29 Aug How Long Can Magnesium Wall Boards Withstand Fire

Table of Contents

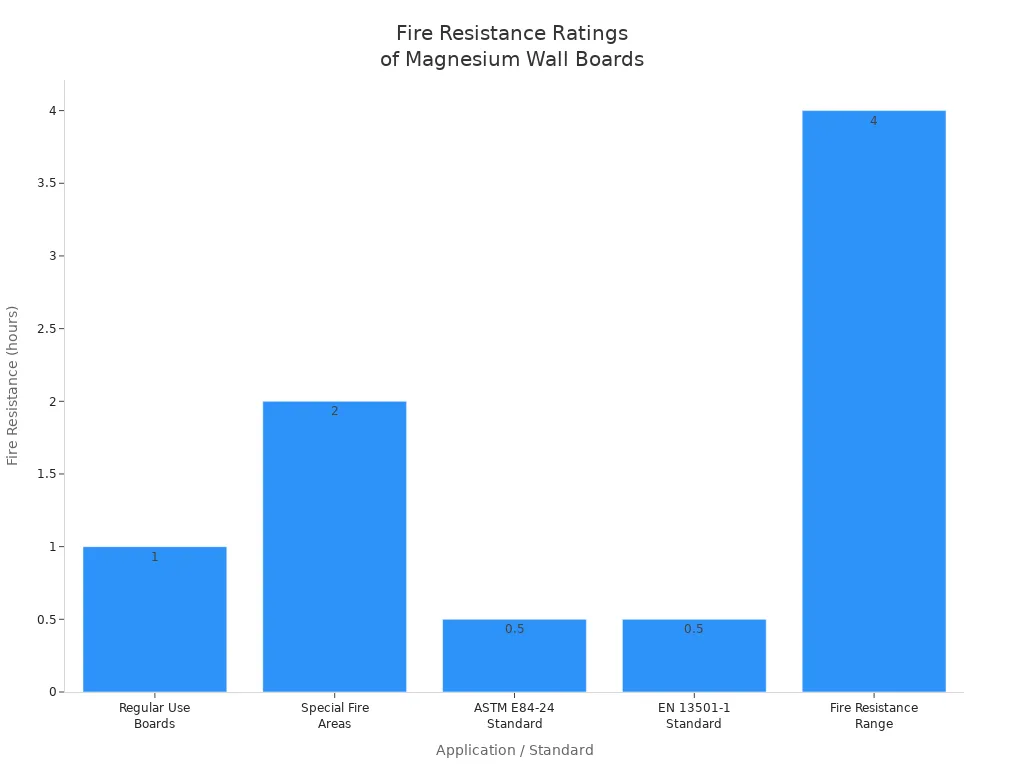

Magnesium wall boards, also known as MgO boards, offer a fire resistance duration ranging from 60 to 120 minutes, with some types lasting up to 4 hours. These boards comply with strict fire safety regulations, helping to keep people safe during emergencies. The table below highlights how their fire resistance duration benefits buildings and occupants:

Aspect | Explanation |

|---|---|

Fire Resistance Rating | MgO boards achieve a Class A rating, indicating low flame spread and minimal smoke production. |

Material Properties | They are non-combustible and maintain strength under high heat, serving as an effective fire barrier. |

Impact on Compliance | Ideal for fire-rated walls, ceilings, stairs, and exits in all types of buildings. |

Occupant Safety Benefits | Their fire resistance duration slows fire spread, reduces heat and smoke, and enhances occupant safety. |

New MgO boards can withstand very high temperatures for extended fire resistance durations, outperforming older materials and significantly improving fire safety.

Key Takeaways

Magnesium wall boards can stop fire for 1 to 4 hours. The time depends on how thick the boards are and how they are put up. They give strong safety during emergencies. Thicker boards and more layers help stop fire for longer. Good installation makes them safer and last longer. MgO boards pass hard fire tests. They get high scores for not burning, making little smoke, and stopping flames from spreading. This makes them good for fire safety. Magnesium boards last longer in fires than gypsum and cement boards. They make less smoke and stay strong when it is very hot. Using certified MgO boards helps buildings follow fire rules. They keep people safe and can lower fire damage and insurance costs.

Fire Resistance Duration

Typical Ratings

Magnesium wall boards can stop fire for a long time in buildings. Tests show they can last 60, 120, or even 240 minutes. This depends on how they are used and built. The A1 fireproof rating means these boards do not catch fire. They can face open flames for at least two hours in walls. This rating also means the boards do not burn or help fire spread.

The table below shows common fire resistance ratings for magnesium wall boards:

Application Area / Certification Standard | Fire Resistance Rating / Description |

|---|---|

Regular Use Boards | At least 1 hour fire resistance |

Special Fire Areas (e.g., fire rooms) | 2 hours or more fire resistance |

ASTM E84-24 Standard | Withstands temperatures over 750°C for 30 minutes, rated A1 |

EN 13501-1+A1:2010 Standard | Meets strict fire safety rules, rated A1 |

Fire Resistance Range | Typically 1 to 4 hours depending on thickness and testing |

Magnesium sulfate boards can take heat up to 1200°C. Groups like K.I.S., ETL-Intertek, and ISO check and confirm these ratings. The chart below shows how fire resistance changes with different standards and uses:

What Affects Duration

Many things change how long magnesium wall boards can stop fire. The most important thing is how thick the board is. Thicker boards, like 15mm to 20mm, stop fire and damage better than 12mm boards. Each 16mm layer adds about 60 minutes of fire protection. Using more layers also helps. More layers mean more time before fire gets through.

How you put up the boards matters too. Boards nailed right to the frame need to be thicker. Boards on top of cement or insulation can be thinner and still work well. The way the wall is built, like sandwich panels, helps the board stay strong in a fire. Adding fiberglass mesh layers, which go up as boards get thicker, can make the boards last longer and be stronger.

Factor | Details and Impact on Fire Resistance |

|---|---|

Board Thickness | Thicker boards (15mm to 20mm) provide enhanced fire and impact resistance compared to standard 12mm boards. |

Installation Method | Direct fastening to framing requires thicker boards (12mm or more); continuous backing surfaces (cement, insulation) allow thinner boards (6mm to 9mm) while maintaining protection. |

Assembly Type | Assemblies with continuous backing support thinner boards without compromising fire resistance. |

Fiberglass Mesh | Number of fiberglass mesh layers increases with thickness (2 layers for 3-12mm, 3 layers for 13-17mm, 4 layers for 18-25mm), potentially affecting durability and fire resistance. |

Magnesium wall boards protect walls by lining them. They keep steel studs from getting too hot. Their special features, like being dense and not letting heat move fast, slow down heat. This helps the wall stay strong during a fire.

The A1 fireproof rating is a big plus for these boards. They do not burn or let out bad gases. They also have a 0/0 rating on the ASTM E84 / UL 723 test, so they make almost no smoke or flames. When there is a fire, the boards let out water vapor. This cools the area and helps stop the fire from spreading.

Note: Magnesium wall boards give people more time to get out safely during a fire. They stop fire and smoke from spreading fast. This makes it easier for people to leave and for firefighters to help. The boards also help keep the building strong, so it is less likely to fall down in a fire.

Testing & Standards

Fire Rating Tests

Magnesium wall boards have to pass tough fire tests before builders use them. These tests check if the boards can stop fire, smoke, and heat. Each test looks at a different part of fire safety. The table below lists some main tests and what they check:

Test Name | Purpose / What It Measures | Description / Key Details | Example Results for MgO Panels |

|---|---|---|---|

NFPA 285 | Fire spread on exterior walls and into upper floors | Simulates a fire in a two-story wall assembly | MgO panels help prevent fire from moving up the wall |

ASTM E119 | Fire endurance and structural strength | Tests how long a wall can hold up under fire and weight | MgO assemblies can last 1-2 hours or more |

ASTM E84 | Flame spread across the board’s surface | Measures how fast flames move along the board | MgO panels often get a zero flame spread rating |

These tests show magnesium wall boards can stop fire for a long time. But, they do not fail the same way as other boards. For example, MgO boards might crack or break at the joints when they get very hot. Gypsum boards usually fail because the steel studs behind them get too hot. MgO boards can lose more material at high heat, which can change how well they work. How builders put up the boards, the space between the studs, and the kind of insulation all matter for fire safety.

Certifications & Codes

Certifications and building codes tell builders which magnesium wall boards are safe. Boards with an A1 non-combustible rating do not burn or make toxic smoke. This rating means the boards can take heat over 750°C for more than 30 minutes without changing shape or color. Many places accept MgO boards that meet these rules.

Certification/Standard | Recognition/Fire Rating | Description |

|---|---|---|

EN 13501-1 | Class A1 Noncombustible | No fire contribution, minimal smoke |

ASTM E136 | Noncombustible | Does not burn in test conditions |

ASTM E84 | Class A Surface Fire Spread | Excellent surface fire resistance |

ASTM E119 | Fire Resistance | Up to 4 hours of fire resistance |

NFPA 285 | Fire Test | Valid for multi-story buildings |

ICC-ES ESR-2880 | Evaluation Report | Meets international building codes |

CCMC 14038_e | Canadian Certification | Approved for fire safety in Canada |

BBA | UK Certification | Meets fire and quality standards |

Note: Not every magnesium wall board passes all the tests. Some boards may fail if they have too much organic stuff or are not made right. Builders should always check for the right certifications and follow the maker’s instructions. This helps make sure the boards meet fire safety rules. It keeps buildings safe and up to code in the US, UK, Australia, and other places.

Comparison to Other Materials

MgO vs. Gypsum Board

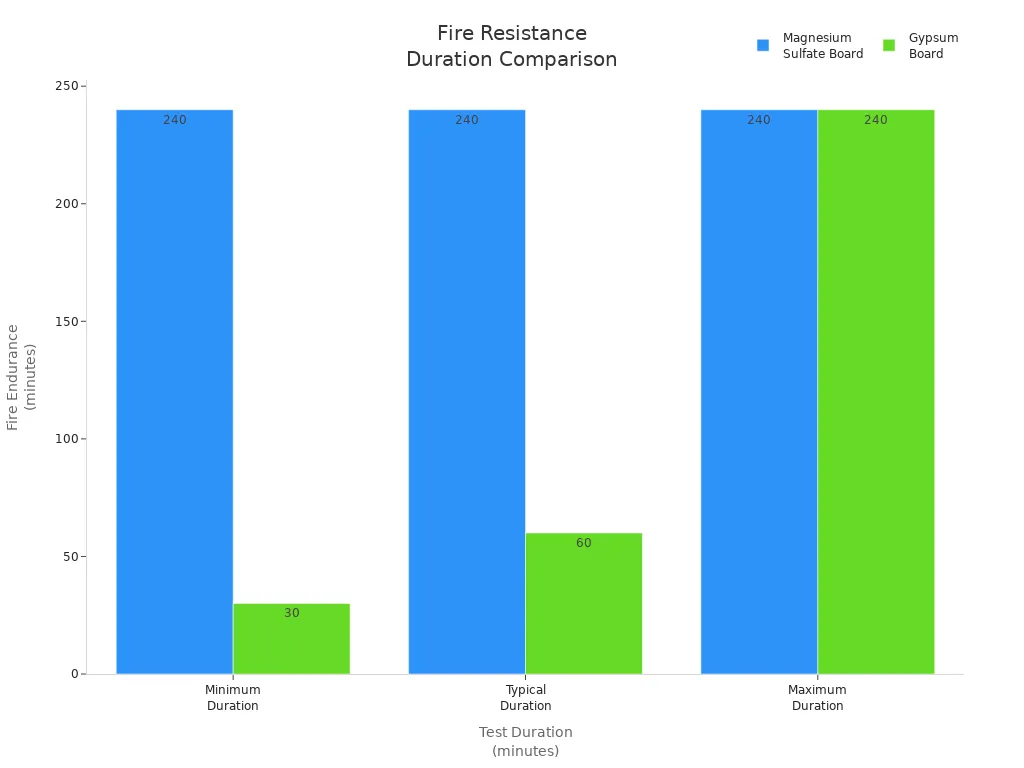

Magnesium oxide boards are much better at stopping fire than gypsum boards. In tests like ASTM E119 and EN 13501-1, MgO boards can last up to 4 hours or more. Gypsum boards, even special ones, usually last only 30 to 60 minutes. Some thicker gypsum boards with extra stuff can last up to 4 hours. Gypsum boards slow fire by turning water into steam, but they get weak as they dry. MgO boards do not burn and keep their shape even at 1200°C. They also make less smoke and almost no bad gases.

Criteria | Magnesium Sulfate Board (MgO) | Gypsum Board |

|---|---|---|

Fire Resistance Rating | A1 Non-Combustible (top rating under EN 13501-1) | Fire-Resistant (Limited, up to 1 hour typical) |

Fire Endurance Duration | Up to 4 hours or more in standardized tests | Typically 30 to 60 minutes, up to 4 hours for special types |

Thermal Combustibility | Non-combustible, withstands temperatures up to 1200°C | Combustible, weakens under heat |

Flame Spread Index | Very low (0 to 25 on ASTM E84) | Moderate flame spread |

Smoke and Toxic Gas Emissions | Low smoke, no toxic gases | Moderate smoke, releases non-toxic gases |

MgO boards stay strong in a fire. Gypsum boards can crack or break when they get too hot.

MgO vs. Cement Board

MgO boards are also better than cement boards for fire safety. Both do not burn, but MgO boards can last up to 4 hours in fire tests. Cement boards often need extra fireproofing to last as long. MgO boards keep their strength and shape in very high heat. This makes them a better pick for places with high fire risk. Cement boards can get weak between 250–750°C and may make more smoke and gases.

Fire Resistance Aspect | Magnesium Oxide (MgO) Boards | Cement Boards |

|---|---|---|

Combustibility | Non-combustible (A1 rating) | Non-combustible but moderate fire resistance |

Fire Resistance Duration | Can withstand fire up to 4 hours | Moderate fire resistance; may require extra fireproofing |

Structural Integrity in Fire | Maintains strength and shape under extreme heat | May lose strength without additional support |

Flame Spread | Low flame spread | Low flame spread |

Smoke and Toxic Gas Emissions | Low emissions | Higher emissions compared to MgO boards |

Suitability for High Fire Risk | Ideal for high fire-risk areas | Suitable for lower fire risk or less extreme heat conditions |

MgO boards do not burn and can take very high heat.

Cement boards resist fire but might not stay strong in big fires.

MgO boards give better safety where fire protection is very important.

Applications & Benefits

Where MgO Boards Are Used

Magnesium oxide wall boards are used in many buildings. Builders put them on both inside and outside walls. You can find MgO boards in places like elevator shafts and stairwells. They are also used between rooms in hospitals, schools, hotels, offices, and apartments. These panels follow strict fire safety rules, like ASTM E119 and ASTM E136. This makes them good for places that need strong fire protection.

MgO boards are often needed where building codes want extra fire safety. The International Wildland-Urban Interface Code says to use ignition-resistant materials in wildfire areas. MgO boards meet these rules, so they help protect homes and businesses near wild plants.

Some common places where MgO boards are required include:

Outside walls in wildfire danger zones

Fire-rated walls in busy public buildings

Stairwells and elevator shafts

Walls between apartments or hotel rooms

These uses help keep people safe and buildings strong if there is a fire.

Fire Safety Advantages

MgO boards have many fire safety benefits. They do not burn or make a fire worse. This helps stop flames from spreading and keeps smoke low. MgO boards can take very high heat, up to 1472°F (800°C), without burning or getting weak. They do not let out bad fumes, so the air stays safer during a fire.

MgO boards slow down fire and block heat. This gives people more time to get out safely.

The boards keep their fire protection for years because they resist water, mold, and bugs.

MgO boards do not need chemical fire retardants, so their fire safety does not fade over time.

Property | Fire Safety Benefit |

|---|---|

Stops fire from starting and spreading | |

High heat resistance | Stays strong in very hot fires |

Low smoke emission | Makes less smoke for people inside |

Durability | Keeps fire protection for many years |

MgO boards hold back flames and smoke. This gives people more time to leave and helps stop fire damage. Their strong fire safety makes them a smart pick for new buildings.

Magnesium wall boards can stop fire for up to four hours. This helps keep buildings safe if there is an emergency. They work better than gypsum and cement boards when there is a fire. The table below shows how each material handles fire:

Material | Fire Resistance Rating | Temperature Resistance | Flame Spread Rating |

|---|---|---|---|

MgO Board | Class A1 Non-Combustible (up to 4 hours) | Up to 1200°F (and up to 1472°F in some cases) | Zero |

Gypsum Board | Fire-Resistant (limited, <1 hour) | Limited | Moderate |

Cement Board | Highly Fire-Resistant | Good | Low |

Fiber Cement Board | Fire-Resistant | Moderate | Moderate |

MgO boards do not burn or make toxic smoke. They stay strong even in a fire. Homeowners and builders like MgO boards because they help meet building codes. These boards make it easier for people to get out safely. They can also help lower insurance costs. Picking certified MgO boards and installing them the right way gives the best fire safety for any building project.

FAQ

How long can magnesium wall boards resist fire?

MgO boards can stop fire for 1 to 4 hours. The time depends on how thick the board is. It also depends on how you put it up. The right certification matters too.

Are magnesium wall boards safe for homes?

MgO boards do not catch fire or make toxic smoke. Builders use them in houses to make fire safety better. They help homes follow building rules.

Do magnesium wall boards need special installation?

Installers must use the maker’s instructions. Fastening the boards the right way is important. Good assembly helps the boards work as they should.

Tip: Always pick MgO boards that are certified before you start.

How do magnesium wall boards compare to gypsum boards?

Feature | MgO Board | Gypsum Board |

|---|---|---|

Fire Resistance | Up to 4 hours | Up to 1 hour |

Smoke Emission | Very low | Moderate |

MgO boards last longer in a fire. They also make less smoke than gypsum boards.