02 Aug Main Types of Floor Sheathing Materials

Table of Contents

You can find many main types of floor sheathing materials. These include plywood, OSB, particle board, concrete slab, engineered wood panels, cement boards, and MgO floor sheathing. Each type has its own good and bad points. The material you pick changes your building in many ways:

It helps stop water from getting in, which stops rot and mold.

Some choices help keep heat in and lower heat loss.

Some materials help stop fires and make things quieter.

Picking the right floor sheathing materials can make your space safer, stronger, and more comfy.

Key Takeaways

Pick floor sheathing by looking at strength, moisture resistance, and cost. This helps your floor stay strong and last a long time.

Plywood and OSB are popular options. Plywood is better with water but costs more. OSB is less expensive but needs sealing to stop water damage.

Use cement board or MgO board in wet places like bathrooms and basements. These boards stop water, mold, and fire from causing problems.

Match your floor sheathing to your finished floor type for the best results. Use cement board under tile. Use plywood or OSB under hardwood or carpet.

Install floor sheathing the right way with gaps, fasteners, and moisture barriers. This keeps your floor steady, safe, and comfortable for many years.

Floor Sheathing Overview

Purpose

You need floor sheathing to create a strong and stable base for your floors. When you install floor sheathing, you place it on top of the floor joists. This layer forms the subfloor, which supports everything above it, like carpet, tile, or hardwood. Floor sheathing connects all the framing parts together, making your floor more solid and less likely to move or squeak.

It gives you a flat surface for your finished flooring.

It helps your building stand up to heavy loads, wind, and even earthquakes.

It acts as a barrier to keep out moisture, which helps prevent mold and rot.

It can improve energy efficiency by stopping air leaks and reducing heat loss.

Some types add fire protection or help control sound.

You can choose from several floor sheathing materials, such as plywood or OSB, to match your needs. Each material offers different benefits for strength, moisture control, and comfort.

Role in Construction

You play an important part in making your building safe and sturdy when you install floor sheathing. You place the panels over the joists and secure them with nails or screws. This step helps spread the weight of furniture, people, and other loads across the whole floor. When you pay attention to how you lay the panels, you make the floor stronger and reduce bending or sagging.

Floor sheathing supports both residential and commercial buildings by connecting the frame and transferring weight to the right places. Careful installation, such as leaving the right gaps between panels and using the correct fasteners, keeps your floor strong for years. When you select the right floor sheathing materials and install them properly, you help your building last longer and perform better.

Floor Sheathing Materials

Plywood

Plywood is a very common floor sheathing material. It is made by gluing thin wood layers together. These thin layers are called veneers. Each layer’s grain goes in a different direction. This makes the panel strong and steady. The table below explains how plywood is made and what is inside:

Aspect | Details |

|---|---|

Wood species | Softwoods like cedar, redwood, pine, Douglas-fir, spruce, fir; also birch and beech |

Veneer thickness | 0.45 to 1.3 mm |

Moisture content | 4–8% after drying |

Adhesives used | Phenol-formaldehyde (for strength and moisture resistance) |

Veneer stacking | Alternating grain direction for strength |

Sheet size | Standard 4′ x 8′ |

Thickness | Commonly around 1/2 inch |

Applications | Floor sheathing, roof sheathing, concrete formwork, wood beam webs |

Start with softwood logs like pine or fir.

Peel the logs into thin sheets.

Dry the sheets to take out water.

Glue the sheets together. Turn each one so the grain changes direction.

Press the stack with heat and pressure to stick the layers.

Cut the plywood into standard sizes.

Pros:

Strong and lasts a long time

Handles moisture well

Light and simple to put in

Easy to find

Cons:

Costs more than OSB

Can have knots or empty spots

Surface can scratch or break

Best use cases:

Use plywood when you need a tough, steady floor base. It is good in places where water might be a problem. Plywood works well for most homes and businesses.

OSB

Oriented Strand Board (OSB) is also a popular floor sheathing material. OSB is made by gluing thin wood strands with resin and wax. The strands are put in layers. Each layer’s strands go in a new direction. This makes OSB strong and stiff.

OSB panels do not have gaps inside. They are thick and even, so they can hold heavy things. OSB resists water because of the wax and resin, but it is not fully waterproof. You must seal the edges to keep water out.

Pros:

Holds heavy loads well

Even strength and thickness

Good for big jobs

Cons:

Edges can chip or break

Not fully waterproof; can swell if wet too long

Needs careful use and sealing

Best use cases:

You can use OSB for most subfloors, especially if you want to save money. It works best in dry or slightly damp places. Do not use it where it will get very wet.

MgO Board

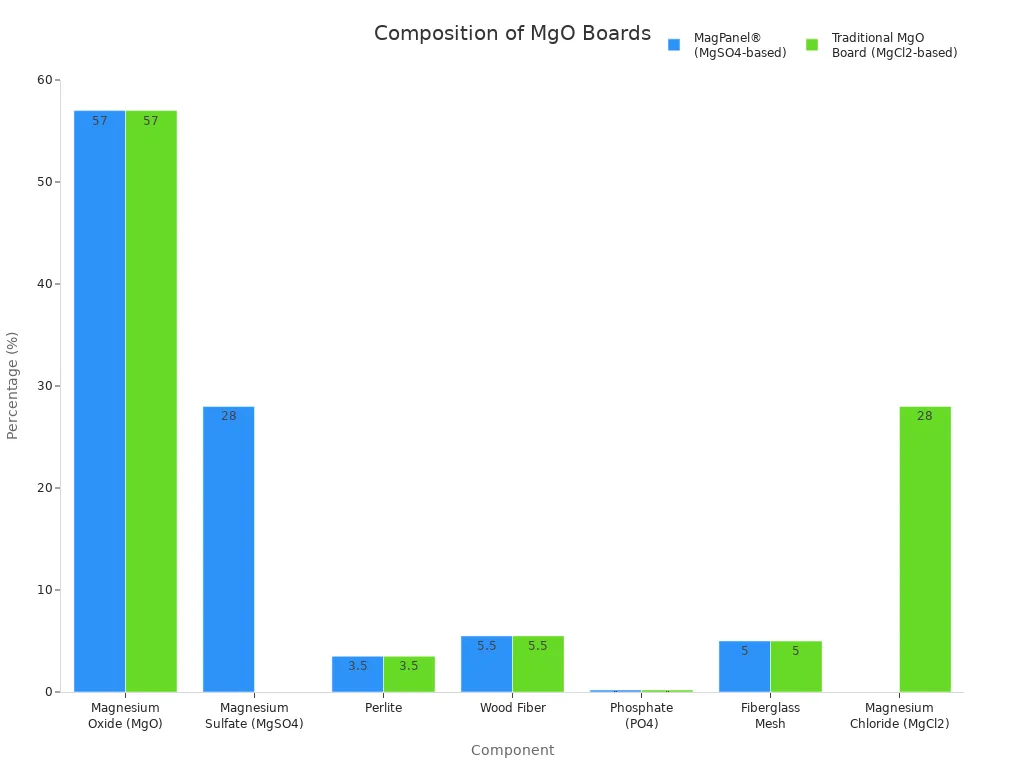

Magnesium Oxide (MgO) board is a newer floor sheathing material. MgO board is made from magnesium oxide, magnesium compounds, perlite, wood fiber, phosphate, and fiberglass mesh. The chart below shows the main parts in two types of MgO board:

Key characteristics:

Does not burn and is very fire safe (Class A1/ASTM E84 Class A)

Great at stopping water and mold

Keeps out bugs and is good for the planet

Lighter and easier to move than many wood panels

No bad chemicals like formaldehyde

Pros:

Very good at stopping fire and water

Does not bend, swell, or rot

Safe for indoor air

Cons:

Costs more than plywood or OSB

Edges can break during setup

Best use cases:

Use MgO board where fire safety and water control are most important. It is great for kitchens, bathrooms, basements, and business buildings.

Particle Board

Particle board is made from small wood pieces like chips, sawdust, and shavings. These are mixed with resin and pressed into sheets using heat and pressure. Sometimes, chemicals are added to stop bugs and mold.

Key characteristics:

Smooth top

Light weight

Cheaper than plywood or OSB

Pros:

Low price

Simple to cut and use

Cons:

Not strong and does not last long

Swells and falls apart if wet

Best use cases:

Do not use particle board as your main floor sheathing. Builders may use it on top of plywood, but never right over joists. It is better for furniture, shelves, or under countertops.

Concrete Slab

Concrete slab is a hard, poured floor that is both the base and the floor sheathing. You often see concrete slabs in basements, garages, and some new homes.

Aspect | Concrete Slab Cons | |

|---|---|---|

Durability | Solid, durable, long-lasting | Expensive to repair or replace |

Moisture Resistance | Inhibits mold, mildew, and odors | Not waterproof; needs moisture barriers for wood/carpet |

Installation | Good for tile and stone flooring | Cold from ground; not ideal for hardwood floors |

Cost | $6 to $8 per sq ft | Higher initial cost |

Environmental Impact | No VOCs | N/A |

Key characteristics:

Very strong and lasts a long time

Good for keeping out bugs and saving energy

Pros:

Lasts many years

Stops mold and bugs

Works well with tile or stone

Cons:

Feels cold on your feet

Hard to fix if broken

Not good for wood floors unless you add more steps

Best use cases:

Use concrete slab in basements, garages, and homes where you want a tough, easy-care floor. It is also good for business spaces.

Engineered Wood Panels

Engineered wood panels include plywood, OSB, and other types made from wood fibers, flakes, or strands glued together. These panels are made by pressing wood pieces with heat and pressure.

Key characteristics:

Strong and steady

Made for special uses (some for floors, others for walls or roofs)

Some can resist water

Pros:

Good strength for their weight

Steady and not likely to bend

Can be made for special jobs

Cons:

Some types may give off VOCs

Quality can change by brand

Best use cases:

You can use engineered wood panels for most floor sheathing jobs. They work well in homes, offices, and schools. Always check the panel type to make sure it fits your project.

Cement Boards

Cement boards are made from cement, cellulose fibers, and other things. You often see them in wet places because they stop water and mold.

Property | Description |

|---|---|

Composition | Cement, cellulose fibers, and additives |

Water Resistance | Good, but not fully waterproof |

Fire Resistance | Naturally fire resistant |

Load-Bearing | Strong enough for floor sheathing |

Durability | Handles water exposure without breaking or deforming |

Pros:

Very tough

Fire safe

Cons:

Heavier than wood panels

Can be harder to cut and put in

Best use cases:

Use cement boards in bathrooms, kitchens, laundry rooms, and near pools. They are also good for balconies and business spaces where water and fire safety matter.

Tip: Always follow the maker’s steps for putting in cement boards. Use the right screws and tape the seams to keep water out.

Comparing Materials

Strength and Durability

Strength and Durability

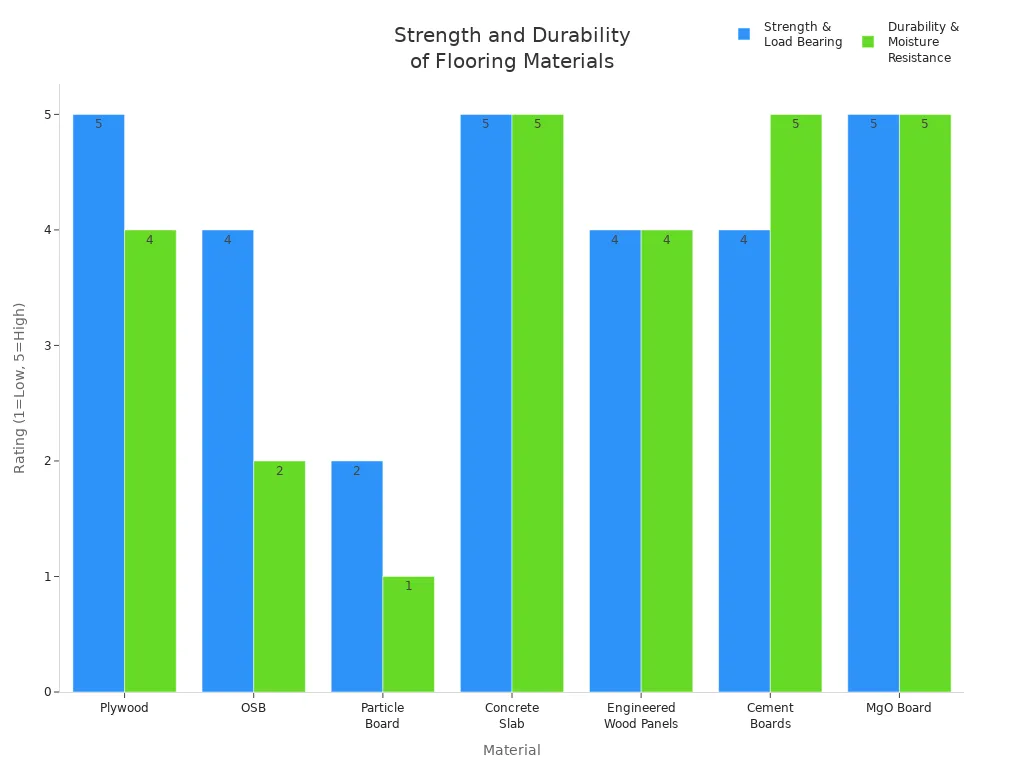

You want your floor to be strong and last a long time. Different floor sheathing materials have different strength and durability. The table below shows how each material does:

Material | Strength & Load Bearing | Durability & Moisture Resistance | Fire Resistance | Typical Applications & Notes |

|---|---|---|---|---|

Plywood | Excellent load-bearing capacity; strong under heavy flooring | Durable; resists warping and swelling; lasts as long as the house if properly installed | Moderate; can delaminate if exposed to prolonged water | Suitable for heavy foot traffic, hardwood, tile, carpet; better thermal insulation; more costly than OSB |

OSB | Good structural integrity; suitable for heavy flooring | Cost-effective; more susceptible to moisture damage and swelling; does not fully recover after wetting | Moderate; less fire resistant than cement or MgO boards | Budget-friendly; larger sheets reduce seams; avoid in moisture-prone areas unless sealed |

Particle Board | Economical; lower strength compared to plywood and OSB | Less durable; swells and weakens in moisture-prone areas | Low | Suitable only for dry, low-load areas; not recommended for wet or heavy-use spaces |

Concrete Slab | Superior hardness and stability; excellent load support | Highly durable; moisture resistant; ideal for wet areas | High | Best for tile, vinyl, and moisture-prone areas like basements and bathrooms |

Engineered Wood Panels | Enhanced stability and strength due to layered construction | Stable under temperature and humidity fluctuations; more costly | Moderate | Suitable for fluctuating environments; supports heavy loads; used in kitchens, entryways |

Cement Boards | Strong and durable; supports tile well | Highly moisture resistant; does not swell or rot | High | Ideal for wet areas, tile underlayment, fire-resistant applications |

MgO Board | Strong; supports heavy loads including multi-story buildings | Moisture resistant; durable; eco-friendly | Very high; withstands temperatures up to 1200°C | Excellent for fire-rated, moisture-prone, and heavy traffic areas; lightweight and sustainable choice |

You can also look at this chart to compare:

Moisture Resistance

Water can hurt your floor if you pick the wrong material. Plywood and OSB soak up water and can get bigger. Cement boards and MgO boards do not let water in as much. MgO boards stay strong even after getting wet and drying many times. In tests, MgO boards kept almost all their strength. OSB lost 40% and plywood lost 9%. In real life, MgO boards do not bend or rot, even in bad weather. Cement boards also stay strong in wet places. For wet rooms, use cement board or MgO board. Always put a moisture barrier under your floor in damp spots.

Board Type | Moisture Absorption | Swelling Risk | Best Use Areas |

|---|---|---|---|

Plywood | High | Yes | Dry interior spaces |

OSB | High | Yes | Dry interior spaces |

Cement Board | Low | No | Wet areas, exteriors |

MgO Board | Very Low | No | Wet, humid locations |

Tip: For rooms with lots of water, use Exterior-rated panels or water-resistant boards. Always add a moisture barrier.

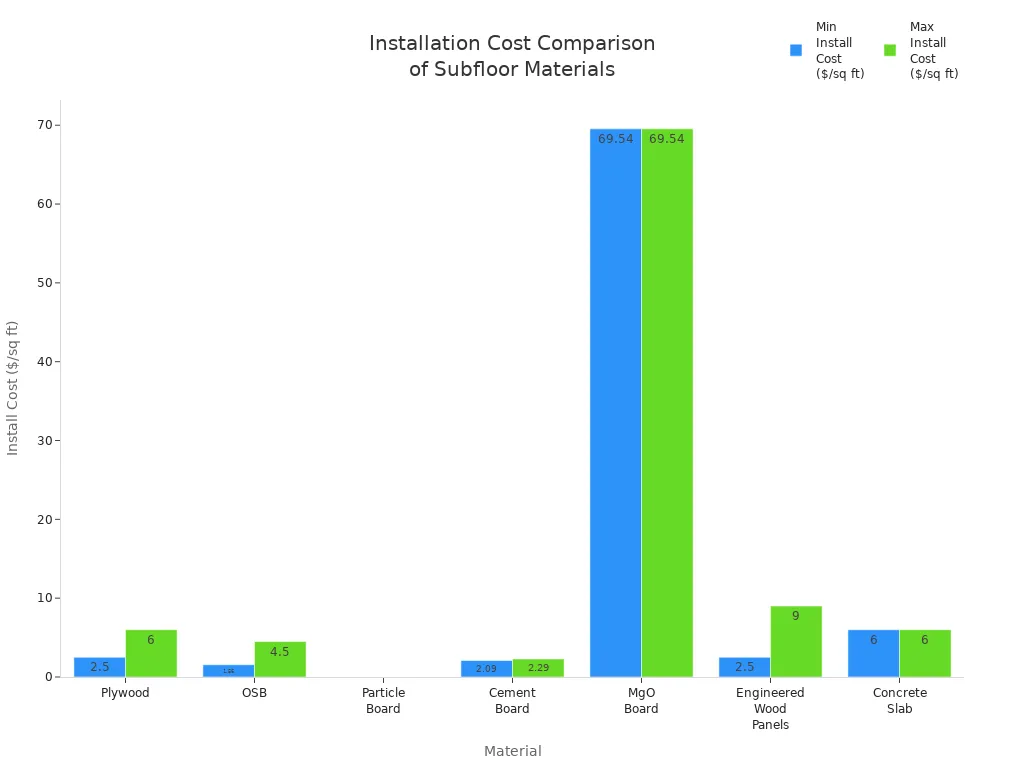

Cost

You should think about both the price to put in the floor and the cost to keep it nice. OSB and particle board are cheaper to install, but they may not last as long. Plywood and engineered wood panels cost more but are stronger. Cement boards and MgO boards cost more at first, but they last longer and need less fixing in wet or fire-prone places. Concrete slabs cost the most to put in but need little care later.

Material | Maintenance & Durability Notes | |

|---|---|---|

Plywood | $2.50 – $6 | Moderate maintenance; less moisture resistant; suitable for dry areas |

OSB | $1.56 – $4.50 | Swells with moisture; weaker than plywood; moderate maintenance |

Particle Board | Very low cost | Very affordable but high maintenance due to water damage risk; weak structure; short lifespan in damp areas |

Cement Board | About $2.09 – $2.29 | Water-resistant, very durable, low maintenance; heavier and harder to install; higher upfront cost |

MgO Board | Higher upfront cost (~$69.54 per panel) | Fireproof, waterproof, mold resistant; low maintenance; may require professional installation |

Engineered Wood Panels | Moderate cost ($2.50 – $9 approx.) | Stable, moisture resistant; moderate installation complexity; moderate maintenance |

Concrete Slab | Around $6 | Durable with moderate installation cost; low maintenance |

Best Applications

You need to pick the right material for your space. For busy places like stores or schools, plywood and OSB are strong and not too expensive. In wet rooms like bathrooms or basements, cement board, MgO board, or concrete slab work best. For dry rooms, you can use plywood, OSB, or engineered wood panels. Particle board is only good for dry, low-use rooms.

🏢 High-traffic commercial spaces: Plywood, OSB, cement board, and MgO board

🚿 Wet areas (bathrooms, kitchens, laundry): Cement board, MgO board, concrete slab

🏠 Dry residential rooms: Plywood, OSB, engineered wood panels

💡 Fire safety zones: MgO board, cement board

Note: Always check the rating of your floor sheathing materials. Exterior-rated panels are best for damp or changing weather. Use a moisture barrier for extra safety in wet places.

Choosing Floor Sheathing

Project Needs

First, think about what your project needs. Every building is different, so you must pick the right floor sheathing. Here are some things to think about: You may need the floor to hold heavy things, like in a garage. Some rooms, like basements and bathrooms, get wet. These places need water-resistant materials. You should also think about how much money you want to spend. OSB costs less but might need more fixing. Plywood costs more but lasts longer. Some products are basic, while others are premium. Some OSB panels have special guarantees. Decide if the floor will be seen or just used as a base.

Tip: Always read the manufacturer’s advice for your material. This can help you stop problems like swelling or squeaks.

Environmental Factors

The weather and room conditions matter a lot. In hot and wet places, wood-based sheathing can swell or bend. Engineered panels, cement boards, and MgO boards do better with water. They stay strong and flat. If your area has big changes in temperature or humidity, pick materials that can handle it. Good airflow and moisture barriers help keep your floor safe.

Note: Keep your home between 60°F and 80°F. Try to keep humidity between 30% and 50%. This helps your floor last longer.

Flooring Compatibility

You must match your floor sheathing to your finished floor. Plywood and OSB work well with hardwood, tile, and carpet. Concrete slabs are good for tile and carpet. They can also work for some hardwood if you prepare them. For tile, you may need cement board or a special layer under it. Always make sure your subfloor is flat, dry, and steady before you add the top floor.

Finished Flooring | Compatible Sheathing Materials |

|---|---|

Hardwood | Plywood, OSB, Engineered Panels |

Tile | Cement Board, Concrete, Plywood |

Carpet | Plywood, OSB, Concrete |

A strong subfloor helps your finished floor look nice and last longer. Always follow the flooring maker’s steps for best results.

When you pick floor sheathing, think about what your project needs. You should also think about the room and how much money you have. Each material is best for certain places. For example:

Use panels that resist water in bathrooms or basements.

Choose strong boards if you have heavy things or lots of people walking.

Make sure the base matches your top floor for good results.

OSB is a cheaper choice, but special boards work for special jobs.

Always get your subfloor ready the right way. Ask an expert if you are not sure.

FAQ

What is the best floor sheathing for wet areas?

You should use cement board or MgO board in wet areas. These materials resist water, mold, and rot. Concrete slab also works well in basements or bathrooms. Always add a moisture barrier for extra protection.

Can you use OSB instead of plywood for subfloors?

Yes, you can use OSB for most subfloors. OSB costs less and supports heavy loads. You must seal the edges to stop water damage. Plywood handles moisture better, so use it if you expect leaks.

How thick should floor sheathing be?

Most homes use panels that are 5/8 inch or 3/4 inch thick. Thicker panels give you a stronger floor. Always check your local building code for the right thickness.

Does floor sheathing affect sound and heat?

Yes! Some materials, like plywood and MgO board, help block sound and keep heat inside. You can add insulation under the sheathing for better results.

Can you install tile directly on plywood?

You should not install tile right on plywood. Plywood moves with moisture and temperature changes. Use a cement board or a tile backer board over the plywood for a flat, stable base.

Strength and Durability

Strength and Durability