29 Oct Fiber Cement Board Sheathing Vs MgO Board Sheathing

Table of Contents

You have two strong choices for wall sheathing. MgO board is good for fire safety, water resistance, and being eco-friendly. Fiber cement board lasts longer and is very tough. Your choice depends on the weather, where you build, and your budget. Here are some common things that help you decide:

Factor | Fiber Cement Board | MgO Board Sheathing |

|---|---|---|

Installation Ease | Heavy, needs special tools | Light, easy to put in place |

Eco-Friendliness | Makes more carbon | Traps CO2, better for the planet |

Cost | Cheaper at first, but labor costs more | Costs more at first, but saves money later |

Maintenance | Needs new paint and sealing | Needs little care, keeps out water and bugs |

Water Resistance | Keeps out some water | Keeps out all water |

Pest Resistance | Very good at stopping pests | Also strong against pests |

Design Versatility | Many looks and styles | Made for good performance |

Key Takeaways

MgO board does not weigh much. It is easy to put up. This makes it good for people who like to do projects themselves.

Fiber cement board is very strong. It can last more than 50 years if you take care of it.

MgO board is very safe in fires. It does not burn. This makes it good for places with high fire risk.

Both boards keep away bugs and mold. MgO board is better at keeping out water. This helps a lot in wet places.

Think about your money and what you need for your project. MgO board may cost more at first. But it can save you money on repairs later.

Key Differences

Fiber cement board vs MgO board

When you look at fiber cement board and MgO board, you notice they are not the same. They work differently, last for different times, and fit in different places. Picking the right sheathing is important for your project. It helps to compare their features side by side.

Feature | Fiber Cement Board | MgO Board |

|---|---|---|

Moderate fire resistance | Superior fire resistance | |

Moisture Resistance | Moisture-resistant | Moisture-resistant with mold resistance |

Environmental Impact | Less eco-friendly, more waste | Eco-friendly, made from natural materials |

Durability | Very strong and highly durable | |

Impact Resistance | Good, plus excellent thermal and soundproofing | |

Weight | Heavy (about 13.5 kg per 1m x 1m x 10mm) | Lighter, easier to handle |

Installation | Needs more support and special tools | Easier to install, less labor-intensive |

Common Applications | Tile backing, wet area walls, exterior sheathing | Interior walls, ceilings, flooring underlayment, fire-rated partitions, exterior facades |

Design Flexibility | Limited | High |

Tip: If you want a board that is simple to put in and better for the earth, MgO board is a good pick. If you need a board that can handle hard hits and lasts a long time, fiber cement board is a great choice.

At a glance

You can see the main differences fast when you check how each board is used:

Fiber cement board protects well against rot and bugs. People use it a lot for tile backing and outside walls.

MgO board is good in places with lots of water or fire danger. It also helps block sound and keeps heat in or out.

Fiber cement board is heavier, so you might need more help to put it up.

MgO board is lighter, so it is easier to move and install.

Both boards stop pests, but MgO board is better at stopping mold.

If you need sheathing for a wet or fire-risk place, MgO board works better. If you want something tough that lasts and can take hits, fiber cement board is still a top pick.

Composition

Fiber cement board materials

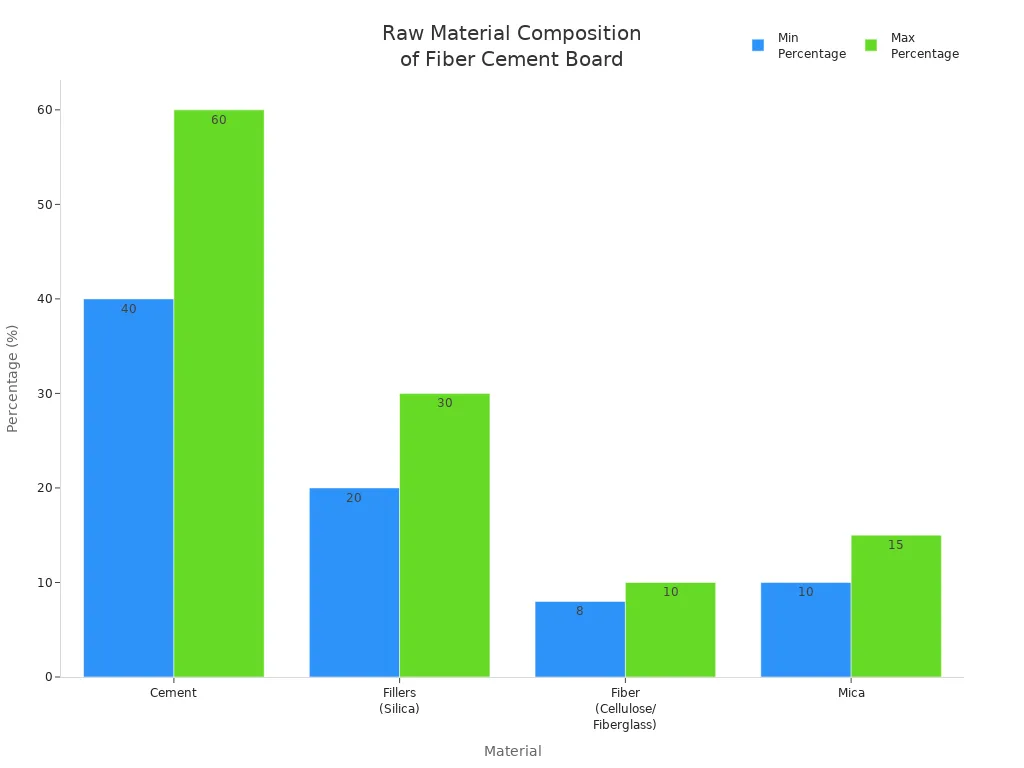

Fiber cement board materials

You may ask what is inside fiber cement board. Makers use a mix of strong and bendy stuff to make it. Cement is the main part. It gives the board its strength and shape. Silica, which comes from quartz sand, makes the board last longer. Cellulose fibers come from plants. They help stop the board from cracking or bending. Small bits of additives help the board fight fire and water. Mica helps keep the board stable and safe from fire.

Here is a table that shows what is in fiber cement board:

Material | Percentage (%) | Purpose |

|---|---|---|

Cement | 40-60 | Structure, strength, fire resistance |

Fillers (Silica) | 20-30 | Density, stability |

Fiber (Cellulose/Fiberglass) | 8-10 | Flexibility, crack prevention, strength |

Mica | 10-15 | Fire resistance, stability |

Additives (Aluminum Stearate, PVA) | Small amounts | Water resistance, setting control |

You can also look at this chart to see the main parts:

Note: This mix of materials makes fiber cement board strong and able to last a long time. It works for many building jobs.

MgO board materials

MgO board is made with different things. The main part is magnesium oxide. It comes from natural minerals. This makes the board good at stopping fire and water. Fillers like perlite and vermiculite make the board stronger and lighter. Wood fibers or fiberglass mesh give more support. Bonding agents like magnesium sulfate or magnesium chloride hold the board together.

Magnesium oxide is the main part of the board.

Fillers such as perlite and vermiculite make it strong and light.

Wood fibers or fiberglass mesh add extra support.

Bonding agents keep the board solid and stable.

MgO board’s special mix of minerals and fibers helps it stop fire, water, and pests. This board works well in hard places.

Durability

Impact resistance

When you choose wall sheathing, you want it to stand up to bumps, knocks, and strong winds. Both fiber cement board and MgO board offer good impact resistance, but they do it in different ways. Fiber cement board is heavy and dense. This weight helps it resist dents and cracks when something hits it. You may need extra support during installation because of its weight. MgO board is lighter but still tough. It stays stable when wind, fasteners, or building movement put stress on it.

Here is a quick comparison:

Material | Impact Resistance Characteristics |

|---|---|

MgO Boards | Impact-resistant and dimensionally stable under stress from wind loads, fasteners, or movement. |

Fiber Cement Boards | Heavier, strong resistance against impact, may need extra support during installation. |

Tip: If you want a board that is easy to handle but still tough, MgO board is a smart choice. If you need extra strength for high-traffic areas, fiber cement board gives you more protection.

Longevity

You want your sheathing to last for many years. Fiber cement board stands out for its long life. Many products last over 50 years, and some even go beyond 100 years if you take care of them. Manufacturers often give warranties of 30 to 50 years, but real-world use shows they can last much longer.

MgO board also lasts a long time, but not as long as fiber cement board in most climates. In places like the UK, MgO board can stay stable for at least 33 years. This makes it a good choice for projects where you want durability but do not need the longest lifespan.

Fiber cement board can last over 50 years, sometimes more than a century.

High-quality fiber cement siding often comes with a 30- to 50-year warranty.

MgO board is expected to remain stable for at least 33 years in average climates.

Note: If you want a sheathing that will last for generations, fiber cement board is the better pick. If you need a board that is durable and stable for a few decades, MgO board works well.

Fire Resistance

Fire performance

Fire performance

You want your building to stay safe during a fire. Both fiber cement board and MgO board help protect your home, but they do not work the same way. MgO board stands out for its fire resistance. It can handle very high heat and does not burn. Fiber cement board also resists fire, but it does not perform as well as MgO board in extreme conditions.

Here is a quick look at how each board handles fire:

Material | Fire Resistance Rating | Notes |

|---|---|---|

MgO Board | Noncombustible | Handles high heat, rated for 1-2 hours of fire resistance. |

Fiber Cement Board | Noncombustible | Less effective in fire resistance than MgO boards. |

MgO board can stop fire from spreading for up to two hours. This gives you more time to get to safety. Fiber cement board also slows down fire, but it may not last as long under direct flames. You can use both boards in places where fire safety matters, but MgO board gives you extra peace of mind.

Tip: If you live in a fire-prone area or want the highest level of fire protection, MgO board is a strong choice.

Building codes

You need to follow building codes when you build or renovate. These codes make sure your materials meet safety standards. MgO boards meet some of the highest fire safety standards in the world. They have an A1 non-combustible rating under EN 13501-1. They also pass ASTM E136 and BS 476 Part 4, which means they do not burn or spread fire.

Fiber cement boards also meet strict fire safety rules. They have excellent fire-resistant properties. In some cases, you may need to add extra treatments or layers to meet local codes.

Here is a table that shows how each board meets fire safety codes:

Material Type | Fire Resistance Rating/Certification | Notes |

|---|---|---|

MgO Boards | A1 non-combustible (EN 13501-1) | Do not spread fire. |

| ASTM E136 | Handles extreme heat without burning through. |

| BS 476 Part 4 | Extra fire safety certification. |

Fiber Cement Boards | Excellent fire-resistant properties | Can handle heat but may need extra treatment. |

Building codes help keep you and your family safe. Always check your local rules before you choose a sheathing material.

Moisture Resistance

Humid and coastal performance

You want your sheathing to stand up to wet weather and salty air. If you build in a humid or coastal area, you need a board that will not break down when exposed to moisture. MgO boards give you excellent protection in these settings. They do not absorb water, so they stay strong even after heavy rain or fog. You will notice that MgO boards do not swell, warp, or corrode nearby metal parts. This makes them a smart choice for homes near the ocean or in places with lots of rain.

Fiber cement boards also resist moisture better than wood-based products. However, they can soak up water if you do not seal them well. Over time, this can make the board heavier and may cause small cracks. In coastal areas, you may need to add a waterproof coating to fiber cement boards to keep them in good shape.

MgO boards: Stay stable in wet and dry cycles, do not swell, and resist mold.

Fiber cement boards: Resist water better than wood, but can absorb moisture and need sealing.

Tip: For homes in humid or coastal regions, MgO boards offer longer-lasting protection with less maintenance.

Mold and mildew

Mold and mildew can damage your walls and harm your health. You want a sheathing that keeps these problems away. MgO boards use a mineral base that stops mold and mildew from growing. They also resist insects and pests, so you get a cleaner, safer home.

Fiber cement boards also fight off mold, rot, and pests. However, if they absorb too much water, they can become a place where mold starts to grow. You need to make sure you install and seal them properly.

Here is a quick comparison:

Board Type | Additional Notes | |

|---|---|---|

MgO Board | Highly resistant | Mineral-based composition |

Fiber Cement Board | Durable, can absorb water | Resists pests, mold, and rot |

MgO boards last a long time and keep out insects, mold, and mildew.

Fiber cement boards are tough and resist many problems, but need good sealing to stay mold-free.

If you want the best defense against mold and mildew, MgO boards give you peace of mind in damp climates.

Health and Safety

Air quality

You want your home to have clean, safe air. The materials you choose for sheathing can affect indoor air quality. MgO boards stand out because they do not release harmful chemicals into the air. You can feel confident using them in your home or workspace.

MgO boards do not give off fumes or dangerous gases, even if exposed to fire.

These boards do not contain formaldehyde or volatile organic compounds (VOCs), which can harm your health.

MgO boards use natural and recyclable materials, making them a safer choice for you and the environment.

The production of MgO boards uses less energy, which helps lower their carbon footprint.

Fiber cement boards also offer good air quality, but you should check the product label. Some brands may use additives that release small amounts of VOCs. Always look for low-VOC or VOC-free options if you want the cleanest air indoors.

Tip: If you or your family have allergies or asthma, MgO boards can help create a healthier living space.

Handling

When you work with fiber cement board or MgO board, you need to protect yourself. Both materials can create dust and sharp edges during cutting and installation. You should always use the right safety gear.

Wear safety glasses or goggles to keep your eyes safe from flying debris.

Use a dust mask or respirator so you do not breathe in fine particles.

Put on protective gloves to avoid cuts or scrapes.

Cut boards in a well-ventilated area or use a dust extraction system.

Store boards flat and on a stable surface to prevent bending or warping.

You can handle MgO boards more easily because they are lighter. Fiber cement boards are heavier, so you may need help lifting or moving them. Always follow safety steps to keep your project safe and your workspace clean.

Note: Good safety habits protect your health and help you finish your project without injury.

Environmental Impact

Sustainability

Sustainability

You want to pick building materials that are good for the earth. MgO boards are a greener choice. They are made from natural minerals. Making MgO boards uses less energy. This process makes fewer greenhouse gases. You can recycle MgO boards all the way. This means less trash goes to landfills.

Fiber cement boards need more energy to make. Factories must dig up limestone and clay. This can hurt the environment. Making fiber cement boards also puts out more carbon dioxide. It is hard to recycle fiber cement boards. They have mixed materials. Most old fiber cement boards end up in landfills.

Material | Environmental Impact |

|---|---|

Fiber Cement Board | Higher carbon footprint; mining and energy-heavy production deplete resources. |

MgO Board | Lower carbon footprint; made from natural materials and fully recyclable. |

🌱 If you want to help the planet, MgO boards are better for green building.

Disposal

When your project is done or you need new boards, think about what happens next. MgO boards give you more ways to get rid of them. You can recycle them into new things. You can use them for garden borders or insulation. This keeps trash out of landfills.

Fiber cement boards do not break down fast. Their mixed materials make recycling hard. Most fiber cement boards go to landfills. This can hurt the earth over time.

Material | |

|---|---|

MgO Boards | Fully recyclable |

Fiber Cement | Limited recyclability |

You help the earth when you pick things that can be reused or recycled. MgO boards make it easier to build green and cut down on waste. Fiber cement boards last a long time, but they make more trash when you throw them away.

♻️ Picking recyclable things like MgO boards helps you keep the planet clean and healthy.

Installation

Tools and techniques

You need the right tools to install fiber cement board and MgO board. Each board type uses some of the same tools, but you will also find a few differences. Safety comes first. Always wear safety glasses, a dust mask, and gloves. These protect your eyes, lungs, and hands from dust and sharp edges.

Here is a table that shows the main tools and techniques for both boards:

Tool/Technique | Description |

|---|---|

Safety Glasses | Protects eyes during installation |

Dust Mask | Reduces inhalation of dust |

Gloves | Protects hands from sharp edges |

Putty Knife | Used for applying adhesives |

Saw Horses | Supports boards during cutting |

Square | Ensures straight cuts |

Carbide Tipped Scoring Knife | For cutting MgO boards |

Fiber Cement Shears | Specialized shears for cutting fiber cement |

Dust Reducing Circular Saw | Minimizes dust during cutting |

Fasteners | Used to secure boards in place |

You cut MgO boards with a carbide-tipped scoring knife. This tool makes clean cuts and keeps dust low. For fiber cement board, you use fiber cement shears or a dust-reducing circular saw. These tools help you cut thick boards and keep your work area safe. Always use saw horses to support the boards and a square to make straight lines.

Tip: Always cut boards in a well-ventilated area. This keeps dust away from your lungs and eyes.

Weight and handling

You must handle both boards with care. Fiber cement board feels heavy. You may need help to lift and move it. MgO board weighs less, so you can carry it more easily. Both boards can break if you do not store or move them the right way.

Place boards flat on a dry surface during storage.

Cover each pallet to protect from rain and sun.

Never store boards vertically. This prevents bending and damage.

Carry boards on their side to protect the edges and corners.

Stack boards flat and avoid direct contact with the ground.

Handle boards gently to avoid chipping or cracking.

You should always check the storage area. Keep it cool and dry. When you move the boards, support them from underneath. This keeps the boards straight and strong.

Remember: Careful handling and proper storage help your boards last longer and look better when installed.

Cost and Value

Material costs

You want to know how much each board will cost before you start your project. Fiber cement board and MgO board have different price ranges. In North America and Europe, fiber cement board usually costs less at first. MgO board costs more per square foot, but you may save money later because it is easier to install and needs less care.

Here is a quick look at the average prices:

Material | Cost per square foot |

|---|---|

Fiber Cement Board | $5 to $14 |

MgO Board (6-12mm) |

You may find that fiber cement board fits your budget better if you want to save money right away. MgO board costs more, but you get extra benefits like better fire and water resistance. You should also think about labor costs. MgO board is lighter, so you can install it faster and with less effort. This can help you save on installation.

Tip: Always check local prices. Costs can change based on where you live and how much material you need.

Long-term ROI

You want your investment to last. Over time, the money you spend on maintenance and replacement matters. Fiber cement board lasts about 15 to 20 years with minimal care. You may need to repaint or reseal it to keep it looking good. MgO board lasts longer and does not break down, even after many years. You will spend less on repairs and upkeep.

Here is a table to help you compare:

Ceiling Type | Maintenance Costs | Longevity |

|---|---|---|

Fiber Cement Boards | 15-20 years | |

Magnesium Boards | Very low; long-lasting | No degradation |

You may pay more for MgO board at first, but you save money over time. You do not need to replace it as often. You also spend less on paint and repairs. If you want a board that gives you the best value for many years, MgO board is a smart choice.

🏆 Choose the board that fits your budget now and gives you savings in the future.

Applications

Best uses for fiber cement board

Best uses for fiber cement board

You want a building material that stands up to tough weather and daily wear. Fiber cement board works best when you need strength and fire resistance. Many homeowners choose it for houses in storm-prone or wildfire-prone areas. You can use it to boost your home’s curb appeal and even raise its resale value. Here are some top uses:

Siding for homes in areas with harsh weather or fire risk

Tile backing in bathrooms and kitchens

Exterior wall sheathing for extra protection

Projects where durability and long life matter most

You should know that fiber cement board costs more to install than some other materials. Prices range from $6.65 to $14.12 per square foot. The final cost depends on your house design and the finish you want. If your project has many corners or windows, the price may go up. This material works best when you want a strong, lasting finish and can handle a higher upfront cost.

Tip: Choose fiber cement board if you want a tough, fire-resistant option that looks good and lasts for decades.

Best uses for MgO board

MgO board gives you high fire and moisture resistance. You can use it in places where safety and durability matter most. This board works well in both homes and commercial buildings. Here is a table to help you see where MgO board shines:

Application Area | Why MgO Board Works Well |

|---|---|

Commercial spaces | Handles heavy use and meets fire codes |

Wet areas (bathrooms) | Does not swell or mold |

Exterior sheathing | Stands up to rain, wind, and sun |

Hospitals, schools | Meets strict safety and health standards |

Kitchens, basements | Resists moisture and keeps mold away |

You can use MgO board in hospitals, schools, hotels, and offices. It meets strict fire safety rules and keeps mold out of damp spaces. You may pay more at first, but you save money over time because it needs little care and lasts a long time.

Note: Pick MgO board for projects that need top fire safety, moisture resistance, and long-term value.

Common Mistakes

Fiber cement board myths

You might hear many things about fiber cement board that are not true. These myths can make you worry or choose the wrong material for your project. Let’s clear up some of the most common misunderstandings:

Myth: Fiber cement board is easily damaged by water.

You do not need to worry about water damage. Fiber cement board resists water and keeps its strength even in wet conditions.Myth: Fiber cement board is hard to install.

Many people think you need special skills to use this board. In reality, professionals find the installation process straightforward and manageable.Myth: Fiber cement board looks boring.

You have many choices. This board comes in different styles, colors, and textures. You can match it to almost any design.Myth: Fiber cement board lasts forever.

No building material lasts forever. Fiber cement board is strong and long-lasting, but it will wear down over time.Myth: You never need to repaint fiber cement board.

You will need to repaint or reseal it after some years. Regular care keeps it looking good.Myth: Fiber cement board contains asbestos.

Modern fiber cement boards do not use asbestos. They are safe for you and your family.

Remember: Fiber cement board was created to replace asbestos siding and to give you a safer option.

MgO board myths

MgO board is a newer material, so you may hear some myths about it as well. Here are some common ones:

Myth: MgO board costs too much.

You might think it is expensive. While the price is higher at first, you save money over time because it lasts long and needs little maintenance.Myth: MgO board is hard to work with.

You can cut and install MgO board easily with the right tools. It is lighter than many other boards, so you can handle it without trouble.Myth: MgO board is hard to find.

You may believe it is not available in your area. Today, more suppliers offer MgO board because demand is growing.

Tip: Do not let myths stop you from choosing the best sheathing for your project. Always check the facts before you decide.

You have two good choices for sheathing. MgO board is best for places that are wet, near the ocean, or have lots of fires. Fiber cement board is strong and lasts a long time. Look at this table to help you pick:

Feature | MgO Board | Fiber Cement Board |

|---|---|---|

Fire Resistance | Superior, ideal for high fire risk | Some resistance, less in extremes |

Moisture Resistance | Highly resistant, prevents mold | Can absorb water, needs care |

Eco-friendliness | Eco-friendly | Less eco-friendly |

Ideal Use | Kitchens, bathrooms, wet climates | Durable, needs maintenance in humidity |

Think about the weather where you live and what your project needs. If you are not sure, ask a builder for help. Pick the sheathing that keeps you safe and works well.

FAQ

What is the main difference between fiber cement board and MgO board?

Fiber cement board lasts longer and feels heavier. MgO board resists fire and water better. You should choose based on your climate, budget, and project needs.

Can you paint or finish both types of boards?

Yes, you can paint both boards. Use exterior-grade paint for fiber cement board. MgO board accepts paint or tile, but always follow the manufacturer’s instructions for best results.

Are these boards safe for people with allergies?

You can use both boards safely. MgO board does not release harmful chemicals or dust. Fiber cement board is also safe, but you should wear a mask when cutting to avoid breathing in dust.

Which board is easier to install by yourself?

MgO board is lighter and easier to handle. You can cut it with simple tools. Fiber cement board is heavier and may need special tools or extra help during installation.

Do these boards attract pests or mold?

No, both boards resist pests and mold. MgO board works better in wet places because it does not absorb water. Fiber cement board also keeps out bugs and mold if you seal it well.

Fiber cement board materials

Fiber cement board materials Fire performance

Fire performance Sustainability

Sustainability Best uses for fiber cement board

Best uses for fiber cement board