21 Jul How Fire Resistant Wallboard Is Tested and Certified in 2025

Table of Contents

Imagine you need to protect your home from fire. You depend on fire resistant wallboard to help stop flames from spreading. When you choose this material, you trust that experts have tested it to keep you safe. Underwriters Laboratories (UL) and the Gypsum Association check fire resistant wallboard using strict fire tests like ASTM E119, E84, and C1396. They set the rules for how fire resistant wallboard must perform during a fire. You see their certification labels and know that your wallboard will hold up when fire strikes. Builders, architects, and homeowners like you rely on these tests to make sure every fire resistant wallboard in your building stands strong against fire.

Key Takeaways

Fire resistant wallboard is tested by strict rules like ASTM E119 and E84. These tests make sure it can stop fire and stay strong in a real fire.

Fire ratings tell how long wallboard can resist fire. They also show how fast flames move on its surface. Higher ratings mean better safety and lower insurance costs.

Certified wallboard has marks from trusted groups like UL, Intertek, or FM Approvals. These marks show it passed hard fire tests and follows safety rules.

The whole wall setup, including studs and fasteners, must match tested designs exactly. This keeps the fire resistance rating valid.

Always look for current certification marks and fire ratings before you buy wallboard. This helps keep your building safe and helps you pass inspections.

Fire Resistant Wallboard Ratings

What Ratings Mean

When you look at fire resistant wallboard, you see numbers and classes that show how well the drywall can stand up to fire. These ratings come from strict standards and tests. You will find two main types of ratings: time-based and class-based.

Time-based ratings tell you how long the fire rated drywall can resist fire. For example:

Type X wallboard usually gives you at least a 1-hour fire resistance rating. This means the drywall can stop fire for one hour before it fails.

Thicker fire rated drywall, like 15.9 mm boards, can last about 52 minutes, while two layers can last up to 79 minutes.

MGO boards can resist fire for up to 4 hours, which is helpful for buildings with strict codes.

Type C wallboard offers even stronger fire resistance and meets higher standards.

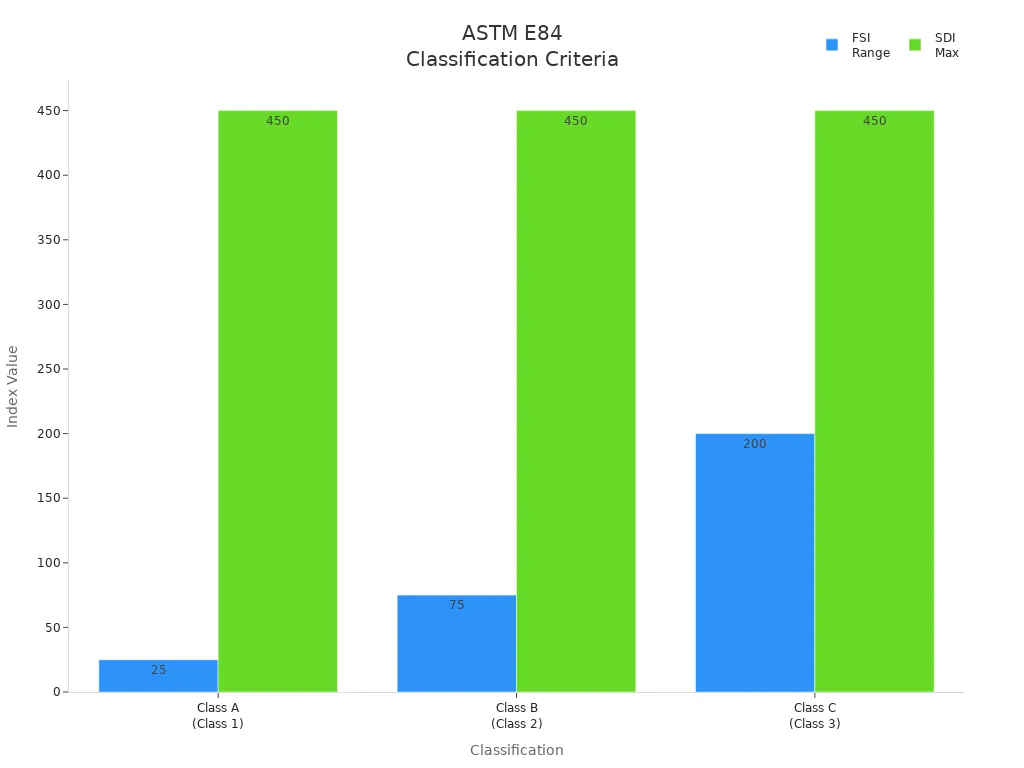

Class-based ratings use the flame spread index. This shows how fast fire moves across the drywall surface. You can see the classes in the table below:

Class | Flame Spread Index | Smoke Development Rating |

|---|---|---|

0 – 25 | Maximum 450 | |

Class B/2 | 26 – 75 | Maximum 450 |

Class C/3 | 76 – 200 | Maximum 450 |

Class A is the best for fire resistance. Hospitals and schools often require this class to meet safety codes. These ratings follow standards like ASTM E119 and E84, which set the rules for fire resistance rating standards.

Why Ratings Matter

You need to pay close attention to fire resistance ratings when you choose fire rated drywall. These ratings help you meet building codes and regulations. They also protect people and property during a fire. Higher fire resistance ratings mean the drywall can hold back fire longer. This gives everyone more time to escape and helps firefighters do their job.

If you use drywall with a high fire resistance rating, you can lower your insurance costs. Insurance companies look at the fire performance of your building. They give better rates to buildings with strong fire resistance. Codes and standards require you to use the right fire rated drywall in each part of your building. If you use drywall with a low rating, you risk failing inspections and putting lives in danger.

Tip: Always check the fire resistance rating on your drywall. Make sure it meets the standards and codes for your project. This simple step can save lives and protect your investment.

Testing Standards

When you pick fire resistant wallboard, you want it to be safe. Strict testing standards help prove this safety. These rules tell companies how to test and rate wallboard for fire resistance. You should know the main fire resistance test standards: ASTM E119, ASTM E84, and ASTM C1396. Each one checks something different and has its own rules.

ASTM E119 and E84

ASTM E119 and ASTM E84 are very important for fire testing. ASTM E119 checks how well a wallboard assembly can stop fire and stay strong. In this test, a big wallboard sample faces very high heat in a furnace. The test checks how long the wallboard can block fire and keep its shape. It also checks if flames or hot gases get through. You see ratings like “1-hour” or “2-hour” fire resistance. These numbers show how long the wallboard lasts. The test also blasts water at the wallboard after the fire. This checks if the wallboard stays strong after being burned.

ASTM E84 uses a different way to test. It checks how fast flames move across the wallboard surface. It also checks how much smoke the wallboard makes. The test uses a long tunnel with flames and air moving through it. You get a flame spread index and a smoke developed index. These numbers help you know if the wallboard is Class A, B, or C.

Type of Standard | Scope and Purpose | |

|---|---|---|

ASTM C1396 | Product Standard | Sets the lowest physical features and performance needs for gypsum wallboard, including Type X gypsum board. |

ASTM E119 | Test Standard | Checks fire resistance of whole building parts, like walls with gypsum board, by testing if they can hold back fire and stay strong, giving an hourly fire resistance rating. |

ASTM E84 | Test Standard | Measures how building materials burn on the surface, giving flame spread and smoke numbers (Class A, B, or C), which is different from how long the whole wall holds up in fire. |

ASTM C1396 and Type X Gypsum

ASTM C1396 gives the rules for gypsum wallboard, including fire rated gypsum like Type X. This standard lists how thick the board must be, how to put it up, and how to treat the joints for fire resistance. For example, 5/8″ Type X gypsum board gives a 1-hour fire rating when you put it on both sides of wood studs. You must follow the rules for nailing, where to put the joints, and taping to get the fire resistance rating.

Additives are important for meeting these rules. Companies add glass fibers to the gypsum core. These fibers make the board stronger and help it last longer in fire. Glass fibers do not burn, so they help keep the wallboard together during a fire. The water in gypsum turns to steam when it gets hot, which slows down the fire. These things help fire rated gypsum meet all the rules and keep your building safe.

Note: Always check that your wallboard meets the newest testing standards and rules. This helps you get the best fire resistance for your project.

Testing Process

Lab Procedures

Experts test fire resistant wallboard in a careful way. They use special labs made for fire testing. These labs have big furnaces that get very hot. The heat goes up slowly, like in a real fire. This helps show how the wallboard acts as the fire gets hotter. Labs use advanced tools to make sure tests are fair. Some labs use propane gas jet fire furnaces. These make strong and real fire conditions. The test area stays safe and controlled. Trained workers watch for toxic gases and heat all the time. Many labs let you watch the test live on video. You can see what happens and the results.

During testing, different methods check how the wallboard works. The fire endurance test burns the wallboard until it fails. Next, the hose stream test blasts water at the wallboard. This checks if it can handle water shock and cooling, like real firefighting. Both tests break the wallboard. The wallboard will not last, but you learn how strong it is.

Here is what you might see in a modern fire testing lab:

Big furnaces for testing wall assemblies

Controlled heat curves to copy real fire growth

High-pressure hose stream tools for tough tests

Watching heat, smoke, and toxic gases all the time

Trained staff who know safety and testing rules

Note: Accredited labs like ICC NTA and NGC Testing Services use these steps. They make sure your wallboard meets fire safety rules.

Assembly Evaluation

Fire resistance comes from the whole wall, not just the wallboard. The whole wall assembly gets tested together. This means the wallboard, studs, fasteners, insulation, and hardware. You must build the test wall just like you will use it. If you change anything, you might lose the fire rating.

Every detail matters during assembly evaluation. The lab checks if the wallboard stays in place and strong as it burns. Shaftliner panels need the right framing to work. If you skip framing, the wall will fail. Some hardware, like aluminum clips, may melt on the fire side. This helps the wall stay together. Doubling the framing can give fire resistance from both sides. This is important for some walls.

The fire resistance rating only counts if you follow the tested design. You must use the same materials, ways to build, and layout. Even the way you put up the wallboard and the fasteners matter. Accredited labs, like those from the Gypsum Association, check these rules. They also do more checks to keep quality high.

Here is a table of some top accredited labs for fire resistance testing in 2025:

Laboratory | Accreditations | Testing Capabilities | Notes |

|---|---|---|---|

ICC NTA | ISO 17025 accredited | Fire resistance testing on gypsum/drywall assemblies | Works with ICC-ES for tailored test plans and compliance with codes |

NGC Testing Services | NVLAP, ISO/IEC 17025, City of NY OTCR, CA State Fire Marshal, IAS, FL Building Commission | Full-scale construction fire testing including wallboard | Multiple state and national accreditations; recognized for fire resistance testing in 2025 |

Tip: Always follow the tested assembly design exactly. This is the only way to make sure your wallboard system will pass inspection and protect your building during a fire.

Certification Process

Certifying Organizations

You trust certain groups to check your fire resistant wallboard. These groups are Underwriters Laboratories (UL), Intertek, and FM Approvals. They do not make wallboard. They test it to see if it is safe. They follow strict fire safety rules.

According to NFPA 13 (2022 edition):

“Approved” means the authority having jurisdiction (AHJ) says it is okay.

“Listed” means a product is on a list from a group the AHJ trusts. The group checks the product often and says it meets the rules or is good for a certain job.

Fire resistant products must be tested by a third party and checked by the maker to be “listed” by groups like UL, Intertek, or FM Approvals. The AHJ, like a fire marshal or building official, gives the final approval. If you see UL Listed or FM Approved, it means the product passed hard tests and gets checked again later.

You can find these groups’ marks on your wallboard. These marks mean the wallboard passed all the tests. When you see a UL Listing or FM Approval, you know the wallboard did well in fire tests. UL checks if the wallboard keeps the cool side safe when the fire side gets very hot, up to 1700°F. They also spray water at the wallboard to see if it stays strong after being hit. These tests show the wallboard will not break or fall apart in a real fire.

Certifying groups do more than just test wallboard. They also look at how it is made. They check the factory and how workers make the wallboard. This makes sure every piece is the same as the one that passed the test. You can trust a certified wallboard to work the same way every time.

Here is a quick look at what these groups do:

Certifying Organization | Main Role in Certification | What It Means for You |

|---|---|---|

UL (Underwriters Laboratories) | Tests wallboard assemblies, checks how it is made, and gives UL Listing | You get a product that resists fire and meets the rules |

Intertek | Runs fire tests, checks factories, and puts out listings | You can look up listings online to check if it is good |

FM Approvals | Focuses on fire safety for big buildings | You see FM Approved marks on trusted wallboard |

Ongoing Compliance

Getting certified does not happen just once. Your fire resistant wallboard must keep its certification over time. Certifying groups use ongoing compliance. This means they check the wallboard again and again to make sure it is still safe.

The certification process works like this:

Fire resistant wallboard is tested by a third party to meet rules like ASTM E119 or UL 263.

The test uses fire to copy what happens in a real fire.

They check flame spread, smoke, heat, and if the wallboard stays strong.

They look at the test results and how the wallboard is made.

If it passes, it gets listed, like UL Listed or FM Approved.

The group keeps checking the wallboard with more inspections.

The AHJ, like a fire marshal, gives the final okay.

When a company wants to get certified, an engineer helps them. The engineer finds all the ways the wallboard will be used. They make a hard test to cover every use. If the wallboard passes, the certifier writes a report. This report is public and shows all the ways the wallboard is certified. You can find these reports online. Builders and code officials use these reports to check if the wallboard meets fire safety rules.

Fire resistant wallboard is put in very hot rooms to copy building fires. They check how fast flames move, how much smoke comes out, how much heat goes through, and if the wallboard stays strong. The wallboard gets certified after groups check the test results and how it is made, making sure it meets fire safety rules.

The report stays good as long as the company keeps up with the program. There is no time limit, but the certifier checks the wallboard often. If the company changes the wallboard or how it is made, the certifier must check and approve the change. This keeps you safe and the report correct.

You should always look for a current certification mark and a good listing before you buy or use fire resistant wallboard. This is the best way to make sure your building is safe and passes inspection. Ongoing checks help you know your wallboard will work in a fire.

When you pick wallboard with the right fire rating, you help keep your building and everyone inside safe. Certified wallboard goes through tough tests to prove it can hold its fire rating, stay strong, and help your fire protection system work. You should always look for certification marks and check the fire rating for each place you use wallboard. Make sure your wallboard follows the latest codes and helps you pass inspections. For the best safety, talk to people who know about fire ratings and building codes. Always put safety first by using certified wallboard that has shown it can resist fire in every job.

Check for certification marks on all wallboard.

Make sure the fire rating fits what you need.

Talk to experts about fire codes and rules.

Pick wallboard that helps your fire protection system.

Choosing certified fire resistant wallboard with the right rating can help save lives and protect your building. Always make fire safety the most important thing.

FAQ

What does a “1-hour fire rating” mean for wallboard?

A “1-hour fire rating” means your wallboard can stop fire for at least one hour during a standard test. This gives you more time to escape and helps firefighters protect your building.

How do you know if wallboard is certified?

You can check for certification marks like UL Listed, Intertek, or FM Approved on the wallboard or packaging. These marks show your wallboard passed strict fire tests and meets safety standards.

Can you use regular drywall instead of fire resistant wallboard?

No, regular drywall does not protect against fire as well as fire resistant wallboard. Only fire rated wallboard has special additives and passes fire tests. Always use certified fire resistant wallboard where codes require it.

Who checks if your wallboard meets fire codes?

Building inspectors and fire marshals check your wallboard during construction. They look for certification marks and test reports. Here is a quick guide:

Who Checks | What They Look For |

|---|---|

Building Inspector | Certification marks, ratings |

Fire Marshal | Test reports, code compliance |

Tip: Always keep your product documentation. This helps you pass inspections faster.