05 Sep How MgO Boards Can Be Used Outside In Steel Buildings

Table of Contents

You can trust mgo boards for your building’s exterior. Magnesium oxide boards stand up to tough weather. They resist moisture and humidity. Mgo boards offer strong durability. You do not have to worry about mold or pests. These magnesium oxide boards protect your steel building from fire. Many builders choose mgo for exterior walls because of its proven strength. Mgo boards give your building long-lasting support. Magnesium oxide boards help you keep your building safe and dry.

Magnesium oxide boards and mgo boards make your exterior walls stronger and safer in any climate.

Key Takeaways

MgO boards stop fire, water, and damage. They work well for steel building outsides. These boards do not let mold grow. Bugs cannot hurt them. Bad weather does not break them. This helps buildings stay safe. It also helps buildings last longer in any weather. MgO boards are light. People can put them up easily. This saves time and money. The boards are still very strong. Always put a weatherproof cover on MgO boards. Use the right fasteners to keep them safe. This helps them last a long time. MgO boards are better than plywood, gypsum, and cement boards. They keep fire away better. They stop water better. They are also better for the environment.

MgO Boards for Exterior Sheathing

Key Properties

Magnesium oxide boards have many good features. They help protect steel buildings from fire, water, pests, and noise. You can trust mgo boards to keep buildings safe and strong in different places.

Here are the main reasons people pick mgo boards for outside sheathing:

Fire resistance: Mgo boards do not burn easily. They can handle heat up to 1200°C. They do not let out bad gases when they get hot.

Moisture and mold resistance: Magnesium oxide boards do not swell or curl. Mold does not grow on them. You can use them in wet or damp places without worry.

Durability and strength: Mgo boards are tough. They do not crack or break easily. This helps buildings stay strong for a long time.

Thermal insulation: These boards help keep buildings warm or cool. They block heat and cold from getting inside.

Soundproofing: Mgo boards make buildings quieter. They stop loud noises from coming in.

Lightweight and easy to handle: Mgo boards are light. You can put them up fast. Their weight makes work easier and saves money.

Pest resistance: Magnesium oxide boards do not attract bugs. Termites and other pests stay away. This helps the sheathing last longer.

Mgo boards have a special design. Many use fiberglass mesh layers. This makes them stronger and tougher. Some types, like magnesium oxysulfate boards, are even better at stopping water and rust. This helps steel buildings last longer.

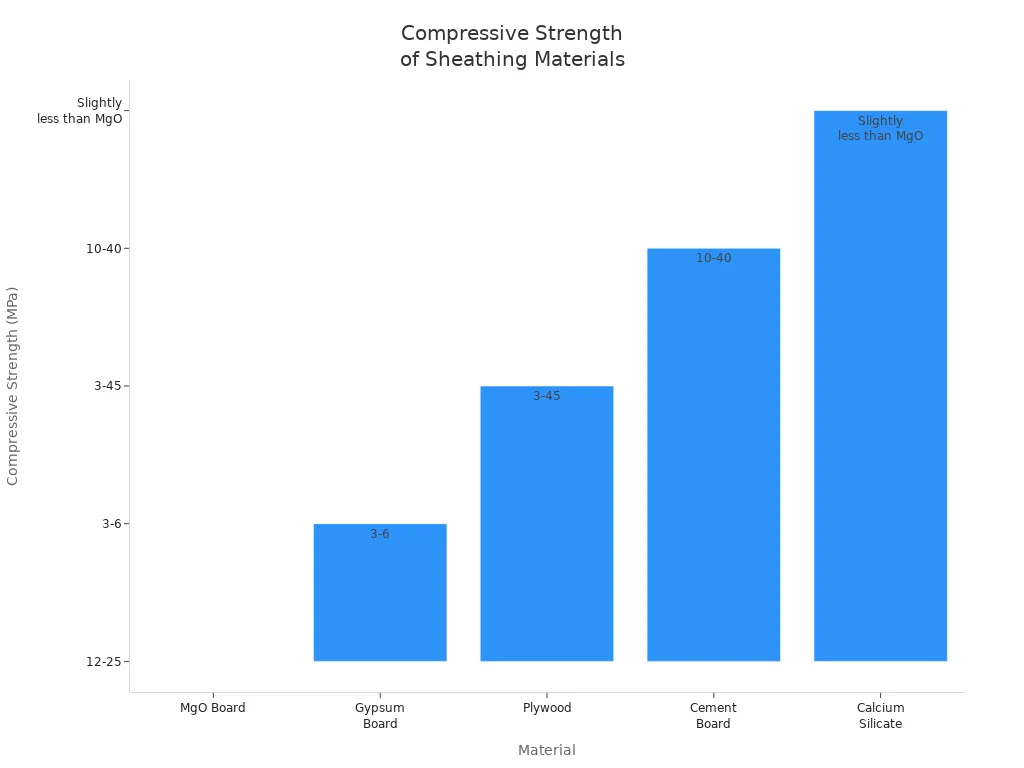

If you look at how mgo boards compare to other sheathing, you see they are better. The table below shows how strong mgo boards are:

Material | Compressive Strength (MPa) | Flexural Strength and Impact Resistance |

|---|---|---|

MgO Board | 12 – 25 | High flexural strength; can bend without breaking; excellent impact resistance |

Gypsum Board | 3 – 6 | Low flexural strength; prone to cracking and breaking |

Plywood | 3 – 45 (varies by grade) | Generally lower flexural strength than MgO; glue layers can fail; less impact resistant |

Cement Board | 10 – 40 | Similar flexural strength to MgO; very strong but heavier and harder to install |

Calcium Silicate | Slightly less than MgO | Lower impact resistance and flexibility compared to MgO |

Magnesium oxide boards are stronger than gypsum and plywood. They also match or beat cement and calcium silicate boards. Mgo boards do not crack or fall apart. Your outside sheathing stays good for many years.

Tip: Magnesium oxide boards are good for the environment. You can use them in green buildings to help the planet.

Applications in Steel Buildings

You can use mgo boards in many ways outside steel buildings. They work well as outside sheathing. You should always cover them with a finish. Do not leave mgo boards uncovered because weather can hurt them.

Here are some common ways to use mgo boards in steel buildings:

Wall sheathing: Mgo boards make walls strong and safe from fire.

Fascia: Magnesium oxide boards cover roof edges for a neat look.

Soffit: Mgo boards protect the bottom of roof overhangs.

Trim: Use these boards for strong trim around doors and windows.

Lap siding substrate: Mgo boards are a good base for lap siding.

Roofing base or roof decking: Magnesium oxide boards help roofs resist fire and water.

Structural Insulated Panels (SIPs): Mgo boards are used as the outside layer in SIPs for more strength and insulation.

Mgo boards are great at stopping fire, water, mold, and damage. This makes them perfect for outside sheathing in steel buildings. You get a material that helps the building and keeps it safe from bad weather. MagPanel® and other brands give extra rust protection, which is important for steel buildings.

When you plan your building, remember to cover mgo boards for outside use. This keeps your sheathing strong and helps your building last longer.

Durability and Strength of MgO Boards

Moisture and Mold Resistance

You want your steel building to last a long time. Some places have lots of rain or are very humid. MgO boards are strong and last long. They do not bend, swell, or break when they get wet. These boards are made from minerals. They can handle hot and cold weather. They also stay strong during storms and floods. You can count on these boards to keep working well.

MgO boards do not soak up water. This helps you control wetness and humidity. They do not bend or get bigger when wet. In a house near the ocean, MgO panels did not grow mold. They also did not have any damage after many years of bad weather. This good moisture control keeps your building safe and strong.

Here is a table that shows how MgO boards and gypsum board are different:

Feature | MgO Board | Gypsum Board |

|---|---|---|

Composition | Fully inorganic, no food for mold | Organic materials, paper facings |

Water Absorption | Higher (nearly 3%) | |

Behavior When Wet | No swelling or breaking | Swells, warps, can break |

Mold Resistance | High (ASTM G21: 0/0/0) | Lower, especially paper-faced |

Wet Area Suitability | Ideal | Not recommended |

MgO boards are better at stopping mold and bugs. They do not let mold or mildew grow, even in wet places.

Tip: MgO boards help keep your building safe and healthy by stopping mold early.

Termite and Pest Protection

You do not want bugs to hurt your building. MgO boards stop termites and other bugs. The boards are not made from things bugs eat. Termites and ants cannot chew through them. The boards stay strong and do not get ruined, even after many years.

MgO boards do not have anything for bugs to eat.

Termites and ants cannot hurt the boards.

The boards stay strong and safe for a long time.

This strong protection saves your building from hidden bug damage. You can feel calm knowing your steel building is safe from pests. MgO boards give you strength and protection in all kinds of weather.

Fire Resistance and Safety

Fire-Rated Sheathing

Fire-Rated Sheathing

You want your steel building to be safe in a fire. MgO boards give strong fire protection. These boards do not burn or help fires grow. You can use them for fire-rated walls outside your building. Both magnesium sulfate and magnesium chloride MgO boards reach Class A fire resistance in most countries. MagPanel® MgO boards do not burn and have a Class A1 rating, which is the best fire safety level.

Here is a table that shows how MgO boards do in fire tests:

Certification/Test Standard | Purpose | Fire Resistance Rating Achieved |

|---|---|---|

ASTM E136 | Checks if material is noncombustible | Classified as Noncombustible |

ASTM E84 | Measures surface flame spread | Class A rating (highest resistance) |

EN 13501-1 | European fire classification | Class A1 (noncombustible) |

CAN/ULC S114 & ULC S135 | Canadian fire safety standards | Meets fire-rated wall requirements |

MgO boards can take heat up to 1200°C. They stay fireproof for up to 4 hours, even in strong fires. You can trust these boards to protect your building and slow down fire.

Note: MgO boards do not make smoke or bad gases in a fire. This helps keep people safe inside.

Safety Standards

You must follow strict safety rules for steel buildings. MgO boards help you meet these rules. They do better than other sheathing in fire tests. Here is a comparison:

Material/Property | MgO Boards | Gypsum Board | Cement Board | Plywood | OSB |

|---|---|---|---|---|---|

Fire Resistance | Up to 4 hours | Medium | High | Low | Low |

Flame Spread | Minimal (Class A) | Moderate | Moderate | High | High |

Non-Combustibility | Yes (A1) | No | No | No | No |

Smoke and Toxicity | Low | Moderate | Moderate | High | High |

Structural Integrity | Maintains strength | Degrades | May crack | Weakens | Weakens |

MgO boards give you better fire safety. They keep your walls strong in a fire. You can use them for fire-rated walls and pass building codes. Many safety groups, like ICC-ES, say MgO boards are good for fireproof outside use.

Tip: Always use MgO boards with a full fire-rated wall system for the best safety.

Installation Best Practices

Fasteners and Compatibility

You need to use the right fasteners. This keeps magnesium oxide boards strong on steel buildings. The correct screws and nails help mgo boards last longer. They also protect the outside from damage. Here are some tips for picking and using fasteners:

Use screws that do not rust, like 316 stainless steel or ceramic coated ones. These keep mgo boards safe outside.

For steel frames that are thick, use #8 flat head screws with self-drilling tips. These go through metal easily and hold boards tight.

If the steel frame is thin, use special nails with a nail gun. Change the pressure so nails fit well and do not hurt the board.

Put screws every 6 inches along the edges. Put screws every 12 inches in the middle. This spreads weight and keeps boards from moving.

Keep screws at least 4 inches from corners and about 9/16 inch from the edge. This stops cracks and keeps boards strong.

Do not put screws in at an angle. Always put them in straight for the best hold.

Make screws sit just below the surface. This helps you finish the board and keeps water out.

Tip: If you use galvanized steel frames, put a barrier between magnesium oxide boards and the frame. This stops chemical problems that can make your building weak.

Using the right fasteners and putting them in the right way helps mgo boards fight moisture and weather. You keep your walls safe and make your building last longer. Strong glue can also help spread weight and keep boards steady, especially when it is very humid.

Weatherproofing and Sealing

It is important to keep water out. You want mgo boards to stay dry and strong, even when it rains or is humid. Follow these steps to protect magnesium oxide boards from water:

Let mgo boards sit in the building area for 48 hours. This helps boards get used to the temperature and humidity.

Leave a small gap, about 1/16 inch, between boards. This lets boards grow or shrink when the weather changes.

Always use a water barrier between mgo boards and the finish. This layer blocks water and keeps your building safe.

Seal all joints with waterproof filler and wide fiberglass tape. Use patching compounds to stop tiny cracks and keep water out.

For the edges, use waterproof sealants. Polyurethane foam or fire-rated sealants work well to fill gaps and keep water out.

Put on a primer that sticks well to masonry or concrete. This helps the topcoat stay on and adds more water protection.

Finish with a topcoat that blocks UV rays, like acrylic stucco or latex exterior paint. In tough weather, elastomeric paint gives extra protection and stops cracks.

Never use mgo boards without a cover. Always put a finish on top to protect from rain, sun, and humidity.

Note: Store magnesium oxide boards inside on a flat, raised spot before you use them. Keep them off the ground and do not put heavy things on top. This stops boards from bending and keeps them ready for building.

Good weatherproofing and sealing keep mgo boards strong in any climate. You stop water and humidity from getting in, so your walls last longer. By following these steps, you make sure magnesium oxide boards work well for wall sheathing and soffits.

Comparing Exterior Sheathing Materials

MgO vs. Plywood

MgO vs. Plywood

If you look at mgo boards and plywood for outside walls, you will notice big differences. Mgo boards do not change shape when wet or dry. Plywood gets wet, swells, and becomes weak. You have to fix plywood more often, especially where it is humid. Mgo boards are much safer in a fire. They do not burn and can protect for up to 4 hours. Plywood burns fast and lasts only about an hour unless you add fireproofing.

Here is a table that shows how they compare:

Property | MgO Board | Plywood |

|---|---|---|

Moisture Resistance | Does not swell or warp; resists mold and water damage | Swells, warps, and loses strength when wet |

Fire Resistance | Non-combustible; up to 4 hours protection | Combustible; up to 1 hour protection |

Durability | High; needs little maintenance | Lower; needs frequent repairs |

Eco-Friendly | Yes; recyclable and supports sustainable construction | Less eco-friendly; not recyclable |

Installation | Fast and easy; lighter weight | Slower; needs extra treatments |

Mgo boards cost more at first. But you save money later. You do not need to fix them as much. Mgo boards also help the environment.

MgO vs. Gypsum

Gypsum board is used a lot, but it is not good for outside. Magnesium oxide boards do not soak up much water. Mgo boards stop mold and stay strong in wet weather. Gypsum boards get wet, break, and grow mold. Use mgo boards for outside walls if you want them to last.

Mgo boards are better in fires. They protect for up to 4 hours. Gypsum boards last only 30 to 60 minutes. You get more time to keep your building safe.

Mgo boards do not burn and pass tough fire tests.

Gypsum boards need extra stuff or layers for better fire safety.

Mgo boards stay strong in heat, but gypsum boards get weak.

If you want strong and safe walls, pick mgo boards.

MgO vs. Cement Board

Cement board is tough and does not burn, but mgo boards have more good points for steel buildings. Mgo boards are lighter and easier to put up. They let air move, so walls stay dry. Magnesium oxide boards made with sulfate do not make steel frames rust.

Aspect | MgO Sulfate Boards | Cement Board |

|---|---|---|

Moisture Resistance | Excellent; stable and breathable | Good, but heavier |

Corrosion Risk | No risk with sulfate type | No risk |

Installation | Lighter, easier to cut and handle | Heavier, harder to install |

Eco-Friendly | Yes; supports sustainable construction | Less eco-friendly |

Mgo boards help you build faster and are better for the planet. You get walls that are strong, safe, and last a long time.

Tip: Pick magnesium oxide boards for your steel building if you want strong, safe, and green walls.

You can count on mgo boards for your steel building’s exterior. These boards give you top fire resistance, strong mold and moisture protection, and long-lasting strength. Many professionals choose mgo boards because they stay stable, block water, and keep your wall safe in any climate. If you plan to use mgo boards, let them adjust to your site, use the right fasteners, and follow all building codes. This way, your building will stay safe and strong for years.

FAQ

Can you use MgO boards as exposed exterior cladding?

You should not use MgO boards as exposed cladding. Always cover them with a weather-resistant finish. This protects the boards from rain, sun, and wind.

Do MgO boards need a water-resistive barrier?

Yes, you need a water-resistive barrier between MgO boards and the exterior finish. This barrier helps keep water out and protects your steel building from moisture damage.

Are MgO boards safe for coastal or humid climates?

MgO boards work well in coastal and humid areas. They resist mold, moisture, and salt air. You can trust them to stay strong and protect your building in these tough conditions.

How do you cut and install MgO boards?

You can cut MgO boards with a standard carbide-tipped saw. Always wear a mask and goggles for safety. Use corrosion-resistant screws for steel frames. Follow the spacing and sealing tips for best results.

Fire-Rated Sheathing

Fire-Rated Sheathing MgO vs. Plywood

MgO vs. Plywood