11 Nov A Comprehensive Guide to Magnesium Oxide Wallboard for Beginners

Table of Contents

Magnesium oxide wallboard, also called MgO wallboard, is strong and safe for building. People like it because it does not burn, get wet, or grow mold. Many choose it since it comes from natural minerals. It is good for the environment. More builders want materials that are safe and last a long time. The need for MgO board keeps growing.

The global market size for MgO wallboard was about $2.1 billion in 2023. It could reach $4.3 billion by 2032.

In 2024, the market size was $1.86 billion. Experts think it will keep growing next year.

If you want to learn more, this magnesium oxide wallboard guide will help. It shows why many builders trust this material.

Key Takeaways

Magnesium oxide wallboard is fire-resistant, water-resistant, and mold-resistant. This makes it a safe choice for many building projects.

MgO boards are made from natural minerals and recycled materials. This helps make buildings more eco-friendly and keeps indoor air healthier.

You need the right tools and safety gear to install MgO boards. This helps the job go smoothly and keeps you safe from dust and sharp edges.

MgO boards are better than drywall and cement boards for fire safety and moisture resistance. This makes them great for places with higher risks.

Think about the long-term benefits of MgO boards, like how strong they are and how little upkeep they need, when you plan your building projects.

Magnesium Oxide Wallboard Guide

What Is Magnesium Oxide wallBoard?

You may ask why this material is special. Magnesium oxide wallboard is a panel for walls, ceilings, and floors. People use it in homes, offices, and schools. It stands out because it does not burn, get wet, or grow mold. Builders like it because it is strong and safe. If you want something that lasts and keeps you safe, this is a good pick.

The magnesium oxide wallboard guide shows these boards come from natural minerals. They do not have harmful chemicals. You can trust them to help make a healthy indoor space. Many people pick them for green building projects.

How MgO Boards Are Made

Let’s see how these boards are made. Makers mix main chemical parts to make magnesium oxide wallboard. Here is what they use:

Magnesium oxide (MgO)

Magnesium hydroxide

Magnesium carbonate

To make the boards better, producers add special things. These help with insulation, bending, and fire resistance. Some common additives are:

Magnesium Chloride (MgCl2): This holds the board together.

Perlite: It makes the board lighter and helps with insulation.

Wood Fiber: This makes the board stronger and more flexible. Many companies use recycled wood fiber to help the earth.

Vermiculite: When heated, it gets bigger and helps the board resist fire.

Glass Mesh: This gives the board more strength and helps it take hits.

The magnesium oxide wallboard guide talks about both the minerals and these helpful extras. The process makes a board that is tough and works well.

Key Features

You might want to know what makes magnesium oxide wallboard special. Here are some key features you will find in any good magnesium oxide wallboard guide:

Tip: If you need a wallboard for tough places, MgO boards are a great choice.

Fire Resistance: MgO boards do not burn easily. You can use them where safety is very important.

Water and Mold Resistance: These boards do not soak up water. Mold cannot grow on them, so your walls stay clean.

Durability and Strength: MgO boards are strong. You can use them in busy places. Here is their compressive strength:

Compressive Strength (MPa) | Notes |

|---|---|

10 – 25 | Typical range for MgO boards |

Up to 40 | Some cement boards can reach this |

12 – 25 | Another reported range for MgO |

Thermal Insulation: MgO boards help keep rooms comfortable. They give better thermal insulation than many other wallboard types. Here is how they compare:

MgO boards use new technology for better insulation.

Fiber cement boards get hotter from the sun.

Magnesium-based boards, like MgO, help keep buildings cool and save energy.

MagPanel® MgO Board is better than wood, gypsum, and cement boards for thermal insulation.

Environmental Impact: MgO boards use natural minerals and recycled things. You help the planet when you pick them.

If you follow the magnesium oxide wallboard guide, you will see why these boards are getting more popular. They give safety, strength, and comfort for many buildings.

Core Properties of MgO Sheathing Board

Fire Resistance

Fire Resistance

Fire resistance is very important for building safety. MgO sheathing board does not break down in high heat. You can use it where fire safety is needed. Here is a table to compare:

Fire Resistance Duration | Rating |

|---|---|

Magnesium Oxide Panels | |

Gypsum Boards | 30–60 minutes |

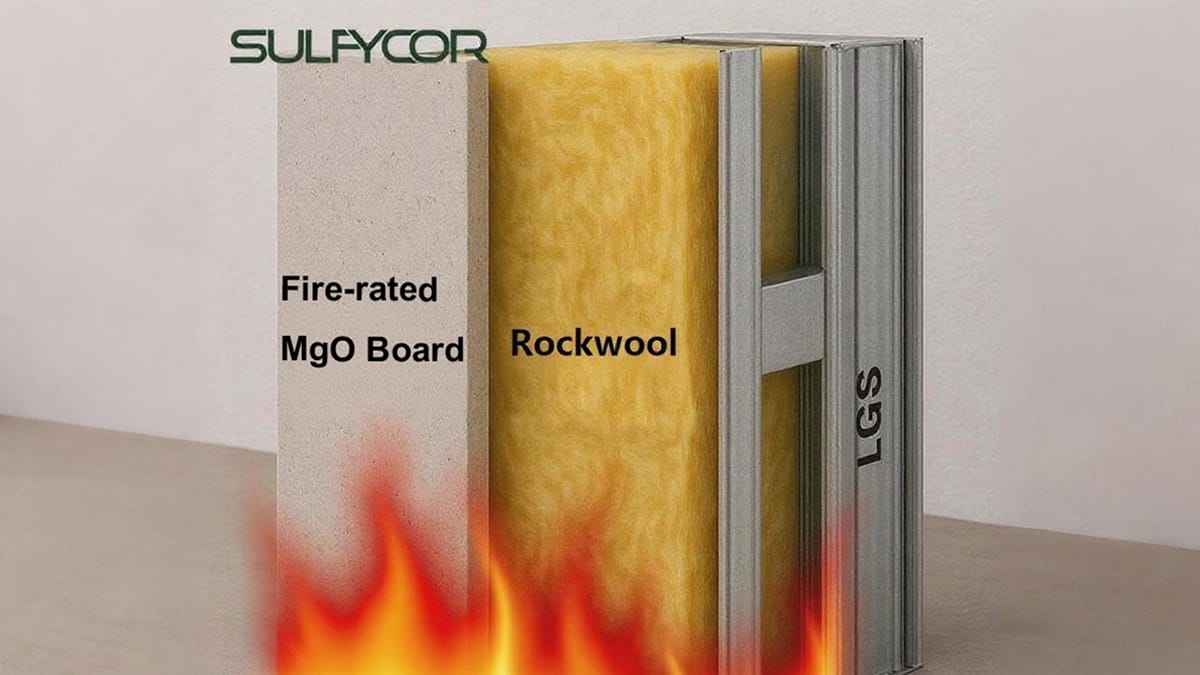

MgO sheathing board can handle over 1,382°F. It does not burn or make toxic smoke. When there is a fire, it lets out water vapor. This cools the area and slows the fire. It meets Class A fire rating and passes the ASTM E136 test. MgO sheathing board is safer than cement boards for fire. It is a good choice for places with fire risk.

MgO sheathing board will not burn.

It is better than cement boards for fire safety.

Cement boards may need more work to be safe from fire.

Water and Mold Resistance

MgO sheathing board is great if you worry about water. It does not soak up much water, only about 0.34%. Gypsum boards can take in almost 3%. That makes them swell and bend. MgO sheathing board does not have this problem. It keeps walls and ceilings in good shape, even when it is humid.

It also stops mold. MgO sheathing board is not made from things mold likes. Mold cannot grow on it. You do not have to worry about rot or bad smells. This makes it good for bathrooms, kitchens, and basements.

Durability and Strength

You want walls that last a long time. MgO sheathing board is very strong. It can take hits and daily use. Plywood can split or fall apart when wet. MgO sheathing board stays strong. You can use it in busy places or where you need extra protection.

MgO sheathing board can take hard hits.

It lasts a long time in tough places.

Environmental Impact

MgO sheathing board is good for the planet. It has a low carbon footprint and helps trap carbon dioxide. Here is a table to show:

Feature | Magnesium Oxide (MgO) Boards | Drywall (Gypsum Boards) |

|---|---|---|

Carbon Footprint | Low, sequesters CO2 | Moderate, higher energy use |

You can recycle MgO sheathing board when you are done with it. Recycling helps cut waste and saves resources.

Recycling Process Steps | Benefits of Recycling MgO Boards |

|---|---|

Collection | Less Waste |

Cleaning | Saves Resources |

Crushing and Grinding | Less Harm to the Environment |

Separation | Saves Money |

Reworking |

|

MgO sheathing board gives you fire safety, water and mold resistance, strength, and helps the environment—all in one board.

Applications of Magnesium Oxide Board

Interior Walls

Interior Walls

You want your walls to stay strong and look good for years. Magnesium oxide board helps you do that. You can use it for inside and outside wall coverings. Many people pick it for walls in homes, offices, and schools. It works well as a backing for tiles in kitchens and bathrooms. You can also use it for decorative finishes that keep heat inside your walls. If you need ceiling panels that resist fire, magnesium oxide board is a smart choice. You will find it in prefab and modular buildings, too.

Inside wall coverings

Outside wall coverings

Ceiling panels

Floor layers

Tile backing in kitchens and bathrooms

Decorative finishes

Siding for outside walls

Underlayers for tiles

Tile backers in wet places

Roofs and soffits

Prefab and modular buildings

Tip: If you want walls that resist mold and water, magnesium oxide board gives you peace of mind.

Exterior Sheathing

You need walls that stand up to tough weather. Magnesium oxide board works well as exterior sheathing. It gives your walls fire resistance, rated up to four hours. You can trust it in fire-prone areas. It also keeps your walls from warping and swelling when it gets wet. In humid climates, you should check the product type and installation. Sometimes, magnesium oxide board can absorb moisture, which may cause mold or corrosion of metal fasteners. Most of the time, it stays strong and keeps your walls safe.

Fire resistance for up to four hours

Moisture resistance to prevent warping

Proven durability in long-term tests

Note: Always follow the right installation steps for your walls to get the best results.

Ceilings and Floors

You want your ceilings and floors to handle heavy loads and stay dry. Magnesium oxide board has strong compressive and flexural strength. You can use it as a floor underlayment because it resists moisture and mold. It is not usually the main support for ceilings or floors, but it works well with other materials. Your walls, ceilings, and floors will last longer with magnesium oxide board.

Property | Description |

|---|---|

Compressive Strength | Strong, good for load-bearing applications |

Flexural Strength | High, keeps its shape over time |

Structural Use | Needs extra support for main structural roles |

Strong compressive and flexural strength

Good for load-bearing in some cases

Common as floor underlayment

If you want floors and ceilings that stay dry and strong, magnesium oxide board is a reliable choice.

MgO Board Installation

Getting started with mgo board installation can feel easy when you break it down into steps. You want your walls, ceilings, or floors to last a long time and look great. Let’s walk through the installation process together.

Getting started with mgo board installation can feel easy when you break it down into steps. You want your walls, ceilings, or floors to last a long time and look great. Let’s walk through the installation process together.

Tools and Preparation

Before you begin, gather the right tools and get your space ready. This helps you work faster and keeps you safe.

Protective gloves

Safety glasses

Dust mask

High-quality circular saw for clean cuts

Utility knife for detailed cuts and scoring

Cordless drill or screw gun

Screws or specialized mgo board nails

Tape measure, square, and level

Tip: Always wear your safety gear. Cutting mgo boards can make dust and sharp edges.

Prepare your site with these steps:

Clean the surface. Remove dirt, grease, or dust. Use a damp cloth for sticky spots and let it dry.

Level and measure the area. Use a level to check for bumps or dips. Fill low spots and sand down high ones.

Plan your layout. Measure the space, draw your layout, and mark where each board will go. This helps you avoid mistakes and keeps your finish neat.

Laying the MgO Boards

Now you’re ready for laying the mgo boards. Start with the frame or keel setup. Make sure the wall studs or ceiling joists are spaced 12 to 16 inches apart. This gives the boards enough support and stops them from sagging.

Place the first board at one corner.

Align the edges with your marks.

Leave a small gap (about 1/8 inch) between boards for expansion.

Check that each board is level before moving to the next.

If you need insulation, add it between the studs before laying the mgo boards. This step helps with sound and temperature control.

Note: Laying the mgo boards in a staggered pattern makes your wall or ceiling stronger.

Cutting and Fastening

Cutting mgo boards is simple when you use the right tools. For thin boards (8mm or less), score with a utility knife and snap along the line. For thicker boards (10mm or more), use a circular saw with a carbide-tipped blade. If you need to cut curves or small holes, a jigsaw with a fine-tooth blade works best.

Always measure twice before cutting mgo boards.

Wear your dust mask and safety glasses when cutting mgo boards.

Keep your hands away from the blade.

When fastening the boards securely, use stainless steel screws or galvanized nails. Place fasteners at regular intervals to prevent sagging. Self-counterboring screws with small nibs work well. Avoid soft galvanized coatings unless you use a barrier coat.

Start fastening the boards securely at the center and work outwards.

Do not over-tighten screws. This can crack the board.

Use both mechanical and adhesive fasteners for extra strength and durability.

Tip: Fastening the boards securely at the edges and corners helps prevent movement over time.

Finishing Techniques

After you finish laying and cutting mgo boards, it’s time to make the surface smooth and ready for paint or tile.

Use a primer made for concrete or masonry.

Choose paints that react with cement in the board for a strong finish.

Acrylic stucco topcoats and polymer-modified cement base coats work well.

For joints, use sandable elastomeric joint compounds or lightweight concrete patching compounds with fiberglass tape.

You can also use finely ground hydraulic cement fillers for strong joints.

Urethanes bond well with mgo boards.

Note: Always let each layer dry before adding the next. This keeps your finish smooth and strong.

Safety Considerations

Safety considerations are important during every step of mgo board installation. Cutting mgo boards creates dust and sharp edges. Protect yourself with the right gear.

Safety Gear | Purpose |

|---|---|

Safety glasses | Protect your eyes from mgo dust |

Dust mask | Keep mgo particles out of your lungs |

Gloves | Shield your hands from sharp mgo edges |

Ear protection | Reduce noise from cutting mgo |

Long sleeves | Cover your skin from mgo dust |

Alert: Never skip safety considerations. Always wear your gear and keep your workspace clean.

With these steps, you can handle mgo board installation like a pro. You will enjoy the strength and durability of your new walls, ceilings, or floors for years to come.

Comparing MgO Board With Other Materials

When you pick a wallboard, you want to know how it stacks up against other choices. Let’s look at how magnesium oxide board compares to drywall and cement board. You will see why many people choose it for fire safety, strength, and more.

When you pick a wallboard, you want to know how it stacks up against other choices. Let’s look at how magnesium oxide board compares to drywall and cement board. You will see why many people choose it for fire safety, strength, and more.

MgO Board vs. Drywall

You might wonder if you should use MgO board or drywall. Both have their place, but they are not the same. MgO board gives you much better fire safety. It does not burn or make smoke, so you feel safer at home or work. Drywall can catch fire faster and does not protect as well in high-risk areas.

MgO board also stands up to water and mold. Drywall can get soft and break down if it gets wet. If you want walls that last, MgO board is the better pick. Drywall is lighter and easier to carry, so it works well for quick jobs.

Here’s how the cost compares:

Material | Price per m² |

|---|---|

Magnesium Oxide | |

Drywall | $6 – $15 |

You pay a bit more for MgO board, but you get extra fire safety and durability.

MgO Board vs. Cement Board

Cement board is another strong choice, but MgO board still leads in some ways. You get better fire safety with MgO board because it can handle higher heat. Cement board does well, but not as well in extreme conditions.

MgO board also gives you better moisture resistance. It does not swell or break down like cement board can if not sealed. You will notice MgO board keeps its shape and strength longer.

Check out this table for a quick look:

Feature | Magnesium Oxide Board | Cement Board |

|---|---|---|

Fire Resistance | Superior due to mineral content, withstands high temperatures | Good, but less effective in extreme conditions |

Moisture Resistance | Impressive, less prone to swelling or degradation | More resistant than drywall, but can absorb water if not sealed |

Durability | Exceptional strength, less susceptible to cracking | Durable, but may wear more in high-impact situations |

Thermal Insulation | Better thermal performance due to lower thermal conductivity | Provides some insulation, but less effective than MgO board |

If you want the best fire safety and moisture protection, MgO board is a smart choice.

Pros and Cons

You want to know the good and bad before you decide. Here’s a quick list to help you:

Superior fire safety: Non-combustible and stands up to high heat.

Excellent moisture resistance: No warping or mold.

Greater durability: Handles bumps and hits better.

Environmentally friendly: Made from natural minerals, no harmful chemicals.

MgO Board Disadvantages:

Higher cost: You pay more than for drywall.

Heavier: Harder to move and install.

Drywall Advantages:

Cost-effective: Cheaper and easy to work with.

Lightweight: Simple to carry and install.

Drywall Disadvantages:

Limited fire safety: Not as safe in a fire.

Susceptible to moisture: Can break down when wet.

Less durable: Dents and cracks more easily.

If fire safety matters most to you, MgO board gives you peace of mind. You get a wall that stands up to heat, water, and daily life.

Practical Tips for Beginners

Cost and Availability

Cost and Availability

You might wonder if magnesium oxide board fits your budget. The price can be a bit higher than regular drywall, but you get a lot for what you pay. The advantages of mgo sheathing include long life, less damage from water, and fewer repairs. You can find these boards at most building supply stores. Many online shops also sell them, so you have options. Because more people want eco-friendly materials, stores keep more in stock. If you plan a big project, ask about bulk discounts. This helps you save money and makes your project easier to manage.

Maintenance

Keeping your walls in good shape is simple if you follow a few steps. The advantages of mgo sheathing include being mold-resistant and easy to clean. In humid places, you should:

Pick boards with low chloride content and check for moisture resistance.

Use waterproof sealants before you finish the surface.

Make sure the room has good airflow.

Keep boards dry before you install them.

Let the boards get used to the room’s air before you start.

Do not over-tighten screws. Use the right fasteners and spacing.

Spread joint compounds and coatings evenly.

Always use safety gear when you work. Wear gloves, a dust mask, and safety glasses. Safety gear keeps you safe from dust and sharp edges. If you cut or sand the boards, put on your safety gear every time. You should also wear safety gear when you move or install the boards.

Suitability for Various Projects

You can use magnesium oxide board in many places. The advantages of mgo sheathing make it a smart pick for homes, offices, and even schools. It works well for both indoor and outdoor jobs. The board is eco-friendly and mold-resistant, so it fits green building projects. Here’s a quick look at where you can use it:

Indoor Uses | Outdoor Uses |

|---|---|

Structural floors | Roof decking |

Fire-rated walls | Sheathing |

Ceilings | Fascias |

Subflooring | Soffits |

Tile backer | Trim work |

Stairways | Balconies |

Corridors | Wall sheathing |

You can use it in homes, theaters, offices, schools, and even data centers. For outdoor jobs, try it on roofs, trim boards, and siding. The eco-friendly nature and the advantages of mgo sheathing make it a top choice for many projects.

You now know the main strengths and weaknesses of magnesium oxide wallboard. Here’s a quick recap:

Pros: Fire safety, water and mold resistance, strong and eco-friendly.

Cons: Higher price, heavier to handle.

Tip: Think about your project’s needs before you choose. MgO boards work best where you want safety and durability. If you want to learn more, check out guides or talk to local suppliers.

FAQ

What tools do you need to cut MgO board?

You can use a utility knife for thin boards. For thicker boards, grab a circular saw with a carbide blade. Always wear safety glasses and a dust mask. Cutting can make dust and sharp edges.

Can you paint or tile over magnesium oxide board?

Yes, you can! Just use a primer made for cement surfaces before painting. For tile, apply a thin-set mortar. MgO board gives you a strong, smooth base for both.

Is MgO board safe for people with allergies?

MgO board does not have harmful chemicals or support mold growth. You get cleaner air indoors. Many people with allergies feel safer using it in their homes.

How do you store MgO boards before installation?

Keep the boards dry and flat. Store them off the ground on a pallet. Cover them with a tarp if you keep them outside. This helps prevent moisture damage.

Fire Resistance

Fire Resistance Interior Walls

Interior Walls Cost and Availability

Cost and Availability