04 Aug What Are the Main Types of Sheathing Materials Used in Construction

Table of Contents

You will see many main sheathing materials used in building. Each one has its own special benefits:

Plywood

OSB (Oriented Strand Board)

Magnesium Oxide (MGO) Board

Fiberboard

Cement Board

ZIP System Sheathing

Foam Board

Gypsum Board

Picking the right sheathing helps keep your building safe from weather. It also makes your building stronger and helps save energy.

Here is how some common sheathing types work:

Sheathing Material | Building Strength | Moisture Resistance | Energy Efficiency |

|---|---|---|---|

Magnesium Oxide (MGO) | Very strong and lasts a long time | Stays strong against water | Makes buildings last longer |

OSB | Strong, but needs to stay dry | Needs to be sealed | Does not insulate well |

Plywood | Stays steady and strong | Better than OSB, but needs care | Good for adding insulation |

Fiberboard | Not as strong | Can get damaged by water | Great for insulation |

ZIP System Sheathing | Very strong, has a built-in barrier | Protects well from water | Helps save energy |

Putting in sheathing the right way and thinking about the weather helps you get the best results. Some, like MGO, do well in tough weather. Fiberboard is best for keeping heat in. ZIP System sheathing is strong and keeps out water, so it helps save energy over time.

Key Takeaways

Pick sheathing materials that fit your weather and building needs. This helps your building stay strong and safe. Structural sheathing like plywood and OSB makes walls stronger. Non-structural sheathing like foam board helps with insulation and fire safety. MgO and cement board can resist fire, water, and mold. These are good for places that get wet or have fire risks. Install sheathing the right way by sealing seams and adding weather barriers. This keeps out wind and rain and stops energy from escaping. Insulated sheathing with high R-values saves energy. It also lowers heating and cooling bills.

Types of Sheathing Materials

Structural vs. Non-Structural

There are two main groups of sheathing materials. These are structural and non-structural. Structural sheathing, like plywood and OSB, makes buildings stronger. It helps walls stand up to wind and snow. Builders use it to make a solid base for siding. Non-structural sheathing, like foam board or gypsum board, is different. It does not add much strength. Instead, it helps with insulation or fire safety. These materials keep buildings warm and safe.

Different places use certain sheathing types for local needs. The table below shows which materials work best in each area:

Region/Climate | Common Sheathing Types | Reason for Use |

|---|---|---|

Coastal (humid, wet) | Cement board, MgO board | High moisture resistance, mold proof |

Cold/Northern | Foam board, OSB, plywood | Good insulation, strong in snow loads |

Hot/Dry | Fiberboard, gypsum board | Fire resistance, cost-effective |

Wildfire-prone | Cement board, MgO board | Fire safety, durability |

Tip: Always check your local building codes before picking sheathing.

Key Characteristics

There are some important things to think about when choosing sheathing:

Structural sheathing makes walls stronger and helps with heavy loads.

Non-structural sheathing helps with insulation or fire safety.

Weather barriers keep rain and moisture away from sheathing.

Sealing seams and gaps stops air and water from getting in.

A rainscreen gap lets water drain away behind the siding.

The perm-rating shows how well the wall can dry out.

Pick materials that let moisture escape to stop mold and rot.

Think about the whole wall system for better air and longer life.

Today, there are new sheathing materials that do many jobs at once. Some insulated sheathing can make your wall much better at keeping heat in. These systems can lower your heating and cooling bills by a lot. They also use recycled materials, which is good for the planet. Companies now make sheathing that is strong and eco-friendly. This helps you build safer and greener homes.

Structural Exterior Wall Sheathing

To build a strong wall, you need the right structural exterior wall sheathing. This layer helps your building stay strong. It keeps out wind and bad weather. There are a few main types you can use for exterior wall sheathing.

To build a strong wall, you need the right structural exterior wall sheathing. This layer helps your building stay strong. It keeps out wind and bad weather. There are a few main types you can use for exterior wall sheathing.

Plywood

Plywood is a common choice for structural exterior wall sheathing. It is made by gluing thin wood layers together. This makes it strong and steady. Plywood sheathing works well for homes and small buildings. You can cut it and nail it easily.

Pros:

Good strength for walls and roofs

Lighter than OSB of the same thickness

Easy to work with

Cons:

Costs more than OSB

Needs protection from water

Not as fire-resistant as MgO board

Plywood sheathing is used for most exterior wall sheathing jobs. It gives a solid base for siding. It helps your building last longer.

Note: Wood-based structural sheathing like plywood stores carbon. It helps lower greenhouse gas emissions compared to concrete or steel.

MgO Board

Magnesium oxide (MgO) board is a newer kind of structural exterior wall sheathing. It is good when you need fire and moisture resistance. MgO board does not burn. It stands up to water and mold. This makes it a good pick for rainy or fire-risk places.

Pros:

Naturally non-combustible and very fire-resistant

Resists water, mold, and insects

Good for humid or wildfire-prone areas

Cons:

Costs more than wood sheathing

Needs special tools for cutting

Heavier than plywood

MgO board is used for exterior wall sheathing in schools, hospitals, and homes in tough climates. It keeps your building safe and strong.

Material | Fire Resistance | Moisture Resistance | Additional Notes |

|---|---|---|---|

Magnesium Oxide (MgO) Board | Naturally non-combustible; withstands higher temperatures; high fire resistance rating | Resistant to water and mold; suitable for humid/wet environments | Environmentally friendly; more expensive; may require special handling |

Structural Fiberboard

Structural fiberboard is made from pressed wood fibers. You can use it as structural exterior wall sheathing if you want some insulation and a smooth surface. It is lighter than plywood or OSB.

Pros:

Easy to cut and install

Adds some insulation value

Smooth surface for siding

Cons:

Not as strong as plywood or OSB

Can get damaged by water

Not fire-resistant

Structural fiberboard is good for exterior wall sheathing in dry places or for extra insulation. It works best if you keep it dry and protected.

OSB

Oriented strand board (OSB) is a popular structural exterior wall sheathing. It is made by pressing wood strands together with glue. OSB gives good strength for walls and roofs. It costs less than plywood and is easy to find.

Pros:

Strong and stiff for walls

Costs less than plywood

Uses wood from small trees, so it is eco-friendly

Cons:

Needs to stay dry; can swell or warp if wet

Heavier than plywood

Oriented strand board is used for most exterior wall sheathing jobs. It works well for homes, sheds, and garages.

Material | Fire Resistance | Moisture Resistance | Additional Notes |

|---|---|---|---|

Fire-rated OSB | Treated with fire-resistant chemicals; slows fire spread but less fire-resistant than MgO boards | Sensitive to prolonged moisture exposure; can swell, warp, or rot | Chemical treatments may raise environmental/health concerns; less fire-resistant than MgO; heavier than plywood |

Tip: Using OSB or plywood for structural wall sheathing helps store carbon. It lowers the carbon footprint of your building.

Cement Board

Cement board structural sheathing is made from cement and fibers. You can use it when you need a tough, fire-safe, and water-resistant wall. Cement board does not rot or burn. It works well for commercial buildings and homes in wet or fire-prone areas.

Pros:

Very strong and durable

Does not burn or rot

Resists mold and insects

Cons:

Heavy and hard to cut

Costs more than wood sheathing

Needs special fasteners

Cement board structural sheathing is good for exterior wall sheathing in places with lots of rain, snow, or fire risk. It gives you a long-lasting and safe wall.

Note: Cement board has a higher carbon footprint than wood sheathing. But it gives you top fire and moisture protection.

Comparing Fire and Moisture Resistance

Here is a quick look at how some structural exterior wall sheathing materials compare:

Material | Fire Resistance | Moisture Resistance |

|---|---|---|

MgO Board | Excellent (non-combustible) | Excellent (water/mold resistant) |

OSB | Good (with treatment, but less than MgO) | Fair (must stay dry) |

Plywood | Fair (not detailed, lighter than OSB) | Fair (needs care) |

Cement Board | Excellent (non-combustible) | Excellent (does not rot) |

Fiberboard | Poor | Poor |

Remember: Always match your structural exterior wall sheathing to your local climate and building needs. The right choice keeps your building safe, strong, and energy efficient.

Non-Structural and Insulating Sheathing

Non-structural exterior wall sheathing helps make buildings more comfortable. It also helps save energy. These materials do not make walls stronger. They are used to add insulation or help protect against fire. Many new buildings use non-structural sheathing. This helps meet energy rules and keeps heating and cooling bills lower.

Some common types of non-structural and insulating sheathing are:

Foam boards (such as polystyrene, polyisocyanurate, and polyurethane)

Cellulose fiber boards

Paper-faced boards

Foil-faced boards

Plastic boards

You often see non-structural sheathing used with structural panels. This gives both strength and better insulation.

Foam Board

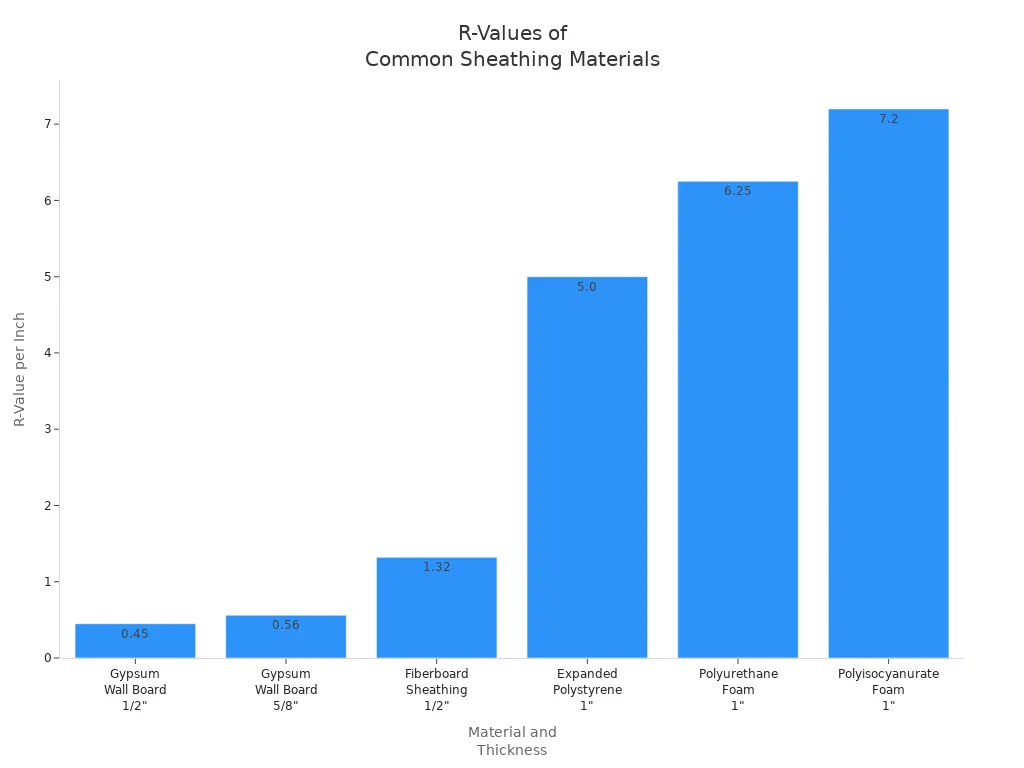

Foam board is a popular choice for insulation. You can choose from expanded polystyrene (EPS), extruded polystyrene (XPS), polyisocyanurate, or polyurethane. These boards keep heat inside during winter. They also keep heat out during summer. Polyisocyanurate foam board has a very high R-value for each inch.

Material Type | Thickness | |

|---|---|---|

Expanded Polystyrene | 1″ | ~5.00 |

Polyurethane Foam | 1″ | ~6.25 |

Polyisocyanurate Foam | 1″ | ~7.20 |

Foam board works well in hot and cold places. It is used as non-structural sheathing to help save energy. But foam board does not stop fire by itself. You should always follow local rules and use it with other tested wall parts.

Tip: Foam board insulation does not let water in. It is a good pick if you worry about water damage.

Gypsum Board

Gypsum board is another kind of non-structural sheathing. You might know it as drywall. It can also be used on the outside of walls. Gypsum sheathing helps protect buildings from fire. Builders use it to meet fire safety rules. But gypsum board does not give much insulation because it has a low R-value.

Material Type | Thickness | Approximate R-Value (per inch) |

|---|---|---|

Gypsum Wall Board | 1/2″ | ~0.45 |

Gypsum Wall Board | 5/8″ | ~0.56 |

You should not use gypsum board for insulation. Use it when you need fire protection as part of a non-structural sheathing system. Remember, fire safety depends on the whole wall, not just the sheathing.

Fiberboard

Fiberboard is a non-structural sheathing made from wood fibers. It gives some insulation and is easy to cut and put up. Fiberboard does not cost much and works best in dry places. It has a higher R-value than gypsum board, but less than foam board.

Material Type | Thickness | Approximate R-Value (per inch) |

|---|---|---|

Fiberboard Sheathing | 1/2″ | ~1.32 |

Do not use fiberboard in wet areas. It can soak up water and grow mold. If you want a cheap, insulating sheathing for dry places, fiberboard is a good choice.

Note: Always use non-structural sheathing with the right weather barriers. Follow local building codes for the best results.

Exterior Wall Sheathing Applications

Weather Resistance

Weather Resistance

You want your building to stay safe from wind and rain. The right exterior sheathing helps protect your walls from bad weather. Many builders pick plywood or OSB for strength. These panels help stop water from getting inside. If you seal the joints and use the right fasteners, you make a barrier. This barrier keeps out wind and moisture.

Some materials, like cement board and glass mat panels, are good for wet places. These do not rot or grow mold. Gypsum-based panels help with fire safety and moisture. But you should not use them alone for strength. Always add extra bracing if you use gypsum panels.

Here is a quick look at how different sheathing materials handle weather:

Sheathing Material | Weather Resistance Features | Notes |

|---|---|---|

Plywood / OSB | Strong against wind and water when installed correctly | Needs sealed seams |

Cement Board | Non-combustible, resists water and mold | Heavy, best for wet climates |

Glass Mat Sheathing | Good for moisture and fire resistance | Used often in commercial buildings |

Gypsum Sheathing | Fire, mold, and moisture resistance | Needs extra bracing for strength |

Tip: Always follow building codes for thickness and fastening. This helps your walls resist wind and water damage.

Energy Efficiency

You can save energy and money with the right sheathing. Some materials, like foam boards and polyisocyanurate panels, have a high r-value. This means they slow heat from leaving or entering. Your building stays warmer in winter and cooler in summer. When you put these boards outside your walls, you stop heat from escaping. This is called reducing thermal bridging.

Adding exterior sheathing with a high r-value makes walls better at keeping heat in. It also makes your building more comfortable. Foam board insulation can reach an r-value of 5 to 7 per inch. Polyisocyanurate boards have some of the highest r-values. If you use a rainscreen system, air can move behind the siding. This lets moisture escape and keeps your wall dry. It also protects the insulation.

Many new systems combine sheathing, air barriers, and insulation in one product. These systems make installation faster and improve energy efficiency. You can also find eco-friendly options that use recycled materials. These help you earn green building credits.

Note: Always check the r-value of your sheathing. Higher r-values mean better energy savings and more comfort for you.

Floor Sheathing Options

When you build a strong and stable floor, you need to choose the right floor sheathing. The most common materials for floor sheathing in new construction are plywood panels, OSB panels, and magnesium oxide (MgO) boards. Each option has unique strengths and works best in different situations.

Plywood Panels

You will find plywood panels used in many homes for floor sheathing. Plywood sheathing is made by gluing thin layers of wood together. This layered design gives plywood great strength and helps it resist warping or splitting. Builders often choose ¾” tongue-and-groove plywood for subfloors because it stays stiff and stable under heavy loads. Plywood also handles moisture better than OSB, so it lasts longer if you keep it dry. However, long-term exposure to water can cause delamination or splitting. You should always install plywood panels properly to get the best results.

Tip: Plywood panels are a top choice for floor sheathing when you want both strength and moisture resistance.

OSB Panels

Oriented Strand Board (OSB) panels are another popular choice for floor sheathing. OSB uses wood strands and glue, pressed into large sheets. This makes OSB strong and flexible for many designs. OSB costs less than plywood, so it is a budget-friendly option. However, OSB can absorb moisture, which may cause swelling or weaken the floor over time. You need to seal OSB edges and keep it dry for the best performance. OSB panels work well for most homes, but they are less durable in wet or humid places.

Material | Moisture Resistance | Durability | |

|---|---|---|---|

Plywood | High | Good | Reliable |

OSB | Good | Fair | Needs protection |

MgO Board | Excellent | Excellent | Very durable |

Mgo Boards

MgO boards are a newer option for floor sheathing. These panels offer high strength and a great strength-to-weight ratio. MgO boards support heavy loads and keep their shape even in tough conditions. You can use MgO boards in places with lots of moisture or where fire safety matters. They do not absorb water, so they resist swelling, mold, and mildew. MgO boards also last a long time and keep their structural integrity. While they cost more than wood sheathing, you get excellent durability and safety.

Note: MgO boards are ideal for floor sheathing in basements, bathrooms, or any area where moisture is a concern.

Choosing the right floor sheathing helps your floors stay strong, safe, and long-lasting. Always match your material to your building needs and local climate.

Comparison Guide

Pros and Cons Overview

There are many sheathing choices for your building. Each one has good and bad points. The table below shows how some common sheathing types compare. It looks at how long they last, their price, and how easy they are to put in:

Sheathing Material | Durability | Cost | Ease of Installation |

|---|---|---|---|

OSB | Strong, but less moisture resistant | Low | Easy to cut; needs weather barrier |

Plywood | More durable, resists moisture | Higher | Heavier; standard tools needed |

Fiberboard | Less durable, good for noise | Low to moderate | Easy to handle; less common |

Foam Board Insulation | Not structural, high R-value | Moderate to high | Needs care; not for nailing |

Fire resistant, less impact strength | Moderate | Similar to drywall | |

Huber Zip System | Weather barrier built-in | High | Fast install; taped seams |

Note: Plywood and OSB can last 20 to 40 years if kept dry. MgO and cement boards are best for stopping water and mold.

Selection Tips

When you pick sheathing, think about more than just the price. Here are some things you should remember:

Look at your local building codes. These rules tell you what kind and thickness you need.

Think about the weather where you live. Wet places need sheathing that stops water and mold, like MgO or cement board.

For strong storms or earthquakes, use plywood or OSB. These make your walls stronger.

If you want to save energy, add foam board insulation with your main sheathing.

Plan your spending. OSB is cheaper, but plywood and special boards last longer.

Always follow the maker’s directions when you put in sheathing. Doing it wrong, like using the wrong nails or storing it badly, can cause trouble later.

Tip: If you are not sure which sheathing to use, ask a builder. Picking the right one keeps your building safe and strong for a long time.

Picking the right roof sheathing is important for any building job. Roof sheathing helps your building stay strong in bad weather. It keeps out water, mold, and rot so your roof lasts longer. Roof sheathing can also help save money on energy by adding insulation. Different types of roof sheathing work better for certain weather and budgets. If you install it well and check it often, your roof sheathing will keep working.

You should always ask a building expert before you choose roof sheathing. Make sure to follow local rules so your roof is safe and lasts many years.

FAQ

What is the main purpose of wall sheathing?

Wall sheathing gives your building strength. It helps keep out wind and rain. Some types also add insulation or fire protection. You need sheathing to make your walls safe and sturdy.

Can you use foam board as the only sheathing?

Foam board works well for insulation, but it does not add strength. You should always use foam board with a structural sheathing like plywood or OSB. This keeps your walls strong and energy efficient.

How do you know which sheathing to pick for your climate?

You should look at your local weather. Wet places need water-resistant sheathing like MgO or cement board. Cold areas do better with foam board for insulation. Always check your local building codes before you choose.

Does sheathing help with fire safety?

Yes, some sheathing materials help slow down fire. MgO board, cement board, and gypsum board all resist fire. You can use these in places where fire safety matters most.

How long does exterior sheathing last?

Most sheathing lasts 20 to 40 years if you keep it dry and install it right. MgO and cement boards can last even longer. Always follow the maker’s instructions for the best results.