05 Jul Understanding Technical Specifications and Certifications of Magnesium Wall Board

Table of Contents

Understanding technical specifications and certifications for magnesium wall board helps keep buildings safe and working well. Builders who pick certified magnesium wall board keep projects safe from problems with bad building material. Recent studies show that green building certifications help people pick materials, save energy, and build in a way that helps the planet. Market research shows that certifications are now very important for making sure things are good quality and easy to get. Picking the right magnesium wall board makes buildings stronger, safer, and more dependable.

Key Takeaways

Magnesium wall board is strong. It does not burn easily. It does not get damaged by water. This makes it good for walls, floors, and ceilings in many buildings. – Certified magnesium wall boards follow strict safety rules. They also meet high quality standards. This helps builders pick safe and reliable materials. – You must install and store the boards the right way. Keep the boards dry. Use the correct fasteners. This helps the boards last long and work well. – Surface treatments and coatings protect the boards. They keep the boards safe from weather and damage. This is important for outdoor use. – Pick boards with trusted certifications and test reports. This makes sure your building project is safe, lasts long, and is good for the environment.

Magnesium Wall Board Specifications

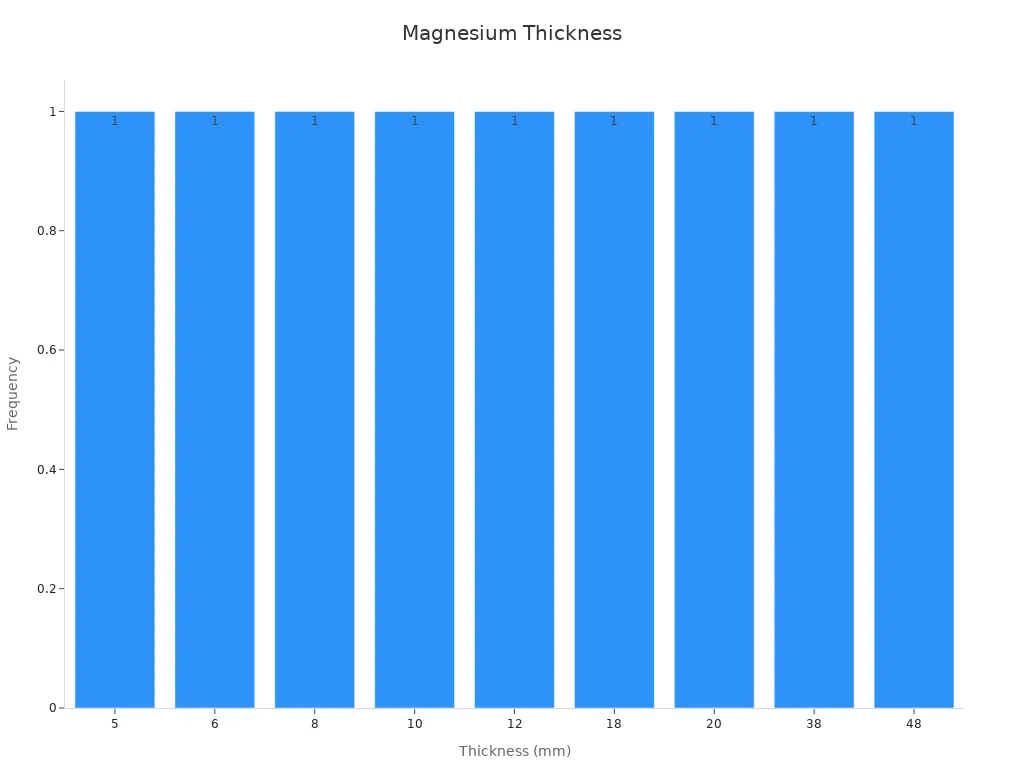

Thickness and Size

Magnesium wall board comes in many thicknesses and sizes. Builders pick the right thickness for each job. Most boards are between 3mm and 19mm thick. Wall panels usually use 8mm, 10mm, or 12mm boards. Floors need thicker boards like 18mm or 20mm. Ceilings use thinner boards, such as 5mm or 6mm. The most common size is 1220x2440mm, which is 4×8 feet. Some projects use bigger boards, up to 1200x3000mm.

Application | Common Thicknesses (mm) | Common Sizes (mm) |

|---|---|---|

Wall Panels | 8, 10, 12 | 1220×2440, 1200×2400 |

Flooring Panels | 18, 20 | Up to 1200×3000 |

Ceiling Boards | 5, 6 | 1220×2440, 1200×2400 |

Tunnel Boards | Up to 40 | N/A |

Door Core Panels | 38, 48 | N/A |

Thin boards, up to 10mm, are light and easy to move. They are good for inside walls and ceilings. Medium boards, from 10mm to 20mm, are strong and can be used in many ways. They work for walls, ceilings, and floors. Thick boards, over 20mm, are best for floors and outside jobs that need more strength. Market data says thin boards are about half of all boards sold. Thin boards are also becoming more popular.

Density and Strength

Density and strength help show how well magnesium wall board works. Most boards have a density between 1200 and 1300 kg/m³. This makes them lighter than many other boards. Lighter boards help keep buildings from being too heavy. Bending strength is tested and ranges from 6 MPa to 23 MPa. Stronger boards are better for floors and roofs that hold heavy things.

Property | Typical Value/Range |

|---|---|

Density | 1200-1300 kg/m³ |

Bending Strength | 6-23 MPa |

Magnesium wall board stays strong even after getting wet or freezing. This makes it a good choice for places that need to last a long time.

Surface Treatments

Surface treatments make magnesium wall board look better and work better. Some boards have PVC film or melamine paper on them. Melamine paper gives a hard, nice-looking surface. It helps protect against fire, water, and scratches. The glue sticks well because of the board’s surface. Melamine paper lasts longer than PVC film. It also protects better from heat and damage. PVC film is easy to shape but does not last as long.

Tip: For outdoor use, always put a protective coating on magnesium wall board. Use strong masonry primers and 100% acrylic latex or elastomeric paints for the best weather protection.

Good surface treatment helps the board resist water and mold. How long and how hard the board is pressed during making affects how well the surface sticks. A well-treated board needs little care and works well in wet places.

Moisture and Dimensional Stability

Magnesium wall board is great at resisting water and keeping its shape. Data shows moisture movement is very low, between 0.1% and 0.12%. The board does not soak up much water, only about 0.34%. This is much less than gypsum boards. The board does not swell, bend, or fall apart when wet. It keeps its shape and strength, even in bathrooms, kitchens, and basements.

Property | Value/Detail |

|---|---|

Moisture Movement | 0.1% – 0.12% |

Surface Moisture Absorption | 0.34% |

Dimensional Stability | Excellent |

Resistance to Warping/Swelling | Maintains integrity under moisture |

Magnesium wall board is safe for the environment and helps with green building. It does not have harmful chemicals like formaldehyde or asbestos. The board does not let mold or fungus grow because it is not porous and has high alkalinity. Tests show magnesium wall board gets a perfect score on the ASTM G21 fungal resistance test. This makes it a safe choice for schools, hospitals, and homes.

- Magnesium wall board keeps its strength after years of wet and cold weather.

- The board does not get damaged by moisture like some other materials.

- Good magnesium wall board can last more than 30 years in buildings.

Magnesium wall board is strong, resists water, and is good for the planet. It works well for walls, ceilings, floors, and roofs. Builders like it because it lasts a long time, is safe, and is eco-friendly.

Fire Resistant Performance

Fire Ratings

Fire Ratings

Magnesium wall board is known for stopping fire. Builders and safety experts trust it because it passes tough fire tests. Different countries use their own tests to check fire safety. Some important tests are EN 13501-1, ASTM E136, and ASTM E84. These tests give fire ratings so builders can pick safe boards.

Standard | Fire Rating Classification | Description |

|---|---|---|

EN 13501-1 | Class A1 Noncombustible | Highest fire resistance; no contribution to fire; minimal smoke and toxic fumes |

ASTM E136 | Noncombustible | Material does not burn under test conditions |

ASTM E84 | Class A (surface fire spread) | Excellent resistance to surface fire spread |

Magnesium wall boards usually get the top rating, Class A1. This means they do not help a fire grow or make much smoke. They also pass the ASTM E136 test, showing they do not burn. These fire resistant boards help stop flames from spreading in buildings. This is very important for tall buildings. Many boards also pass other fire tests like ASTM E119 and NFPA 285. These tests show the boards can resist fire for up to four hours.

Note: Test reports with ILAC-MRA logos mean the results are trusted everywhere. These reports prove that magnesium wall boards meet world fire safety rules.

High Temperature Endurance

Magnesium wall board stays strong even in very hot fires. In fire tests, panels face direct flames in a special oven. The boards do not melt or lose shape, even at 1200°C. Some tests show the board lasts 90 minutes or more before failing. This makes it a good choice for fire-rated walls and ceilings.

The special makeup of magnesium wall board helps it work well in fire. When heated, the board lets out water from its minerals. This slows down the fire. The binder turns into magnesium oxide, which melts at about 2800°C. This helps the board stay strong and fire resistant. Studies show magnesium wall board keeps heat down by over 70°C compared to other boards. Builders use these boards in places where fire safety is most important, like schools, hospitals, and tall buildings.

Certifications and Compliance

Major Certifications

Magnesium wall board must follow strict rules before use. Many groups give certifications to show the board is safe and strong. These certifications help builders and inspectors trust the board. Some important certifications are:

- CE Marking (Europe)

- ISO 9001 (Quality Management)

- EN ISO 1716 (Fire Performance)

- EN 13501 (Fire Classification)

- ICC-ES ESR-2880 (International Code Council Evaluation Service)

- CCMC 14038_e (Canadian Construction Materials Centre)

- BBA (British Board of Agrément)

- Kiwa BDA (European Technical Approval)

- INTERTEK and ILAC-MRA (International Laboratory Accreditation)

- Material Safety Data Sheet (MSDS)

- VOC Report (Volatile Organic Compounds)

- Asbestos, Chloride, Formaldehyde, and Radioactivity Reports

These certifications show magnesium wall board meets world safety and quality rules. ILAC-MRA means test results are trusted in many countries. This makes it easier for builders to use the board everywhere.

Manufacturers often give free samples so customers can get local certifications. This helps builders follow local building codes and rules.

Testing and Verification

Testing and checking are very important for magnesium wall board. Each board is tested for size, strength, safety, and how long it lasts. Magpanel MGO boards have passed fire tests and got an A1 Fire Rating under EN 13501-1+A1:2010. These boards can handle heat over 750°C for more than 30 minutes. They do not change color during the test. They also meet EN ISO 1716 and EN 13501 standards for fire safety.

The table below shows the main testing steps:

Testing/Verification Aspect | Description |

|---|---|

Dimensions and tolerances | Checks if boards meet size and tolerance requirements |

Physical requirements and characteristics | Tests for strength, flexibility, and other physical properties |

Durability | Measures how well the board lasts over time |

Release of dangerous substances | Ensures the board does not release harmful chemicals |

Moisture movement | Tests how the board reacts to water |

Reaction to fire | Fire safety test reports confirm resistance to flames |

Performance in humid environment | Checks if the board stays strong in wet conditions |

Quality management system verification | Looks at factory controls and inspections |

Product traceability | Tracks each batch for quality assurance |

Fire safety test reports and other papers prove the board meets tough rules. These reports help builders and inspectors trust the product.

Third-Party Approvals

Third-party certification gives extra trust that the board is safe. Independent labs test the boards using strict rules. ICC-ES gives reports like ESR-5418 after checking many things. These reports show the board passed tests for corrosion, fire, and strength.

The table below lists some main third-party tests and standards:

Test Categories and Characteristics Tested | Relevant Standards and Acceptance Criteria |

|---|---|

Structural floor and roof sheathing use | ICC-ES AC386, AC367, AC318, AC319, AC376, AC378, AC269.1 |

Wall, ceiling sheathing, floor underlayment | ASTM C473, C666, C1185, C1186, C1396, D1037, D2394 |

Physical properties and fire resistance | ASTM E84, E119, E136, ANSI A118.1, A118.4, NFPA 285, NFPA 286 |

Innovation MgO Wall Panels passed new corrosion tests and showed very low corrosion. This is good for buildings near the ocean. The panels also passed fire safety tests like ASTM E84 and ASTM E119. Builders can use them in fire-rated walls. The ESR report includes approvals for Florida and California. This proves the board meets tough state rules.

Third-party certification and testing help builders avoid unsafe products. These approvals show the board is safe for many places and weather.

Selecting Magnesium Oxide Board

Interpreting Certifications

Interpreting Certifications

To pick the best magnesium oxide board, you need to know about certifications. Builders should always look at the certification label and technical data sheet before buying. Certifications like EN13501-1 A1, ASTM E84 Class A, and ISO 9001 mean the board is safe and high quality. Certified boards usually have reports from trusted labs like Intertek. These reports show the board is strong, safe in fires, and good for the environment.

- A big office building used certified magnesium oxide board for its walls and ceilings. The building got a high fire safety score and a green building award.

- A school used boards with the right certifications for a remodel. This made the school safe and free from harmful chemicals for students.

- A house near the ocean picked boards with moisture and mold resistance certifications. Now, the house has cleaner air and strong walls that last longer.

Builders can use reviews and technical data sheets to compare boards. Boards like MGOTECH and MagPanel® have shown they work well in places with fire or lots of water. These certifications help builders feel sure about their choice.

Installation and Storage

Installing and storing magnesium oxide board the right way keeps it strong and safe. Builders should do these things:

- Keep boards flat in a dry place with air flow. Do not put heavy things on top.

- Take off the packaging and let boards sit for 48 hours to get used to the room.

- Clean where you will put the boards. Get rid of dust, grease, and trash.

- Measure and mark the boards using tape measures and square rulers.

- Cut thin boards with a utility knife. Use a saw with a carbide blade for thick boards. Always wear safety gear.

- Leave a small gap, about 6mm, from the wall so the board can expand.

- Start fastening boards in the middle and move out. Put screws 200-250mm apart. Keep screws at least 12mm from the edge and 50mm from corners.

- Use screws that do not rust. Do not screw at an angle.

- Put joint compound on the seams. Make the surface smooth and sand it.

- Use primer and waterproof sealant, especially in wet places.

Tip: Always check for certifications and read the technical data sheet before you install. Do not use boards without clear certification or with bad packaging. These might not be safe or good quality.

A table can help builders find good boards:

What to Look For | Why It Matters |

|---|---|

Clear certification labels | Shows the board is safe |

Detailed technical data sheet | Proves the board was tested |

Trusted third-party reports | Means testing was fair |

Proper packaging and labeling | Helps keep the board safe |

Picking the right magnesium oxide board with the right certifications makes buildings safe, strong, and high quality.

Checking technical specifications and certifications makes sure magnesium wall board is safe and good quality. Builders and homeowners must look at the paperwork before buying.

- Ask experts or building pros for help.

- Look at certification labels and test papers.

- Pick products with trusted approvals only.

Choosing the right board keeps buildings and people safe. Good choices help buildings last longer and stay strong. 🏠

FAQ

What makes magnesium wall board different from gypsum board?

Magnesium wall board resists water, fire, and mold better than gypsum board. It lasts longer in wet places. Builders use it for walls, ceilings, and floors where extra strength and safety matter.

Can magnesium wall board be used outside?

Yes, builders can use magnesium wall board outside. They must add a weatherproof coating or paint. This protects the board from rain and sun. Proper sealing helps the board last longer outdoors.

How does magnesium wall board help with fire safety?

Magnesium wall board does not burn easily. It gets top fire ratings like Class A1. The board slows down fire and does not make much smoke. Builders use it in schools, hospitals, and tall buildings.

Is magnesium wall board safe for people with allergies?

Yes, magnesium wall board does not have formaldehyde or asbestos. It does not let mold or fungus grow. This makes it a safe choice for people with allergies or asthma.

How should builders store magnesium wall board before use?

Store boards flat in a dry, well-ventilated area. Keep them off the ground and away from water. Remove packaging before use and let the boards adjust to room conditions for at least 48 hours.

Fire Ratings

Fire Ratings Interpreting Certifications

Interpreting Certifications