24 Aug Fire-Resistant Joint Treatment For Magnesium Wall Board

Table of Contents

You can make a fire-resistant joint for magnesium wall board by using fire-rated joint tape and compound at each seam. Good joint treatment makes the wall better at stopping fire and keeps the panel system strong. Some MgO boards already have fire ratings, but you still need to treat the joints to keep everything safe. Always use materials that are tested for working together and for fire resistance.

Key Takeaways

Put fire-rated joint tape and compound on each seam. This helps magnesium wall boards stay fire-resistant and strong.

Clean, level, and prime surfaces before using joint materials. This gives you the best results.

Pick certified, noncombustible materials that fit magnesium boards. This keeps fire safety and wall strength.

Follow every step closely when treating joints. This stops cracks and weak spots that let fire and smoke in.

Check and fix joints every year to catch damage early. This keeps your wall system safe and strong for a long time.

Fire-resistant Joint Importance

Fire Ratings and MgO Boards

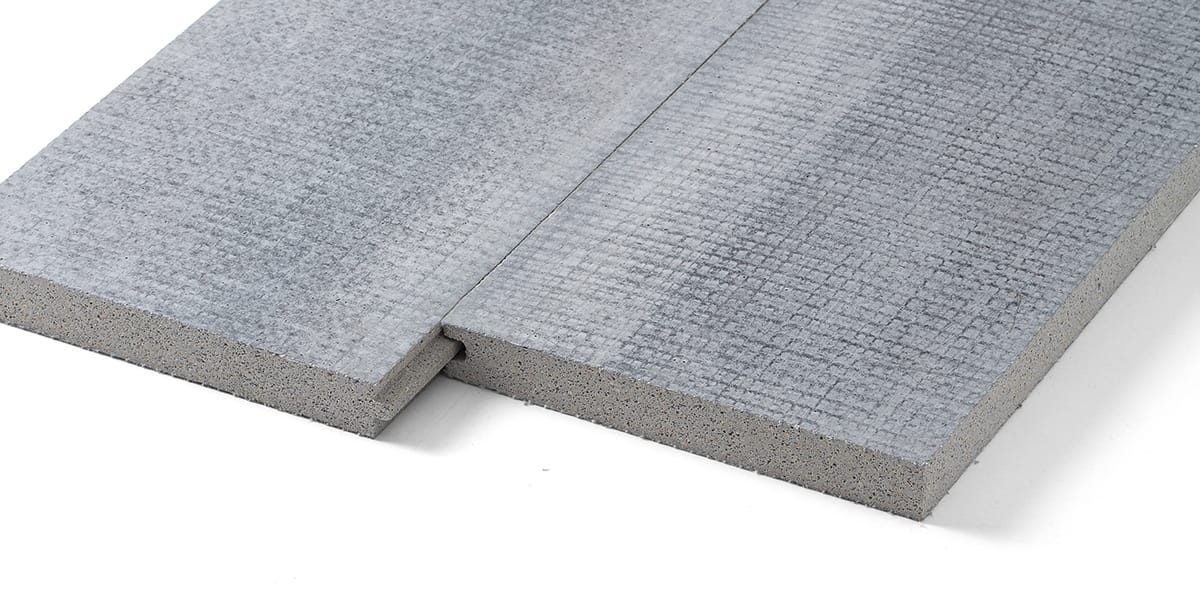

You need to understand how magnesium oxide (MgO) boards perform in fire-rated wall assemblies. MgO boards can withstand temperatures up to 1200°C and keep their strength for up to four hours during a fire. Most wall assemblies using MgO panels achieve fire resistance ratings of 1 to 2 hours. These ratings mean the wall can hold back fire and stay strong for that amount of time. You will see MgO boards used in places like stairwells and hallways, where fire protection matters most. Manufacturers test these panels under strict standards, such as ASTM E119 for fire endurance and ASTM E136 for noncombustibility. The panels must also meet codes like EN 13501-1 and CAN/ULC S114. These standards make sure the boards work well in fire-rated walls.

Tip: Always check that your MgO panels have been tested and certified for the fire rating you need. Not all panels meet every standard, so review the product documentation before installation.

Standard | Purpose |

|---|---|

ASTM E119 | Fire endurance of wall assemblies |

ASTM E136 | Noncombustibility of materials |

EN 13501-1 | European fire classification |

CAN/ULC S114 | Canadian noncombustibility |

Role of Joint Treatment

You might think the MgO board alone gives enough fire protection, but the seams between panels are just as important. If you skip the fire-resistant joint treatment, micro-cracks can form at the seams. These cracks let fire and smoke pass through, which lowers the wall’s fire rating and weakens its structure. You must use proper joint tape and fire-rated compound to seal every seam. This step keeps the wall strong and helps it meet the required fire resistance. Joint treatment also prevents gaps caused by changes in temperature and humidity. When you use the right materials and follow installation standards, you protect the entire wall system.

Use fire-resistant joint tape and compound at every seam.

Follow manufacturer guidelines for joint treatment.

Inspect joints for cracks or gaps after installation.

A fire-resistant joint is not just a detail—it is a key part of the wall’s safety. You keep your building safer and help the wall assembly pass fire code inspections.

Joint Treatment Steps

Making a fire-resistant joint for magnesium wall board takes care and focus. You need to follow each step in order. This helps the wall keep its fire rating and stay strong. Here is a simple guide to get good results.

Surface Prep

Getting the surface ready is very important for a strong joint. You should:

Leave a small gap, about 1/8 inch, between each MgO board. This gap lets the boards move when it gets hot or cold. It stops the boards from bending or cracking.

Fill all the gaps with a fire-rated sealant. This keeps the wall fire-resistant.

Look for cracks, holes, or uneven spots on the surface. Fix any damage so the base is solid.

Clean the surface well. Use a vacuum or a damp cloth to get rid of dust and dirt. Do not use strong chemicals because they can hurt how things stick.

Make sure the surface is flat by using a spirit level. Sand down high spots and fill low spots with leveling compound.

The surface must be dry before you move on. If it is humid, use a dehumidifier to help.

Lightly sand the board edges before you put on caulk or trim. This helps things stick better and look nicer.

For best results, use a primer made for concrete or masonry. This gives a good base and helps the joint compound stick.

Tip: Test a small spot with your primer and finish first. This makes sure everything sticks well.

Taping Joints

Taping the joints is a key part of making a fire-resistant joint. Use wide fiberglass mesh tape, at least 6 inches wide. This tape is strong and helps stop fire.

Put a thick layer of joint compound over the seam. Spread it a few inches past the edges.

Press the fiberglass mesh tape onto the wet compound. Line up the tape with the joint.

Add more compound over the tape. Smooth it out with a feathering motion.

Make sure there are no air bubbles under the tape. This keeps the joint strong and stops cracks.

Note: Fiberglass mesh tape works best because it is fire-resistant and matches MgO boards.

Applying Compound

You need to use a fire-rated joint compound that works with MgO boards. Sandable elastomeric joint compounds or lightweight concrete patching compounds are good choices. Some people use fine hydraulic cement fillers for extra strength.

Fill the joints with compound so it is even with the board.

When the first layer dries, add a second layer. Make this layer go at least 2 inches past the joint edges.

For cut edge joints, make each layer go 4 inches farther.

Let each layer dry before you add the next one.

Keep the temperature and humidity steady to stop small cracks.

A good finishing compound, spread out 18 to 24 inches, makes the joint look smooth and last longer.

Sanding and Finishing

Sanding and finishing make the joint look nice and keep it fire-resistant.

Lightly sand the joint compound when it is still a little damp, like leather. This helps stop small cracks.

Wipe away dust with a damp cloth.

Put on a final coat of finishing compound. Feather it out so it blends with the board.

When the last coat dries, sand it lightly for a smooth finish.

Reminder: Keep the temperature and humidity steady while sanding and finishing. This helps the fire-resistant joint stay strong and free from cracks.

If you follow these steps and use products made for MgO boards, you will make a fire-resistant joint that is safe and lasts a long time.

Material Selection

Fire-resistant Joint Materials

Fire-resistant Joint Materials

You have to pick joint materials that follow fire safety rules. These materials must not burn and should be tested for use with magnesium wall boards. Look for products that have certifications like ASTM E136 for noncombustibility and EN 13501-1 for fire classification. The Perseverance Magnesium Oxide Board has an A1 rating under EN 13501-1. This means it does not help fire spread and makes very little smoke or harmful fumes. It also passes ASTM E119 for fire endurance, so it can resist fire for two hours in steel stud walls.

When you choose joint compounds and tapes, check for these certifications. Manufacturers put them on product labels or technical sheets. Do not use any material that does not show these standards. Using the wrong product can lower your wall’s fire rating and make it unsafe.

Certification/Standard | Purpose/Requirement | Description |

|---|---|---|

EN 13501-1 | Fire classification | Class A1 Noncombustible – highest fire resistance, no help to fire, little smoke and toxic fumes |

ASTM E136 | Noncombustibility test | Material does not burn during tests, proving it will not catch fire |

ASTM E84 | Surface fire spread | Class A rating means it stops fire from spreading on the surface |

EN ISO 1716 | Fire performance | Measures how much energy the material gives off in a fire |

ICC-ES ESR-2880 | Evaluation report | Shows the material meets building codes and fire safety rules |

CCMC 14038_e | Canadian certification | Proves the material works well and is safe in Canada |

BBA | British certification | British Board of Agrément says the material is good and safe |

Kiwa BDA | European technical approval | Shows the material meets European fire safety and quality rules |

INTERTEK and ILAC-MRA | Laboratory accreditation | Makes sure test results are trusted and accepted everywhere |

Tip: Always look for certifications like ASTM E136 and EN 13501-1 before buying joint materials. These standards show the product is safe for fire-rated walls.

Compatible Tapes and Compounds

You need to use tapes and compounds that work with MgO boards and keep the fire-resistant joint strong. Some products are tested for this and for fire safety. Here are some good choices:

Manus-Bond 75-AM is a flexible filler for gaps between boards.

Sandable joint compounds help you make the surface smooth after filling.

Use 6-inch wide fiberglass tape with RapidSet “Wunderfixx” for seams. This tape stops fire and makes the joint stronger.

Spread the tape and compound 12 to 18 inches on both sides of the seam for more protection.

When the compound dries and feels like leather, sand it lightly to make it smooth.

For the last coat, use a finishing compound like Murco Wall M-100 or Westpac Materials “Red Dot.” Spread this coat out 18 to 24 inches for a smooth look.

⚠️ Warning: Do not use regular paper tape or compounds that are not fire-rated. These products can fail in a fire and make the wall unsafe. Always follow the manufacturer’s instructions and use only products tested for MgO boards.

Leave a small gap, about 1/6 to 1/8 inch, between boards so they can expand. Fill this gap with Manus-Bond 75-AM, then put the fiberglass tape in RapidSet “Wunderfixx.” This way, the fire-resistant joint stays strong and helps the wall pass fire safety checks.

Picking the right materials keeps your building safe and makes the wall system strong. You make sure the fire-resistant joint works well when you use certified and matching products.

Mistakes to Avoid

Wrong Materials

You must choose the right materials for fire-resistant joints. Many people make the mistake of using regular joint compounds or paper tape. These products do not have fire ratings and can fail during a fire. Always check that your joint compound and tape are labeled as fire-rated and compatible with MgO boards. If you use the wrong materials, you risk lowering the wall’s fire rating and making the building unsafe.

⚠️ Warning: Never use non-fire-rated compounds or tapes. These can burn or break down under heat, letting fire and smoke pass through the joints.

You should also avoid using fasteners that rust or corrode. Corrosion can weaken the joint and create gaps. Use corrosion-resistant screws and make sure they fit the type of framing you have. Always follow the manufacturer’s instructions for all products.

Poor Application

Even the best materials will not work if you apply them poorly. Skipping steps or rushing the process can lead to weak joints and cracks. You need to prepare the surface well and follow each step carefully.

Here are some best practices to help you get a professional, durable finish:

1. Clean the surface and remove all dust and old material. 2. Level uneven areas to create a flat base. 3. Check that studs or subfloors are straight and spaced correctly. 4. Leave small expansion gaps between boards. 5. Use corrosion-resistant fasteners and avoid over-tightening. 6. Apply primer before finishing to help the compound stick. 7. Fill all gaps and cover screws with joint compound. 8. Sand the compound lightly for a smooth finish. 9. Seal all edges and joints with quality sealant. 10. Finish with paint, tile, or wallpaper as needed.

Tip: Take your time with each step. Careful work now means fewer repairs later and a safer wall system.

If you avoid these common mistakes, you will create joints that last and keep your building safe. Always use fire-rated, compatible materials and follow best practices for every project.

Durability and Safety

Maintenance Tips

Maintenance Tips

You need to care for your MgO wall joints to keep their fire resistance strong over time. Simple maintenance steps help you avoid bigger problems later. Here are some best practices:

Inspect your walls once or twice a year. Check for cracks, chips, or worn seams, especially after storms or heavy use.

Clean the boards with a damp cloth or mild soap. Avoid harsh cleaners that can damage the surface or weaken the joint compound.

If you see worn or damaged joints, apply new joint compound or patching compound. Sand the area smooth after it dries.

Make sure all screws stay tight and free from rust. Replace any corroded fasteners right away.

In wet areas, use a primer or waterproof sealant every few years. This keeps moisture out and protects the board.

For small damage, sand the spot, clean it, fill with patching compound, let it dry, sand again, and repaint or refinish to match the rest of the wall.

Always check for moisture before making repairs. Fix any water leaks or damage first.

Tip: Regular cleaning and quick repairs help prevent cracks and moisture from getting into the joints. This keeps your fire-resistant wall system working as it should.

Inspection

You should inspect fire-resistant joints at least once a year. Annual checks help you spot cracks, gaps, or damage that could lower the wall’s fire resistance. Fire safety codes like NFPA 1 and NFPA 101 recommend yearly inspections for all fire barriers, including MgO wall assemblies.

Look for cracks, chips, holes, or gaps in the joints.

Check if fire-rated sealants and tapes are still in good shape.

Make sure there is no rust on screws or fasteners.

Watch for signs of water damage or mold.

If you find small dents or scratches, fill them with a compatible repair compound right away. For larger damaged areas, you may need to replace the affected section. Always use patching materials and sealants made for MgO boards. Managing moisture and keeping the area clean will help your wall system last longer and stay safe.

🛠️ Note: Prompt repairs and regular inspections keep your fire-resistant joints strong and help your building meet safety codes.

You can make fire-resistant joints for magnesium wall boards by doing these steps. First, seal the joints with wide fiberglass tape and joint compound that matches. Next, use fire-rated fillers or special sealants in places with lots of moisture or where fire safety matters. Pick sandable elastomeric compounds or hydraulic cement fillers to make strong joints. Leave small gaps between boards and use elastic caulking so cracks do not form. Prime the joints and finish them with paint that keeps out moisture. Put in fasteners that do not rust and keep them spaced right.

Check your wall system often and fix problems quickly. This helps your wall stay safe and strong. Using fire-rated materials and following good steps protects your building from fire, water, and damage. If you are not sure what to do, ask a professional or read the manufacturer’s instructions to keep your wall safe for a long time.

FAQ

What joint compound should you use for magnesium wall boards?

You should use a fire-rated joint compound tested for MgO boards. Look for products with ASTM E136 or EN 13501-1 certification. These compounds help your wall keep its fire resistance and stay strong.

Can you use regular drywall tape on MgO boards?

No, you should not use regular drywall tape. You need fiberglass mesh tape that resists fire. This tape works with MgO boards and helps stop fire from spreading through joints.

How often should you inspect fire-resistant joints?

You should inspect fire-resistant joints at least once a year. Check for cracks, gaps, or damage. Regular inspection helps you keep your wall safe and maintain its fire rating.

What happens if you skip joint treatment?

If you skip joint treatment, fire and smoke can pass through seams. Your wall loses its fire rating and becomes unsafe. Always treat every joint with fire-rated tape and compound.