11 Dec The Best Subfloor For High Moisture Areas

Table of Contents

You need the best subfloor in wet areas to stop water damage. Magnesium oxide panels are great at keeping out water, helping your floor stay strong when it is damp. Cement board also works well against water and lasts many years. Treated plywood and waterproofed OSB or plywood provide some water protection, but you must seal them the right way. Look at how these materials match up:

Material | Moisture Resistance | Durability | Cost-Effectiveness |

|---|---|---|---|

Magnesium Oxide Panels | Superior | High | Higher upfront cost but long-term savings |

OSB Panels | Poor | Low | Affordable but requires careful handling |

Treated Plywood | Moderate | Moderate | Varies by grade, requires proper sealing |

Waterproofed Plywood | Moderate | Moderate | Varies by grade, requires proper sealing |

Key Takeaways

Pick magnesium oxide panels for better moisture protection and strength in wet places. – Put cement board in bathrooms and kitchens, but make sure to add waterproof layers for the best outcome. – Waterproofed OSB and treated plywood cost less, but you must seal them well to stop damage. – Check your subfloor often for wet spots, mold, or harm to avoid expensive fixes. – Always use moisture and vapor barriers to keep your subfloor safe from water damage.

Moisture Risks for Subfloors

Common Damage Issues

Moisture in your subfloor can cause many problems. Water might get in from floods, leaks, or broken appliances. If you have a vented crawl space, water from the ground can move up and cause trouble. When the air is very humid, wood soaks up water. This can make it bend or rot. Bad airflow keeps areas wet, so damage gets worse over time.

Floods can quickly let water into the subfloor and cause damage.

Leaks and broken appliances can soak the floor and make it weak.

Water vapor from concrete can rise up and hurt the floor later.

Humid air and bad airflow in crawl spaces can cause wood to rot and mold to grow.

Wet shoes and feet can bring in more water, making things worse in busy places.

If you do not fix these problems, your floor may become uneven or sag. The building might even get weaker. Fixing subfloor damage from water can cost between $25.87 and $44.35 for each square foot. Stopping moisture early can help you save money on repairs.

Tip: Check for soft spots or musty smells. These are signs of moisture, especially if you have a vented crawl space or bad drainage.

Why Material Choice Matters

Picking the right subfloor material helps protect your home or business. Some materials do not swell or grow mold as easily as others. For example, luxury vinyl stays flat in damp places. Ceramic and porcelain tiles do not bend or buckle. Untreated wood can rot and lose strength, making floors uneven. Using moisture barriers and putting the floor on a dry, flat base helps keep it strong.

Water damage to floor joists can make your building weak, especially in crawl spaces.

If you do not treat water damage, wood can rot, bend, and lose support.

Humid air and bad airflow are big reasons for wood rot.

Using moisture-resistant materials and barriers helps your floor last longer.

You should think about drainage and airflow when you plan your subfloor. The right material and good moisture control will keep your floor safe and strong for a long time.

Best Subfloor Options

MgO Panels

MgO panels are a good choice for wet places. They do not swell or break down when wet. You can use them in bathrooms and kitchens. These panels help control vapor. MgO panels are also very good at stopping fires. They do not burn and stay strong in a fire. Here is a table that shows how they compare for fire resistance:

Feature | MgO Boards | OSB | Plywood | Gypsum Boards |

|---|---|---|---|---|

Fire Resistance Rating | Excellent | Poor | Limited | Excellent |

Combustibility | Non-combustible | Highly combustible | Combustible | Non-combustible |

Structural Integrity Under Fire | Maintains integrity | Fails quickly | Fails quickly | Weakens over time |

MgO panels help keep your floor safe from vapor. If the air stays wet for a long time, problems like weeping can happen. You should check for moisture often. MgO panels are great for wet places, but you still need to look for signs of water.

Note: MgO panels do not soak up water fast, but you should use moisture and vapor barriers for extra safety.

Cement Board

Cement board is another strong choice for wet areas. It makes a tough base that slows down water. You can use it in bathrooms, laundry rooms, and kitchens. You need to add waterproof layers to keep water out. Brands like PermaBase, WonderBoard, and Durock need extra waterproofing. If you use vapor and moisture barriers, cement board lasts a long time.

Cement board stops water but is not fully waterproof.

You need to seal it to stop mold and cracks.

Waterproofing helps your floor last longer.

Cement board works well in places with lots of humidity. Always use vapor and moisture barriers to protect your floor.

Waterproofed OSB/Plywood

Waterproofed OSB and plywood are good and cheap for wet areas. You can use sealants, waterproof paints, or membranes to protect them. Sealants are good for small jobs. Waterproof paints cover big areas and bend easily. Waterproof membranes give strong protection in wet places.

Sealants: Polyurethane, silicone, and acrylic sealants block water.

Waterproof paints: Elastomeric paints work best for wood and OSB.

Waterproof membranes: Bitumen, EPDM rubber, and PVC keep water out.

Marine-grade plywood lasts longer than regular plywood in wet places. Untreated OSB does not last long outside, but treated OSB can last years. You should use vapor and moisture barriers to keep your floor safe. Waterproofed OSB and plywood are good for places with changing humidity.

Tip: Use AFM Safe Seal to lower moisture and toxic fumes from OSB and plywood.

Treated Plywood

Treated plywood is a strong choice for wet areas. Chemicals like propiconazole, triadimefon, ACQ, copper azole, and copper naphthenate stop mold and decay. Treated plywood does not swell or break apart as much as regular wood. You should use it in crawl spaces, basements, and other damp places.

Chemical Treatment | Description |

|---|---|

Propiconazole | Put on the surface or use pressure for plywood and wood. |

Triadimefon | Fungicide for wood-based products. |

ACQ | Water-based preservative that stops fungi and bugs. |

Copper Azole | Water-based preservative for fungus and bugs. |

Copper Naphthenate | Used for wood in ground and water contact. |

Treated plywood helps control vapor and moisture. You need to watch for swelling, breaking apart, and mold. Use vapor and moisture barriers to protect your floor and make it last longer. Treated plywood is great for wet places, but you need to check it often to stop damage.

Reminder: Always look for mold and decay in treated plywood, especially in places with lots of humidity.

Subfloor Comparison

Performance

Performance

You want your subfloor to stay strong even when the air has high relative humidity. MgO panels give you the best performance. They block vapor and resist mold. Cement board also works well in wet places. Waterproofed OSB and treated plywood can handle some water, but you need to use moisture barriers and vapor barriers for extra safety. Here is a quick look at how these materials compare:

Material | Fire Resistance | Moisture Resistance | Durability |

|---|---|---|---|

MgO Boards | Fireproof; handles high heat | Blocks water, mold, and mildew | Very strong; resists impacts |

OSB Boards | Burns unless treated | Swells and molds when wet | Strong but weakens in water |

Plywood | Burns easily | Warps when soaked | Strong but can split or peel |

Tip: Always check your floor for soft spots or changes in color. These signs show you where water might be causing damage.

Cost

You need to think about your budget when you pick a subfloor. Plywood and OSB cost less than other options. MgO panels and cement board cost more at first, but they save you money over time because they last longer. Here is a table with average prices per square foot:

Subfloor Material | Average Cost (Per Square Foot) |

|---|---|

Plywood | |

Oriented strand board (OSB) | $2.50–$4.50 |

Cement Board | $3–$10 |

MgO Panels | $4–$8 |

Installation

You can install plywood and OSB with basic tools. MgO panels and cement board need special fasteners and careful handling. You should always use moisture barriers and vapor barriers under every subfloor in high moisture areas. This step keeps your floor safe and dry.

Plywood and OSB: Easy to cut and nail.

Cement board: Needs screws and mesh tape.

MgO panels: Needs special screws and sealing.

Note: Wear gloves and a mask when you cut cement board or MgO panels. The dust can bother your skin and lungs.

Durability

MgO panels last the longest. They do not break down when wet. Cement board also stays strong in damp places. Waterproofed OSB and treated plywood work well if you keep them dry and check them often. If you use the right barriers, your subfloor will last for many years.

MgO panels: Best for wet places and heavy use.

Cement board: Good for bathrooms and laundry rooms.

Waterproofed OSB/treated plywood: Good for basements if you check for leaks.

Key Features to Consider

Moisture Resistance

When you choose a subfloor for a high-moisture area, you want strong moisture-resistance. Exposure ratings tell you how much water a material can handle before it gets damaged. Always check the manufacturer’s specifications for each product. Some panels have higher perm ratings, which means vapor can pass through more easily. Lower perm ratings block vapor better and help keep your floor dry. In places like basements or crawl spaces, you should use moisture barriers and vapor barriers to stop water from reaching the subfloor.

Look for panels with high exposure ratings.

Use moisture barriers and vapor barriers in damp spaces.

Check product labels for perm ratings and moisture-resistance details.

Tip: A good moisture-resistant subfloor helps prevent costly repairs later.

Mold Prevention

Mold can grow fast in wet areas. You can stop mold by using the right treatments and products. Some of the best ways to prevent mold include:

Use borax to leave an anti-fungal film on wood.

Apply EPA-registered fungicides for tough mold.

Seal wood with mold-resistant primer and paint.

Make sure the area has good ventilation.

Pick subfloor materials with built-in antimicrobial technology.

You can also use mold-resistant drywall or other certified materials for extra protection. These steps help keep your floor safe from mold.

Strength

You need a subfloor that stays strong, even when it gets wet or sees a lot of foot traffic. MgO panels keep their strength in high humidity. Plywood can lose up to 9% of its bending strength after getting wet. MgO panels can support over 350 pounds per square foot in shear force. They also resist impacts better than plywood. This makes MgO a smart choice for busy, wet spaces.

MgO panels: High strength and impact resistance.

Cement board: Good for heavy use.

Plywood: Loses strength when wet.

Installation Ease

Some subfloor materials are easier to install than others. Plywood and OSB cut and nail easily. Cement board and MgO panels need special screws and careful handling. Always follow the manufacturer’s instructions for best results. Wear gloves and a mask when cutting panels to protect yourself from dust.

Plywood and OSB: Simple tools and fast installation.

Cement board: Needs screws and mesh tape.

MgO panels: Needs special fasteners and sealing.

Note: Good installation helps your subfloor last longer and keeps water out.

Installation Tips

Preparation

Preparation

Get the area ready before you put in the subfloor. First, clean the surface well. Take away all dirt and dust. Fix any cracks or broken spots. Make sure everything is dry. There should be no water anywhere. If you use epoxy primer, mix it as the instructions say. Spread the primer in a thin, even layer. Wait for it to dry all the way. Good airflow helps the primer dry and keeps you safe. If your subfloor is concrete, look for hidden water. In basements or near the coast, water can come up from the ground. Always put down a moisture barrier on a clean, dry floor. Seal all seams and gaps so water cannot get in.

Best Practices

You want your floor to last a long time, so do these things:

Use moisture-resistant construction glue to seal the panel joints.

Put flexible sealant around utility holes to keep the vapor barrier strong.

Fit panels close together in modular systems to protect the barrier.

Do not poke holes in vapor barriers with fasteners. Use perimeter attachment instead.

Let flooring materials get used to the room before you install them. This stops gaps and buckling.

Tip: Always follow the instructions from the manufacturer and local building codes for every step.

Mistakes to Avoid

People often make mistakes when putting in subfloors in wet places. These mistakes can cause problems later. Here is a table that shows common mistakes and how to avoid them:

Mistake | Explanation |

|---|---|

Overlooking Moisture Protection | Not using a moisture barrier can cause rot and mold in damp places. |

Inadequate Prep Work | Not cleaning, leveling, or drying the subfloor can make your floor weak. |

If you ignore the subfloor, you might get squeaks and mold. If you skip inspections, your floor may be uneven. Always check for water and fix problems before you start. Careful prep and sealing help your floor last longer.

Maintenance and Longevity

Routine Care

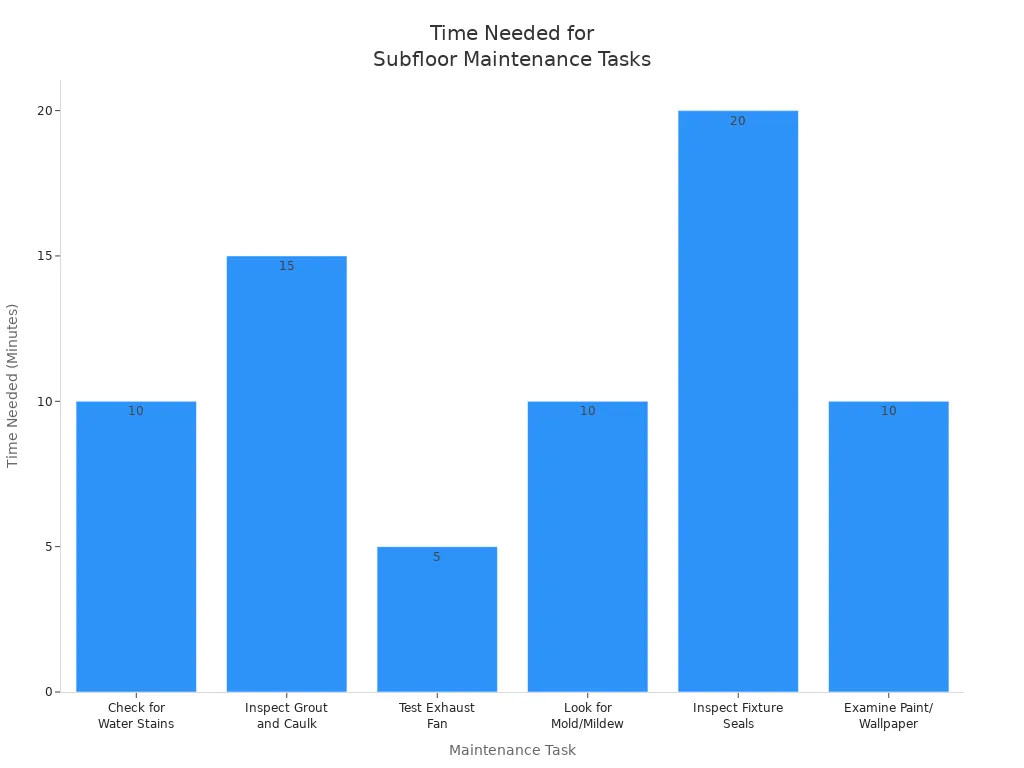

You can make your subfloor last longer if you take care of it often. Look for water stains every month. Check for mold or mildew each month too. Every three months, look at the grout and caulk. Test your exhaust fan and check paint or wallpaper every quarter. Look at fixture seals two times a year. Doing these things helps you find problems early and stop damage.

Frequency | Time Needed (Minutes) | |

|---|---|---|

Check for Water Stains | Monthly | 10 |

Inspect Grout and Caulk | Quarterly | 15 |

Test Exhaust Fan | Quarterly | 5 |

Look for Mold/Mildew | Monthly | 10 |

Inspect Fixture Seals | Bi-Annually | 20 |

Examine Paint/Wallpaper | Quarterly | 10 |

Keep the air in your home between 40% and 50% humidity. Run the exhaust fan for 20 to 30 minutes after you shower. Open windows to let in fresh air. Use a squeegee to wipe water off shower walls and mirrors. Try a dehumidifier if your room is very damp. Grout and sealants help keep water away from your floor. Clean grout before you put on new sealant. Add new sealant every one or two years.

Preventing Mold

You can stop mold from growing if you act fast. Fix leaks from sinks, appliances, or pipes right away. Clean up spills so water does not stay on the floor. Use exhaust fans in the kitchen, bathroom, and laundry room. Dehumidifiers help keep the air dry, especially in basements. After a flood, check the subfloor for hidden water. Pick moisture-resistant underlayment when you put in new floors. Check for mold often so you can catch it early.

Signs of Damage

You should look for signs that your subfloor is in trouble. Soft or bouncy spots mean water damage. Musty smells can mean mold is there. Cracks in the floor can happen when water makes materials weak. High humidity and wet windows show bad airflow. Mold or mildew means water is still a problem. Warping, crowning, and cupping change how wood floors look. Too much water can also cause stains and wet spots. Concrete can get pop-outs and spalling. Loose tiles, bugs, and musty smells are other signs of subfloor damage.

You need a subfloor that does not get ruined by water. It should last a long time. MgO panels, cement board, waterproofed OSB/plywood, and treated plywood all help keep your floor safe from water. These materials make your floor strong. MgO panels do not break down when wet or attacked by bugs. Studies show MgO panels stay strong, even with vapor and pests. When you pick a subfloor, think about these things:

Factor | Description |

|---|---|

Keeps water from hurting your floor. | |

Type of Finished Flooring | Works with the surface you want. |

Expected Foot Traffic | Stays strong in busy places. |

Proper Installation | Stops bending and other problems. |

Pick the best material for your room. Take care of your floor so it lasts many years.

FAQ

What is the best subfloor for a bathroom?

You should choose MgO panels or cement board for a bathroom. These materials resist water and mold. They help keep your floor strong in wet conditions.

Can I use regular plywood in high moisture areas?

You should avoid regular plywood in wet places. It can swell and rot. Treated plywood or waterproofed OSB works better for moisture resistance.

How do I prevent vapor from damaging my subfloor?

You can install a vapor barrier under your subfloor. This barrier blocks moisture and helps protect your floor from damage.

How often should I inspect my subfloor for problems?

You should check your subfloor every month for water stains, mold, or soft spots. Early detection helps you avoid costly repairs.

Are MgO panels safe for homes?

MgO panels are safe for homes. They do not burn easily and resist mold. You can use them in kitchens, bathrooms, and basements.

Performance

Performance Preparation

Preparation