13 Feb A Guide to Magnesium Sulfate Board and Magnesium Oxide Board Differences

Table of Contents

You might wonder what makes magnesium sulfate board and magnesium oxide board different. The answer starts with what chemicals they are made of and how they act in real life. Builders and architects pick these materials for different reasons. For example, magnesium oxide board is strong and can be used in many ways. It does not break or scratch easily. You will see it in busy places in homes and other buildings. Magnesium sulfate board has its own special benefits too. It is important to know which board is best for your needs.

Key Takeaways

Magnesium sulfate board works well in wet places. It does not soak up water, so it is good for bathrooms and kitchens.

Magnesium oxide board is very strong and does not burn easily. Use it where fire safety matters, like in schools and hospitals.

Think about the environment when picking a board. Magnesium sulfate board is better for nature and makes less carbon.

Both boards are safe for the air inside your home. They do not let out bad chemicals and stop mold and mildew from growing.

Always look at local building rules before you pick a board. Make sure it fits what your project needs.

Magnesium Sulfate Board and Magnesium Oxide Board: Key Differences

Quick Comparison Overview

You might want to see how magnesium sulfate board and magnesium oxide board are not the same. The table below shows their main features in a simple way:

Feature | Magnesium Sulfate Board | Magnesium Oxide Board |

|---|---|---|

Composition | Magnesium, sulfur, and oxygen | Magnesium oxide, magnesium chloride, and fibers |

Rust Resistance | Does not cause rust due to lack of chloride | Can cause rust due to magnesium chloride |

Water Resistance | Highly resistant; does not swell or lose shape | Less resistant; can be affected by moisture |

Environmental Impact | Made with fewer harmful materials; eco-friendly | Chloride content can harm the environment |

Moisture Resistance | Better; does not absorb water | Can have water problems; absorbs water easily |

Likelihood of Swelling | Rare | Happens often |

Tip: If you build things, use this table to help pick the right board for your job.

Main Distinctions

It is important to know how magnesium sulfate board and magnesium oxide board are different before you choose. Here are the main things to remember:

Magnesium sulfate board does not soak up water. You can put it in bathrooms, kitchens, or other wet places. It will not get bigger or change shape.

Magnesium oxide board can soak up water. It might get bigger or weaker if it stays wet for a long time.

Magnesium sulfate board does not make metal rusty. It does not have chloride, so it is safe with metal parts.

Magnesium oxide board has magnesium chloride. This can make metal fasteners or frames rusty.

Both boards stop fire, but magnesium oxide board can take more heat for longer. You might want it where fire safety is very important.

Magnesium sulfate board is better for the earth. It uses less harmful stuff and does not hurt nature as much.

Magnesium sulfate board stays strong when wet. Magnesium oxide board can get weak if it gets wet a lot.

Note: Pick the board that fits your space. For wet rooms, magnesium sulfate board is best. For places where you need fire safety, magnesium oxide board is a good pick.

Now you know how these boards are not the same. This helps you choose the right one for your next building or fixing project.

Composition and Manufacturing

Magnesium Sulfate Board Composition

Magnesium Sulfate Board Composition

Magnesium sulfate board is made from several ingredients. Each ingredient helps the board work well in tough places. The table below shows what goes into the board and why each part is important:

Ingredient | Role in Composition |

|---|---|

Magnesium oxide (MgO) | Makes up most of the board |

Magnesium sulfate (MgSO₄) | Holds everything together |

Wood dust or cellulose | Makes the board flexible and textured |

Perlite or vermiculite | Helps with insulation and fire safety |

Glass fiber mesh | Makes the board stronger and tougher |

This board is strong and does not rust. It uses sulfate salts that do not cause corrosion. These salts help the board stay safe in wet places. You can use it in bathrooms, kitchens, and other damp rooms.

Magnesium Oxide Board Composition

Magnesium oxide board uses different ingredients. Here are the main things inside:

Magnesium Oxide (MgO): Gives the board strength and fire safety.

Magnesium Chloride (MgCl2): Holds the board together but can cause rust.

Perlite: Makes the board lighter and helps with insulation.

Wood Fiber: Adds strength and flexibility.

Vermiculite: Helps protect against fire.

Glass Mesh: Makes the board tougher and stronger.

This board is strong and handles heat well. But magnesium chloride can make metal parts rusty. You should think about this if you want the board to last a long time.

Impact on Performance

The chemicals in each board change how they work. Magnesium sulfate board is better at handling water. It does not swell or lose its shape when wet. This makes it last longer in damp places. Magnesium oxide board can soak up water. It might show white spots and get weaker if not protected. The table below compares water resistance and strength:

Board Type | Water Resistance | Mechanical Strength |

|---|---|---|

Magnesium Sulfate | Works best in wet places | Less likely to rust because of low alkalinity |

Magnesium Oxide | Soaks up water and may show white spots | Not good for wet places unless protected |

Sulfate salts in magnesium sulfate board stop rust and keep it strong for years. It resists moisture and stays stable. Magnesium oxide board is good for dry places and fire safety. But you need to keep it away from water to make it last.

Tip: If you need a board for wet rooms, magnesium sulfate board is better at resisting water and staying strong over time.

Performance and Durability

Strength Comparison

Strength Comparison

You want a strong board for your project. Magnesium oxide board is tough and strong. It works well in busy places. It gives extra support where needed. Magnesium sulfate board is also strong. It is best for places that need strength and can get wet. Both boards can handle daily use. Magnesium oxide board lasts longer in rough places.

Water and Moisture Resistance

It is important for building materials to resist water. You want your board to stay strong when wet. Magnesium sulfate board is best at stopping water. It does not soak up water easily. It keeps its shape and strength in wet rooms. Magnesium oxide board also resists water well. It does not take in much water for short times. It keeps its shape. In humid places, magnesium sulfate board does not have the “weeping problem.” Magnesium oxide board can have this issue. Magnesium sulfate board is better for long-term water resistance.

Here is a simple table to compare both boards:

Board Type | Moisture Resistance Level | Best Use Areas |

|---|---|---|

Magnesium Sulfate Board | Excellent | Wet rooms, kitchens |

Magnesium Oxide Board | Good | Dry or semi-damp areas |

Tip: Pick a board with high moisture resistance for wet rooms.

Dimensional Stability in Wet Conditions

You want your board to keep its size when wet. Magnesium oxide board does not bend or swell. It stays flat and strong in humid weather. Plywood can bend, but magnesium oxide board does not. Magnesium sulfate board also does not swell or shrink. Both boards are good for places that need water resistance and strength.

Both boards help your walls and ceilings last longer. You do not need to worry about big changes in size or shape.

Fire Resistance

Fire Performance of Magnesium Sulfate Board

You want your building to be safe from fire. Magnesium sulfate board is very good at stopping fire. This board can take a lot of heat and not break. It keeps its shape and stays strong during a fire. Builders use magnesium sulfate board where fire safety is important.

International rules show how well this board works. The table below shows the main fire safety tests and ratings:

Certification Standard | What It Tests | Fire Rating |

|---|---|---|

ASTM E84-24 | Handles over 750°C (1,382°F) for 30 minutes without damage | A1 |

EN 13501-1+A1:2010 | Follows strict fire safety rules | A1 |

EN ISO 1716 | Confirms fire safety | N/A |

You can see that magnesium sulfate board gets top fire safety ratings. It does not burn or make bad smoke. You can put this board in walls, ceilings, and floors to make your building safer from fire.

Tip: If you want the best fire safety, magnesium sulfate board is a smart pick.

Fire Performance of Magnesium Oxide Board

Magnesium oxide board is also great at stopping fire. This board stands up to flames and heat for a long time. You can use it in places where fire safety is needed, like stairs or escape paths. Magnesium oxide board does not melt or catch fire easily.

You get strong fire safety with magnesium oxide board. It passes the same tough tests as magnesium sulfate board. Builders use it in schools, hospitals, and offices to make them safer from fire. You can trust this board to protect people and buildings.

Magnesium oxide board keeps its shape during a fire.

You do not need extra coatings for fire safety.

This board helps slow down flames.

Note: Both boards are very good at stopping fire, but magnesium oxide board is best for places where you need extra fire safety.

You can pick either board for fire safety, but always check your local building rules before you start.

Environmental Impact and Safety

Sustainability

Sustainability

You want to pick materials that are good for the earth. Magnesium oxide board is better because it has a low carbon footprint. When it dries, it takes in CO2 from the air. This helps lower greenhouse gases. Gypsum boards use more energy and do not take in CO2. Magnesium sulfate board uses fewer bad materials and helps with green building.

Here is a table that shows how magnesium oxide board compares to other materials:

Material Type | CO2 Emissions (kg/t) | Energy Consumption | Resource Consumption |

|---|---|---|---|

Magnesium Oxide (MgO) | 340 | Lower | Less |

Calcium Oxide (CaO) | 740 | Higher | More |

You can see magnesium oxide board uses less energy and fewer resources. Mining magnesite is gentle on nature. Magnesium sulfate board does not let out bad chemicals when made. Both boards help builders make eco-friendly buildings.

Magnesium oxide board traps CO2 while drying.

Both boards use less energy than gypsum boards.

You help nature when you choose these boards.

Indoor Air Quality

You want your rooms to be safe and healthy. Both magnesium sulfate board and magnesium oxide board use safe, natural stuff. They do not have formaldehyde or asbestos. You do not need to worry about breathing bad chemicals.

These boards fight mold and mildew well. Mold resistance helps keep you and your family healthy. Good moisture resistance means the board will not break or let out dust. Both boards help you get LEED points for green buildings.

Made from safe, natural stuff

No dangerous chemicals added

Mold resistance keeps air clean

Helps keep indoor air healthy

Tip: Pick a board that fights mold and moisture for the cleanest air.

Cost and Availability

Price Factors

When you look at magnesium sulfate board and magnesium oxide board, price changes for many reasons. The cost of the materials is important. If magnesium oxide costs more, the board price goes up. How the board is made also matters. Fancy machines and special ways to make it can raise the price of magnesium oxide board.

Prices get higher when more people want the boards. Builders like eco-friendly boards, so magnesium oxide board costs more. The steel industry uses lots of magnesium oxide. This means there is less for making boards. The thickness and size of the board also change the price. Thicker boards cost more because they last longer and are stronger.

Here are the main things that change the price:

Raw material costs

How the board is made

How many people want it

Other uses in factories

Thickness and size

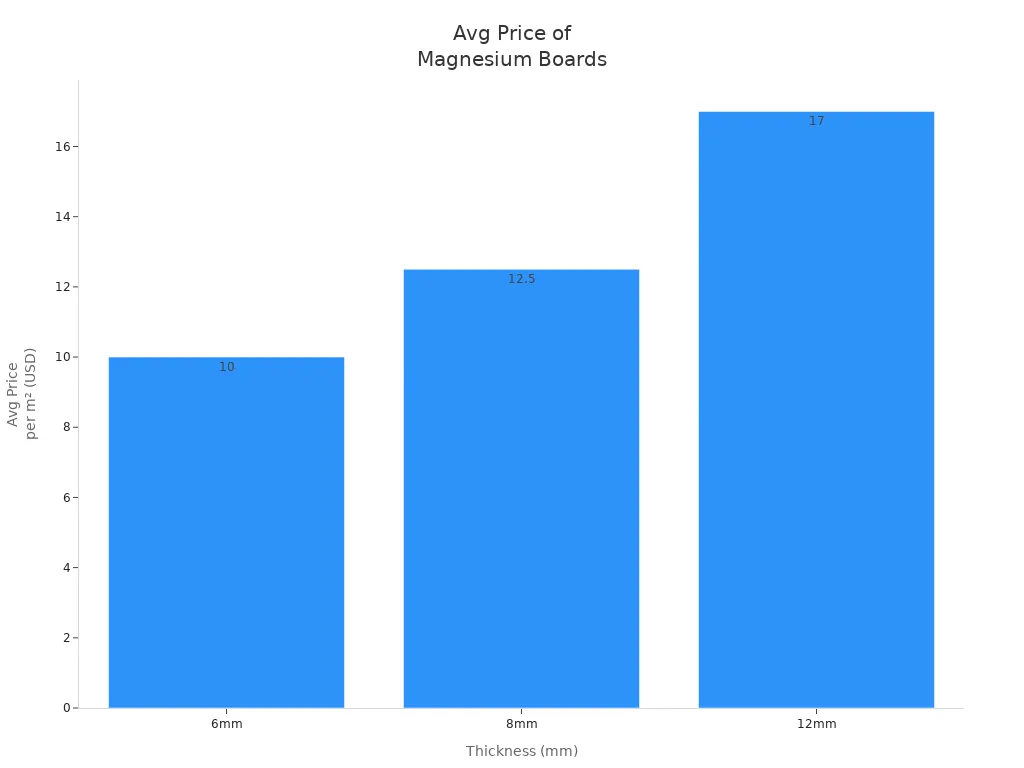

You can see the price for different thicknesses in this table:

Thickness | Price Range (per m²) |

|---|---|

6mm | $8–$12 |

8mm | $10–$15 |

12mm | $14–$20 |

Tip: Thicker boards are stronger but cost more. Pick the thickness that fits your project.

Market Access

You can find magnesium oxide board and magnesium sulfate board in many places. Local and global sellers have these boards for building. Magnesium oxide board is popular because it stops fire and water. Builders use it for safe and green buildings.

In North America, more people want these boards. Many boards come from other countries, so shipping can cost more. In Europe, demand is high, but rules make boards cost more. Asia Pacific and the Middle East are growing markets. There are more sellers and lower prices in these areas.

Chloride-free magnesium oxide board is getting popular. Companies now make boards with special designs and better features. These boards are strong, safe, and good for nature.

Note: Always check local supply and shipping costs before you buy a board for your project.

Pros and Cons of Each Board

Magnesium Sulfate Board Advantages and Disadvantages

Magnesium sulfate board has many good points. It is tough and lasts a long time. The board does not burn or get moldy. It stops mildew and water from causing problems. You can use it in wet places or where safety matters. The board helps keep rooms warm in winter. It also keeps rooms cool in summer. This saves energy and lowers your bills. Making this board puts out less carbon dioxide. You help the earth by using it. You can recycle the board or let it break down. This means less trash goes to landfills.

Here is a table that lists the main good points:

Performance Metric | Description |

|---|---|

Durability | Stops fire, mold, mildew, and water. Lasts longer and makes less waste. |

Recyclability | Can be reused or breaks down, so less trash. |

Energy Efficiency | Keeps rooms warm or cool. Saves energy. |

Low Carbon Emissions | Makes less CO₂ than old materials when made. |

There are some bad points too. The board costs more at first. You pay more than for regular drywall. Some builders do not like the high price. But the board lasts longer and works better.

Tip: Pick magnesium sulfate board if you want something strong and good for the planet.

Magnesium Oxide Board Advantages and Disadvantages

Magnesium oxide board has many good things too. It is very strong and does not break easily. You can use it in busy places like schools and hospitals. It works well in hotels, offices, and apartments. The board holds more weight and does not rip like drywall. It is lighter than other cement boards. This makes it easier to move and use.

Here is a table to show the main good and bad points:

Pros | Cons |

|---|---|

Great at stopping fire | Costs more than gypsum boards |

Saves energy when made | Quality can change depending on the maker |

Makes less waste and traps CO2 when made | Needs special tools or skills to install |

Stops fungus, rot, mildew, allergens, and mold | May not work well in very wet places |

20-30% lighter than other cement boards |

|

There are some bad points with this board. It costs more than gypsum boards. The quality can be different depending on where you buy it. Some boards need special tools or skills to put in. In very wet places, the board may not last as long.

Note: Magnesium oxide board has many good points, but make sure it fits your project.

Applications in Construction

Best Uses for Magnesium Sulfate Board

Best Uses for Magnesium Sulfate Board

Magnesium sulfate board is used a lot in building. It works best where you need something strong and that does not get damaged by water. People use it in homes that save energy, mostly for walls and ceilings. It is also good for modular buildings. These buildings go up fast and make less waste. Pick this board if you want something that stops fire and water.

Energy-saving homes (walls and ceilings)

Modular buildings for quick and green building

Projects that need fireproof and waterproof boards

You can use this board outside too, like on the outside walls or for cladding. It stands up to bad weather, rust, and sunlight. Builders like it because it is good for the earth and can be recycled. It does not make much pollution and helps you get green building points for homes.

These boards can handle bad weather, rust, and sunlight. That makes them good for outside walls and cladding.

Best Uses for Magnesium Oxide Board

Magnesium oxide board is also used in many building jobs. Use it in dry or a little wet places where you want fire safety and a light board. It is great for schools, hospitals, and offices. It works well for inside walls, ceilings, and floors in homes. Use it when you need a strong board but do not want it to touch water.

Inside walls and ceilings

Floors in dry or a little wet rooms

Busy public buildings

Some magnesium oxide boards, like MagPanel®, are good in places with lots of moisture or salt. You can trust these boards for special jobs where you need fire safety and strength.

Choosing the Right Board for Your Project

You have to pick the board that fits your building job. Use this table to see the main things to think about:

Criteria | Magnesium Sulfate Board | Magnesium Oxide Board |

|---|---|---|

Fire Resistance | High | Moderate |

Moisture Resistance | Excellent | Moderate |

Durability | High | Moderate |

Weight | Heavier for thicker | Lighter options |

Strength | Stronger with thickness | Varies with thickness |

Building Codes | Consult local codes | Consult local codes |

Specific Project Needs | Tailored to project | Tailored to project |

If you are building in a wet place, pick a board that does not soak up water and stays strong. If you need a board for heavy jobs, get a thicker one. Always check your local building rules before you start. Ask an expert if you do not know which board is best for your job.

Tip: Think about the earth, fire safety, and your building type when you pick your board.

You now know how magnesium sulfate board and magnesium oxide board are not the same. They have different strength, water resistance, and fire safety. For building projects, pick the board that fits what you need. Look at the table below to see which board is best for wet places or strong walls.

Board Type | Recommended Use |

|---|---|

Magnesium Oxide | Fire safety and strength |

Fiber Cement Board | Fire and water safety |

Both magnesium sulfate board and magnesium oxide board make buildings safer and stronger. Always think about where you will use the board. Ask an expert before you choose which one to use.

FAQ

What makes magnesium sulfate board better for wet areas?

You get better water resistance with magnesium sulfate board. It does not swell or change shape when wet. You can use it in bathrooms, kitchens, or laundry rooms without worrying about damage.

Can you paint or finish these boards easily?

You can paint both boards with regular primers and paints. Make sure the surface is clean and dry before you start. You get a smooth finish that lasts for years.

Do these boards help with fire safety in buildings?

You get strong fire protection from both boards. Magnesium oxide board handles higher heat for longer. You can use either board to meet most fire safety codes.

Are magnesium boards safe for indoor air quality?

You get safe indoor air with these boards. They do not release harmful chemicals. You can use them in homes, schools, or hospitals without worrying about air pollution.

How do you choose the right board for your project?

You should look at your project needs. Pick magnesium sulfate board for wet areas. Choose magnesium oxide board for places where you need extra fire safety or strength.

Magnesium Sulfate Board Composition

Magnesium Sulfate Board Composition Strength Comparison

Strength Comparison Sustainability

Sustainability Best Uses for Magnesium Sulfate Board

Best Uses for Magnesium Sulfate Board