subfloor for 2025, pick magnesium sulfate subfloor. It offers strong performance, good safety, and great value. Magnesium sulfate subfloor is known for its fire resistance and moisture protection, making it a top choice. You will find it simple to install, which helps keep costs down. Look at the safety ratings below:

Feature | Cement Board | MGO Board |

|---|---|---|

Fire Resistance | Very Good | Excellent |

Moisture Proof | Good | Superior |

This article compares magnesium sulfate subfloor vs fiber cement subfloor, helping you choose the best one for your project.

Key Takeaways

Pick magnesium sulfate subfloor for great fire safety and water protection. It helps keep your house safe and dry.

Magnesium oxide board is lighter than fiber cement board. It is also easier to put in. This makes installation faster and simpler.

Magnesium sulfate subfloor saves money over time. It lasts long and does not need much care.

Magnesium oxide board is good for the environment. It needs less energy to make and can be recycled. This helps protect the planet.

Use magnesium sulfate board in wet places like bathrooms or kitchens. It stops mold and water damage better than other choices.

Magnesium Sulfate Subfloor vs Fiber Cement Subfloor Overview

MgO Board Properties

Magnesium oxide board is a new building material. It has many good features. People talk about magnesium sulfate subfloor vs fiber cement subfloor a lot. Both work well, but magnesium oxide board is different because of what it is made of. Here are the parts that make it special:

Component | Description |

|---|---|

Magnesium oxide (MgO) | Makes up most of the board. |

Magnesium sulfate (MgSO₄) | Helps hold the board together. |

Wood dust or cellulose | Adds bend and feel to the board. |

Perlite or vermiculite | Helps keep heat in and stops fire. |

Glass fiber mesh | Makes the board stronger and tougher. |

This board is light and does not rust. It can handle water well. You can cut and put it in place easily. Magnesium oxide boards stop fire, soak up little water, and last a long time. You can use them where you need to stop mold and rot. If you want a subfloor that stays strong and safe, magnesium oxide board is a good pick.

Fiber Cement Properties

Fiber cement board is also used a lot. People compare mgo vs fiber cement boards often. It is made from cement, sand, and fibers from plants. This board is thick and heavy. It feels strong when you walk on it. Fiber cement board stops fire and water, but it weighs more than magnesium oxide board. Cutting and putting it in place can be harder. It is tough and lasts long, but it can rust if it touches some chemicals.

When you look at magnesium sulfate subfloor vs fiber cement subfloor, you see big differences. Magnesium oxide board is lighter and easier to move. Fiber cement board is heavier and may need more support. Magnesium oxide boards do not rust as much and are easier to put in. If you want a subfloor that saves you time and work, magnesium oxide board gives you more good things.

Tip: If you need a subfloor for wet or damp places, magnesium oxide board protects better than fiber cement board. You get safety and value for a long time.

Performance Comparison

Durability and Longevity

You want your subfloor to last a long time. When you look at mgo and fiber cement boards, you notice big differences. Magnesium oxide board is strong and handles lots of people walking on it. It keeps its shape and does not get weak. Fiber cement board is also strong, but it can wear out faster in busy places.

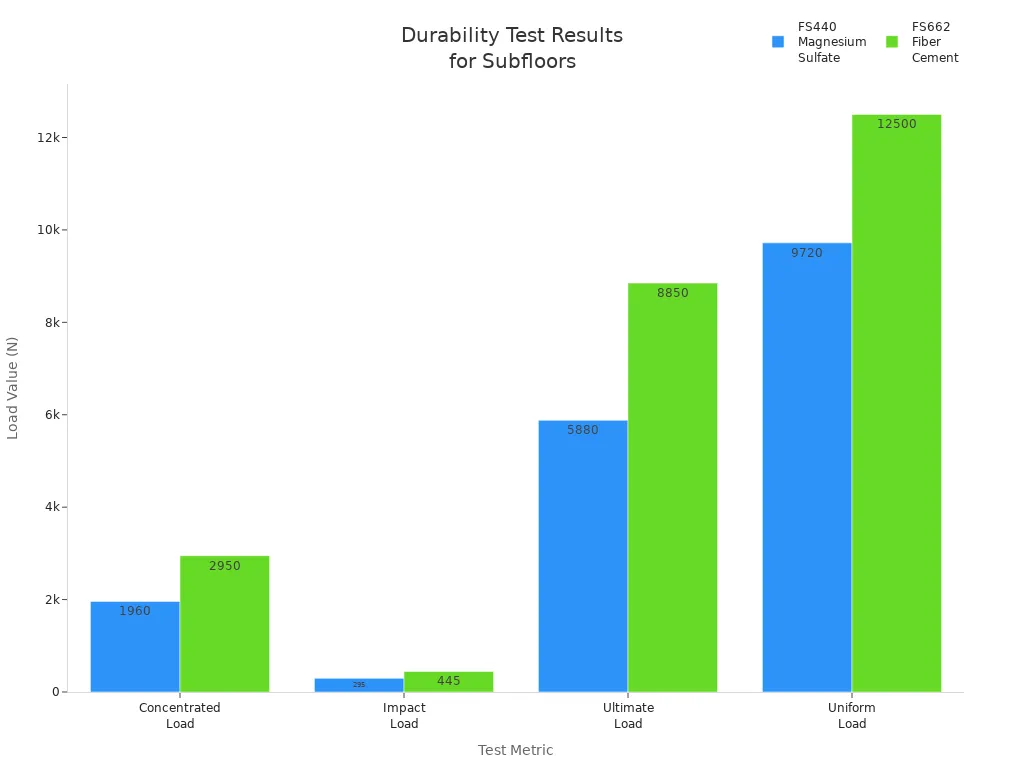

Check this table to see how each board deals with heavy loads and hits:

Type | Specification | Concentrated Load | Safety Factor | Impact Load | Ultimate Load | Uniform Load | Standard | Fire Protection |

|---|---|---|---|---|---|---|---|---|

FS440 | 500500/600600 | ≥1960 | Pass | 295 | ≥5880 | 9720 | ClSCA | A1 |

FS662 | 500500/600600 | ≥2950 | Pass | 445 | ≥8850 | 12500 | ClSCA | A1 |

Magnesium oxide board is very tough and strong. Fiber cement board is tough too, but it does not do as well as magnesium oxide board in these tests.

Here is a chart that shows how both boards do under stress:

If you want a subfloor that lasts, magnesium oxide board is a better choice. It does not crack or break easily. You will not need to replace it soon. Fiber cement board works, but it may wear out faster in busy spots.

Moisture and Mold Resistance

It is important for subfloors to resist water. You do not want mold or mildew under your floor. When you compare mgo and fiber cement boards, magnesium oxide board is better at stopping water. It only takes in a little water—about 0.34%. This helps it stay strong and keep its shape, even if it gets wet.

Fiber cement board can soak up water if you do not seal it well. Over time, this can cause mold and mildew. You might need to seal fiber cement board often to keep it safe. If you forget, water can hurt the board and cause mold.

Magnesium oxide board does not need much care. Its special makeup stops mold from growing. You get a clean and safe floor with less work. Fiber cement board needs more care to stay dry and mold-free. If you want a subfloor that fights water and mold, magnesium oxide board is the best pick.

Fire Resistance

Fire safety is very important for many people. You want a subfloor that keeps you safe if there is a fire. When you compare mgo and fiber cement boards, magnesium oxide board is better. It has an A1 non-combustible rating. This means it does not burn and stays strong for up to four hours in a fire.

Fiber cement board also resists fire, but it may need extra help to be as good. It can handle heat, but sometimes it needs more support. Magnesium oxide board does not spread flames much and makes little smoke or bad gas. This makes it great for places that need fire safety.

Here is a table that shows how both boards resist fire:

Property | Magnesium Oxide (MgO) Board | Cement Board |

|---|---|---|

Fire Resistance Rating | A1 Non-Combustible; excellent fire resistance | Moderate fire resistance; may need treatments |

Fire Duration Resistance | Up to 4 hours maintaining strength and shape | Handles fire but may require extra support |

Flame Spread | Low flame spread | Low flame spread |

Smoke and Toxic Gas Emissions | Low emissions; minimal smoke and toxic gases | Low emissions but generally higher than MgO |

Performance in High Heat | Maintains strength and shape under extreme heat | May require additional fireproofing |

Installation Ease | Lightweight and easier to install | Heavier and harder to install |

Suitability for Fire-Rated Applications | Preferred for high fire-risk areas due to superior fire resistance and low smoke emission | Suitable for lower fire risk or less extreme heat environments |

If you need a subfloor for fire safety, magnesium oxide board gives the best protection. Fiber cement board works in some places, but it is not as good as magnesium oxide board for fire resistance.

Note: When you look at magnesium sulfate subfloor and fiber cement subfloor, you see magnesium oxide board is better for strength, water resistance, and fire safety. You get more good things and feel safer with magnesium oxide board.

Installation and Cost

Installation Ease

Installation Ease

When you look at mgo vs fiber cement boards, you notice big differences in how easy they are to install. Magnesium oxide board is lighter, so you can move and cut it with less effort. Fiber cement board installation takes more time because the boards are heavy and tough to handle. You might need extra help or special tools for fiber cement board installation. Here are some common challenges you might face with both types:

Moisture vapor issues can cause adhesive problems and even mold.

Cracking may happen if the subfloor moves or shifts.

Adhesion issues can lead to the floor coming loose.

Magnesium oxide board helps you avoid many of these problems. You get smoother fiber cement board installation if you plan ahead, but magnesium oxide board makes the job easier.

Upfront and Long-Term Costs

You want to know how much you will spend. When you compare mgo vs fiber cement boards, magnesium oxide board usually costs less to install. Fiber cement board costs more than plywood, but it gives you savings over time by stopping water damage. For a quick cost analysis, you can expect to pay more upfront for fiber cement board installation. Magnesium oxide board keeps your costs lower at the start.

Value Over Time

You care about roi and long-term performance. Magnesium oxide board stands out for its durability, moisture resistance, and fire resistance. Fiber cement board also lasts, but you may spend more on repairs. Here’s a quick cost comparison for long-term maintenance over 20 years:

Cost Type | |

|---|---|

Running Costs | 50-70 |

Repair Costs | 10-20 |

Energy Costs | 5-10 |

Magnesium oxide board gives you a better roi because you spend less on repairs and upkeep. Fiber cement board installation can be costly, and you might see more issues over time. When you look at mgo vs fiber cement boards, magnesium oxide board offers the best return on investment and long-term performance. You get peace of mind and real value for your money.

Environmental and Health Impact

Sustainability

You might care about the environment when you pick a subfloor. Magnesium oxide board is a greener choice. It is made from materials that are good for the planet. Making this board uses less energy, so it does not make much pollution. When you are done with magnesium oxide board, you can recycle it. Some people even use old boards to help soil, so less trash goes to landfills.

Fiber cement boards are not as eco-friendly. They are made from cement, sand, and plant fibers. Making these boards uses a lot of energy. There is not much information about recycling fiber cement boards. This means they may end up as trash after you use them.

Magnesium oxide board can be recycled or used to help soil.

Fiber cement boards are not easy to recycle and may make more trash.

Magnesium oxide board uses earth-friendly materials and makes less pollution.

Fiber cement boards use materials that need a lot of energy.

If you want to build green, magnesium oxide board helps you do that. You make a smart choice for the earth and your project.

Safety Considerations

You want your home or work area to be safe. Magnesium oxide board helps keep you safe. It does not let out bad chemicals into the air. You can use it where people have allergies or breathing problems. The board stops mold and mildew, so the air inside stays clean.

Fiber cement boards can make dust when you cut them. You need to wear a mask and work where there is fresh air. The dust can bother your lungs if you breathe it in. Magnesium oxide board is easier and safer for people who put it in.

Tip: If you want a subfloor that is good for health and safety, magnesium oxide board is a great choice. It gives you strong fire safety and cleaner air inside.

Best Use Cases

Residential Spaces

You want your house to be safe and last long. Magnesium sulfate subfloor is good for homes. It keeps water out and stops mold from growing. It also protects against fire. You can use it in bedrooms, living rooms, and basements. It stays strong in dry rooms and helps keep heat inside. Fiber cement boards are also used in homes, mostly outside. They work well for siding because they handle weather and last a long time. If you need a subfloor for places with fire danger, magnesium sulfate boards protect best.

Here’s a simple chart showing where each board works best in homes:

Environment | Best Cement Board | Why It Works Well |

|---|---|---|

Wet indoor areas | Magnesium oxide board | Stops water, mold, and fire |

Dry indoor spaces | Magnesium oxide board | Keeps heat in, stays stable |

Outdoor siding | Fiber cement boards | Handles weather, lasts long |

High fire risk | Magnesium oxide board | Top fire resistance |

Heavy use outdoors | Fiber cement boards | Strong, resists impact |

Tip: If you want a subfloor that keeps your house dry and safe, magnesium sulfate boards are a smart pick for homes.

Commercial Spaces

You need tough floors for busy places like stores and schools. Magnesium sulfate boards are strong and last a long time. They do not break easily, even with lots of people walking on them. You can put them in faster than gypsum underlayment. This saves you time and money. These boards also help keep rooms quiet. Fiber cement boards are good for outdoor spots in businesses. They can take hits and bad weather, so they are good for entryways and outside walls.

Here’s a chart showing how both boards do in busy places:

Feature | Magnesium Sulfate Boards | Fiber Cement Subfloor |

|---|---|---|

Durability | Strong, withstands wear |

|

Fire Resistance | Lasts up to 4 hours |

|

Water Resistance | Resists water |

|

Note: Magnesium sulfate boards help keep busy places safe. You get floors that last and protect people.

Wet and Humid Areas

Bathrooms, kitchens, and laundry rooms need special floors. You want a subfloor that fights water and mold. Magnesium sulfate boards are best for wet places. They do not soak up much water and do not change shape. You can trust them in damp rooms because they block mold. Fiber cement boards also stop water, but you might need to fix cracks to stop mold. If you want the best floor for wet rooms, magnesium sulfate boards are the top choice.

Subfloor Material | Moisture Resistance | Suitability for Wet Areas |

|---|---|---|

MgO Board | Ideal | |

Cement Board | Completely water-resistant | Suitable |

Callout: Magnesium sulfate boards keep your bathrooms and kitchens safe and clean. You will not worry as much about repairs or mold.

MGO vs Fiber Cement Boards: Which Is Best for 2025?

Final Recommendation

Final Recommendation

You want the best subfloor for your project in 2025. When you compare mgo vs fiber cement boards, you see big differences in how they work and last. Experts say magnesium sulfate subfloor is the top choice for wet areas because it resists water and stays strong. You get better performance in places where moisture is a problem. MgO board stands out as the best subfloor material for 2025. It gives you strength and keeps water damage away.

Let’s look at why builders and homeowners pick MgO board over fiber cement board:

MgO board has a lower carbon footprint. It uses less energy and captures CO₂ during curing.

You get sustainability benefits. MgO board uses recycled materials and farm by-products.

MgO board is non-toxic. It does not have asbestos or formaldehyde.

You get top fire resistance. MgO board keeps its shape in high heat and fire-prone areas.

MgO board absorbs little water. Mold does not grow easily, even in humid rooms.

You can install MgO board quickly. It is light and easy to cut.

Fiber cement board works well in some places, but it does not match the performance of MgO board in wet or fire-risk areas. If you want a subfloor that lasts and keeps your space safe, MgO board is the better pick.

MgO board is better for the planet if you want an eco-friendly subfloor.

Choosing for Your Project

You might wonder which board fits your needs. When you look at magnesium sulfate subfloor vs fiber cement subfloor, you should think about your budget, your space, and what you want from your floor. Here’s a table to help you compare the main factors:

Aspect | Fiber Cement Board | MgO Board |

|---|---|---|

Carbon Footprint | High due to cement | Low, captures CO₂ |

Resource Use | Mining for minerals | Uses magnesite, less impact |

Recyclability | Hard to recycle | Fully recyclable |

Toxicity | May contain harmful stuff | Non-toxic, safe |

You pay less upfront for fiber cement board. It costs $5–$14 per square foot. MgO board costs more, between $8–$20 per square foot. You save money over time with MgO board because it lasts longer and needs fewer repairs.

Here are some things to think about when you choose between mgo vs fiber cement boards:

MgO board is easier to cut and install. You do not need special tools.

Fiber cement board needs special shears for neat cuts.

MgO board gives you better long-term value. You spend less on maintenance.

Fiber cement board may end up in a landfill. MgO board is fully recyclable.

You want good performance and value. MgO board gives you both. If you care about the environment, MgO board is the smart choice. You get a strong, safe, and green subfloor for your home or business.

Tip: Pick MgO board if you want a subfloor that lasts, protects against fire and water, and helps the planet.

If you still have questions about mgo vs fiber cement boards, think about your project’s needs. Do you need fire safety? Is your space wet or humid? Do you want to save money over time? MgO board is the answer for most projects in 2025.

You’ve seen how magnesium sulfate subfloor stands out for fire safety, moisture protection, and easy installation. If you want a subfloor that lasts and keeps your space safe, MgO board is the best pick for 2025. Need to save money? Fiber cement board works for tight budgets. Live in a wet climate? MgO board protects better. Think about your project’s needs and weigh the pros and cons. You’ll make the right choice for your home or business.

FAQ

What makes magnesium sulfate subfloor better for wet areas?

You get better moisture protection with magnesium sulfate subfloor. It absorbs less water and resists mold. This keeps your floors safe in bathrooms, kitchens, and laundry rooms.

Can I install magnesium sulfate boards by myself?

Yes, you can! Magnesium sulfate boards are lightweight and easy to cut. You don’t need special tools. Most people find installation quick and simple.

Is fiber cement board safe for homes with kids or pets?

Fiber cement board is safe, but you should wear a mask when cutting it. The dust can bother your lungs. Once installed, it’s fine for families and pets.

How long does magnesium sulfate subfloor last?

You can expect magnesium sulfate subfloor to last for decades. It resists cracking, water, and fire. You won’t need to replace it often.

Which subfloor is more eco-friendly?

Magnesium sulfate board is more eco-friendly. It uses less energy to make and is recyclable. You help the planet when you choose this option.

Installation Ease

Installation Ease Final Recommendation

Final Recommendation