22 Sep MgO vs. Gypsum and Cement Boards on Fire Resistant Protect

Table of Contents

MgO boards give the best fire protection compared to other boards. House fires are very dangerous. In 2023, there were about 344,600 house fires. In 2022, 13.3 people out of every million died in fires. Using non-combustible materials keeps buildings safer in a fire. It also gives you more time to escape. The MgO vs. Gypsum debate shows that picking the right board matters for safety.

Category | Value |

|---|---|

National fire death rate | 13.3 per million population (2022) |

National fire injury rate | 39.8 per million population (2022) |

Estimated residential building fires (2023) | 344,600 |

Leading cause of home fires | Cooking (48.7%) |

Key Takeaways

MgO boards give the best fire protection. They can last up to four hours in a fire. Pick them for places with high fire risk.

Gypsum boards are cheap and simple to put in. But they only protect from fire for up to one hour.

Cement boards are tough and do not get damaged by water. They work well in wet places. But they might need extra steps to be very safe from fire.

MgO boards are great for wet rooms like kitchens and bathrooms. They stop water and mold very well.

Think about costs over time. MgO boards cost more at first. But they save money on repairs and keep you safer.

Board Types

MgO Board

MgO board is known for being strong and fire resistant. Its main part is magnesium oxide, which helps stop fires. Makers mix magnesium oxide with other things like magnesium chloride, perlite, wood fiber, vermiculite, and glass mesh. This mix makes the board safe from fire, mold, and bugs. The board is made by mixing and curing these materials. This makes it tough and steady.

MgO board can be used in many ways:

Roofing base for better fire safety

Soundproof panels in studios and theaters

Wall panels for inside and outside

Underlayment for ceilings and floors in wet places

Fireproof doors and room dividers

Builders like to use MgO board for green buildings. It can be recycled and does not harm the environment much. This board is safe and good for the planet.

Gypsum Board

Gypsum board is very common in building today. People use it for inside walls and ceilings. The main part is gypsum, a soft mineral made of calcium sulfate dihydrate. Makers put gypsum between two paper sheets. This makes the board light and easy to cut.

Gypsum board is good for:

Inside wall dividers

Ceilings in homes and offices

Soundproofing in schools and libraries

You can put up gypsum board fast. It is not as strong as MgO board, but it costs less and is simple to use. Gypsum board does not do well with water, so do not use it in wet places.

Cement Board

Cement board is strong and lasts a long time. It is made from cement, sand, and fibers that make it tougher. Some types, like fiber cement board, use cellulose fibers for more strength. Cement board can handle water, mold, and fire.

You can use cement board in many spots:

Tile backing in bathrooms and kitchens

Outside wall covering

Underlayment for floors

Fire-rated wall systems

Wet places where water is a problem

Cement board is heavier than gypsum board and MgO board. You might need special tools to cut it. Fiber cement board is often used for siding because it lasts and can handle bad weather.

Tip: Pick cement board or fiber cement board for wet places or where you need something extra strong.

Fire Resistance

Ratings

Ratings

You want to know how different boards stand up to fire. Fire resistance ratings help you compare them. These ratings show how long a board can stop fire from spreading. You should look for boards with high fire ratings if you want the best protection.

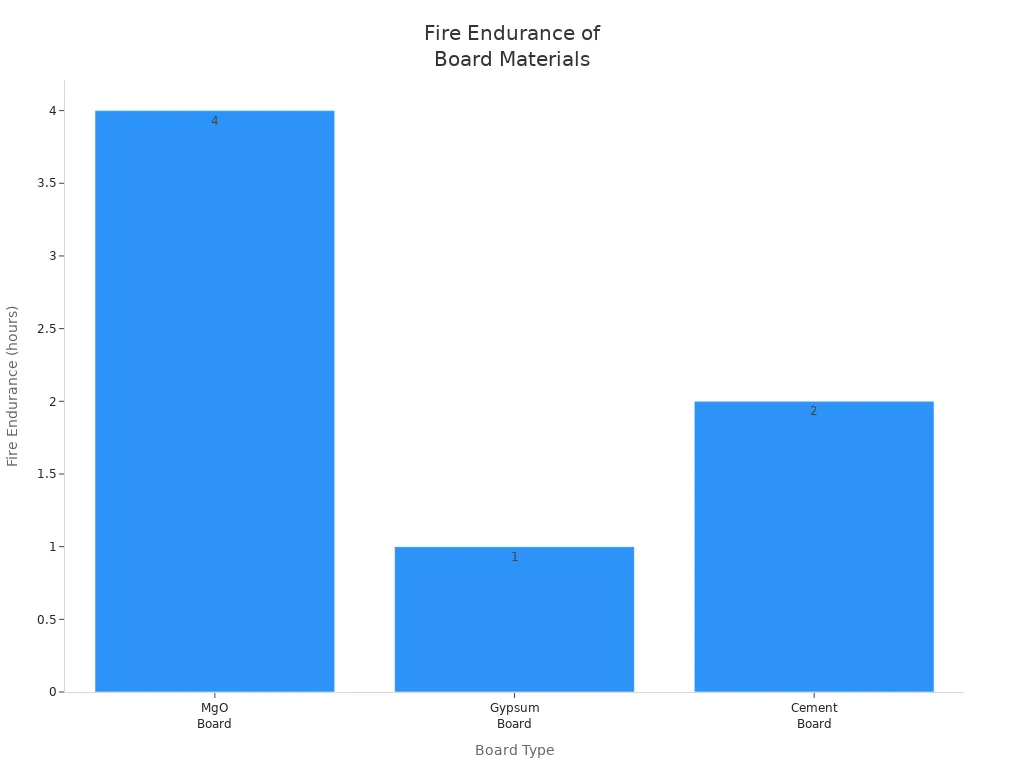

Here is a table that compares the fire resistance ratings of MgO, gypsum, and cement boards:

Property | MgO Board | Gypsum Board | Cement Board |

|---|---|---|---|

Fire Resistance Rating | A1 Non-Combustible (highest class) | Fire-resistant up to 1 hour | Fire-resistant up to 2 hours |

Fire Endurance | Up to 4 hours | 30-60 minutes | Up to 2 hours |

MgO board stands out because it is non-combustible and can last up to four hours in a fire. Gypsum board gives you some fire resistance but only for a short time. Cement board does better than gypsum, but it still cannot match the performance of MgO board.

You can also see how these boards perform in official tests. MgO boards pass strict tests like ASTM E119 and EN 13501-1. These tests check how long a board can resist fire and if it stays strong. MgO boards earn the A1 rating in Europe, which means they do not burn at all. Gypsum board and cement board do not reach this level.

Certification/Standard | What It Proves |

|---|---|

ASTM E119 | Tests fire resistance and strength over time. |

ASTM E136 | Confirms non-combustibility; MgO boards pass this test. |

EN 13501-1 | European fire safety rating; MgO boards earn A1. |

Note: If you need fire-rated partitions or fire rated applications, MgO board gives you the highest level of safety.

You can see the difference in fire endurance in this chart:

Real-World Fire

You want to know how these boards work in real fires, not just in labs. MgO boards show strong performance in real-world fires. They keep their shape and strength even when exposed to high heat. Hospitals, schools, and other important buildings use MgO boards because of this fire-resistant performance.

MgO boards do not catch fire or help flames spread. They have a zero flame spread rating and can handle heat up to 1200°C. You will not see toxic smoke or gases if MgO boards burn. This makes them safe for people inside the building.

Here is a table with real product examples and their fire resistance:

Product Name | Fire Resistance Rating | Certification Standards | Key Applications |

|---|---|---|---|

DragonBoard | Up to 2 hours | UL and Intertek certified | Fire-rated subfloor assemblies, wall sheathing, shaft walls, mezzanines, modular buildings |

Suparna MgO Board | Class A (EN 13501-1 standard) | ISO and CE standards | Internal partition walls, subflooring, modular panels, fire-rated ceilings, doors |

MgO boards give you up to four hours of fire resistance. Gypsum board can only last up to one hour. Cement board can last up to two hours. If you want the best fire-resistant partitions, MgO board is the top choice.

MgO boards do not burn or help fire spread.

They do not make toxic smoke.

They keep their strength during a fire.

You can use them in places where fire safety matters most.

Tip: For high fire ratings and the best fire resistance, choose MgO board for your fire-rated partitions.

MGO vs. Gypsum

Key Differences

When you look at mgo and gypsum, you find many differences. These differences help you choose the right board for your building. The main things to think about are fire resistance, durability, moisture resistance, cost, and how easy it is to install.

Here is a table that shows how mgo and gypsum boards handle fire:

Material Type | Weight Loss at High Temperatures | Structural Integrity Under Heat | |

|---|---|---|---|

MgO Boards | Superior fire resistance, non-combustibility, maintains structural integrity under high temperatures | N/A | Maintains integrity |

Gypsum Boards | Needs extra layers or treatments for better fire resistance | 23% weight loss due to dehydration | May lose integrity under extreme heat |

MgO boards stay strong in a fire. Gypsum boards can lose weight and break down in high heat. This is a big difference between the two boards.

There are also differences in how they handle water and mold. Look at this table:

Feature | MgO Boards | Gypsum Boards |

|---|---|---|

Moisture Resistance | High, great for wet areas | Low, gets damaged in wet conditions |

Mold Growth | Stops mold | Mold can grow |

Installation Areas | Kitchens, bathrooms | Needs special versions for wet areas |

You can use mgo board in kitchens and bathrooms. It works well in wet places. Gypsum board does not work well in wet areas unless you buy a special kind. This is another important difference.

Cost is different too. MgO boards cost more at first, about $15 to $25 per sheet. Gypsum boards cost less, about $6 to $12 per sheet. But mgo boards save money later because you do not need to fix them as much. Gypsum boards might cost more over time if you have to repair water or mold damage.

MgO boards are tough and do not rust or crack, even in damp places. Gypsum boards are lighter and easy to carry, but they can crack or break in busy spots. This matters if you want your walls to last a long time.

Tip: If you want strong fire resistance, good moisture protection, and walls that last, mgo boards are a better value over time.

Applications

You need to know where each board works best. Comparing mgo and gypsum helps you pick the right one for your job. Here is a table that shows the best uses for each board:

Material | Recommended Use Cases | Key Features |

|---|---|---|

MgO Board | High-performance applications, fire-rated walls, fireproof partitions, wet areas, ceilings, interior/exterior wall panels, flooring, high-traffic areas like schools, hospitals, and offices. | Fire resistance, moisture resistance, durability, sound insulation |

Gypsum Board | Standard interior applications, commonly used for interior walls and ceilings in residential and commercial construction. | Cost-effective, easy to install |

Use mgo board for tough jobs. These include fire-rated walls, fireproof partitions, and wet places. You also want mgo board in busy places like schools and hospitals. It gives you fire resistance, moisture protection, and blocks sound.

Gypsum board is best for regular walls and ceilings in homes and offices. It is easy to put up and costs less. It works well for simple projects.

Here is a quick list to help you choose:

MgO Boards: Use for fire-rated walls, wet places, busy spaces, and when you need strong, long-lasting protection.

Gypsum Boards: Use for normal walls and ceilings in dry places when you want a simple, low-cost choice.

The mgo vs. gypsum choice depends on what you need. If you want the best fire resistance and strength, pick mgo board. If you want to save money on basic walls, gypsum board is a good pick.

Note: Always check your local building rules before you decide. Some jobs may need special fire or water protection.

Safety

Smoke and Toxicity

Smoke and Toxicity

When you pick building materials, you want to keep the air safe if there is a fire. Some boards can make smoke and bad gases when they burn. This smoke can make it hard to breathe and can hurt your health.

MgO board is different because it does not burn or make toxic gases. It makes very little smoke, even in hot fires. Gypsum board can make more smoke and bad gases when it burns. This can be dangerous for people inside.

Here is a table that shows how MgO and gypsum boards are different:

Feature | MgO Boards | Gypsum Boards |

|---|---|---|

Combustibility | Non-combustible | Combustible |

Smoke Production | Minimal smoke | Higher smoke |

Toxic Gas Emission | No harmful gases released | Harmful gases released |

Health Risks | Reduced during fires | Increased during fires |

Tip: If you want to stay safer and have cleaner air in a fire, use boards that do not make smoke or toxic gases.

Structural Integrity

You want your walls and ceilings to stay strong in a fire. This helps keep you safe and gives you more time to leave. Strong walls are very important during a fire.

MgO board keeps its shape and strength in high heat. It does not bend, crack, or fall apart. Gypsum board can lose its strength and break down in heat. Cement board stays strong too, but it may start to weaken after two hours.

Here is a table that shows how these boards do in a fire:

Material | Fire Resistance Characteristics | Structural Integrity During Fire Exposure |

|---|---|---|

MgO Boards | Non-combustible, high fire ratings, maintains integrity under high temperatures | Excellent resistance to bending, cracking, and collapsing |

Gypsum | Limited fire resistance, may degrade under heat | May lose strength and emit harmful substances |

Cement | Non-combustible, highly fire-resistant, maintains integrity for up to 2 hours | Strong performance under fire exposure |

Note: For the strongest and safest walls in a fire, MgO board is the best choice.

Durability

Wear Resistance

You want your building materials to last a long time, even in tough conditions. Durability and strength matter most when you choose between mgo board, gypsum board, and cement board. Each board handles daily wear in a different way.

Mgo board stands out for its durability and longevity. It resists cracking, warping, and sagging, even if you use it in places with high humidity or changing temperatures.

Gypsum board does not hold up as well. It absorbs water quickly, which can lead to mold and damage. You may see it break or crumble in busy areas.

Cement board offers good resistance to wear, but you need to seal it for the best results in wet places.

Here is a quick comparison:

Material | Wear Resistance | Mold Resistance | Best Use Areas |

|---|---|---|---|

Mgo Board | Excellent | Excellent | Bathrooms, kitchens, schools |

Gypsum Board | Fair | Poor | Dry, low-traffic rooms |

Cement Board | Good | Good | Wet areas, tile backing |

Tip: Choose mgo board if you want walls and ceilings that stay strong and look good for years.

Fire Impact

Fire can test the durability of any board. You need a material that keeps its shape and strength during and after a fire. Mgo board is non-combustible and keeps its structure, even in high fire-risk areas. It blocks fire from spreading and does not lose its strength over time.

Mgo board maintains its fire resistance, even in places with high humidity or temperature swings.

Gypsum board weakens when exposed to fire or moisture. It may lose its shape and need replacement.

Cement board gives moderate fire safety, but sometimes needs extra treatments for the best results.

Material | Fire Resistance | Moisture Resistance |

|---|---|---|

Mgo Board | Non-combustible; great for high fire-risk areas. | Excellent; blocks water and mold. |

Cement Board | Moderate fire safety; may need extra treatments. | Good; needs sealing for long-term use. |

You want durability and longevity in your building. Mgo board gives you both, even in the toughest conditions.

Moisture

Wet Areas

You want your walls and floors to stay strong in places with lots of water. Wet area applications like bathrooms, kitchens, and pool rooms need special boards. Not all boards work the same in these spots.

Here is a table that shows how each board handles water:

Material | Performance in Wet Areas | |

|---|---|---|

MgO Board | High | Excellent for constant water exposure, does not absorb water. |

Cement Board | Moderate | Good for wet areas, often used under tiles in bathrooms. |

Gypsum Board | Low | Suitable for light moisture, can weaken with prolonged exposure. |

You can see that mgo board gives you the best protection. It does not soak up water, so it stays strong even if water touches it all the time. Cement board works well in wet areas, but you may need to seal it to keep it safe for a long time. Gypsum board can handle a little moisture, but it gets weak and soft if it stays wet.

Mgo board is waterproof and resists mold, so you can use it for pools and outdoor spaces.

Cement board is tough in wet areas but needs sealing for the best results.

Gypsum board is not good for very wet places.

Tip: For wet area applications, pick mgo board if you want the best moisture protection and mold resistance.

Mold

Mold can grow fast in damp places. You want to stop mold before it starts. Some boards help you do this better than others.

Mgo board gives you strong mold resistance. It does not absorb much water, so mold cannot grow easily. Even in humid rooms, mgo board keeps mold away. Cement board also resists water, but it can soak up some moisture. If you do not seal it, you might see swelling or cracks, which can let mold grow. Gypsum board has the most trouble. It can swell, crack, and let mold spread if it gets wet.

Gypsum subfloors often get water damage, which leads to swelling, cracking, and mold growth.

Mgo board prevents mold growth, even in humid conditions.

Cement board resists water but needs sealing to keep its mold resistance.

You want a board that keeps your home safe from mold. Mgo board works best for this. It keeps its shape and blocks mold, even after a fire or in wet rooms.

Note: Mold can cause health problems and damage your home. Choose boards with high mold resistance for the safest results.

Cost

Material

When you plan a building project, you want to know how much each board will cost. The price of materials can change your decision. You might see big differences between mgo board, gypsum board, and cement board. Here is a simple table to help you compare:

Material Type | |

|---|---|

MgO Boards | $1.50 – $2.50 |

Gypsum Boards | $0.50 – $1.00 |

You can see that gypsum board costs less than mgo board. If you have a tight budget, gypsum board may look like the best choice. Mgo board costs more, but it gives you better protection from fire and water. Cement board usually costs about the same as mgo board or a bit more. You should think about how long you want your walls to last and how much safety you need.

Tip: If you want the best value for fire safety and durability, mgo board may save you money in the long run, even if it costs more at first.

Installation

You also need to think about how much it costs to put up each board. Some boards are heavy or hard to cut, so you pay more for labor. Gypsum board is light and easy to install. You can finish a room quickly and pay less for labor. Mgo board is a bit heavier, but you can still install it with basic tools. Cement board is the hardest to work with. It is heavy and needs special tools, so you pay more for labor.

Here is a table to show the cost comparison for installation:

Board Type | Material Cost per Sq.Ft. | Installed Cost per Sq.Ft. (Material + Labor) | Notes on Labor and Installation |

|---|---|---|---|

Gypsum Board | $1.50 – $2.50 | Light, easy to install, lower labor costs | |

Cement Board | $1.50 – $3.50 | Higher than gypsum board | Heavier, more complex installation, higher labor costs |

Mgo board usually falls between gypsum board and cement board for installation costs. You can install it with standard tools, but it takes a little more time than gypsum board. If you want to save on labor, gypsum board is the cheapest. If you want better fire and water protection, mgo board is a smart choice.

Note: Always include both material and labor costs in your budget. The cheapest board may not give you the best protection or last the longest.

Environmental Impact

Sustainability

Sustainability

You want to choose building materials that help the planet. When you look at the life cycle of mgo board, gypsum board, and cement board, you see big differences in their environmental impact.

MgO made with natural gas produces 18% less CO2 than MgO made with coal.

MOC panels, which use magnesium, emit 22% less CO2 than concrete-based boards.

The cement industry creates about 5-7% of all human-made CO2 emissions each year. Each ton of cement releases between 900 and 1200 kg of CO2.

If you use mgo board, you help lower pollution compared to gypsum board or cement board. Mgo board also helps you earn points for green building certifications like LEED or BREEAM. These boards improve indoor air quality and reduce the carbon footprint of your building. Their carbon-negative properties and long life make them a smart choice for sustainable construction.

Tip: If you want to build green and meet sustainability goals, mgo board is a top pick.

Health

You want your home or office to be safe and healthy. The materials you choose can affect the air you breathe and your overall well-being.

Mgo board is non-toxic and gives off very low levels of VOCs. You can use it in hospitals, schools, and other places where clean air matters.

Gypsum board absorbs more moisture, which can lead to mold growth. Mold can harm indoor air quality and cause health problems.

Mgo board stops mold from growing because it is inorganic and does not feed mold spores. Its moisture absorption rate is only 0.34%, while gypsum board absorbs almost 3%.

The high alkalinity of mgo board also keeps microbes from growing, making your space healthier.

If you want to avoid mold and keep your air clean, mgo board is a safer choice. It keeps its strength even after a fire and does not release harmful substances.

Note: Choosing the right board helps protect your health and the environment at the same time.

Board Selection

Residential

When you pick a board for your house, you want your family to be safe. You also want your home to stay strong. You should think about a few things before you choose. The table below shows how mgo board, gypsum board, and cement board compare for fire safety at home:

Factor | MgO Board | Gypsum Board | Cement Board |

|---|---|---|---|

Fire Resistance | Superior, often non-combustible | Basic protection for moderate risk | Higher resistance, withstands extreme conditions |

Moisture Resistance | Excellent, mold-proof properties | Sensitive to moisture | Better in humid conditions |

Durability | Long-term durability | Degrades over time if wet | Moderate durability |

Environmental Impact | Eco-friendly, low emissions | Energy-intensive processes | Moderately eco-friendly |

Cost | Slightly more expensive than gypsum | Most economical | Heavier and costlier |

You want strong fire protection for bedrooms and kitchens. Mgo board gives you the best safety and lasts many years. Gypsum board is cheaper and works well in dry rooms. Cement board is good for bathrooms and laundry rooms because it does not get damaged by water. If you care about the planet, mgo board is a smart pick because it is better for the environment.

Tip: Always use the right board for each room. Pick mgo board for wet or high-risk places to keep everyone safer.

Commercial

Commercial buildings have more risks and must follow strict rules. You need to think about where fires could start, like kitchens or storage rooms. Here are some tips for picking fire-resistant boards in commercial buildings:

Check fire risks in each room, like electrical rooms and kitchens.

Talk to fire safety experts early to pick the best materials and follow safety codes.

Learn about new fire-resistant boards and building methods by going to industry events and training.

Fire-rated gypsum board is often used for walls and ceilings in offices, schools, and hospitals. It has a core that does not burn and can protect for up to two hours, giving people time to escape. Mgo board gives even better fire protection and works well in places that need extra safety, like stairwells or emergency exits. Cement board is tough and handles water, so it is good for kitchens and bathrooms.

Note: Always check local building codes before you choose a board. Picking the right board keeps people safe and helps your building pass inspections.

You want the best protection for your building. MgO boards stand out for fire safety. They are naturally non-combustible and keep their strength even at high temperatures.

Property | MgO Boards | Drywall | Cement Boards | Plywood/OSB |

|---|---|---|---|---|

Inherent Non-Combustibility | Yes | No | No | No |

Fire Ratings | 1 hr | 2 hr | Low |

Choose MgO for high-risk or wet areas. Weigh fire protection, cost, and installation. Always check building codes and ask a professional before you decide.

FAQ

What makes MgO board better for fire resistance?

MgO board does not burn. It can handle heat up to 1200°C. You get up to four hours of fire protection. This board does not make smoke or toxic gases. You stay safer during a fire.

Can you use MgO board in bathrooms or kitchens?

Yes, you can use MgO board in wet areas. It resists water and mold. You do not need special coatings. You get strong walls that last in bathrooms, kitchens, and laundry rooms.

How does gypsum board compare to MgO board for fire safety?

Gypsum board gives basic fire protection. It lasts up to one hour in a fire. MgO board lasts longer and does not break down in heat. You get better fire safety with MgO board.

Is cement board a good choice for fire-rated walls?

Cement board gives good fire resistance. It can last up to two hours. You may need extra treatments for the best results. MgO board gives you higher fire ratings and better protection.

Does MgO board cost more than gypsum board?

Yes, MgO board costs more at first. You pay more for each sheet. Over time, you save money because you do not need as many repairs. You also get better fire and water protection.

Ratings

Ratings Smoke and Toxicity

Smoke and Toxicity Sustainability

Sustainability