27 Dec Comparing Basement Subfloor Boards and Their Features

Table of Contents

- 1 Key Takeaways

- 2 Types of Basement Subfloor Boards

- 3 Key Features of Different Basement Subfloor Board Options

- 4 Comparing Basement Flooring Options

- 5 How to Choose the Best Flooring to Use in Your Basement

- 6 Basement Subfloor Installation Tips

- 7 FAQ

- 7.1 What is the best basement subfloor for moisture protection?

- 7.2 How do I install a moisture barrier under my basement subfloor?

- 7.3 Can I use waterproof laminate as basement flooring?

- 7.4 What are the most durable basement subfloor options?

- 7.5 Do I need a moisture barrier with all basement subfloor types?

When you look at basement flooring, you see many options, including different basement subfloor board types like plywood, OSB, cement board, MgO board, rigid foam panels, sleeper systems, and premade panels. Each one has something special. Some work better with water, while others last longer or are quicker to put in. Choosing the right different basement subfloor board is important for ensuring your basement stays dry, strong, and cozy. You need a floor that can handle water and daily use, and you also want it to be easy to install.

Key Takeaways

Pick a subfloor board that keeps out water. This helps stop water damage in your basement. Cement boards and MgO boards do a great job keeping out moisture.

Think about how tough the subfloor is. MgO boards and cement boards are very strong. They can handle lots of use. This makes them good for busy basements.

It is important that installation is easy. Premade subfloor systems are fast to put in. You do not need many tools. This is good for people who like DIY projects.

Look at your budget closely. Plywood and OSB do not cost much. But better materials like cement or MgO boards may save money later. You might spend less on repairs.

Check what your basement needs. Think about moisture, how you will use the space, and building rules. These things help you pick the best subfloor.

Types of Basement Subfloor Boards

Plywood Boards

Plywood is a popular choice for basement subfloors. This different basement subfloor board gives strong support for many uses. Plywood comes in different grades and thicknesses. For basements, CDX or marine-grade plywood is best. These types help keep water out and protect your floor. Tongue-and-groove edges make it easier to put the boards together. They also help the panels stay in place. If you buy better plywood, it costs more at first. But you might save money later because you avoid big repairs. Check out this table to see what makes plywood special:

Characteristic | Description |

|---|---|

Thickness and Grade | Standard thickness is 3/4 inch; CDX plywood is recommended for its moisture resistance. |

Tongue and Groove | Interlocking edges provide stability and reduce movement between panels. |

Exposure Rating | ‘Exposure 1’ plywood withstands moisture during construction but not prolonged wet conditions. |

Marine-grade or pressure-treated plywood is ideal for high moisture areas like basements. | |

Structural Plywood | Engineered for load-bearing applications, ensuring support and longevity. |

Cost Considerations | Higher-grade plywood may be more expensive but prevents costly repairs in the long run. |

Oriented Strand Board (OSB)

OSB is a different basement subfloor board that can save you money. OSB is strong and lasts a long time. It gives a flat and even surface. OSB also helps keep your basement quiet. It uses fewer chemicals than some other wood boards. This makes it better for the environment. Here are some things you should know:

OSB is strong and good for building.

It is more even in thickness and density than plywood.

It is cheaper and easy to take care of.

OSB is better for the environment because it uses less formaldehyde.

It helps block sound for more privacy.

But OSB does not do well with water. If water gets in, OSB can swell and stay wet. This can damage the board. The edges of OSB swell more than plywood. Over time, the board can break down. If your basement is damp, you may want to pick something else.

OSB does not resist water well and can swell.

It holds water and does not dry out, which can cause damage.

The edges of OSB swell more than plywood when wet.

If OSB gets wet, it can break down and cause problems.

Cement Board

Cement board is a different basement subfloor board that handles water very well. It has great moisture resistance. You do not have to worry about mold or rot. Cement board lasts a long time, even in tough places. If you want a subfloor that stays dry and strong, cement board is a good choice. Here is a quick table:

Subfloor Type | Moisture Resistance | Durability |

|---|---|---|

Traditional Plywood | Fair | Moderate |

Fiber Cement Board | Very Good | Very High |

MgO Board

MgO board is another different basement subfloor board with special features. It resists fire, water, and pests. MgO board lasts a long time. You will not need to replace it soon. The main downside is that it costs more. But you get extra peace of mind. Here is what makes MgO board different:

Unique Properties | Limitations |

|---|---|

Fire resistance | Higher initial cost |

Moisture resistance |

|

Durability |

|

Pest resistance |

|

Rigid Foam Panels

Rigid foam panels are a different basement subfloor board that keeps your basement warm and dry. These panels seal and insulate the floor. This helps stop water from getting in. Many people like rigid foam because it is not expensive. It also handles water better than wood boards. You can use a vapor barrier like Delta FL with rigid foam for more protection. If your basement is damp, rigid foam panels may be the best choice.

Rigid foam panels seal and insulate the basement floor.

Many people like rigid foam because it is cheap and handles water well.

A vapor barrier with rigid foam helps control water in basements.

Rigid foam can protect better in wet areas.

Sleeper Systems

A sleeper system uses wood strips called sleepers on the concrete floor. You put your different basement subfloor board on top of the sleepers. This setup makes a gap for air. The air gap helps keep water away and your floor dry. You can add insulation between the sleepers for more comfort. Sleeper systems are good if you want hardwood or engineered wood floors in your basement. Here is a quick table:

Type | Description | Common Applications |

|---|---|---|

Wood Sleeper | A wood member laid on a concrete floor to support and receive fastening of wood subfloor or finish flooring. It creates an air space between the concrete and wood flooring, preventing moisture damage. | Basement Floors: Used to support subflooring in basements. |

The sleeper system acts like a frame on the concrete.

It gives a place to nail hardwood flooring.

The air gap under the floor helps control water.

You can add insulation between sleepers for comfort and saving energy.

Premade Subfloor Systems

Premade subfloor systems like DRIcore, Barricade, and Tyroc are modern options for basements. These panels snap together with tongue-and-groove edges. This makes them fast and easy to install. They resist water well and can hold heavy things. Some brands use recycled materials, which is good for the planet. If you want a different basement subfloor board that is easy to put in and lasts a long time, premade systems are a good pick. Here is a table to compare them:

Feature | DRIcore | Barricade | Tyroc |

|---|---|---|---|

Moisture Resistance | Yes | Yes | Yes |

Installation Ease | Easy, tongue-and-groove | Easy, tongue-and-groove | Easy, tongue-and-groove |

Durability | Supports 7,000 lbs/sq ft | Supports 6,000 lbs/sq ft | Supports 7,000 lbs/sq ft |

Sustainability | Standard polymer materials | Recycled foam core | Recycled rubber and plastics |

Warranty | 25-year limited warranty | 25-year limited warranty | 25-year limited warranty |

Tip: If you want a basement floor that is easy to put in and keeps out water, premade subfloor systems like DRIcore and Barricade are a simple choice.

When you look at all these different basement subfloor board choices, you see that water resistance and strength are most important for basements. Plywood and OSB are good for dry places. Cement board, MgO board, rigid foam panels, and premade systems protect better against water. Sleeper systems give you more options and comfort, especially if you want wood floors. Think about what your basement needs before you pick a subfloor.

Key Features of Different Basement Subfloor Board Options

When you pick a basement subfloor board, you want to know what makes each one special. Let’s look at the main features so you can choose the best for your home.

When you pick a basement subfloor board, you want to know what makes each one special. Let’s look at the main features so you can choose the best for your home.

Moisture Resistance

Basements can get wet. Water might come from the ground, pipes, or rain. If you want your floor to last, you need a subfloor that keeps water out.

Here’s a quick chart showing how each subfloor board deals with water:

Subfloor Type | Moisture Resistance Level | Special Features |

|---|---|---|

Moderate | Needs sealing or special grade for wet areas | |

OSB | Low | Swells and breaks down if it gets wet |

Cement Board | High | Won’t rot or mold, great for wet basements |

MgO Board | Very High | Resists water, mold, and pests |

Rigid Foam Panels | High | Blocks water, adds insulation |

Sleeper Systems | Moderate | Air gap helps, but wood can still get wet |

Premade Systems | Very High | Built-in moisture barriers and air gap technology |

Tip: Premade subfloor systems like DRIcore and Barricade use strong plastic membranes and air gaps. This helps keep water out and lets air move under your floor. The air flow helps dry out any water before it causes problems.

Too much water from leaks, high humidity, or bad seals can ruin your subfloor. Plumbing leaks from sinks or toilets can also hurt your floor. To stop these problems, pick a board with high moisture resistance.

Durability

You want your basement floor to last a long time. Durability means the subfloor can hold heavy furniture and lots of walking. It should not break if you drop something.

Let’s see how each type does:

Plywood: Strong and bends a little. Works best in dry basements. If it gets wet, it can bend or rot and not last as long.

OSB: Almost as strong as plywood and costs less. It is flat but gets weak fast if it gets wet.

Cement Board: Very tough. It does not dent, scratch, or get water damage. It lasts a long time.

MgO Board: Very durable. It stands up to fire, water, and bugs. You will not need to replace it often.

Rigid Foam Panels: Good for most uses. They do not rot or mold, but they can dent if you drop something heavy.

Sleeper Systems: How long it lasts depends on the wood. If it stays dry, it lasts a long time. If it gets wet, it can break down.

Premade Systems: Very durable. These panels hold a lot of weight and resist water, so they last a long time.

Note: Concrete subfloors are very tough, but you need a moisture barrier to keep them safe from water. Without it, even concrete can get damaged over time.

Installation Complexity

Some subfloor boards are easy to put in. Others are harder and may need a pro. Let’s see how hard each one is to install:

Subfloor Type | DIY Friendly? | Installation Notes |

|---|---|---|

Plywood | Moderate | Needs cutting, sealing, and careful placement |

OSB | Moderate | Like plywood, but edges swell if wet |

Cement Board | Hard | Heavy, needs special tools and fasteners |

MgO Board | Hard | Heavy, may need pro help for best results |

Rigid Foam Panels | Easy | Light, simple to cut and fit |

Sleeper Systems | Moderate to Hard | Needs framing skills and careful leveling |

Premade Systems | Very Easy | Snap-together panels, minimal tools needed |

If you are new to DIY, premade subfloor systems are a good choice. You can snap them together fast and do not need special tools. If you try plywood or OSB, you might have trouble with cutting and sealing. Cement board and MgO board are heavy and hard to move alone.

Here’s a quick chart comparing DIY and pro installation:

Aspect | DIY Homeowners | Professional Installers |

|---|---|---|

Expertise | May make mistakes | High skill and experience |

Quality of Installation | Can be lower if not careful | Top-notch workmanship |

Time Efficiency | Takes longer | Much faster |

Warranty | Usually none | Often includes a warranty |

Subfloor Preparation | Can be tricky | Pros know how to prep floors properly |

Cost

You want a subfloor that fits your budget. Prices change a lot based on the material and if you hire a pro.

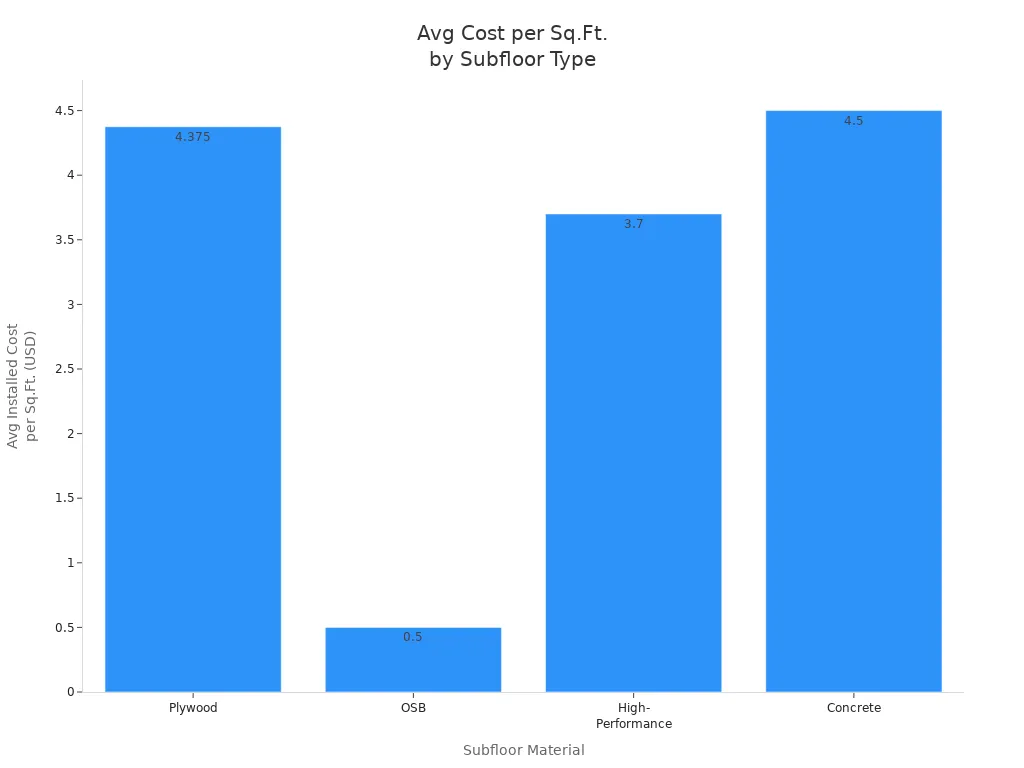

Here’s a chart showing the average installed cost per square foot for each type:

Subfloor Material | Installed Cost per Sq.Ft. |

|---|---|

Plywood | |

OSB | $3 – $4.40 |

High-Performance | $3.50 – $10.50 |

Concrete | $4.25 – $12 |

DRIcore® | $2.50 – $9 |

Amdry | $3 – $10 |

Barricade | $2 – $10 |

Warmboard | $7 |

Note: Installing a subfloor usually costs $4.11 to $6.28 per square foot. If you do it yourself, you might save money, but mistakes can cost more later.

When you compare all these features, you see each subfloor board has good and bad points. Plywood and OSB are cheap and easy to find, but they do not like water. Cement board and MgO board cost more, but they last longer and work better. Rigid foam panels and premade systems give you good moisture resistance, comfort, and easy installation. Think about what matters most for your basement—moisture, durability, ease, or price—before you choose.

Comparing Basement Flooring Options

Feature Comparison Table

When you look at basement flooring, you want to know how each type compares. The table below shows the main features of popular subfloor choices. This helps you see which one might work best for your basement.

Material | Fire Resistance | Moisture Resistance | Cost | Durability | Installation Ease | Comfort |

|---|---|---|---|---|---|---|

Plywood | Moderate | Excellent | Higher | Good | Moderate | Good |

OSB | Low | Poor | Affordable | Fair | Moderate | Fair |

MgO Boards | High | Excellent | Higher | Excellent | Hard | Good |

Cement Board | High | Excellent | Higher | Excellent | Hard | Fair |

Rigid Foam | Low | High | Moderate | Good | Easy | Excellent |

Sleeper System | Moderate | Moderate | Moderate | Good | Hard | Excellent |

Premade Panels | Moderate | Very High | Moderate | Excellent | Very Easy | Good |

The table shows MgO boards and cement board are best for fire and water. OSB is cheap, but it does not do well with water. Plywood is strong and balanced, but it costs more than some other types.

Pros and Cons of Each Type

There are many subfloor choices for your basement. Each one has good and bad points. Here is a quick list to help you pick:

Plywood

👍 Handles water well, strong, lasts a long time

👎 Costs more than some, needs to be sealed

OSB

👍 Cheap, easy to buy

👎 Does not handle water, swells if wet

MgO Boards

👍 Best for fire and water, very tough

👎 Costs a lot, hard to put in

👍 Great with water and fire, lasts long

👎 Heavy, hard to cut, costs more

Rigid Foam Panels

👍 Easy to put in, warm and comfy

👎 Can dent, not good with fire

Sleeper Systems

👍 Makes floor comfy, works with many floors

👎 Hard to install, wood can rot

Premade Panels

👍 Quick to install, great for water

👎 Can cost more than basic types

No single choice is perfect for everyone. Think about what is most important for your basement. Some types keep water out better, while others save money or time. Try to pick the one that fits your needs and budget.

How to Choose the Best Flooring to Use in Your Basement

Assessing Moisture and Water Issues

Assessing Moisture and Water Issues

Before you make any choices, check your basement for water problems. Look for stains, mold, or soft spots on the floor. Use a moisture meter to find hidden dampness. Make sure the surface is clean and level. Moisture can hide for a long time and cause warped or moldy floors. Ask your installer about moisture testing and vapor barriers. These steps help you avoid trouble later and make better choices for your basement.

Considering Use and Traffic

Think about how you plan to use your basement. Will it be a playroom, gym, or storage? The type of finished flooring matters. If you expect lots of foot traffic, pick a subfloor that can handle it. Thicker engineered hardwoods resist warping and last longer in busy areas. More layers mean more stability. Your choices should match how you use the space and how much wear you expect.

Budget and Value

Your budget shapes your choices. If you want to save money, you might pick OSB or plywood. These are affordable and easy to find. If you want long-term value, look at durable options like MgO boards. These cost more but work better in damp basements. Think about how much you want to spend now and how much you want to save on repairs later. The best flooring to use often balances cost and performance.

Local Codes and Recommendations

Don’t forget about basement-specific considerations like local building codes. In some places, you need to meet certain height and clearance rules for finished basements. Always check the total thickness of your subfloor and flooring. This helps you keep enough headroom and follow the rules. Following codes keeps your project safe and legal, and it helps you make smart choices for your home.

Basement Subfloor Installation Tips

Preparing the Floor

Getting your basement ready is very important. You need a strong base before you start. Here are some tips to help you get ready:

Take out all trash, old flooring, and nails from the room.

Make sure the floor is clean, dry, and flat. Use a broom and vacuum to clean up.

Use a long level to find uneven spots. Sand down high spots. Fill low spots with leveling mix.

If you skip these steps, your subfloor may not be flat. This can make squeaks or cause damage later. Take your time with this part.

Common Mistakes to Avoid

Many people have problems when they install subfloors. You can avoid trouble by learning about common mistakes. Look at this table for quick fixes:

Common Mistakes | Solutions |

|---|---|

Inadequate Preparation | Make sure the area is clean and dry before starting the installation. |

Incorrect Fastening | Use the right screws or nails and follow local building codes for fastening patterns. |

Overlooking Moisture Protection | Always use a moisture barrier, especially in humid areas, to protect the subfloor. |

Ignoring Subfloor Thickness | Check the manufacturer’s recommended thickness for proper support and durability. |

Not Acclimatizing the Subfloor | Let the subfloor adjust to room conditions before installation to prevent expansion. |

Tip: Check your steps before you begin. This can help you save time and money.

Maintenance and Longevity

You want your basement subfloor to last a long time. Good care starts with smart installation. Here are some easy ways to keep your subfloor strong:

Stop moisture with vapor barriers, waterproof sealers, or a sump pump.

Pick moisture-resistant materials like marine-grade plywood.

Make sure the concrete slab is clean and flat before you start.

Let your boards sit in the basement for a day or two before you install them. This helps them get used to the room.

Leave small gaps between boards so they can expand.

If you follow these tips, your subfloor will stay strong and dry. Check for leaks or wet spots often. A little care helps your basement floor last longer.

There are lots of basement subfloor board options. Cement board and MgO board are best if you want to stop water. Plywood works well in dry basements and is strong for the price. Premade panels are simple to put in. Picking the right subfloor for your basement helps you block water, stop mold, stay warm, and make the job easier.

You can keep water out and stop mold.

Your basement will feel warmer and more comfy.

It is easier to put in the floor.

Check your local rules before you begin. Look at things like exits, air flow, insulation, and pipes. If you are not sure, ask a flooring expert or look at websites like Elephant Floors. Here is a quick chart:

Material | Best Use |

|---|---|

Plywood | Dry basements |

Cement Board | Wet areas |

MgO Boards | Damp basements |

Plan ahead before you start. The right subfloor will help your basement stay safe and cozy for a long time.

FAQ

What is the best basement subfloor for moisture protection?

You need a subfloor that blocks water. Premade panels and cement boards are great for this. They work well in basements that get wet. You can also pick waterproof laminate with a special core. This gives extra protection from water.

How do I install a moisture barrier under my basement subfloor?

Put the moisture barrier right on the concrete. Make sure it covers the whole floor. Overlap the edges so water cannot get through. This step stops water problems and keeps your floor safe.

Can I use waterproof laminate as basement flooring?

Yes, you can use waterproof laminate in your basement. This type has a special core that resists water. It works best with a moisture barrier under it. Waterproof laminate helps stop water damage and makes your floor last longer.

What are the most durable basement subfloor options?

MgO boards and cement boards are very strong. Premade panels also last a long time. These choices resist water and heavy use. They give you a solid base for any floor you want.

Do I need a moisture barrier with all basement subfloor types?

You should use a moisture barrier with every subfloor. This layer keeps water from hurting your floor. Even in dry basements, it helps stop future problems and keeps your choices open.

Assessing Moisture and Water Issues

Assessing Moisture and Water Issues