04 Sep How Mgo Boards Help With Fire Safety

Table of Contents

You want the best fire safety for your building. Mgo boards give you that peace of mind. These boards stay non-combustible even in high heat. When fire strikes, mgo boards hold their strength and do not melt or burn. You face less smoke and zero toxic gases, which keeps you safe. Unlike gypsum boards, mgo boards do not lose their fire resistance when wet. They also help slow the spread of fire, giving you more time to evacuate and protect your property. Mgo boards raise safety to a new level.

Key Takeaways

Mgo boards do not burn or melt. They stay strong during fires. This gives buildings good fire protection. These boards make almost no smoke or toxic fumes. This keeps the air safer to breathe during emergencies. Mgo boards let out water vapor when they get hot. This cools surfaces and slows down fire spread. People get more time to leave safely. They meet top fire safety standards and codes. This means they protect many building types and places. Installing them the right way is important. Picking certified mgo boards helps keep people and property safe.

Mgo Boards Overview

What Are Mgo Boards

You might ask how mgo boards are different from other materials. Mgo boards, also called magnesium oxide panels, are made with special minerals. These minerals make the panels strong and safe for building. The boards use natural ingredients that help protect buildings from fire and other dangers.

Here is what you find inside mgo boards:

Magnesium Oxide (MgO): This main part gives the panels fire resistance and strength.

Vermiculite: This mineral gets bigger when heated, so the boards stay strong in a fire.

Magnesium Chloride (MgCl2): This binder mixes with MgO to make a tough, fire-resistant board.

Perlite: This ingredient helps with insulation, which supports fire safety.

Curing Process: MgO and MgCl2 react during curing to lock in fire-resistant features.

These panels are tough and work well for many things. Mgo boards do not have harmful chemicals like asbestos or formaldehyde. You can use these panels in homes, offices, or modular buildings.

Fire Safety Features

Mgo boards are known for their fire safety features. When you use these panels, you add extra protection to your building. Mgo panels do not burn or melt, even in high heat. They keep their shape and strength for hours during a fire. You will not see toxic fumes or thick smoke, so people stay safer in emergencies.

Mgo boards meet strict fire safety rules, like ASTM E136 and the International Building Code. These panels can resist fire for up to four hours, so they are great for fire-rated walls and ceilings. Mgo boards are good for the environment because they use natural minerals and make low emissions when made. They can be recycled and last a long time, which helps green building goals.

When you pick mgo panels, you get fire safety and help the planet. These boards protect your building, make indoor air better, and lower the risk of fire damage.

Fire Resistant Benefits

Non-Combustible Properties

Non-Combustible Properties

You want your building to be safe in a fire. Mgo boards help keep you safe because they are non-combustible. These panels do not burn or melt, even in very high heat. You can trust mgo boards to stay strong during a fire. The wall panels use minerals like magnesium oxide, which do not let flames grow. This makes them a great choice for fireproof wall panels and fireproof insulation boards.

Premium mgo boards like MagMatrix BMSC 517 pass tough tests such as ASTM E136 and EN 13501-1.

These panels get top fire safety awards, like UL Two-Hour Fire Rating and BS 476 Part 4.

The inorganic parts of mgo boards stop flames and resist heat well.

You have more time to get out because these boards slow fire down.

You see mgo boards used in fire-rated walls, ceilings, and other important places. Some studies show that fire resistance can change depending on how you use the boards. For example, adding steel sheathing can make them work even better against fire. Always check what kind of mgo panels you pick, since some may have organic stuff that lowers their non-combustible rating. When you choose high-quality non-combustible wall panels, you get the best fire safety.

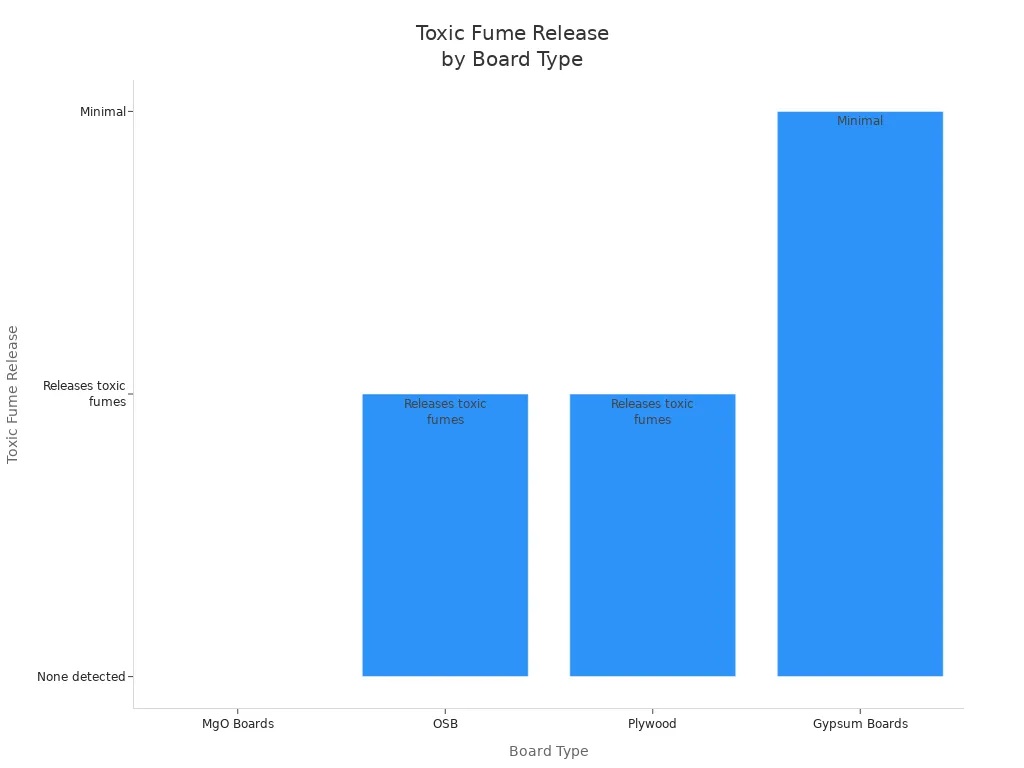

Smoke and Toxic Fume Reduction

Smoke and toxic fumes can be very dangerous during a fire. You want panels that keep the air clean and safe. Mgo boards are special because they make almost no smoke and do not let out harmful gases. These fireproof wall boards help protect people by keeping the air easy to breathe in emergencies.

Here is a table that compares mgo boards to other building materials:

Feature | MgO Boards | OSB (Oriented Strand Board) | Plywood | Gypsum Boards |

|---|---|---|---|---|

Fire Resistance Rating | Non-combustible, excellent | Poor, combustible | Limited, combustible | Non-combustible, excellent |

Combustibility | Non-combustible | Highly combustible | Combustible | Non-combustible |

Structural Integrity Under Fire | Maintains integrity | Fails quickly | Fails quickly | Weakens under prolonged exposure |

Smoke Emission | Minimal | High | High | Minimal |

Temperature Resistance | High (up to 1472°F/800°C) | Low | Low | Moderate |

Toxic Fume Release | None detected | Releases toxic fumes | Releases toxic fumes | Minimal |

You can see mgo boards are better than OSB and plywood for fire safety. These fireproof wall panels do not burn or give off toxic fumes. They keep their shape and do not fill rooms with smoke. In lab tests, mgo boards show a Smoke Developed Index of zero, which means almost no smoke comes out when fire hits the panels.

You feel safer knowing mgo boards help keep escape paths clear for everyone. Firefighters also have less risk from smoke and toxic gases when they go into buildings with mgo panels.

Water Vapor Release

Mgo boards do more than just stop fire. These heat-resistant panels also slow fire by letting out water vapor. When fireproof wall boards get very hot, special things like magnesium hydroxide inside the panels make steam. This water vapor takes in heat, which cools the panels and the air nearby.

Tip: Water vapor acts like a shield and makes it harder for fire to move through walls and ceilings.

This helps in two ways:

The steam cools the side of the wall away from the fire.

The vapor makes a barrier that stops flames from moving fast.

You get better fire control and more time to act. Fireproof insulation boards with this feature make your building safer and help protect your things. The water vapor release also makes mgo boards better at keeping heat out, so they are good heat-resistant panels for any place where fire might happen.

Mgo boards mix non-combustible properties, low smoke and fume output, and smart water vapor release. You get a full fire resistant solution that keeps people and buildings safe.

Fire Performance

Fire Resistance Ratings

You want to know if mgo boards work well in a fire. These boards have some of the best fire resistance in buildings. Mgo panels protect your building because they meet tough rules. When you use mgo boards for fire-rated sheathing, you get strong safety.

Here is a table that shows how mgo boards meet fire safety standards around the world:

Fire Resistance Aspect | Standard(s) | Rating / Duration | Certification / Recognition |

|---|---|---|---|

Fire Rating | Chinese GB 8624 (equiv. EN 13501-1) | A1 (highest fire rating) | ILAC-MRA (international recognition) |

Fire Resistance Duration | Chinese GB/T 9978.1-2008 (equiv. ISO 834-1-1999) | 90 minutes | ILAC-MRA |

Fire Door Core Foam Boards | Australian AS 1530.1.1994 and ASNZS 1530.3.1999 | Classified as non-combustible | – |

You see mgo boards get the top A1 fire rating. These panels can stop fire for 90 minutes or more. When tested with ASTM E84, mgo boards often get a Class A rating. This means flames do not spread fast and there is little smoke. You can use these boards in fire-rated panels for walls and ceilings.

Certification | Purpose | Result for MgO Boards |

|---|---|---|

ASTM E136 | Noncombustibility test | Passed; boards do not burn |

ASTM E84 | Surface flame spread and smoke development | Class A rating; low flame spread and smoke |

Note: Always check the fire rating of the mgo boards you pick. The thickness and how you install them can change how they work in a fire.

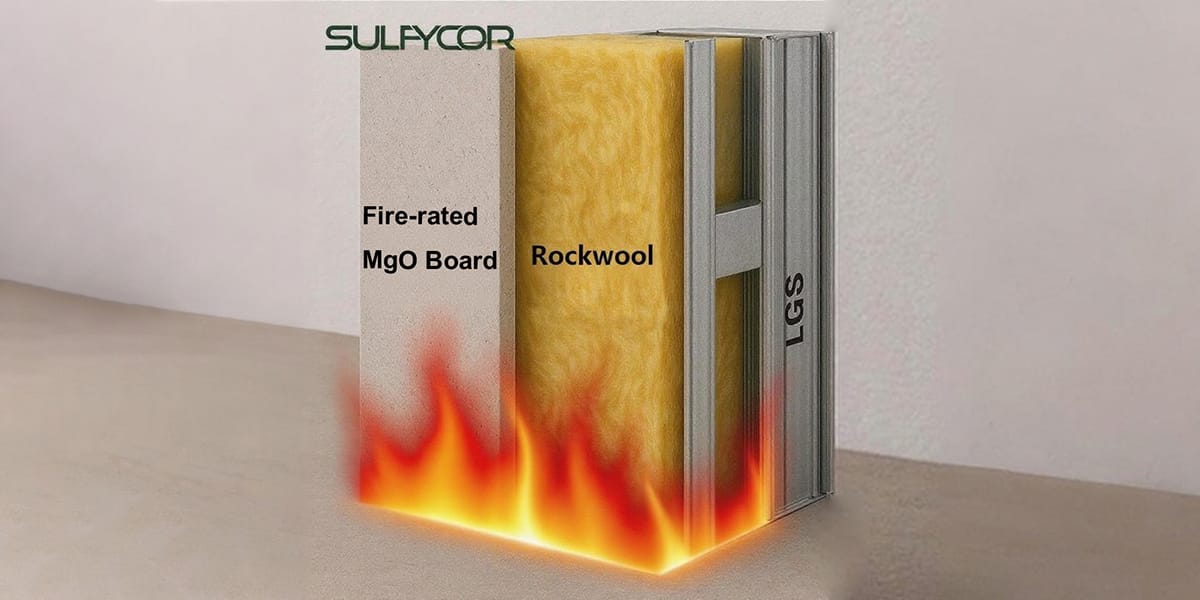

Real-World Fire Scenarios

You want to know if mgo boards work in real fires, not just in tests. In real fires, mgo panels slow down fire spread. When you use mgo boards with metal studs and rock wool, you get more safety. These panels might crack or lose small pieces on the fire side, but they do not fall apart. The boards keep their shape and help stop fire from moving to other rooms.

Mgo boards in walls with metal studs and rock wool may crack and lose some pieces on the fire side, but the main wall stays strong.

The fire resistance depends on the board thickness and how you join the panels.

Rock wool, glass fiber, and mineral wool all work well with mgo boards. The type of insulation does not change fire resistance much.

Mgo panels move heat faster than gypsum, but they still protect the building.

Most problems happen because of cracks or small pieces falling off, not because the whole wall breaks.

You see mgo boards in hospitals, schools, hotels, offices, and apartments. These panels do not catch fire or help fire spread. They stay strong in high heat and do not bend or swell. Mgo boards also resist water, so they are good for outside walls where water is a problem.

Tip: Mgo boards let out water vapor during a fire. This cools the panels and slows the fire.

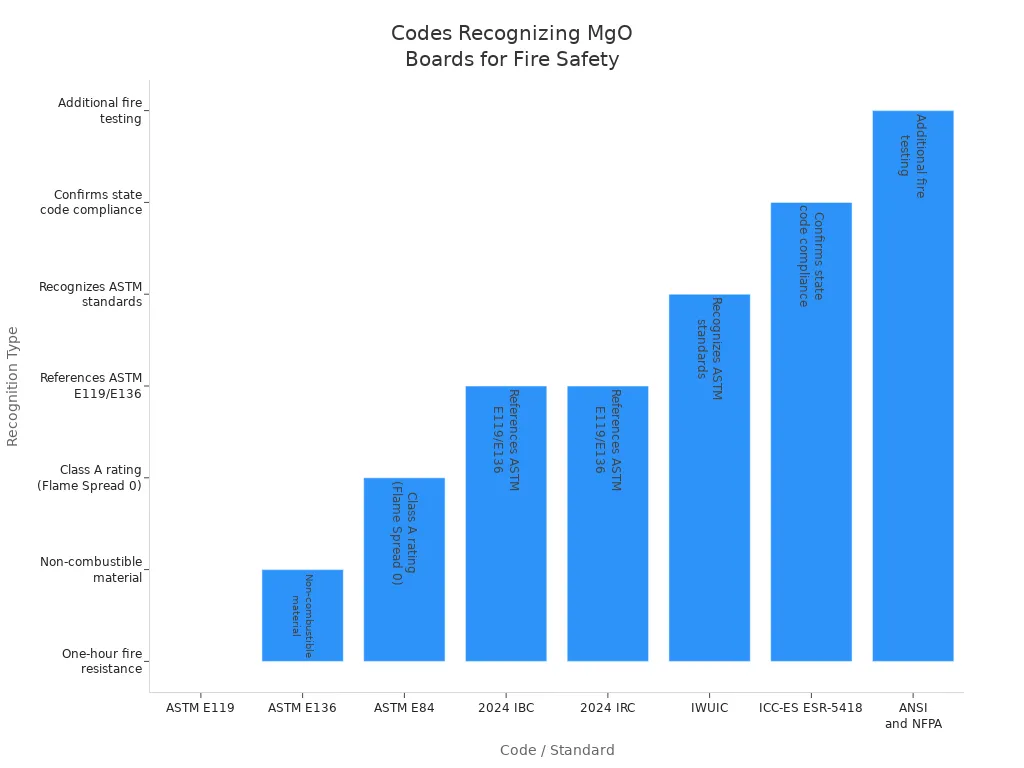

Compliance with Standards

You need your building to follow fire safety rules. Mgo boards help you do this. These panels pass many important tests and meet codes in the United States and other countries. You can use mgo boards in places with strict rules, like Florida and California.

Recognition of MgO Boards for Fire Safety Compliance | |

|---|---|

ASTM E119 | MgO boards tested and certified for one-hour fire resistance rating |

ASTM E136 | MgO boards classified as non-combustible material |

ASTM E84 | MgO boards tested for flame spread index, achieving Class A rating (Flame Spread 0) |

2024 International Building Code (IBC) | References ASTM E119 and ASTM E136 for fire resistance and non-combustibility |

2024 International Residential Code (IRC) | References ASTM E119 and ASTM E136 for fire safety compliance |

International Wildland-Urban Interface Code (IWUIC) | Recognizes MgO boards meeting ASTM standards for wildfire risk zones |

Confirms compliance of MgO boards with stringent state codes (e.g., Florida, California) | |

ANSI and NFPA Standards | Additional testing for fire resistance, strength, and moisture resistance |

You can trust mgo boards to meet the newest fire safety rules. These panels get tested every year for fire resistance, strength, and water safety. You feel safe knowing your fire-rated sheathing meets the highest standards.

Remember: Always look for mgo boards with certifications like ASTM E119, ASTM E136, and ICC-ES reports. These show the panels meet top fire safety standards.

Comparing Fire-Resistant Construction Materials

When you pick fire-resistant materials, you want to know how they work in a real fire. Mgo boards are special because they stop fire, make little smoke, and do not let out bad fumes. Let’s look at how mgo boards stack up against other boards used in buildings.

Mgo Boards vs. Gypsum

Gypsum boards are used a lot in homes and offices. Both mgo boards and gypsum boards help with fire safety, but they do not work the same way.

Mgo boards do not burn or help flames grow.

These boards can last in fire for 1 to 4 hours.

Mgo boards do not make smoke or toxic fumes in a fire.

Gypsum boards slow fire because water inside turns to steam.

Gypsum boards can break and get weak if fire lasts too long.

You might need more layers or special treatments for gypsum boards to get better fire ratings.

Feature | MgO Board | Gypsum Board |

|---|---|---|

Combustibility | Non-combustible; does not burn | Fire-resistant but can burn and emit smoke |

Smoke and Toxic Fumes | Does not release harmful smoke or toxic fumes | Emits smoke when exposed to fire |

Fire Resistance | Withstands high heat without damage | Contains water in core that slows fire but weakens under high heat |

Mgo boards give stronger fire protection, especially where you need tough fire-resistant materials.

Mgo Boards vs. Plywood

Plywood is often used for walls and floors, but it does not do well in a fire. When you compare mgo boards to plywood, you see big changes.

Feature | MGO Boards | Plywood |

|---|---|---|

Combustibility | Non-combustible; does not ignite or spread fire | Combustible; catches fire easily and spreads flames |

Temperature Resistance | Can withstand temperatures up to 800°F without losing integrity | Vulnerable to high temperatures; loses integrity quickly |

Fire Resistance Rating | Up to 4 hours | Typically up to 1 hour without fireproofing treatments |

Fire Safety Suitability | Highly suitable for fire-prone areas due to non-combustibility and high resistance | Less suitable for high fire resistance applications due to combustibility and limited rating |

Mgo boards are much safer in a fire. Plywood burns quickly and helps fire move. Mgo boards stay strong and do not burn, so they are better for fire-resistant building.

Mgo Boards vs. Cement Board

Cement boards are another choice for fire-resistant materials. Both mgo boards and cement boards fight fire, but mgo boards have some big pluses.

Feature | MGO Boards | Cement Board |

|---|---|---|

Fire Resistance Rating | High, but often less than mgo boards | |

Smoke and Toxic Fumes | Very low emission | Low emission |

Structural Integrity | Maintains shape under high heat | May lose shape faster under extreme heat |

Mgo boards keep their shape and strength longer in a fire. Cement boards might need extra fireproofing to be as good as mgo boards. You get better fire safety and less smoke with mgo boards, so they are a smart pick for fire-resistant building.

Note: Mgo boards might cost more at first, but you save money later because they last longer and do not need to be replaced as much after a fire.

Applications for Fire Safety

Where to Use Boards

Where to Use Boards

You can put mgo boards in lots of places to make buildings safer from fire. These boards work in houses and big buildings. People use mgo boards for:

Walls, ceilings, and floors in new homes

Hospitals and health clinics

Factories, storage buildings, and power plants

Airports and busy public spots

Areas with wildfires or near the ocean

Mgo boards protect inside and outside walls, fire-safe walls, and even roofs. You also find these boards in tunnels, kitchens for businesses, boiler rooms, and places with lots of wires. Builders use mgo boards in special panels that save energy and keep out water. These boards stay strong in fires and tough weather.

Tip: Mgo boards help you follow strict fire safety rules in crowded places or where fire is a big risk.

Some hotels in Melbourne and New York got safer and better by using mgo boards. Resorts in wet places use these boards to stop mold and keep air clean, which makes things even safer.

Installation Tips

You get the best fire safety if you put mgo boards in the right way. Follow these steps to make sure your boards work well:

Always do what the maker says when cutting, putting up, and sealing mgo boards. This stops fire from getting through cracks.

Be careful when you move the boards. If they get damaged, they may not protect against fire as well.

Keep mgo boards dry before and while you put them up. Only use things that work with mgo so you do not lower fire safety.

Pick mgo boards that have passed top safety tests and meet fire rules.

Step | Why It Matters for Fire Safety |

|---|---|

Follow instructions | Stops fire from finding weak spots |

Handle carefully | Keeps boards strong in a fire |

Avoid moisture | Helps boards stay fire and water safe |

Choose certified boards | Makes sure boards are tested and safe |

Note: Good joints and the right space between studs help mgo boards work best for fire safety.

When you use mgo boards in the right spots and install them with care, your building is safer and stands up to fire.

You want your building to have great fire protection. Mgo boards help because they do not burn or make much smoke. They also stay strong when it gets very hot. Studies show mgo boards work better than other boards for fire safety and do not catch fire easily:

Feature | MgO Boards | Gypsum Boards | Fiber Cement |

|---|---|---|---|

Fire Rating | 1 to 2 hours | Varies | Varies |

Noncombustibility | Class A1 | Combustible | Combustible |

Performance at 800°C | Does not burn | Burns | Burns |

Fire Spread | Slows fire spread | Moderate spread | Moderate spread |

When you use mgo boards for walls and ceilings, you help keep people and things safe. Mgo boards also make the air inside cleaner and can lower insurance bills. Experts say mgo boards are a good choice because they last a long time and keep you safe. Your building will be safer and stronger with mgo boards.

FAQ

What makes mgo boards different from regular drywall?

You get better fire safety with mgo boards. These panels do not burn or melt. Regular drywall can weaken in high heat. Mgo boards also resist water and mold, so you can use them in more places.

Can you use mgo boards outside?

Yes, you can use mgo boards for outdoor walls and ceilings. These panels resist water, mold, and fire. You get strong protection in wet or dry weather. Always follow the maker’s instructions for best results.

Are mgo boards safe for people with allergies?

You stay safer with mgo boards because they do not have asbestos or formaldehyde. These panels do not give off harmful fumes. You get cleaner air inside your building.

How do you cut and install mgo boards?

You can cut mgo boards with a standard saw. Always wear a mask and gloves for safety. Use screws or nails to attach the panels. Seal the joints well to keep fire and water out.

Non-Combustible Properties

Non-Combustible Properties Where to Use Boards

Where to Use Boards