31 Aug Comparing Quality Standards of Magnesium Wall Boards and Other Materials

Table of Contents

- 1 Key Takeaways

- 2 Fire Resistance

- 3 Moisture and Mold

- 4 Durability

- 5 Environmental Impact

- 6 Quality Standards and Certification

- 7 Drawbacks

- 8 FAQ

- 8.1 What certifications should builders look for when choosing magnesium wall boards?

- 8.2 Are magnesium wall boards safe for people with allergies?

- 8.3 How do magnesium wall boards handle moisture compared to gypsum boards?

- 8.4 Can magnesium wall boards be recycled?

- 8.5 Do magnesium wall boards cost more than other wall boards?

Magnesium wall boards have special features compared to gypsum and cement boards. Quality standards for wall boards check how well they work, how safe they are, and what certifications they have. These standards look at fire resistance, moisture and mold protection, durability, environmental impact, cost, and official certification.

Gypsum boards are the most used choice in the world because they are cheaper. Magnesium boards do better in many ways. The construction industry uses famous quality standards like ASTM C1396 and ASTM E119. These standards test wall boards for fire safety and how they are made. Meeting these standards helps builders and designers trust the material. It also helps keep people safe.

Key Takeaways

Magnesium wall boards are very good at stopping fire. They stay strong and do not burn, even when it is very hot. This helps keep buildings safer. These boards do not get damaged by water easily. They also stop mold and mildew better than gypsum and fiber cement boards. This makes them great for places that are wet or have a lot of moisture. Magnesium boards are stronger and last longer. They do not break or swell easily. They are also good for the environment. They are made from natural minerals and do not have bad chemicals. They help keep the air inside buildings cleaner. Builders should pick magnesium wall boards that have passed strict quality checks. This makes sure the boards are safe, work well, and can be trusted.

Fire Resistance

Magnesium vs. Gypsum

Fire resistance is very important for wall boards. Magnesium oxide boards and gypsum boards go through tough fire tests. ASTM E136, EN ISO 1716, EN 13501, and PAS 670:2021 are used to check fire safety.

MgO boards do well in fire tests. Innovation MgO 1/2″ wall panels pass ASTM E136 as noncombustible. They do not burn at temperatures up to 800°C. MgO panels pass ASTM E119 for 1-hour and 2-hour fire ratings. They do not need tapes, sealants, or extra treatments. This makes installation faster and saves money. MgO boards char instead of burning. This helps absorb heat and slows fire and smoke.

Gypsum boards, like Type X and Type C, have moderate fire resistance. They can resist fire for up to four hours. They often need extra treatments to reach these ratings. Gypsum boards burn faster and lose strength when wet.

The table below shows flame spread index and fire ratings for magnesium, gypsum, and cement boards:

Board Type | Flame Spread Index (FSI) | EN 13501-1 Rating | Additional Fire Performance Details |

|---|---|---|---|

Magnesium Sulfate (MgO) | 0 to 25 | A1 (Non-combustible) | Handles heat up to 1200°C; ASTM E84 FSI 0; Smoke Developed Index low; Passes ASTM E136 non-combustibility test |

Gypsum Boards | Moderate (varies by type) | Class A to C | Fire resistance up to 4 hours (Type X, Type C); Moderate flame spread; ASTM E84 tested but lower than MgO boards |

Cement Boards | Lower fire resistance | Lower than MgO | Less effective fire resistance compared to MgO boards |

MgO boards have a 0/0 rating on the ASTM E84 Flame Spread and Smoke Developed Index. This means they make almost no smoke during fires. Gypsum boards make more smoke and can add fuel in a fire.

MgO boards release water vapor during fires. They can give off up to 30 lbs. of water vapor. This helps cool and control the fire. It also helps lower smoke spread. Gypsum boards do not have data on water vapor. They break down when exposed to fire and moisture.

Tip: Builders should always check if MgO boards meet all fire safety standards. Some boards may not meet every requirement, so reviewing certifications is important.

Magnesium vs. Cement

Cement boards have some fire resistance. Magnesium wall boards do better in most tests. MgO panels get an A1 non-combustible rating under EN 13501-1. They pass ASTM E136 non-combustibility tests. Cement boards do not reach the same fire safety level. They often have a lower flame spread index.

MgO boards handle heat up to 1200°C. They keep their shape under full load during fire tests. Cement boards lose strength faster. They do not absorb as much heat. MgO panels do not need extra fireproofing. Cement boards sometimes need more treatments.

MgO boards protect better against fire and smoke. They slow down flames and keep smoke low. Cement boards have less fire resistance. They may not meet the highest fire safety standards.

Moisture and Mold

Magnesium vs. Fiber Cement

Magnesium vs. Fiber Cement

Magnesium oxide boards are very good at stopping moisture, mold, and mildew. Their inorganic structure does not let mold grow. This makes them great for wet places like bathrooms and basements. MgO boards take in only a little water, about 0.34%. Because of this, they keep their shape and strength when wet. Fiber cement boards also resist water but can still soak up some over time. Builders need to seal and check fiber cement boards often to stop water problems.

If fiber cement boards are not sealed, they can get mold or mildew. Water can get inside and cause damage after a while. Newer sulfate-based MgO boards stay dry and strong even in humid places. They do not bend, swell, or rot. This makes them better for places with lots of moisture.

Note: Not all MgO boards work the same way. Boards made with magnesium chloride can soak up water and leak salty liquid. This can cause mold and rust. Newer magnesium oxysulfate boards are better at stopping water and do not have these issues.

Magnesium vs. Gypsum

Gypsum boards soak up much more water than MgO boards. They can take in up to 3% water. When they get wet, gypsum boards swell, break, and can grow mold. Even special moisture-resistant gypsum boards do not work as well as MgO boards. The paper on gypsum boards gives mold food to grow. This makes mold and mildew more likely in damp places.

MgO boards do not feed mold. They stay dry and strong in bathrooms, kitchens, and basements. Lab tests show MgO boards do not get mold, but gypsum boards get wet spots and break down. Quality standards now prefer wall boards that stop water and mold. MgO boards meet these rules better than gypsum or fiber cement boards.

Durability

Impact Strength

Magnesium wall boards are very tough. They can handle strong hits. Tests show magnesium oxide boards reach up to 10 KJ/m2 impact strength. This is much more than gypsum and cement boards. Gypsum boards break or crack when hit. Cement boards are stronger than gypsum. But they are not as strong as magnesium boards.

Board Type | |

|---|---|

Magnesium Oxide | ≥4.5 |

Cement Board | ≥3.5 |

Gypsum Board | ≤1 |

The table shows magnesium oxide boards are the strongest. Builders use them where walls might get hit. Magnesium sulfate boards also fight rust better than other boards. They do not have chloride ions. This means they work well with metal studs and nails. They are good for bathrooms and kitchens. These places have lots of water and metal.

Note: Magnesium chloride boards can make metal parts rust. Magnesium sulfate boards do not cause this problem. They last longer in wet places.

Longevity

Magnesium wall boards last a long time. They do not crack, swell, or grow mold easily. These boards keep their shape in storms or big temperature changes. Gypsum boards break down faster, especially if they get wet. Cement boards last longer than gypsum. But they may need repairs if wet for a long time.

Aspect | Magnesium Oxide (MgO) Boards | Cement Boards |

|---|---|---|

Higher material cost but saves money later | Lower material cost at first | |

Installation | Lighter and easier to cut; installs faster | Heavier and needs more help; takes longer to install |

Moisture Resistance | Great at stopping swelling, mold, and mildew | Stops water but needs sealing or it can have problems |

Durability | Very strong, cracks less, great fire resistance | Strong but wears out more from hits and water |

Long-term Maintenance | Needs less fixing because it stops mold, fire, and water | Needs more fixing if wet for a long time |

Thermal Insulation | Keeps heat in better, saves energy | Keeps heat in okay |

Performance in Extreme Conditions | Stays strong in storms and temperature changes | May need extra help; cracks and water can hurt it |

MgO boards cost more at first but save money later.

They install faster and need less work.

Cement boards need more sealing and fixing in wet places.

MgO boards meet tough rules for strength and care.

Magnesium wall boards are a strong choice for builders. They last a long time and do not rust easily. This makes them smart for many building jobs.

Environmental Impact

Composition

Magnesium wall boards are made from minerals and fiber mesh. They also use magnesium sulfate as a main ingredient. These materials come from nature. They do not have harmful chemicals. The boards do not use formaldehyde or other toxic stuff. This makes them safer for people and the planet.

MgO boards need less energy to make than many other materials. Their process uses natural minerals and makes less pollution. The boards last a long time because they fight fire, water, and pests. Builders throw away less waste over time. Gypsum boards also use less energy and make fewer gases when made. They can be recycled and help save energy in buildings by keeping heat in. Cement boards made with 3D printing have lower carbon emissions and use less energy than regular cement. But it is hard to compare cement, gypsum, and MgO boards directly.

Tip: Builders should check what wall boards are made of. This helps make sure they meet safety and sustainability standards.

Air Quality

Magnesium wall boards help keep indoor air clean. Their makeup stops mold, mildew, and fungus from growing. The boards do not soak up much water. They stay dry in bathrooms and basements. This helps stop mold and keeps the air free from allergens.

MgO boards do not give off harmful gases or VOCs. They do not have formaldehyde or cancer-causing chemicals. People with allergies or asthma can breathe easier with MgO boards. Gypsum boards can soak up water and grow mold. This can make air quality worse and cause health problems. Cement boards do not release VOCs. But they may not stop mold as well as MgO boards.

Quality standards now focus on materials that protect indoor air. Magnesium wall boards meet these standards by staying dry, clean, and safe for people.

Quality Standards and Certification

Industry Standards

Industry Standards

Industry standards help builders pick safe wall boards. Magnesium wall boards must follow strict rules to show they work well. Two big groups make these rules: ASTM in the U.S. and EN in Europe.

ASTM rules check fire, water, and strength.

EN 13501 rules split fire tests into two parts:

Reaction to fire (EN 13501-1) checks if a board helps fire spread. It uses tests like EN ISO 1716 and EN 13823. Boards get a grade from A1 (does not burn) to F (fails).

Resistance to fire (EN 13501-2) checks how long a wall or ceiling stays strong in a fire. The time can be from 15 to 240 minutes.

ASTM E119 checks how long a board can stop fire. ASTM E84 checks how fast flames and smoke move. ASTM E136 checks if a board burns at high heat.

EN rules split up how boards react to fire and how whole walls resist fire. ASTM tests look at the whole wall or ceiling together.

Standard | Region | Focus Area | Key Tests & Ratings |

|---|---|---|---|

ASTM | United States | Fire, moisture, durability | E119 (fire endurance), E84 (flame spread), E136 (combustibility) |

EN 13501 | Europe | Reaction & resistance to fire | EN ISO 1716, EN 13823, A1-F ratings, time intervals |

PAS 670:2021 | UK | MgO board performance | Fire, moisture, durability |

PAS 670:2021 is a rule in the UK for magnesium wall boards. These rules check fire safety, water control, and how long boards last. Groups like ICC-ES and ANSI keep making these rules better.

Tip: Builders should use wall boards that pass ASTM, EN, and PAS rules. These boards have passed hard tests for safety and strength.

Testing and Verification

Testing makes sure magnesium wall boards are safe and strong. Special labs do many tests to check strength, fire safety, and how long boards last.

Labs test how much a board bends, how it handles freezing, how it moves with water, how much water it soaks up, and how strong it is when hit.

Fire tests include ASTM E84, ASTM E119, ASTM E136, and EN ISO 1716.

ICC-ES rules like AC386 help test magnesium boards.

Safety checks look for VOCs, asbestos, chloride, formaldehyde, and radioactivity.

ILAC-MRA labs give trusted test results around the world.

Magnesium wall boards are often tested for:

How much they dent

How well screws stay in

How strong the glue is

How much they bend in wet air

How much weight they hold

How they handle wind

How they work as a wall system

How long they last

Technical sheets show test results and product facts. Builders should ask for these sheets before picking a wall board.

Note: Always look for certifications from trusted labs. Look for marks like ASTM, EN 13501, PAS 670:2021, ICC-ES, and ILAC-MRA. These marks show the wall board meets high quality rules.

Drawbacks

Quality Variation

Magnesium wall boards can be different in quality. Some are made in other countries. These factories do not always use the same rules. Boards from the same company can look or work differently. Builders and architects worry about this. They want every board to meet the right standards.

Most magnesium wall boards come from other countries. Long shipping and storage can change how boards work.

No set rules mean some panels are weaker or take in more water.

Some boards get worse during shipping. This makes it hard for builders to trust them.

Local companies like ZS2 Technologies use local materials and strict checks. Their boards work better and are always available.

Issue | Overseas MgO Boards | Locally Made MgO Boards |

|---|---|---|

Quality Consistency | Low | High |

Supply Reliability | Variable | Reliable |

Manufacturing Standards | Not uniform | Strict |

Note: Builders should ask for test reports and certifications. This helps make sure the boards are good quality.

Moisture Issues

Some magnesium wall boards have water problems. Boards made with magnesium oxychloride cement can leak salty water in wet air. People call this “crying” or “sweating.” This water can make mold grow on wood and rust metal. Sometimes, the boards get damaged too.

MOC boards with lots of chlorine leak salty water when it is humid.

Mold and rust can show up on things nearby.

Magnesium oxysulphate boards do not have this problem. They stay dry and do not let mold or rust grow.

The chance of water problems depends on how the boards are made and what minerals are used.

The boards usually stay strong, but water drops and leaks are the main problem. Builders should check what kind of magnesium wall board they use. They should ask about how well it keeps out water.

Tip: Boards with MOS formulas keep out water better and help stop common problems.

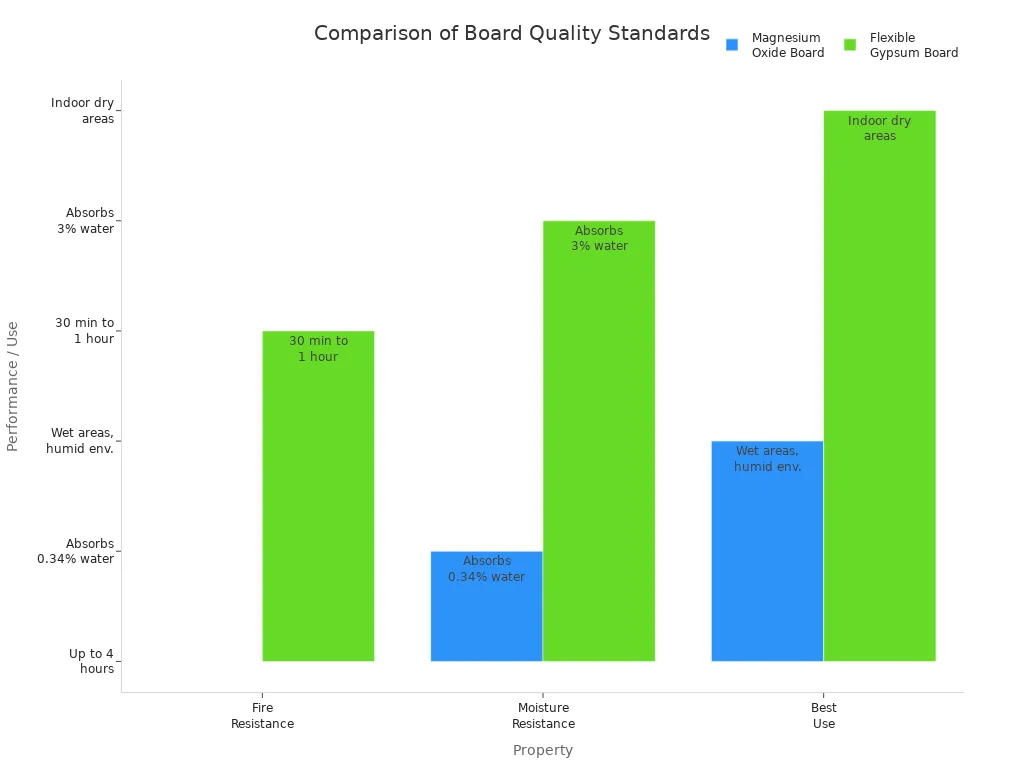

Magnesium wall boards work well for fire, strength, and water safety. The table below shows how they stack up against gypsum boards:

Feature | Magnesium Wall Board (MgO) | Gypsum Board |

|---|---|---|

Fire Resistance | Up to 4 hours fire rating, non-combustible | Typically 30 minutes to 1 hour |

Durability | High impact resistance, strong, supports heavy fixtures | Softer, prone to cracking and damage |

Moisture Resistance | Excellent, resists mold and mildew, maintains integrity in humid conditions | Poor, swells, warps, and disintegrates when wet |

Environmental Impact | Eco-friendly, absorbs CO2 during curing, highly recyclable | Higher carbon footprint, limited recyclability |

Cost-effectiveness | Higher upfront cost but lower maintenance and longer lifespan | Lower upfront cost but higher maintenance and replacement costs |

Experts say you should pick wall boards with strong certifications. These include EPA TSCA Title VI, CANFER, VOC Green, and structural panel certifications. These programs help keep people safe and protect the environment. They also make sure the boards meet quality rules. Builders should check for these certifications. It is smart to talk to experts before picking wall boards.

FAQ

What certifications should builders look for when choosing magnesium wall boards?

Builders need to look for ASTM, EN 13501, PAS 670:2021, and ICC-ES marks. These marks mean the board passed tests for fire, water, and strength.

Are magnesium wall boards safe for people with allergies?

Magnesium wall boards do not let out VOCs or formaldehyde. They help keep the air inside clean. People with allergies or asthma can breathe better with these boards.

How do magnesium wall boards handle moisture compared to gypsum boards?

Feature | Magnesium Wall Board | Gypsum Board |

|---|---|---|

Moisture Damage | Rare | Common |

Mold Growth | Unlikely | Likely |

Magnesium boards stop moisture and mold. Gypsum boards get wet and mold grows on them.

Can magnesium wall boards be recycled?

Magnesium wall boards are made from natural minerals.

Many boards can be recycled after people use them.

Recycling helps cut down on waste and supports green building.

Do magnesium wall boards cost more than other wall boards?

Magnesium wall boards cost more at first. They save money later because they last longer and need fewer repairs.

Magnesium vs. Fiber Cement

Magnesium vs. Fiber Cement Industry Standards

Industry Standards