17 Aug Magnesium Wall Board Uses In Commercial Buildings

Table of Contents

Magnesium wall board is used in many commercial buildings. It resists fire, lasts a long time, and helps keep spaces healthy. This board has magnesium oxide inside. That makes it non-combustible and able to handle heat over 1,000°F for hours. Builders pick magnesium wall board to follow strict safety rules. They also use it to make strong and clean spaces. More projects now focus on green building and safety. So, knowing about the board’s uses, strengths, and how to choose it is important for good results.

Key Takeaways

Magnesium wall board is tough and does not burn easily. It does not get damaged by water. This helps buildings stay safe and last longer.

You can use it in many places like walls and ceilings. It also works for floors and cabinets. It helps rooms stay clean and quiet.

The board is good for the environment. It uses natural minerals and makes less pollution than other things.

You can install it with simple tools. You need to control moisture and take care of it often. This helps the board last a long time.

It costs more at first, but it saves money later. It needs fewer repairs and makes buildings safer.

What Is Magnesium Wall Board?

Composition

Magnesium wall board is made from a few main things. The biggest part is magnesium oxide. This mineral makes the board strong and steady. Magnesium sulfate helps the board stay tough and not get damaged by water or fire. Fiberglass mesh is inside to make the board bend without breaking. It also helps stop cracks, which is good if there are earthquakes. Water-resistant agents keep out mold and water. Smoothening agents make the board easy to touch and finish. The board has very little chloride ion, so it will not rust as time goes on.

Magnesium wall board is made with special minerals and other things. These make it strong, safe, and last a long time.

Component / Property | Description / Role |

|---|---|

Magnesium Oxide (MgO) | Provides strength and stability to the boards. |

Magnesium Sulfate (MgSO₄) | Enhances toughness, water resistance, and fire resistance. |

Fiberglass Mesh | Adds strength, flexibility, and crack resistance, useful in seismic zones. |

Water-Resistant Agents | Prevent water damage and mold growth. |

Smoothening Agents | Improve handling and surface finish. |

Chloride Ion Content | Very low (0.01%), preventing rust over time. |

Key Properties

Magnesium wall board is special because of its strong features. It does not catch fire, even when it gets very hot. The board does not get bigger or change shape when wet. It stays strong in places like bathrooms and kitchens. Builders use it for walls, ceilings, and floors in many buildings.

Physical / Mechanical Property | Typical Value |

|---|---|

Flexural Strength | 11 MPa |

Impact Strength | 20.3 KJ/m² |

Apparent Density | 1049 kg/m³ |

Moisture Content | 9% |

Drying Shrinkage | 0.2% |

Swelling Rate | 0.4% |

Holding Bolt Strength | 49 N/mm |

Thermal Conductivity Coefficient | 0.206 W/(m·K) |

Combustion Property | A1 Grade (non-combustible) |

Magnesium wall board follows strict safety and quality rules. It passes fire tests like EN 13501-1 and ASTM E119. Groups such as ICC-ES and INTERTEK check if the board is strong and lasts long. Factories use ISO 9001 rules to keep the board good. These certificates show the board is safe for buildings and meets the rules.

Applications in Commercial Buildings

Walls and Partitions

Magnesium wall board is a good choice for walls. It is used in offices, schools, and stores. These boards stop fire and water from causing damage. They help keep mold away and make the air cleaner. Builders like them because they last long and are simple to put up. The boards also help the planet since they use green materials.

Application Aspect | Description |

|---|---|

Fire Resistance | Magnesium wall boards do not burn easily, so buildings are safer. |

Moisture Resistance | They keep out water and mold, which is good for wet places. |

Durability | These boards last a long time in busy areas. |

Eco-friendliness | They are made from green materials, which helps the earth. |

Ease of Installation | They are light and easy to put up, so work is faster. |

Health Benefits | They stop mold and bugs, so people breathe better air. |

Sound Insulation | They help keep rooms quiet by blocking noise. |

Magnesium wall board makes rooms safe, quiet, and healthy for everyone.

Ceilings and Soffits

Ceilings and soffits need strong boards. Magnesium wall board is a smart pick for this job. It can stop fire for up to four hours. The board does not burn or make much smoke. It stays strong even when it is hot or wet. This is why hospitals, hotels, and malls use it.

Does not burn and is safe for fire-rated ceilings

Makes little smoke if there is a fire

Strong and does not break easily

Keeps out water and does not swell

Light and simple to install

These things help keep people safe and lower repair costs.

Exterior Cladding

Magnesium wall board is also used outside on buildings. The panels do not burn, even in bad fires. They are strong and do not scratch or break easily. The boards can handle rain, sun, and wind. They also stop bugs and fungus from hurting the building. The thick boards help keep noise out.

Does not burn and has top fire safety

Very strong and keeps its shape

Does not scratch or break from weather

Stops bugs and fungus from causing harm

Blocks sound for quieter rooms

Good for the earth and has no bad chemicals

Easy to put up and can look many ways

Magnesium wall board works with brick, metal, tile, and more. Builders save time and money since it goes up fast and needs no special tools.

Flooring and Subflooring

Floors in busy places need to be tough. Thick magnesium wall board is used under many floor types. The boards are very strong and do not bend or swell when wet. They stop fire, mold, and mildew, so floors last longer.

Very strong and lasts in busy places

Keeps out water and does not rot

Light and easy to move

Stops mold for cleaner air

Some boards for subfloors have extra fiberglass and are thicker. This makes them great for malls, offices, and hospitals.

Cabinets and Panels

Magnesium wall board is good for cabinets and wall panels. It does not burn, get wet, or grow mold. This makes it perfect for kitchens, bathrooms, and busy places. The boards do not crack or get eaten by bugs. The smooth surface is easy to paint or cover.

Safe from fire for kitchens and offices

Keeps out water and mold in wet rooms

Lasts long and bugs do not eat it

Light and easy to put in place

Smooth for paint or other finishes

Good for the earth and can be recycled

Blocks noise and does not scratch in busy areas

Magnesium wall board helps builders make safe, nice, and strong rooms in commercial buildings.

Magnesium Wall Board Benefits

Fire Resistance

Fire Resistance

Magnesium wall board is great at stopping fire. Builders use it to keep people safe in big buildings. These boards do not burn and can block fire for up to four hours. Their special mix helps them pass hard fire tests like ASTM E84-24 and EN 13501-1+A1:2010. Many boards get top safety marks like UL 055 and ASTM A+. The table below shows how well these boards work:

Material | Fire Resistance Rating (Hours) | Non-Combustible | Smoke/Toxic Fumes |

|---|---|---|---|

Magnesium oxide boards | 1 to 4 | Yes | No |

Fire-resistant boards help keep people and buildings safe in places like offices, hospitals, and schools.

Moisture and Mold Resistance

Magnesium wall board works well in wet places. It keeps out water and mold better than gypsum or cement boards. There are two main types: magnesium sulfate boards and magnesium chloride boards. Magnesium sulfate boards stay strong in humid air and do not soak up much water. New ideas have made magnesium chloride boards better, so both types are good for big buildings.

Stops mold and mildew from growing

Stays strong in damp rooms

Lighter and stronger than gypsum or cement boards

These things make the board a smart pick for bathrooms, kitchens, and health care rooms.

Sound and Heat Insulation

Magnesium wall board helps keep rooms quiet and warm. It blocks noise between rooms and keeps heat inside. The table below shows how well it blocks sound:

Assembly Type | Sound Insulation Value | Notes |

|---|---|---|

Wall assemblies (UL-rated) | STC 53 – 54 | Exceeds building code requirements |

Floor assemblies with MgO sheathing | STC 53, IIC 72 | ASTM tested |

Standard 6mm MgO board | 29 dB | Single board |

Partition system (double-sided 9mm boards + 75mm keel + 50mm rock wool) | >42 dB | Enhanced soundproofing |

Good sound and heat insulation make buildings nicer and more comfortable for everyone.

Environmental Impact

Magnesium wall board is good for the earth. It takes less energy to make than gypsum boards, so it makes less CO2. When it dries, the board even soaks up some CO2. The stuff used to make it comes from safe, natural places. When the board is old, it can be used again or recycled. It does not let out bad gases or toxins when thrown away.

Made from safe, natural minerals

Recyclable and landfill-friendly

No toxic chemicals or VOCs

These things help make buildings safer, healthier, and better for the planet.

Installation and Challenges

Installation Practices

Installers get the area ready by moving things out of the way. They check if the wall framing is strong enough. They measure and mark where the boards will go. Workers use tools like a tape measure, level, knife, saw, and safety gear. To cut the boards, they score and snap with a knife or use a fine saw. Small gaps are left between boards and edges so the boards can move and not crack. Installers use screws that do not rust and put them 12 to 16 inches apart. The screws must be even with the board. Joints are overlapped and not lined up in a row. Workers put fiberglass mesh tape and joint compound on the seams. When the compound dries, they sand it to make it smooth. Holes for outlets and pipes are planned and cut before putting up the boards. Safety is important, so workers wear masks, goggles, and gloves. They follow building rules and keep the area clean and with fresh air.

Tip: Let the boards sit in the room for a few days before putting them up. This helps stop small cracks from forming.

Moisture Management

Water can hurt wall boards if not handled right. Installers make sure the surfaces are dry and clean first. Boards need time to get used to the room’s air before going up. Workers use special joint compounds and sealants made for magnesium oxide boards. Screws or anchors that do not rust help stop damage. Gaskets keep water away from outlets and pipes. A small gap between the board and floor keeps water from soaking up. After the boards are up, workers check often for water problems. Good airflow keeps the boards dry and strong.

Make sure surfaces are dry and clean.

Use sealants made for magnesium oxide boards.

Use gaskets to protect outlets and pipes.

Leave a gap between boards and the floor.

Check for water damage often.

Keep air moving to lower humidity.

Maintenance

Taking care of wall boards helps them last longer. Workers look for signs of water, cracks, or rust. They fix joints and seams with the right compounds. If a board is damaged, they replace it fast to stop bigger problems. Cleaning with a damp cloth gets rid of dust and dirt. Workers do not use strong chemicals that could hurt the board. In wet places, they check metal parts for rust and use stainless steel if needed. Checking and fixing things often helps the boards stay strong and the building safe.

Maintenance Task | Description |

|---|---|

Inspect for moisture | Look for stains, swelling, or soft spots |

Repair joints/seams | Use the right compounds to patch |

Replace damaged boards | Take out and put in new boards if needed |

Clean surfaces | Wipe with a damp cloth, skip harsh cleaners |

Check metal fixtures | Watch for rust, use stainless steel if needed |

Ventilate spaces | Move air to keep humidity low |

Note: Checking and fixing wall boards often helps avoid big repairs and keeps everyone safe.

Value in Commercial Projects

Cost vs. Lifecycle

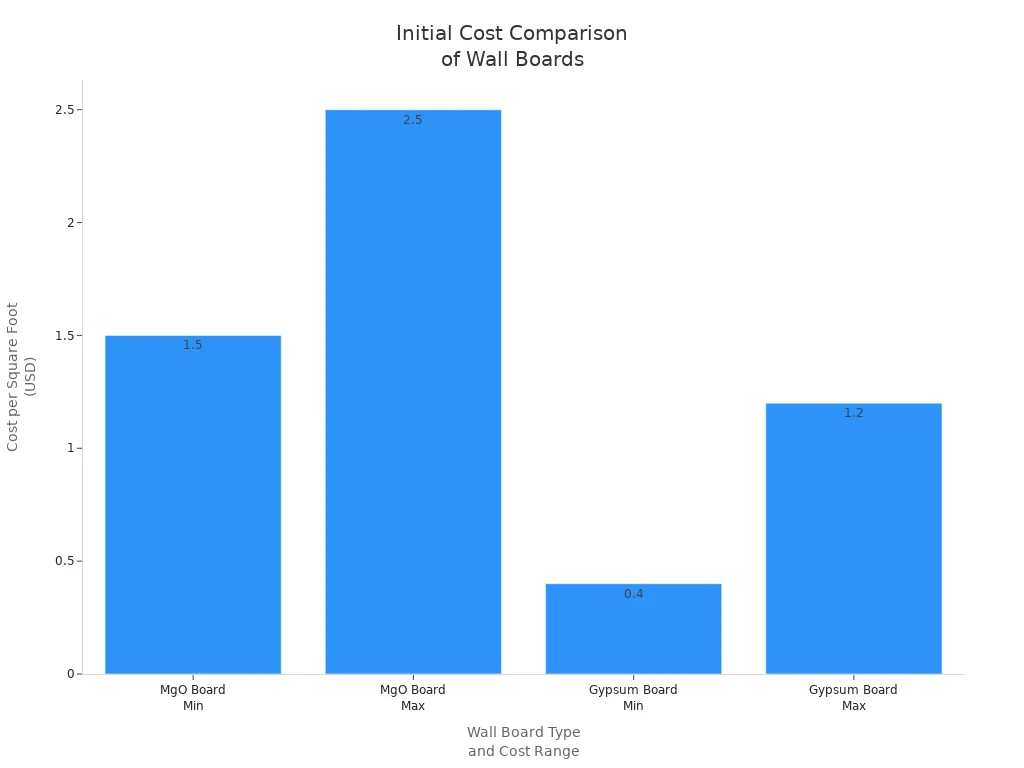

Builders often look at prices before picking wall boards. Magnesium oxide boards cost more than gypsum boards at first. This is because they are harder to make and use green materials. Putting them in can take longer since they are heavier. The table below shows how the costs are different:

Magnesium Oxide (MgO) Boards | Traditional Gypsum Boards | |

|---|---|---|

Initial Cost | $1.50 – $2.50 per square foot | $0.40 – $1.20 per square foot |

Manufacturing Cost | Higher due to complex processing and eco-friendly materials | Lower due to mass production and cheaper materials |

Installation | Heavier and more labor-intensive, increasing installation costs | Lightweight and easier to install, reducing labor costs |

Even though you pay more at first, magnesium oxide boards last longer. They stay strong and do not change shape, even after many years. Builders do not see much warping or mold. The boards stop fire and water, so there are fewer repairs. These things help save money over time.

Boards stay strong for many years.

Tests show they do not change much in tough places.

Boards do not warp or get moldy.

They stop fire for up to 4 hours.

They keep water out and buildings dry.

There is less fixing or replacing needed.

ROI

People who build or own buildings want good value. Magnesium oxide boards give many long-term benefits:

Boards stop fire, water, and mold to keep buildings safe.

Building work can go on in any weather, which saves time.

Panels let workers build upper floors without waiting for drying.

Boards stay strong during and after building.

Panels can be left out for months and still have a warranty.

Using these boards can lower insurance costs by meeting fire rules.

Strong boards mean less fixing and better protection.

You can put cladding right on, which saves money and time.

Picking strong boards helps owners save money over the years. Good boards make buildings safer and give better value for every dollar spent.

Magnesium wall boards help buildings follow tough safety and green rules. They do not burn, get moldy, or let bugs in. This makes them good for places like offices and schools. Builders like that they are strong and keep out water. The boards also help save energy. Using them makes the air inside cleaner and cuts down on repairs. Many experts say these panels are great because they stop fires, are simple to put up, and last a long time in new buildings.

FAQ

What makes magnesium wall board safer than gypsum board?

Magnesium wall board resists fire and does not burn. It blocks smoke and toxic fumes. Builders use it in places where safety rules are strict. The board helps keep people safe during emergencies.

Can magnesium wall board be used in wet areas?

Yes, magnesium wall board works well in bathrooms, kitchens, and laundry rooms. It does not swell or grow mold. Water-resistant agents protect the board from damage.

Tip: Always check for leaks and keep air moving to help the board last longer.

How does magnesium wall board help the environment?

Magnesium wall board uses natural minerals. Factories make it with less energy, so it creates less pollution. The board can be recycled or reused. It does not release harmful chemicals.

Feature | Environmental Benefit |

|---|---|

Low energy use | Less CO₂ produced |

Recyclable | Reduces landfill waste |

No VOCs | Cleaner indoor air |

Is magnesium wall board easy to install?

Installers find magnesium wall board light and simple to cut. They use basic tools like a knife and saw. The board fits many building systems. Workers finish jobs faster and with fewer mistakes.

What maintenance does magnesium wall board need?

Workers inspect boards for cracks, water spots, or rust. They clean with a damp cloth. Damaged boards get replaced quickly. Stainless steel screws help prevent rust. Regular checks keep the board strong.

Note: Quick repairs and cleaning help the board last for many years.

Fire Resistance

Fire Resistance