18 Aug Magnesium Wall Board Application In Basement

Table of Contents

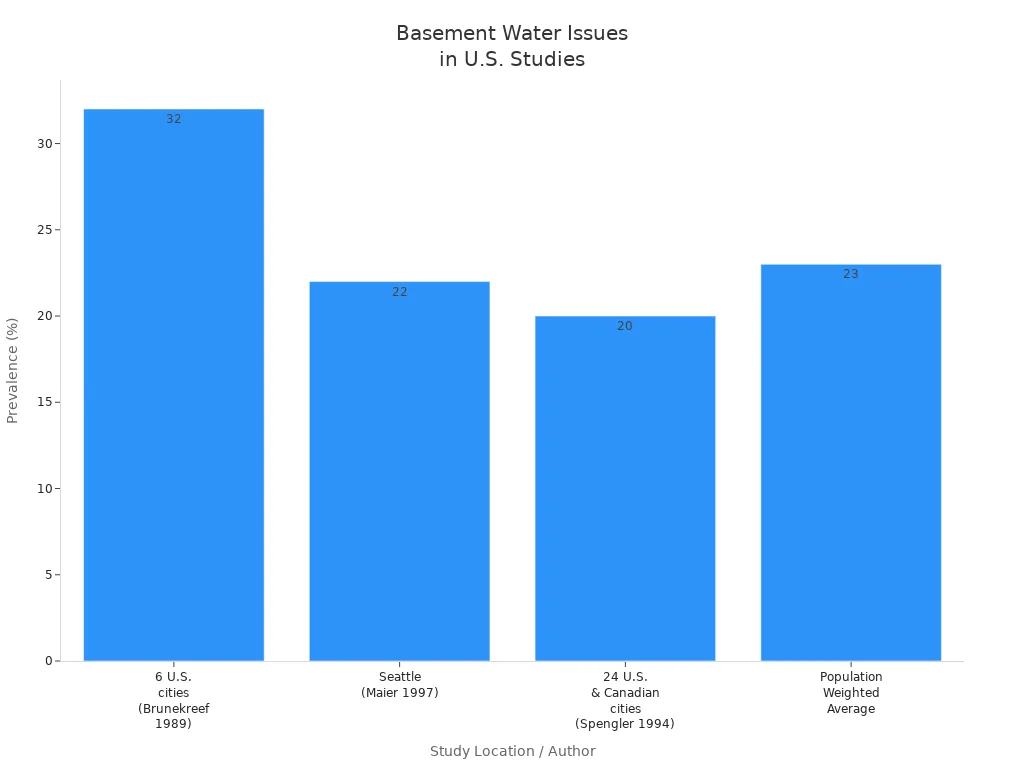

You have a big problem when you finish or fix up a basement. About 23% of basements in U.S. homes get wet or moldy each year, as you can see in the table below. Magnesium wall board gives you a strong answer. It stands up to water, mold, and fire better than old materials. Builders like it because it lasts long and is good for the environment. You can put it in both finished and unfinished basements.

Study Location / Author | Sample Size (Housing Units) | Basement Water Prevalence (%) |

|---|---|---|

6 U.S. cities (Brunekreef 1989) | 4625 | 32 |

Rhode Island (Chiaverini 2003) | 2600 | N/A (reported 23% any dampness/mold) |

Seattle (Maier 1997) | 925 | 22 |

24 U.S. & Canadian cities (Spengler 1994) | 12,842 | 20 |

Boston (Stark 2003) | 492 | N/A |

Population Weighted Average | – | 23 |

Key Takeaways

Magnesium wall board stops water, mold, fire, and pests. This makes it great for wet basement spaces. The board stays strong and does not get bigger or break down. It helps basements stay dry, safe, and nice to use. To install it right, clean and level the area first. Use screws that do not rust. Put on waterproof layers and sealants. Magnesium wall board is good for the earth. It uses natural minerals and lasts longer than drywall or cement board. Picking magnesium wall board means fewer repairs. It makes air better and helps your home be greener and healthier.

What is Magnesium Wall Board?

Composition

Magnesium wall board is made from a special mix of things. The main part is magnesium oxide, which holds everything together. There are two kinds of salt used to make different boards: magnesium chloride and magnesium sulfate. Each kind has its own good points for basements. Magnesium chloride boards have magnesium oxide, magnesium chloride, fibers, and fillers. Magnesium sulfate boards have magnesium oxide and magnesium sulfate, so they work better in wet places. Here are the main things used:

Magnesium oxide (MgO)

Magnesium chloride (MgCl₂) or magnesium sulfate (MgSO₄)

Reinforcing fibers (like wood fibers or glass mesh)

Fillers (such as perlite or vermiculite)

The way these boards are made makes them strong and tough. Magnesium oxide comes from rocks with lots of magnesium and gives the board strength. Magnesium chloride helps hold the board together and reacts with magnesium oxide when the board dries, making it hard and good against water and fire. Perlite makes the board lighter and helps keep heat in. Wood fibers make the board bendy and stop cracks. Vermiculite gets bigger when hot, so the board does not burn easily. Glass mesh spreads out pressure, so the board lasts longer. When the board dries, it forms magnesium oxychloride cement, which makes it stronger and keeps it safe from fire. If you worry about water, magnesium sulfate boards protect better against rust and mold.

Core Properties

Magnesium wall board is special because of its strong and useful features. These features help a lot when you use it in basements, as shown in the table below:

Property | Description and Performance | Relevance to Basement Applications |

|---|---|---|

Stays strong if wet; does not swell or rot | Great for wet basements; stops mold | |

Fire Resistance | Does not burn; handles heat up to 1200°C; no bad smoke | Makes basements safer from fire |

Impact Strength | Very tough and hard to break | Stays strong against hits and damage |

Mold and Mildew Resistance | Stops mold, mildew, and bugs | Keeps basements safe and air clean |

Soundproofing | Blocks noise and absorbs sound | Makes basements quieter and more comfy |

Thermal Insulation | Keeps heat in and saves energy | Helps basements stay warm and lowers bills |

Pest Resistance | Bugs like termites cannot get in | Lasts longer and needs less fixing in basements with bugs |

Tip: If you need a board that fights water, fire, and bugs, magnesium wall board is a smart choice for your basement.

Magnesium Wall Board Benefits

Moisture and Mold Resistance

Basements can be damp and have leaks. This makes mold a big problem. You need a wall board that can handle wet air and keep your basement safe. Magnesium wall board protects well against water and mold.

This board does not take in water, so it stays dry in wet basements.

Mold grows in wet places and needs things like wood or paper to eat. Magnesium wall board has no food for mold, so it cannot grow.

The board helps keep the room at a steady temperature. This stops water drops from forming, which can cause mold.

When you put up the board, seal the edges and keep the area clean and dry. Good airflow also helps stop mold.

Many homes and schools use this board and see less mold and better air.

This board blocks mold better than drywall or plywood and does not let out bad gases.

Check your basement for leaks and keep the air dry, under 50% humidity. Cleaning with safe products keeps the board strong.

If you keep the board off the floor or use treated wood, you lower the chance of mold even more.

Tip: If you want a dry and safe basement, pick a wall board that stops mold from the start.

Fire and Pest Resistance

Basements can have fire risks from wires, heaters, or storage. You need a wall board that can take heat and keep your family safe. Magnesium wall board has top fire ratings from trusted groups.

Product Name | Fire Resistance Rating / Classification | Testing Standard / Certification | Recognized Agency / Standard Body |

|---|---|---|---|

Innovation MgO Wall Panels | ICC-ES ESR-5418 (ASTM E84, ASTM E119) | ASTM E84, ASTM E119 | ICC-ES |

MagPanel MgO Board | A1 Fire Rating | EN 13501-1+A1:2010, EN ISO 1716, EN 13501 | European Fire Safety Standards |

Product Name | Fire Resistance Rating | Fire Performance Details | Certification Standards |

|---|---|---|---|

MagPanel MgO Board | A1 Fire Rating | Handles heat over 750°C for more than 30 minutes without changing color | EN 13501-1+A1:2010 (clause 12), EN ISO 1716, EN 13501 |

You also want to keep bugs out of your basement. Bugs like termites and ants cannot eat or live in magnesium wall board. The board does not break down or attract bugs. This means your basement walls last longer and need fewer fixes.

Note: Fire and pest resistance are very important in basements, where you keep things or spend time with family.

Eco-Friendly Aspects

You may care about the planet and clean air in your home. Magnesium wall board helps keep your home and the earth healthy.

Many boards have LEED and GREENGUARD labels, which means they meet green rules.

The board uses natural minerals and can be recycled when you are done with it.

It does not let out bad gases when made or if there is a fire.

Some boards meet ISO 14001, which is a top green rule.

The board also passes the ASTM E136 test, which checks if it will not burn.

When you look at magnesium wall board and regular drywall, you see clear green benefits.

Feature | MgO Boards | Traditional Drywall (Gypsum Boards) |

|---|---|---|

Raw Material Source | Made from lots of natural minerals | Gypsum is not as common and not as green |

Eco-Friendliness | Green, natural, and can be recycled | Not as green, has chemical extras |

Energy Consumption | Uses more energy to make | |

Durability | Very strong and lasts a long time | Gets damaged by water and mold, needs more fixes |

Chemical Emissions | Has no bad chemicals or VOCs | Has chemical extras and VOCs |

Making magnesium wall board uses less energy and does not need harsh chemicals. This means it is better for the earth and makes your basement safer for your family.

🌱 Pick materials that keep you and the planet safe. Magnesium wall board helps you make a better basement and a greener home.

Installation

Preparation and Tools

Preparation and Tools

Proper preparation ensures your basement project starts on the right foot. Follow these steps to get your surface ready for magnesium wall board:

Clean the wall surface. Remove all dirt, grease, and dust. This helps the adhesive stick and keeps the boards stable.

Use a moisture meter to check that the wall is dry. Wet surfaces can cause mold or warped boards.

Level the wall. Use a level to find uneven spots. Fill low areas with cement mix or foam. Sand down high spots until the wall is flat.

Seal and smooth the surface. This gives a strong, stable base for the boards.

Plan your layout. Mark where each board will go and leave small expansion gaps for movement.

You need the right tools for a safe and smooth installation. Here is a list of recommended tools:

Safety gear: dust mask, safety glasses, gloves

Cutting tools: carbide-tipped scoring knife, utility knife, fiber cement shears, or a dust-reducing circular saw with a carbide blade

For tricky cuts: rotary tools like a Roto Zip or Dremel with carbide bits

Installation tools: putty knife, saw horses, T-square, measuring tape

Fasteners: 316-stainless steel screws or ceramic-coated fasteners made for cement boards

Tip: Always acclimate your boards in the basement for at least 48 hours before you start. This helps them adjust to the room’s temperature and humidity.

Cutting and Handling

Handling magnesium wall board with care prevents damage and makes your job easier. Use these best practices:

Acclimate the boards in the basement for 48 hours. This step helps prevent cracks from temperature or moisture changes.

Store boards flat on wood supports, not directly on the ground. Do not stack heavy items on top.

Carry boards on their side. This protects the edges and corners from chipping.

Use a carbide-tipped scoring knife or a saw with a carbide blade for cutting. Avoid using power saws indoors to reduce dust.

Support the ends of each board on joists. Leave a 1/8 inch gap between boards and walls for expansion.

Use corrosion-resistant screws. Place screws 6 inches apart around the edges and 12 inches apart in the center. Keep screws at least 4 inches from corners.

Countersink screws slightly so they sit flush with the board.

Start fastening from one side and move across the board. This helps avoid stress and micro-cracks.

Wear safety glasses, gloves, and a dust mask when cutting or sanding. Use a HEPA vacuum or wet methods to clean up dust.

Note: Never dry sweep dust from cutting. Wet cleaning or a HEPA vacuum keeps the air safe.

Waterproofing Tips

Basements need extra protection from water. Magnesium wall board resists moisture, but you can boost its performance with these waterproofing steps:

Apply a waterproof membrane under the boards. Liquid-applied membranes work well for uneven surfaces and around pipes. Sheet membranes made from PVC, rubber, or bitumen suit flat walls but need careful seam sealing. Self-adhesive and polyethylene membranes are also good choices for wet areas.

Use flexible sealants on all joints and edges. These sealants stretch with the board as it moves, stopping water from getting in.

Pick adhesives made for humid environments. These adhesives keep their strength even when exposed to moisture.

Always seal seams and edges after installing the boards. This step blocks leaks and keeps your basement dry.

💧 For the best results, combine a waterproof membrane with flexible joint sealants. This double layer of protection helps keep your basement safe from leaks.

Finishing

Finishing your basement walls gives them a clean, polished look and adds another layer of protection. Magnesium wall board supports many types of finishes:

Use primers and paints that block moisture. These products help prevent water from soaking into the board.

For joints, apply a sandable elastomeric joint compound or a lightweight concrete patching compound. Use wide fiberglass tape (at least 6 inches) for extra strength.

If you plan to install flooring over the boards, use polyurea or modified epoxy seam fillers. These create a smooth, moisture-resistant surface.

Always use corrosion-resistant fasteners to avoid rust in damp environments.

Leave small gaps between boards. Fill these with elastic caulking, then apply primer and moisture-resistant paint.

For exterior walls, you can use synthetic stucco, lap siding, brick veneer, or stone. These finishes work well with magnesium wall board and stand up to moisture.

Tip: Let the boards sit in the finished basement for 3-5 days with the HVAC running before you paint or finish. This helps prevent micro-cracks and keeps your walls looking great.

Challenges and Solutions

Common Issues

When you put wall boards in a basement, you can run into special problems. Basements have more water in the air than other rooms. This makes some issues happen more often:

Boards can get wet on the outside when the air is damp. People sometimes call this “crying.”

Water can help mold grow, make screws rusty, and hurt the board.

Some boards, like ones with magnesium chloride, can fall apart if they get too wet.

Not all brands are the same, so some boards do not stop water as well.

Boards can get bigger when they get wet, more than other materials.

Sometimes glue does not stick well to the boards.

Screws might not hold the boards tight enough.

Cutting the boards can make a lot of dust.

Note: These problems happen more in basements because the air is wet and there can be leaks.

Practical Fixes

You can fix most of these problems if you use the right things and steps. The table below shows real ways people have solved these problems:

Challenge | Solution | Result |

|---|---|---|

High humidity and mold risk | Use boards that do not soak up water and put a waterproof layer behind them | Boards stay dry and mold does not grow for years |

Need for fire and moisture safety | Pick boards without chloride and use screws that do not rust | Boards pass safety tests and do not get damaged |

Surface cracks or defects | Put fiberglass tape and joint compound on cracks, then sand with fine sandpaper | The wall is smooth and strong, and cracks do not come back |

Dust during cutting | Cut boards outside or use a HEPA vacuum and wear a mask | The air stays clean and it is safer to work |

For small cracks or spaces, fill them with caulk that does not shrink. Always do what the maker of the board says. Leave little spaces between boards so they can get bigger if needed. Put primer and sealant on all sides to keep water out. Use screws that do not rust to stop rust from starting. When you sand the joints, use fine sandpaper for a smooth and strong finish.

Tip: If you finish the boards all the way and keep them dry, your walls will last longer and look better.

Comparison

Magnesium Wall Board vs. Drywall

You might want to know how magnesium wall board compares to drywall. The table below shows how they are different in moisture, fire, and strength:

Aspect | Magnesium Oxide (MGO) Board | Drywall (Gypsum Board) |

|---|---|---|

Highly resistant to moisture and mold; suitable for humid or wet environments; reduces risk of mold and structural damage | Susceptible to water damage and mold growth; core deteriorates in damp conditions | |

Fire Safety | Superior fire resistance due to mineral composition; often achieves higher fire ratings; preferred in fire-prone or commercial settings | Good fire resistance from gypsum core but generally lower fire ratings compared to MGO board |

Durability | Greater structural strength and impact resistance; maintains integrity in harsh conditions; longer lifespan | Lighter and easier to install but less durable; prone to deterioration especially in moist environments |

Magnesium wall board does not soak up water. It stays strong in wet basements. Drywall gets soft and breaks when it gets wet. You can use screws or nail guns to put up magnesium wall board. It does not make bad dust. Drywall is lighter but not as tough, especially if it gets wet.

Magnesium Wall Board vs. Cement Board

You may also want to see how magnesium wall board and cement board are different. The table below shows how they compare in weight, how easy they are to put up, and how they handle basement problems:

Aspect | Magnesium Oxide (MgO) Board | Fiber Cement Board |

|---|---|---|

Weight | Lighter; easier to lift and install, even in high spots | Heavier; requires more labor and specialized tools |

Ease of Installation | Easier and faster due to lighter weight and workability | More labor-intensive and slower installation |

Resistance to Basement Conditions | Fully waterproof; resists swelling, warping, mold, and rot; better for high humidity and damp spaces | Moisture-resistant but not fully waterproof; requires regular maintenance to prevent water ingress and mold |

Cement board is good for wet places but is heavy and hard to cut. Magnesium wall board is lighter and cuts easier. Both stop mold, but magnesium wall board is safer in a fire. You still need to keep both dry in very wet basements.

Cost and Longevity

When you plan your basement, you should think about price and how long things last. Mold-resistant drywall costs less, about $0.70 to $1.10 for each square foot. Magnesium wall board costs more, but it lasts longer and needs fewer fixes. Cement board is also pricey to put in because it is heavy and hard to work with.

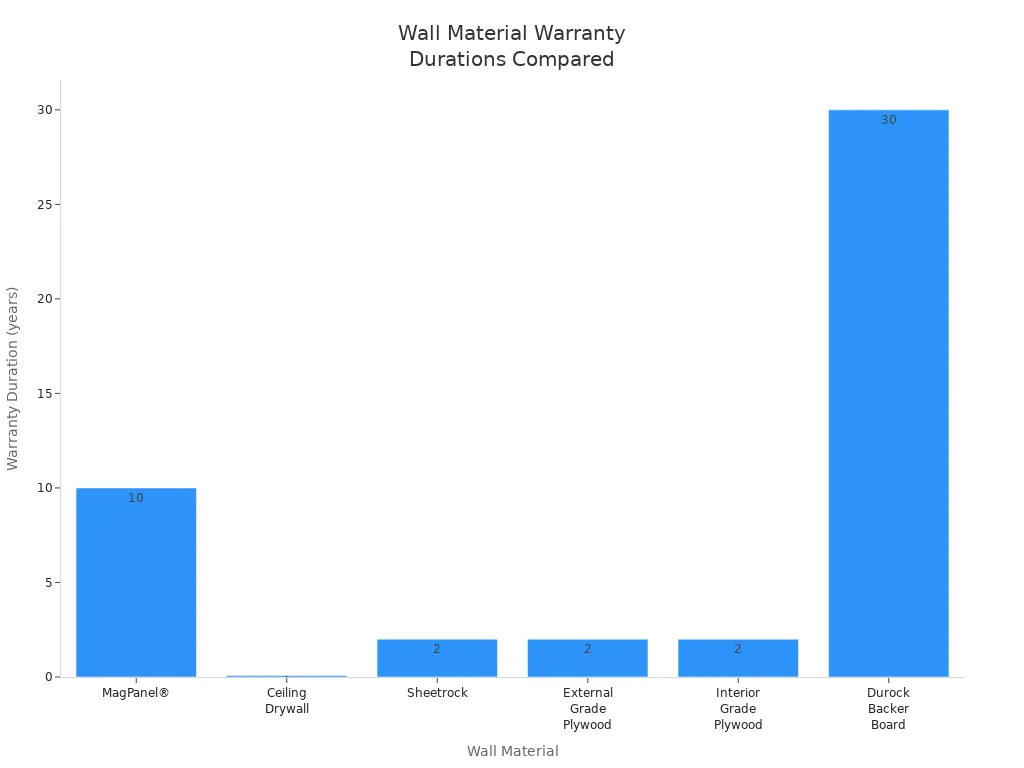

Magnesium wall board is strong and lasts a long time. It does not get ruined by water, mold, or rot. It does not bend or swell. The chart below shows how long each material lasts in basements:

Magnesium wall board gives you a wall that lasts longer. It keeps your basement safe and strong for many years, even if it gets wet.

Tip: If you want walls that last and need less fixing, magnesium wall board is a smart choice for your basement.

You want a basement that stays dry, safe, and strong. Magnesium wall board gives you these benefits. It resists moisture, mold, and fire. You also get better air quality and fewer repairs.

These boards keep their shape in wet conditions and help lower energy bills.

They use safe, eco-friendly materials and support green building goals.

Think about your basement’s needs and follow good installation steps. For more tips, check guides from building experts or local hardware stores.

FAQ

How do you clean magnesium wall board in a basement?

You can wipe the surface with a damp cloth or sponge. Use mild soap for tough stains. Avoid harsh chemicals. For dust, use a vacuum with a HEPA filter.

Tip: Always dry the board after cleaning to prevent moisture buildup.

Can you paint or wallpaper over magnesium wall board?

Yes, you can paint or wallpaper over it. Use a primer made for masonry or cement boards.

For paint, choose moisture-resistant products.

For wallpaper, use adhesive for non-porous surfaces.

Does magnesium wall board need extra waterproofing in basements?

You should add a waterproof membrane behind the board for best results. Seal all seams and edges with flexible caulk.

This extra step helps keep your basement dry and protects your walls.

Is magnesium wall board safe for people with allergies?

Yes, magnesium wall board does not support mold or mildew growth. It does not release harmful chemicals or VOCs.

This makes it a good choice if you want cleaner air in your basement.

How long does magnesium wall board last in a basement?

Magnesium wall board can last for decades in a basement. It resists water, mold, and fire.

Feature | Lifespan Estimate |

|---|---|

MgO Board | 30+ years |

Drywall | 10-15 years |

Preparation and Tools

Preparation and Tools