01 Feb Fire Resistance Showdown Magnesium Sulfate Boards Versus OSB and Gypsum

Table of Contents

- 1 Key Takeaways

- 2 Magnesium Sulfate Subfloor Fire Resistant Performance

- 3 OSB and Gypsum Fire Resistance Compared

- 4 Fire-Resistant Materials: Head-to-Head Comparison

- 5 Safety, Cost, and Suitability Factors

- 6 FAQ

- 6.1 What makes magnesium sulfate boards the safest subfloor option?

- 6.2 Can you install magnesium sulfate boards as a subfloor in wet areas?

- 6.3 How does OSB compare to other subfloor materials for fire safety?

- 6.4 Is gypsum board a good subfloor for fire resistance?

- 6.5 What should you consider before choosing a subfloor material?

If you want the best fire resistance in subfloor materials, magnesium sulfate subfloor fire resistant boards are the top choice. Fire can move fast in a building, but good subfloor materials slow it down and help save lives. Magnesium sulfate subfloor boards have great fire resistance and help keep your building safer during a fire.

Fire-resistant subfloor materials make fire safety better by giving firefighters more time and helping them make smart choices in emergencies.

These materials increase fire resistance in floor systems, making your building safer and helping experts plan better ways to protect against fire.

Picking the best fire-resistant subfloor is a strong way to keep your property and everyone inside safer.

Key Takeaways

Magnesium sulfate boards have the best fire resistance. Their flame spread index can be zero. This makes them great for building safety.

Picking the right subfloor can help save lives. Magnesium sulfate boards slow fires down. This gives people more time to escape. Firefighters also get more time to help.

OSB panels catch fire easily. They are not good for places needing fire safety. OSB panels can make fires spread faster.

Gypsum boards have some fire resistance. They need more care and fixing. Gypsum boards work for simple fire safety needs.

Magnesium sulfate boards cost more at first. But they last longer and need fewer repairs. This makes them a smart choice for the future.

Magnesium Sulfate Subfloor Fire Resistant Performance

Fire Ratings and Zero Flame Spread

If you pick magnesium sulfate subfloor fire resistant boards, you get top fire ratings. These boards are very safe for buildings. Look at the table below to see how magnesium sulfate subfloor fire resistant boards compare to other boards:

Board Type | Flame Spread Index (FSI) | EN 13501-1 Rating | Additional Fire Performance Details |

|---|---|---|---|

Magnesium Sulfate (MgO) | 0 to 25 | A1 (Non-combustible) | Handles heat up to 1200°C; ASTM E84 FSI 0; Smoke Developed Index low; Passes ASTM E136 non-combustibility test |

Gypsum Boards | Moderate (varies by type) | Class A to C | Fire resistance up to 4 hours (Type X, Type C); Moderate flame spread; ASTM E84 tested but lower than MgO boards |

Cement Boards | Lower fire resistance | Lower than MgO | Less effective fire resistance compared to MgO boards |

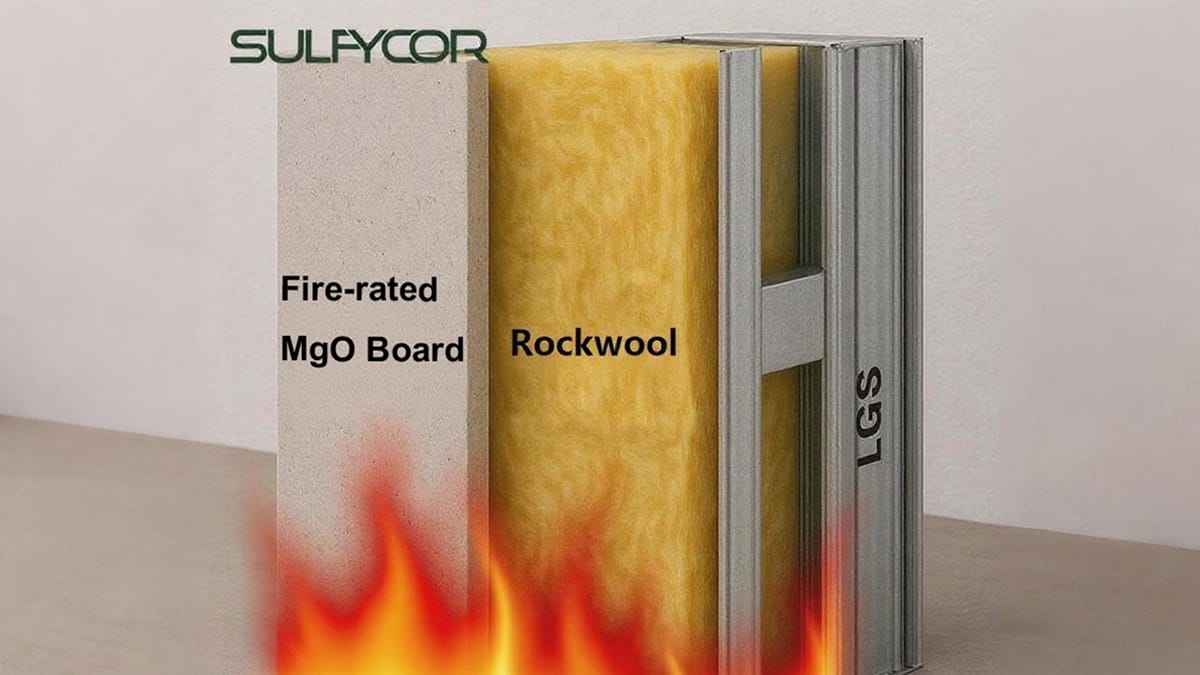

Magnesium sulfate subfloor fire resistant boards, called mgo boards or mgo panels, have a flame spread index as low as zero. This means flames do not move across the board. The A1 rating means these boards do not burn or melt, even in very hot fires. You can count on mgo boards to stay strong during a fire. Magnesium oxide board lets out water vapor when heated, which slows down fire and helps keep your building safe.

You should know the fire ratings for magnesium sulfate subfloor fire resistant boards from building codes:

Area of Use | |

|---|---|

Regular Use | At least 1 hour |

Special Areas (like fire rooms) | 2 hours or more |

These high fire ratings give you more time to act in an emergency. Mgo boards follow strict fire codes and help make spaces safer.

Tip: Magnesium sulfate subfloor fire resistant boards often have a flame spread index of zero. This is important for fire safety and saving lives.

Durability and Moisture Resistance

You want your subfloor to last a long time. Magnesium sulfate subfloor fire resistant boards are tough and resist water. Mgo panels keep their shape and strength when there is fire, humidity, or water. You do not need to worry about these boards burning, melting, or getting weak.

Magnesium sulfate subfloor fire resistant boards stay the same size in humid places.

Mgo boards do not soak up water and stop mold from growing.

These boards are stronger than regular drywall, so they work well in wet areas.

See how different boards do in wet-dry cycles:

Board Type | Performance under Wet-Dry Cycles |

|---|---|

Mg oxysulphate boards | More sensitive to high humidity |

Mg oxychloride boards | Relatively good performance under soak-dry cycles |

Other boards (fibre cement, gypsum, wood) | Suffered greater changes in bending strength compared to magnesium-based boards |

Mgo panels are special because they keep their strength and shape, even after getting wet many times. You get a subfloor that lasts longer and stays safe.

Note: Magnesium sulfate subfloor fire resistant boards do not let flames spread and do not soak up water. You get fire safety and strong boards that last.

You can trust magnesium sulfate subfloor fire resistant boards for high fire ratings, zero flame spread, and good performance in tough conditions. Mgo boards and mgo panels help you feel safe and meet building rules.

OSB and Gypsum Fire Resistance Compared

OSB Fire Ratings and Limitations

OSB Fire Ratings and Limitations

You need to know how osb panels perform when exposed to fire. Osb panels are made from wood strands and adhesives. This makes their combustibility high. Osb panels can catch fire quickly and help flames spread. You should not use osb panels in places where fire safety is a top concern.

The fire resistance of osb panels is much lower than magnesium sulfate boards. Osb panels have a flame spread rating between 76 and 200. This puts them in Class III or C for fire classification. Osb panels also have a smoke developed index below 450. You can see the difference in this table:

Material | Fire Resistance Rating | Additional Notes |

|---|---|---|

osb panels | Inherently flammable | Contributes to flame spread |

fire-rated osb | Slows fire spread but still flammable | |

MgSO₄-MgO Boards | Non-combustible | Withstands high heat, does not release smoke |

You may find fire-rated osb in the market. Fire-rated osb panels have chemicals added to slow down fire. Even with these treatments, fire-rated osb does not match the fire resistance of magnesium sulfate boards. Fire-rated osb still burns and adds to the combustibility of your building.

Osb panels are less expensive than other options. You may choose osb panels for cost reasons, but you must consider the risk. Osb panels are not recommended for mid-rise buildings because of their combustibility.

Note: Osb panels are not suitable for areas where you need high fire resistance. Fire-rated osb helps, but it does not remove the risk of combustibility.

Gypsum Board Fire-Resistant Properties

Gypsum board gives you better fire resistance than osb panels. Gypsum board is made from a mineral core that does not burn easily. The combustibility of gypsum board is low. You can use gypsum board to meet fire codes in many buildings.

Gypsum board passes important fire tests like ASTM E84 and ASTM E119. These tests check how long a wall or floor can resist fire. Gypsum board can last one or two hours in a fire, depending on the type. Some gypsum boards have a flame spread rating as low as 15. A few even reach zero. Most gypsum boards do not produce much smoke when they burn.

In fire endurance tests, gypsum board lost 24% of its mass. This is better than osb panels, which ignite quickly. Gypsum board stays strong longer and helps stop fire from spreading. You can trust gypsum board for walls and ceilings where fire safety matters.

Tip: Use gypsum board in places where you need good fire resistance and low combustibility. It is a common choice for safe buildings.

Fire-Resistant Materials: Head-to-Head Comparison

When you look at fire-resistant materials for your subfloor, you want to see how they perform in real life. Comparing fire ratings, durability, and cost helps you make the best choice for your project. You need to know which material gives you the most value and safety.

Quick Table: Fire Ratings, Durability, Cost

Here is a table that shows how magnesium sulfate boards, OSB, and gypsum boards compare:

Material | Fire Rating | Durability | Cost per Sq.Ft. | Maintenance Cost |

|---|---|---|---|---|

Magnesium Sulfate | Non-combustible, up to 4 hours | High, few repairs needed | $1.50 – $3.50 | Low |

Gypsum Board | Moderate, 1–2 hours | Lower, needs frequent repairs | $0.30 – $0.70 | High |

OSB | Low, flammable | Moderate, not for wet areas | $0.25 – $0.50 | Moderate |

You can see that magnesium sulfate boards cost more at first, but you save money over time. These boards last longer and need fewer repairs. Gypsum boards cost less to buy, but you may spend more on repairs because they crack and grow mold. OSB is the cheapest, but it does not work well in wet places and has low fire resistance.

If you want the best fire-resistant materials, magnesium sulfate boards give you top performance. They resist fire for up to four hours and stay strong in tough conditions.

When comparing fire ratings, magnesium sulfate boards stand out. Gypsum boards offer moderate protection, while OSB falls behind. You should choose your subfloor based on your building’s needs, safety rules, and budget.

Magnesium sulfate boards: Best for high fire resistance and durability.

Gypsum boards: Good for basic fire protection, but need more care.

OSB: Best for low-cost projects where fire risk is not a big concern.

You can trust magnesium sulfate boards when you need fire-resistant materials that last and protect your building.

Safety, Cost, and Suitability Factors

Safety and Building Codes

Safety and Building Codes

You should always think about safety first. Fire safety keeps people and buildings safe. Building codes say you must use safe materials. Magnesium sulfate boards give the best fire safety. These boards slow fire and give you more time to get out. Gypsum boards help with fire safety too, but not as much as magnesium sulfate boards. OSB panels do not give enough fire safety for most buildings. Insurance companies might lower your cost if you use safer materials. You should check your local rules to make sure you follow them. Fire safety is not just about rules. It is about keeping everyone safe.

Cost Analysis and Value

You need to think about both cost and safety. Magnesium sulfate boards cost more than gypsum or OSB. They last longer and are safer. Here is a table to show the costs:

Material | Cost per Square Foot |

|---|---|

MgO Boards | |

Regular Gypsum Boards | |

OSB | $0.25 to $0.50 |

You pay more for magnesium sulfate boards at first. You save money later because they last longer and need fewer repairs. Gypsum boards cost less, but you might pay more for repairs. OSB is the cheapest, but it does not keep you as safe. If you pick better fire safety, you protect your building and save money in the long run.

Suitability for Different Projects

You need to choose the right material for your project. Magnesium sulfate boards are best where safety and fire safety are very important. Use them in schools, hospitals, and big apartment buildings. Gypsum boards are good for homes and offices where you want basic fire safety. OSB works for sheds or garages where fire safety is not a big worry. If you build in a wet place like a basement or bathroom, you need a subfloor that does not soak up water. Magnesium sulfate boards keep you safe and do not soak up water. Always pick the material that fits your safety needs and building type.

Tip: Always put safety and fire safety first when you pick subfloor materials. The right choice keeps everyone safe and helps you worry less.

Magnesium sulfate boards give you the best fire safety. These panels do not burn or make dangerous smoke. They also stay strong in very hot fires. When you look at fire ratings, how long they last, and price, magnesium sulfate boards are the safest and a good deal over time. Experts say to use A1-rated non-combustible panels in places with wildfires. If you need something cheaper, OSB is okay for places with little fire risk. Gypsum board is good for simple fire safety. Always check your local rules and talk to building experts before you pick.

Material | Fire Resistance | Durability | Cost |

|---|---|---|---|

MgO Panels | Excellent | High | |

Gypsum Board | Moderate | Lower | Low-Med |

OSB | Low | Moderate | Low |

Tip: Pick fire-rated boards if you want the most safety and to feel calm.

FAQ

What makes magnesium sulfate boards the safest subfloor option?

You get top fire resistance with magnesium sulfate boards. These boards do not burn or let flames spread. You can trust them to keep your subfloor strong during a fire. Builders use them for safety in schools, hospitals, and apartments.

Can you install magnesium sulfate boards as a subfloor in wet areas?

You can install magnesium sulfate boards in wet areas. These boards resist water and mold. Your subfloor stays strong and does not change shape. You get reliable performance in bathrooms, basements, and kitchens.

How does OSB compare to other subfloor materials for fire safety?

You find OSB less safe than other subfloor choices. OSB burns quickly and helps fire spread. You should not use OSB as a subfloor in places where fire safety matters. Magnesium sulfate boards give you better protection.

Is gypsum board a good subfloor for fire resistance?

You get moderate fire resistance with gypsum board as a subfloor. Gypsum board does not burn fast, but it needs repairs often. You can use it for basic fire safety. Magnesium sulfate boards last longer and protect your subfloor better.

What should you consider before choosing a subfloor material?

You should look at fire ratings, water resistance, and cost. Your subfloor must meet building codes and keep people safe. Magnesium sulfate boards offer the best fire safety. OSB works for low-risk areas. Gypsum board fits simple projects.

OSB Fire Ratings and Limitations

OSB Fire Ratings and Limitations Safety and Building Codes

Safety and Building Codes