29 Aug Key Features of A1 Fire Rated Magnesium Wall Boards

Table of Contents

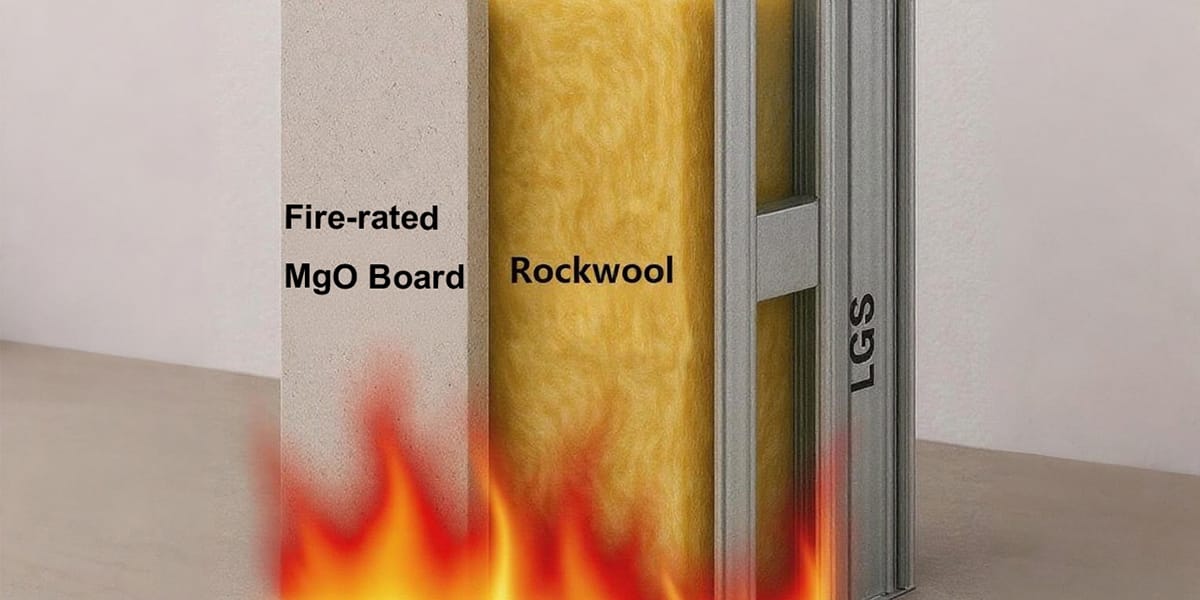

A1 fire rated magnesium wall boards do not burn easily. They follow strict rules for fire safety. These panels can face open flames and do not make smoke or harmful gases. This makes them good for places where fire safety is very important. New studies show health and safety benefits like fire resistance, water resistance, pest control, and long-lasting strength:

Health and Safety Benefit | Description |

|---|---|

Fire Resistance | MgO panels have a Class A1 fire rating. They let out water vapor in a fire. This helps cool and stop the fire. |

Water Resistance | The panels do not let water or moisture in. They stay strong and keep their shape even when wet. |

Pest Resistance | The chemicals in the panels keep away termites and bugs. This lowers health risks from pests. |

Durability and Stability | Because they resist water and pests, the panels stay strong. This makes them safer in wet or bug-filled places. |

Magnesium boards work better than gypsum or cement boards. They are stronger against fire, water, and pests. More people use them in building projects around the world.

Key Takeaways

A1 fire rated magnesium wall boards stop fire, water, and pests. They stay strong for many years. This helps buildings stay safe.

These boards pass the best fire safety tests in the world. They do not burn in a fire. They do not make smoke or bad gases.

They do not get damaged by water or mold. This keeps the air inside healthy. It also stops problems in wet places like bathrooms and basements.

Magnesium boards are simple to use and put up. Workers can cut them easily with tools. The boards help keep workers safe from dust.

Magnesium boards are better than gypsum and cement boards. They protect better from fire. They last longer. They are also better for the environment.

A1 Fire Rating

Standards and Tests

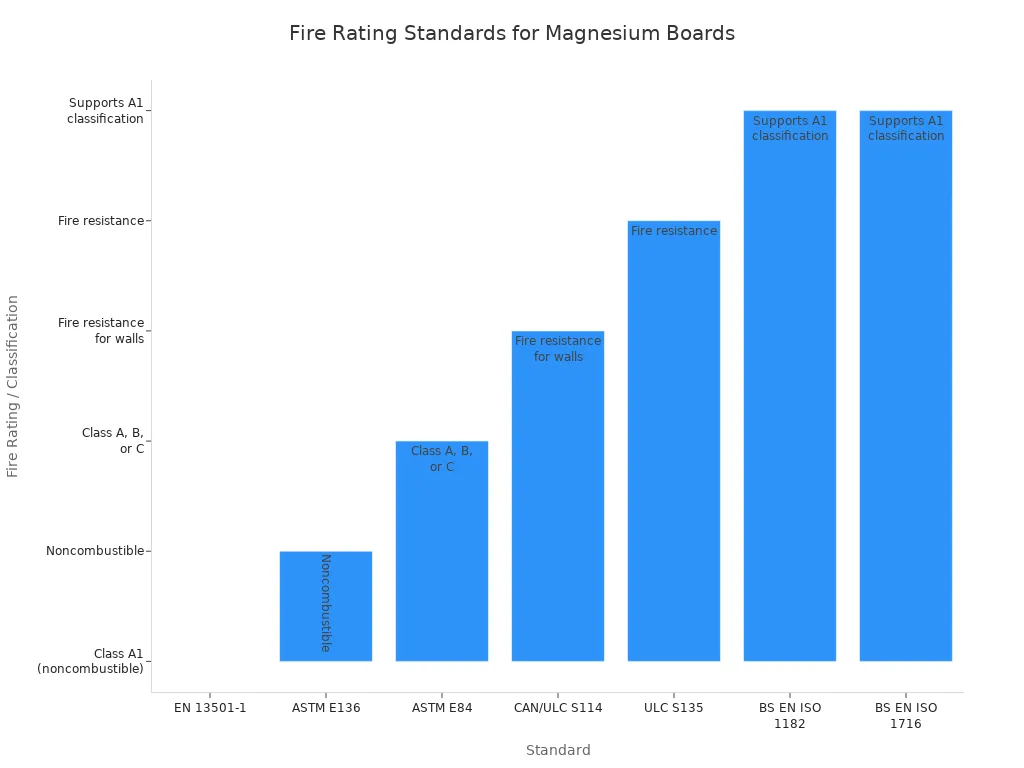

The A1 fire rating is the top level for fire safety. Magnesium wall boards get this rating by passing hard tests. These tests are used in Europe, the United States, Canada, and other places. Some of the tests are EN 13501-1, ASTM E136, and ISO tests. Each test checks if the board burns, spreads flames, makes heat, or makes smoke.

Standard | Purpose / What It Tests | Fire Rating / Classification |

|---|---|---|

EN 13501-1 | Classifies materials by combustibility | Class A1 (noncombustible) |

ASTM E136 | Tests for noncombustibility | Noncombustible |

ASTM E84 | Measures fire spread on surfaces | Class A, B, or C |

CAN/ULC S114 | Canadian fire test for noncombustibility | Fire resistance for walls |

ULC S135 | Canadian test for fire propagation | Fire resistance |

BS EN ISO 1182 | Non-combustibility testing (European) | Supports A1 classification |

BS EN ISO 1716 | Determines gross calorific value | Supports A1 classification |

The Euroclass system puts materials in groups from A1 to F. A1 materials like magnesium oxide boards, concrete, and brick do not burn at all. They do not make smoke or burning drops. The A1 fire rating is needed for tall buildings and outside walls.

Note: The A1 fire rating matches rules like the UK’s Approved Document B and EN 13501-1:2018. For balconies and outside walls, only Class A1 or A2 materials are allowed by new fire safety rules.

Fire Performance

Magnesium wall boards with an A1 fire rating work very well in fires. These boards do not catch fire, burn, or help fire spread. Lab tests show magnesium oxide boards get 0 for flame spread and smoke on the ASTM E84 test. This means they do not make smoke or bad gases in a fire.

When there is a fire, magnesium boards let out up to 30 pounds of water vapor. This vapor cools the area and slows the fire. The boards do not have bad chemicals like asbestos, ammonia, silica, benzene, or formaldehyde. They stay safe for people and nature, even in high heat.

Key fire performance features:

Do not burn at any time during a fire

Do not make smoke or bad gases

Stay strong in flames for hours

Help cool and stop fires by letting out water vapor

Builders pick A1 fire rated magnesium wall boards for important fire safety jobs. These boards pass the hardest tests and keep people safe in homes, schools, hospitals, and offices.

Certifications and Compliance

Key Certifications

A1 fire rated magnesium wall boards have top certifications in building. These show the boards are safe and high quality. Builders and inspectors check for these marks. They want to make sure the boards work well in real buildings.

Certification / Standard | Description / Relevance |

|---|---|

UL (Underwriters Laboratories) | Known for fire safety, can protect for up to 2 hours. |

ISO (International Organization for Standardization) | Shows the boards are safe and good quality worldwide. |

CE Marking (European Conformity) | Proves the boards follow European fire safety rules. |

ASTM Standards (e.g., ASTM E119, ASTM E84) | Used to test fire resistance and flame spread. |

EN 13501-1 | European rule for fire safety; Class A1 is best. |

Labels from trusted labs like Intertek and UL show these boards follow building codes like IBC and IRC. Boards such as DragonBoard and Suparna MgO Board have these labels, so people trust them.

Building Safety

A1 fire rated magnesium wall boards help keep buildings safe, especially tall ones. Their features protect people and things during emergencies.

Property | Description | Fire Safety Contribution in High-Rise Buildings |

|---|---|---|

Fire Resistance | Does not burn, has A1 Class rating | Stops fire from spreading, meets top codes, gives more time to escape |

Thermal Stability | Handles heat up to 1200°C (1472°F) | Keeps the building strong in high heat, slows down collapse |

Smoke and Toxicity | No bad smoke or gases | Less harmful fumes, safer during fires |

Structural Integrity | Stays strong in fire | Gives more time to escape and fight the fire |

Moisture Resistance | Fights water and mold | Stays safe and strong after fire or water |

Certification | Passes ASTM E84, ASTM E119, EN 13501-1 | Meets world fire safety rules for tall buildings |

Insurance companies know these boards lower risks. They might give cheaper insurance for buildings that use them.

Hospitals and other risky places use these boards to keep buildings safe in fires.

These boards also help with green building awards like LEED and WELL:

Good for the planet and can be recycled

No bad chemicals, so air inside is better

Lasts long and saves energy, so less waste

A1 fire rated magnesium wall boards help buildings follow strict safety rules and help the planet. Their labels and good results make them a smart pick for safe, new buildings.

Durability and Moisture

Water Resistance

A1 fire rated magnesium wall boards are very good at stopping water and moisture. They let water vapor move through, so water does not get trapped inside. This helps stop wet air from building up and keeps mold and mildew from growing. These boards work well in wet places like bathrooms and basements. Magnesium oxide boards stay strong and keep their shape even when they get wet. They do not bend or change shape like plywood or OSB panels.

In tests where boards were put in water, magnesium oxychloride boards with A1 fire rating took in less water than most other magnesium boards. For example, board C stayed dry after being partly in water for 24 hours, and board A only had a little bit of water. This shows these boards are very good at keeping water out. Fiber cement boards also stay strong after being in water for a long time, but magnesium boards still do better than gypsum plasterboard, which gets ruined by water. Because these boards are not made from things that can rot, mold cannot grow on them, which helps keep buildings healthy.

Tip: Builders like to use magnesium boards in places that might get wet or before the building is fully closed up, because these boards do not let water cause problems.

MgO boards do not soak up much water, so they do not bend or change shape.

They do not fall apart when they get wet.

They let air move through, so water does not build up inside.

The boards stop mold and mildew, which helps keep the air inside healthy.

Physical Strength

A1 fire rated magnesium wall boards are strong and can be used in tough jobs. They can handle at least 12 MPa of pressure, which is enough for most building needs. The boards are light but still tough, so they are easy to carry and put up. They do not break easily if they get hit or bumped during building or when people use the space.

Property | Value/Description |

|---|---|

Compressive Strength | ≥ 12 MPa |

Fire Rating | A1 (highest fire resistance classification) |

Impact Resistance | High; impact-resistant |

The boards stay strong even in wet or damp places. Because they are not made from things that can rot, they do not get mold or fungus, even in hard places. Builders use these boards for walls, ceilings, and room dividers when they need something safe and strong.

Installation and Use

Handling and Cutting

Handling and Cutting

A1 fire rated magnesium wall boards are easy to move and cut. Workers can use many tools to make clean cuts and shapes. The boards do not break or bend when being cut.

Circular saws with thin carbide blades make straight cuts and help blades last longer.

Utility knives let workers score and snap small pieces fast.

Fiber cement shears are good for careful cuts and make less dust.

Oscillating multitools are helpful in small spaces or odd angles.

Workers should put boards on steady tables like sawhorses so they do not move.

After cutting, sanding the edges makes them smooth.

Carrying boards upright keeps them from bending or breaking.

Letting boards get used to the room before putting them up works best.

Leaving small gaps and using fire-rated sealants at seams keeps the fire rating.

Using glue on corners helps stop tiny cracks after cutting.

Safety is very important when putting up these boards. Workers must wear masks to keep from breathing in dust. Safety glasses keep eyes safe from flying bits. Gloves protect hands from sharp edges and tools. Working in places with good airflow or using dust collectors keeps dust down and the area clean.

Tip: Taking breaks during long cutting jobs helps workers stay alert and make fewer mistakes.

Applications

A1 fire rated magnesium wall boards work for many building jobs. Builders pick these panels because they stop fire and are strong. The boards are good for inside and outside use.

Application Area | Examples of Construction Projects and Uses |

|---|---|

Floors, walls, fire walls, ceilings, subfloors, tile backers, stairs, hallways, ceiling tiles, cubicle walls | |

Indoor Projects | Homes, theaters, offices, schools, libraries, gyms, data centers, warehouses, shelters, modular buildings, apartments |

Outdoor Uses | Roof decks, sheathing, fascias, soffits, trim work |

Outdoor Projects | Shafts, balconies, home and business roofs, wall sheathing, trim boards, siding |

Additional Indoor Applications | Meeting rooms, classrooms, panel rooms, hospitals, control rooms, kitchens, wet areas, hotel rooms, stages, modular schools |

Fire Resistance & Durability | Stops fire, mold, bugs; good for fire walls, ceilings, and outside jobs needing fire safety and strength |

Common Building Types | Homes, theaters, offices, schools, libraries, gyms, data centers, warehouses, hospitals, modular buildings, airports, big apartment buildings |

Builders use A1 fire rated magnesium wall boards in busy places and where there is a lot of use. These panels help keep people and things safe in homes, businesses, and apartment buildings. Their many uses and safety make them a top pick for new buildings.

Comparison with Other Boards

Gypsum vs. Magnesium

Magnesium wall boards are better than gypsum boards for fire safety and strength. Magnesium sulfate boards get the best fire safety rating, called A1, under EN 13501-1. They can handle heat up to 1200°C. These boards do not spread flames much and make very little smoke. Gypsum boards, even special ones like Type X and Type C, only give some fire protection and last about one hour. Gypsum boards get hot fast, make more smoke, and break down quicker when heated.

Criteria | Magnesium Sulfate Board (A1 Fire Rated) | Gypsum Board (Type X, Type C) |

|---|---|---|

Fire Resistance Rating | A1 Non-Combustible (top rating under EN 13501-1) | Fire-Resistant but Limited (up to 1 hour typical) |

Thermal Combustibility | Non-Combustible; withstands temperatures up to 1200°C | Combustible; softens and degrades under heat |

Flame Spread | Low flame spread index (0-25), slows fire movement | Moderate flame spread |

Heat Resistance | High; maintains structural integrity in extreme heat | Medium; weakens with prolonged heat exposure |

Smoke and Toxic Gas Emissions | Low emissions; little smoke, no toxic gases | Moderate emissions; non-toxic smoke but more smoke produced |

Fire Endurance | Very high; can protect up to 4 hours or more | Limited; typically protects 30-60 minutes |

Magnesium boards keep people safer in fires because they last longer and work better.

Cement vs. Magnesium

Magnesium wall boards also do better than cement boards when it comes to water and strength. MgO boards stay strong and keep their shape in wet places. They stop mold, mildew, and bugs without extra help. Cement boards need extra layers and coatings to stop water from hurting them. Cement boards can get fungus and need more care in wet rooms.

Aspect | MgO Boards (A1 Fire Rated Magnesium Wall Boards) | Cement Boards |

|---|---|---|

Excellent; maintain strength and shape in high moisture environments | Good; require additional sealing/coatings | |

Performance in Humid Areas | Suitable for bathrooms, basements, coastal areas; resist bending/breaking | Adequate for slightly wet areas; less durable |

Mold and Mildew Resistance | Naturally resist mold, mildew, and pests effectively | More prone to fungal growth; need extra treatment |

Long-term Durability in Moisture | High; little upkeep needed, resist water damage over time | Lower; may suffer damage without maintenance |

Suitability for Wet Spaces | Best choice for wet and damp environments | Can be used but need extra care and maintenance |

Key Differences

MgO boards use less energy to make and take in carbon dioxide as they dry.

They do not have formaldehyde, VOCs, or bad glues, so they do not let out harmful gases.

MgO boards can be recycled and even used to help soil.

These boards are better at stopping fire, mold, mildew, and bugs, so they last longer.

Magnesium boards help keep the air inside buildings healthier than gypsum or cement boards, which can let out some VOCs.

MgO boards are the best for fire safety, water resistance, and helping the environment. Builders pick them for jobs that need safe, strong, and earth-friendly materials.

A1 fire rated magnesium wall boards are very safe in fires. They are strong and do not get damaged by water. Builders and architects like these boards because they are tough and easy to put up. These boards do not have bad chemicals. They help stop fires from spreading. They can lower damage to buildings. They also help keep the air inside clean.

These boards follow strict building rules. They fit with new ideas for safer and greener buildings.

They can be used in many ways and help save money. This makes them a good pick for new building projects.

Picking A1 fire rated materials can keep people safe. They also protect buildings and help the planet. If you need help, talk to a building materials expert.

FAQ

What does “A1 fire rated” mean for magnesium wall boards?

A1 fire rated means the board does not burn or release smoke. It meets the highest fire safety standards. Builders use these boards in places where fire protection matters most.

Can magnesium wall boards be used in wet areas?

Yes. Magnesium wall boards resist water and moisture. They do not swell or break down in bathrooms, basements, or kitchens. Builders choose them for wet spaces because they stay strong.

Tip: Use magnesium boards in areas with high humidity to prevent mold and mildew.

Are A1 fire rated magnesium wall boards safe for indoor air quality?

Magnesium wall boards do not contain harmful chemicals. They do not release formaldehyde or VOCs. These boards help keep indoor air clean and safe for people.

How do magnesium wall boards compare to gypsum boards?

Feature | Magnesium Wall Board | Gypsum Board |

|---|---|---|

Fire Resistance | Highest (A1) | Moderate |

Water Resistance | Excellent | Poor |

Mold Resistance | Strong | Weak |

Magnesium boards last longer and protect better than gypsum boards.

Handling and Cutting

Handling and Cutting