16 Aug Magnesium Wall Board Density And Weight

Table of Contents

Magnesium wall board panels have a density from 950 to 1300 kg/m³. A 12mm magnesium oxide board weighs about 1.5 to 2.2 lbs/ft². Mgo panels use magnesium oxide, fiberglass, and fillers. These materials help balance strength and weight. Magnesium boards stay strong even with lower density. This is because mgo panels use fiber reinforcement. Some people think lighter magnesium panels are weaker. But magnesium oxide board panels often do better than gypsum boards. It is easier to handle mgo panels because of their weight and stiffness. Magnesium wall board panels are durable. They also make installation easier than other wall boards.

Key Takeaways

Magnesium wall boards have a density of 1 gram per cubic centimeter. They weigh about 1.5 to 2.2 pounds per square foot at 12mm thickness. These boards are stronger than gypsum boards. They are lighter than cement boards.

The weight of magnesium boards depends on thickness, additives, and coatings. Thicker panels weigh more. Additives like perlite can make boards lighter. Perlite also helps with insulation.

Builders should pick board thickness for each use. Use thinner panels for ceilings and walls with support. Use thicker panels for floors or when fire resistance is needed.

Magnesium wall boards resist fire and moisture well. They are also very durable. This makes them good for bathrooms and kitchens. They work well in places needing safety and long-lasting boards.

Handle and install boards the right way. Use the correct fasteners. Let panels get used to the room before installing. This keeps boards strong and fire resistant. It also makes installation easier and safer.

Magnesium wall board density

Density values

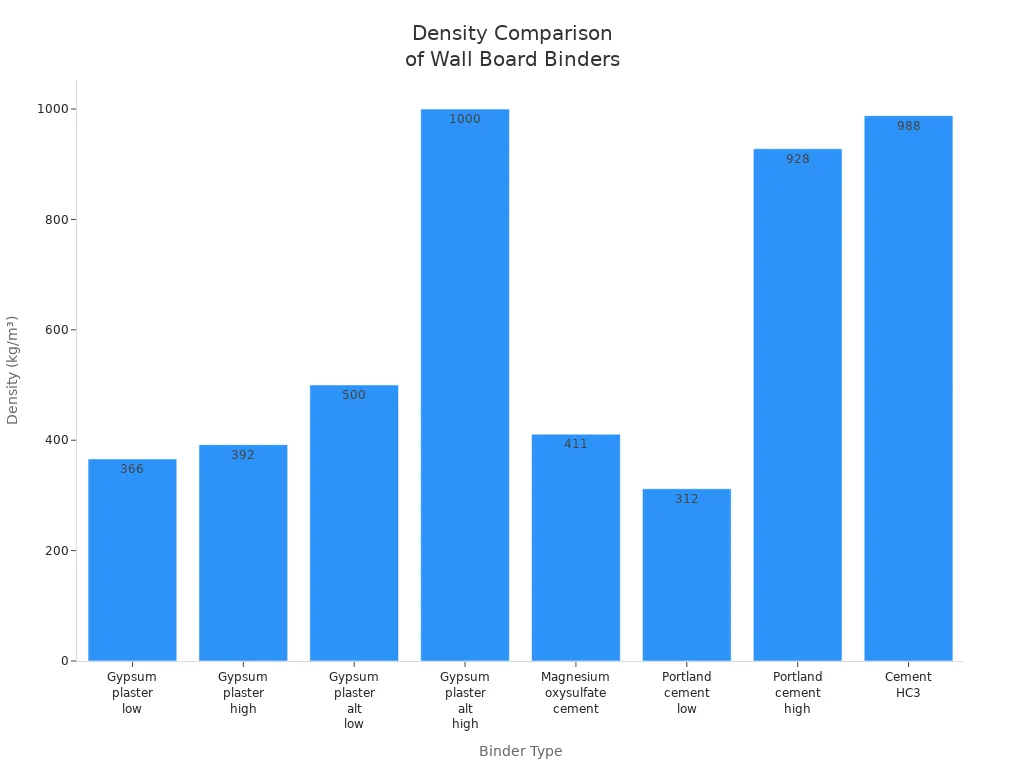

Magnesium wall board panels have a density from 950 to 1300 kg/m³. This is about 0.95 to 1.2 g/cm³. Most companies, like MagPanel, say their magnesium oxide boards are close to 1 g/cm³. This means mgo panels are denser than gypsum boards. But they are less dense than cement boards with the same thickness. The density of magnesium wall board panels changes for different reasons:

The kind and amount of filler, like sawdust, bamboo fiber, or perlite, can change how strong and dense the panels are.

The quality and source of magnesium oxide powder affect how tough and dense the boards are. Better magnesium oxide makes panels last longer and be stronger.

The way fiberglass mesh is put in helps make the panels stronger. It can also change the density a little.

The type of bischofite in magnesium oxychloride cement changes how the panels work. Salt lake bischofite has fewer impurities. It makes the panels stronger and more stable with heat.

Note: Magnesium oxide wall boards usually have a density from 0.85 to 1.2 g/cm³ (1000 to 1300 kg/m³). There are no strict rules for these numbers worldwide. Good mgo panels follow safety rules like EU REACH and US EPA standards.

Density is important when picking magnesium wall board panels. Higher density means the panels are stronger and last longer. This matters for tough jobs. Lower density makes panels lighter and easier to move. Builders pick different thicknesses and densities for walls, ceilings, or floors. They want the right mix of weight, strength, and easy installation. The density and strength of magnesium oxide board panels help them work well in tough conditions. They also protect against fire and impacts.

Measurement units

Manufacturers use two main ways to show density:

Volumetric density: grams per cubic centimeter (g/cm³) or kilograms per cubic meter (kg/m³)

Areal weight density: pounds per square foot (lbs/ft²) for a certain thickness, like 12mm

Volumetric density, like 1 g/cm³, shows how packed and strong the material is. Areal weight density, like 2.2 lbs/ft² for a 12mm magnesium oxide board, helps builders know the total weight for building and planning. These units make it easy to compare mgo panels, gypsum boards, and cement boards. Builders and engineers use these numbers to pick the best panels for their projects. They look for the right weight, strength, and how easy the panels are to use.

Tip: Always check both volumetric and areal weight density when you compare sanded mgo board panels to other wall boards. This helps you get the best mix of weight and performance for your needs.

Weight of mgo panels

Weight per sheet

Weight per sheet

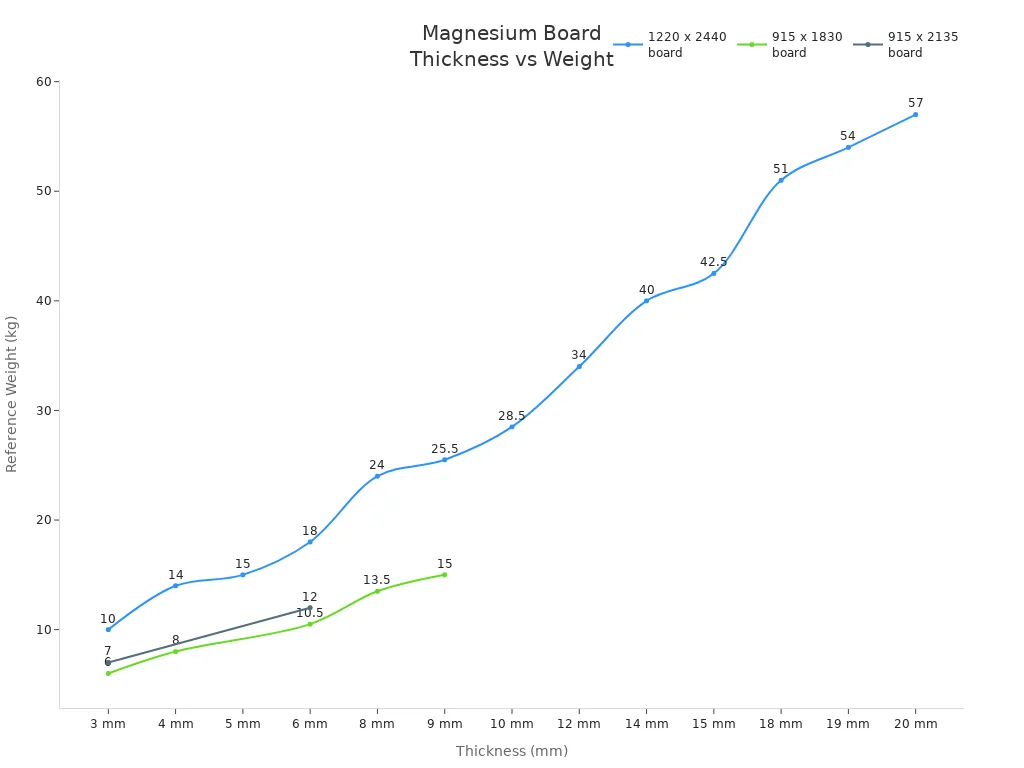

Manufacturers tell us the weight of mgo panels by looking at density and thickness. A magnesium oxide board that is 12mm thick usually weighs between 31 and 40 kilograms for each sheet. This weight comes from how dense magnesium is, which is about 1 gram for every cubic centimeter. If the panel gets thicker, it gets heavier. For example, a big 8 ft by 4 ft magnesium oxide board at 12mm thickness weighs about 87 pounds. Builders pick thinner mgo panels for ceilings or walls that have support behind them. Thinner panels are lighter and make it easier to install them.

Many things change how much mgo panels weigh:

Thickness makes a big difference. Thicker panels are heavier.

Fiberglass mesh layers add a little weight. More mesh means a heavier panel.

Surface coatings, like water or fireproof layers, make the panel heavier.

Additives such as perlite, wood fibers, and vermiculite change the weight and density. Perlite makes panels lighter and helps with insulation. Wood fibers make panels stronger and more flexible but also heavier. Vermiculite helps with fire resistance and changes the weight.

Magnesium oxide board panels are often heavier than gypsum boards with the same thickness. But they are still lighter than cement boards. Builders use thinner mgo panels because they are strong. This helps lower the total weight when installing them.

Note: Always check the weight of mgo panels before you start your project. The right thickness and additives help you pick the best panel for your job.

Weight per square foot

Manufacturers figure out the weight of mgo panels per square foot by using density and thickness. Magnesium oxide board panels at 12mm thickness weigh about 1.5 to 2.2 pounds for each square foot. This is a little heavier than gypsum drywall but lighter than cement board. Builders use this number to plan how to handle and install the panels.

The table below shows how much mgo panels weigh at different thicknesses and compares them to other wall boards:

Thickness (mm/inch) | Approximate Weight (lbs/ft²) | Comparison to Other Wallboards |

|---|---|---|

3 mm (1/8″) | Lighter, good for drop ceilings | Lighter than thicker mgo panels, lighter than cement board |

6 mm (1/4″) | Light, used for walls with backing or ceilings | Lighter than 12mm mgo, lighter than cement board |

9 mm (11/32″) | Medium weight, used for walls with backing | Heavier than 6mm, lighter than cement board |

12 mm (1/2″) | 1.5 to 2.2 lbs/ft² | Heavier than gypsum drywall, lighter than cement board |

15 mm (19/32″) | Heavier, used for fire or impact resistance | Heavier than 12mm mgo, still lighter than cement board |

20 mm (3/4″) | Heaviest, used for floors and strength | Heavier than thinner mgo panels, about the same or lighter than cement board |

Magnesium oxide board panels work well even when they are thin. Builders often pick thinner mgo panels to make big projects lighter. The weight per square foot helps builders guess the total load and plan for safe handling.

Manufacturers use density and thickness to tell us the weight of mgo panels. For example, a 12mm magnesium oxide board weighs just over 2.2 pounds for each square foot. This number helps builders compare mgo panels to gypsum and cement boards. The weight of mgo panels changes with thickness, additives, and coatings. Builders should always check these numbers to pick the best panels for their needs.

Tip: Use the weight per square foot to plan for lifting, moving, and installing. Lighter mgo panels make work easier and safer.

Factors affecting density and weight

Thickness

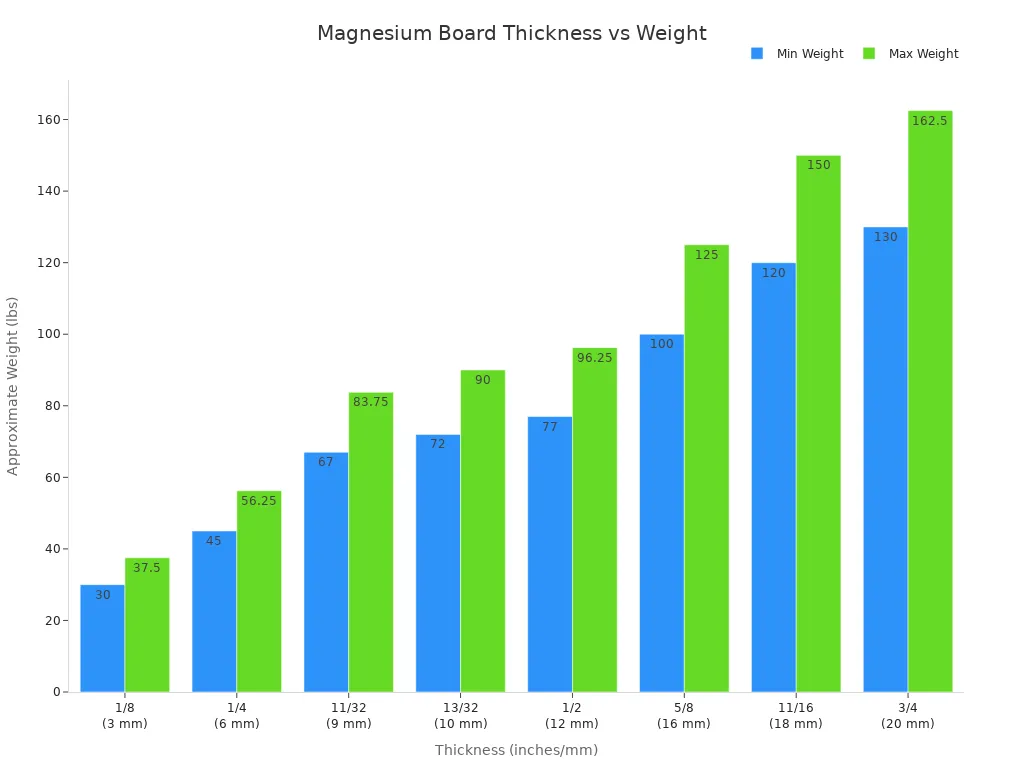

How thick a magnesium wall board is changes its weight. When the board gets thicker, it also gets heavier. The density does not change much when thickness changes. Builders pick the right thickness for each job. Thin mgo panels are good for ceilings. Thicker panels are better for floors or strong walls. The table below shows how weight goes up as boards get thicker:

Thickness (inches/mm) | Approximate Weight (lbs) | Notes |

|---|---|---|

1/8 (3 mm) | 30 – 37.5 | Walls and Ceilings |

1/4 (6 mm) | 45 – 56.25 | Walls and Ceilings |

11/32 (9 mm) | 67 – 83.75 | Walls and Ceilings |

13/32 (10 mm) | 72 – 90 | Walls and Ceilings |

1/2 (12 mm) | 77 – 96.25 | Walls and Ceilings |

5/8 (16 mm) | 100 – 125 | Walls, Ceilings, Subfloor |

11/16 (18 mm) | 120 – 150 | Walls and Ceilings |

3/4 (20 mm) | 130 – 162.5 | Subfloor |

The chart shows that thicker boards weigh more. The density stays about the same. More material makes the board heavier.

Additives

Additives in mgo panels change how heavy and strong they are. Makers use things like perlite, wood fiber, magnesium sulfate, and fiberglass mesh. Perlite makes boards lighter and helps keep heat in. Wood fiber makes boards stronger but also heavier. Magnesium sulfate helps the board resist water and rust. Fiberglass mesh makes the board stronger but does not add much weight. Using the right additives keeps mgo panels strong, light, and safe from water. Builders choose panels with the best mix for their project.

Additive | Effect on Panels |

|---|---|

Perlite | Lowers weight, adds insulation |

Wood fiber | Increases strength and weight |

Magnesium sulfate | Improves water resistance |

Fiberglass mesh | Adds strength, little weight |

Manufacturing

How mgo panels are made changes their weight and density. Makers start by picking the right magnesium oxide powder and additives. Mixing spreads everything out evenly. This keeps the density the same everywhere. Shaping the board sets how thick it will be. Pressing the board removes air and makes it stronger. Curing and drying finish the board and lock in its features. Some boards use magnesium chloride, but others use magnesium sulfate to stop rust and water damage. Boards with magnesium sulfate last longer and work better in wet places. Surface coatings help protect the board and add a little weight.

Note: If mgo panels get wet, they can get heavier. Water can make them 4% to 11% heavier. This makes them harder to move and install. Surface coatings help stop water from getting in and keep the panels steady.

Comparison with other wall boards

Gypsum board

Gypsum board remains a popular choice for interior walls and ceilings. It has a density between 1.2 and 1.3 g/cm³. This density makes gypsum board lighter than cement board but similar to some magnesium wall boards. Most gypsum boards weigh less than 2 pounds per square foot at 12mm thickness. Builders often select gypsum board for its easy handling and low weight. However, gypsum board offers less fire resistance than magnesium wall board. It can break down faster in high heat. When builders compare in cost with other wall boards, gypsum board usually has a lower price. Still, it may need more repairs over time, especially in wet or fire-prone areas.

Cement board

Cement board provides strong support and high durability. Its density often exceeds 1.3 g/cm³, making it heavier than both gypsum and magnesium wall boards. A standard cement board at 12mm thickness can weigh over 2.5 pounds per square foot. This extra weight means more effort during installation. Cement board stands out for its excellent fire resistance and moisture protection. Builders use it in places that need extra strength and safety, such as bathrooms and exterior walls. When they compare in cost with other wall boards, cement board usually costs more to install because of its weight and handling needs. However, its long-term performance can offset these costs.

Comparison table

The table below shows how magnesium wall boards, gypsum boards, and cement boards compare in density, weight, and fire resistance:

Material | Density (g/cm³) | Weight (lbs/ft², 12mm) | Fire Resistance |

|---|---|---|---|

Gypsum Board | 1.5 – 2.0 | Moderate | |

Magnesium Wall Board | 0.85 – 1.2 | High | |

Cement Board | 1.3 – 1.5 | 2.5 – 3.0 | Very High |

Magnesium wall boards balance weight and fire resistance better than most alternatives. Their lighter weight makes installation easier than cement board. Their fire resistance outperforms gypsum board. Builders often choose magnesium wall boards for projects that need both safety and manageable weight.

Tip: Always check the weight and fire resistance ratings before selecting a wall board. The right choice depends on the project’s needs and the environment.

Applications

Selection guide

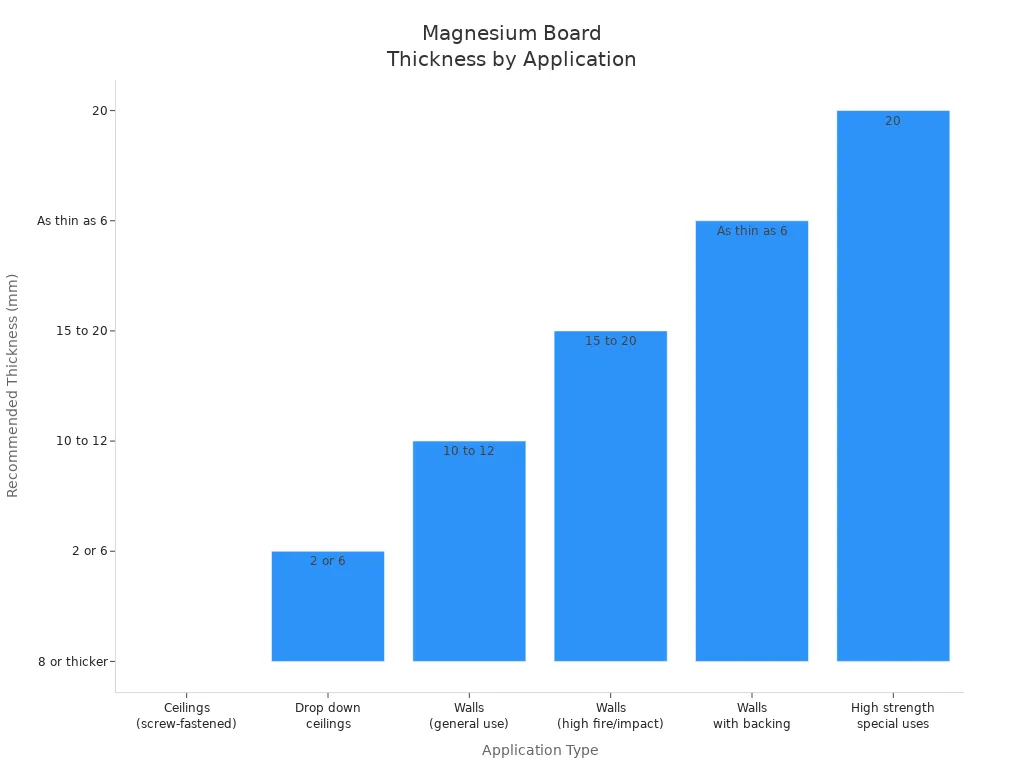

Picking the right magnesium wall board depends on where you use it. You also need to think about weight and fire resistance. Builders often wonder what thickness is best. The answer changes based on the location. For ceilings, use boards that are 8 mm thick or more. This works well for inside walls with steel or wood frames. Drop-down ceilings can use thinner panels, like 2 mm or 6 mm. Most walls need boards that are 10 to 12 mm thick. If you need extra fire or impact resistance, pick boards that are 15 to 20 mm thick. For inside walls with backing, panels as thin as 6 mm are strong enough and lighter.

Application Type | Recommended Thickness (mm) | Notes and Considerations |

|---|---|---|

Ceilings (screw-fastened) | 8 or thicker | Thicker for countersunk screws |

Drop down ceilings | 2 or 6 | Panel use |

Walls (general use) | 10 to 12 | Common thickness |

Walls (high fire/impact) | 15 to 20 | Enhanced fire and impact resistance |

Walls with backing | As thin as 6 | Weight-sensitive, with support |

High strength/special use | 20 | Maximum strength |

Magnesium oxide boards are good at stopping fire and water. Their density is about 1 g/cm³. This means even thin boards can resist fire well. Magnesium oxide boards last a long time. They do not soak up much water. They also stop mold from growing. These features make them great for bathrooms, kitchens, and places that need fire protection.

Handling and installation

You must handle and install panels the right way. This keeps them strong and fire-resistant. Carry boards on their side to protect the edges. Always stack panels flat on dunnage, not on the ground. Do not bend boards or put heavy things on top. Let boards sit in the room for 48 hours before installing. This helps them get used to the temperature and humidity.

When you fasten boards, support the ends with joists. Put fasteners in the right spots. For most jobs, use 16-inch centers. For floors or roofs, use 24-inch centers. Leave a 1/8 inch gap between boards and walls. This lets the boards expand. Use fasteners that do not rust, like 316 stainless steel or ceramic coated screws. For wood frames, #8 flat head screws with sharp drill points work best.

Always follow building codes for mgo boards. Use the right cutting tools. Wear dust masks and safety glasses. Use ways to keep dust down. Fire safety rules like ASTM E84 and E119 are important for magnesium oxide boards. These panels meet Class A fire ratings. They can stand heat up to 1200°F. Magnesium oxide boards are safe, strong, and meet building code rules for mgo boards.

Magnesium wall boards have a density close to 1 gram/cm³. Their weight is between 1.5 and 2.2 pounds for each square foot when they are 12mm thick. These panels are stronger than gypsum boards. They are also lighter than cement boards. This makes them good for many building jobs.

Property | Value |

|---|---|

Density | About 1 gram/cm³ |

Weight (12mm / 1/2 inch) | 1.5 to 2.2 pounds/ft² |

Comparison to gypsum | Denser and stronger |

Comparison to cement board | Lighter |

Builders can use the chart below to match thickness and weight. This helps them pick the right magnesium wall board for their project.

To choose the best magnesium wall board, you need to know these numbers. The tables and guides help builders find panels that are easy to install, strong, and not too heavy.

FAQ

What is the typical density of magnesium wall boards?

Magnesium wall boards usually have a density between 950 and 1300 kg/m³. Most manufacturers list their panels at about 1 g/cm³. This density helps the boards stay strong and easy to handle.

How much does a standard magnesium wall board weigh?

A 12mm magnesium wall board weighs about 1.5 to 2.2 pounds per square foot. A full 8 ft by 4 ft sheet can weigh between 77 and 96 pounds, depending on additives and coatings.

Are magnesium wall boards fire-resistant?

Magnesium wall boards offer high fire resistance. They meet Class A fire ratings and withstand temperatures up to 1200°F. Builders use them in areas that need extra safety from fire.

Can magnesium wall boards be used in wet areas?

Manufacturers design magnesium wall boards to resist moisture. Panels work well in bathrooms, kitchens, and other damp spaces. Surface coatings improve water resistance and prevent mold growth.

How do magnesium wall boards compare to gypsum and cement boards?

Material | Density (g/cm³) | Weight (lbs/ft², 12mm) | Fire Resistance |

|---|---|---|---|

Gypsum Board | 1.2 – 1.3 | 1.5 – 2.0 | Moderate |

Magnesium | 0.85 – 1.2 | 1.5 – 2.2 | High |

Cement Board | 1.3 – 1.5 | 2.5 – 3.0 | Very High |

Magnesium wall boards balance weight and fire safety better than gypsum or cement boards.

Weight per sheet

Weight per sheet