14 Jul Top 7 Cost-Effective Sheathing Board Alternatives to OSB in 2025

Table of Contents

Are you exploring affordable sheathing board options for your upcoming subfloor or exterior wall project? Here are the top 7 alternatives to oriented strand board (OSB) that you should consider. These include plywood, high-density fiberboard, Advantech, magnesium subfloor board, fiberglass-faced gypsum panels, rigid-foam insulation, and concrete subfloor panels. Many builders face challenges with OSB’s high cost, slow delivery times, and inconsistent quality. Additionally, OSB often struggles with water exposure, making it a risky choice for subfloor or exterior wall sheathing. If you want to save money, find stronger boards, and maintain a stable price, it’s wise to explore these other sheathing board options. The table below highlights that plywood and high-density fiberboard offer excellent value for subfloor and exterior wall sheathing, while Advantech, magnesium, and rigid-foam insulation perform better in moist environments. Choose the best sheathing board option for your budget and project requirements to achieve optimal results in 2025.

Alternative Material | Cost Positioning | Ideal Use Cases |

|---|---|---|

plywood | One of the cheapest options | subfloor, exterior wall sheathing |

high-density fiberboard | One of the cheapest options | subfloor, apartments |

Advantech | More expensive than plywood | subfloor, wet areas |

magnesium subfloor board | More expensive | subfloor, garages |

fiberglass-faced gypsum panels | More expensive | subfloor, bathrooms |

rigid-foam insulation | More expensive; not standalone | subfloor, energy-efficient homes |

concrete subfloor panels | More expensive; heavy labor cost | subfloor, patios |

Key Takeaways

Look at different sheathing boards besides OSB. You can find choices that match your budget, strength needs, and weather. Plywood is strong and keeps out water. It costs more than OSB. It works well for floors, roofs, and walls that need to last. MgO board, Advantech, and rigid foam insulation are good in wet or fire-risk places. They protect well from water and fire. Fiberboard costs less and helps with insulation and noise. But it is not as strong as plywood or OSB. SIPs make walls strong and save energy. They are quick to put up. But they cost more at first and need good moisture control.

Mgo Board

Overview

Overview

If you want a sheathing board that stands out for fire and moisture resistance, magnesium oxide (MgO) board could be a smart choice. MgO board uses natural minerals to create a strong, dense panel. You often see it in places where you need extra strength and safety. This board has become popular in 2025 for projects that demand more than what wood-based panels can offer.

Benefits

MgO board gives you several benefits.

You get excellent fire resistance, which means it does not burn or give off toxic smoke.

The board resists water and mold, so it works well in damp or humid places.

You also enjoy high strength and durability, even in tough weather or high-traffic areas.

MgO board keeps its shape and strength over time, so you do not have to worry about swelling or rotting.

It also resists pests like termites, which can damage wood-based boards.

Many builders like that it is eco-friendly and can help with soundproofing.

Drawbacks

MgO board does have some drawbacks you should know about.

The cost is higher than many other sheathing options, especially compared to gypsum or oriented strand board.

Quality can vary between brands, so you need to choose carefully.

Some boards may crack if the frame moves or if there is an earthquake.

In very humid climates, MgO board can form water droplets, which may cause corrosion on metal fasteners.

You must use stainless steel fasteners to avoid rust.

Some countries have banned MgO board because of these moisture and corrosion issues.

Cost Analysis

You will notice that the cost of MgO board is higher than oriented strand board. In 2025, MgO board usually costs between $1.50 and $3.00 per square foot. OSB, on the other hand, costs about $0.50 to $1.00 per square foot. Here is a quick look at bulk pricing:

Quantity Range (Pieces) | Price per Piece (USD) |

|---|---|

1,000 – 2,999 | 7.05 |

3,000+ | 5.98 |

The higher cost comes from the board’s strength, durability, and resistance to fire and moisture. You may pay more up front, but you get a board that lasts longer and performs better in tough conditions.

Best Uses

MgO board works best in places where you need extra strength and safety.

Use it in fire-prone areas, like wildfire zones, because of its fire resistance.

It is great for bathrooms, kitchens, and basements where moisture is a problem.

Coastal homes benefit from MgO board since it stands up to salty air and harsh weather.

You can use it in schools, hospitals, and commercial buildings where durability and indoor air quality matter.

MgO board also fits well in eco-friendly projects and high-rise buildings that need strong, long-lasting materials.

Tip: Always follow the manufacturer’s installation guide to avoid moisture and corrosion problems. This helps you get the most out of the board’s strength and durability.

Plywood

Overview

Plywood is a common choice for subfloors and walls. Builders have used plywood for many years. It is strong and lasts a long time. Plywood is made from thin wood layers glued together. These layers are stacked in different directions. This makes plywood tough and steady. You can buy plywood at most hardware stores. It usually comes in 4×8 sheets.

Benefits

Plywood has many good points. It is strong, so floors feel solid. Plywood is about 10% stiffer than oriented strand board. This means floors squeak less. Plywood also handles water better. Its layers help stop swelling and shrinking. Plywood does not warp easily. You can use it where water might be a problem. It works well for roofs and outside walls. Plywood lasts a long time, even in bad weather. Many builders pick plywood for peace of mind.

Drawbacks

There are some downsides to plywood. The biggest one is the price. Plywood costs more than oriented strand board. This can make big jobs more expensive. Plywood comes in standard sizes. You may have more seams in your floor or wall. If plywood stays wet too long, the layers can peel apart. This is called delamination. These problems matter if you want to save money or need big panels.

Disadvantage | Explanation |

|---|---|

Plywood usually costs more than OSB, so projects cost more. | |

Limited Sheet Size | Plywood sheets are 4×8 feet, so you get more seams and weak spots than OSB. |

Susceptibility to Delamination | If plywood gets wet for a long time, the layers can come apart. |

Cost vs. OSB

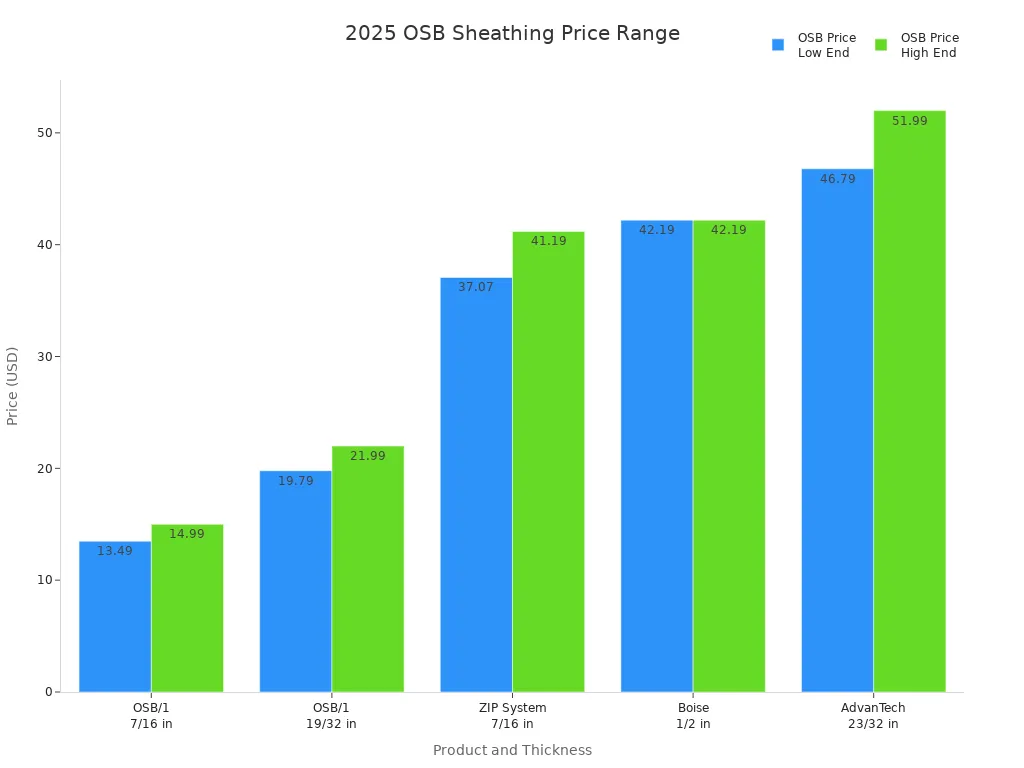

You might wonder how much plywood costs compared to OSB. In 2025, OSB is still cheaper. Plywood costs about 60% more than oriented strand board. Here is a quick price chart:

Material | Price per 4×8 sheet | Price per square foot | Installation Cost | Notes |

|---|---|---|---|---|

OSB | About $6 | $1 to $2.40 | Same as plywood | Cheaper choice in 2025 |

Plywood | About $10 | $4.50 to $10 | Same as OSB | About 60% more than OSB |

You pay more for plywood, but it is stronger and lasts longer. Advantech costs even more than plywood.

Best Uses

Plywood is best for subfloors, roofs, and outside walls. Use plywood when you need strength and water resistance. Builders use plywood on corners or cut spots. Oriented strand board edges can swell with water. Plywood is good under tile because it stays flat. If you want a strong and lasting floor or wall, plywood is a smart pick. You can also use plywood with Advantech or OSB for extra strength.

Tip: Use plywood in wet places or where you need strong boards, like bathrooms, kitchens, and roofs.

Fiberboard

Overview

If you want your house to stay warm and quiet, fiberboard is a good choice. This board is made from pressed wood fibers, often from recycled wood. Many builders like it because it is light and easy to cut. You can put it up fast. It works well where you do not need much strength but want better insulation. People use fiberboard in energy-saving homes and apartments for outside walls.

Benefits

Fiberboard gives you many good things. It keeps heat inside better than oriented strand board. This means your house can stay warmer and you might pay less for energy. It also helps block noise, so rooms are quieter. Fiberboard is often made from recycled wood, so it is good for the environment. You can use it on roofs or walls because it is light and easy to install. Look at this table to see how fiberboard compares to oriented strand board:

Property | Fiberboard (½-inch) | OSB (½-inch) |

|---|---|---|

R-value (insulation value) | 1.3 | 0.5 – 0.62 |

Thermal resistance | Higher | Lower |

Dimensional stability | Stable (resists expansion/contraction) | Susceptible to dimensional instability |

Water vapor permeability | More permeable | Less permeable |

Strength | Lower | Higher |

Fastener holding capability | Lower | Better |

Cost | Less expensive | More expensive |

Fiberboard is a smart pick if you want to save money and make your home quieter and warmer.

Drawbacks

There are some things to think about before picking fiberboard.

It is not as strong as plywood or oriented strand board. The board can break and does not hold nails or screws well.

If you use thick insulation, the board might bulge out.

Some people say it is messy to use and smells like asphalt.

Fiberboard is not made for heavy loads, so do not use it where you need a lot of strength.

You have to be careful when putting it in to stop bulging or other problems.

Fiberboard does not rot or get eaten by termites, but the wood next to it can still get damaged if it gets wet.

Cost Comparison

Fiberboard costs less than oriented strand board or plywood. This makes it a good choice for big jobs or buildings that will not last long. Even though it is cheaper, you still get good insulation and easy setup. If you do not need a strong board, fiberboard helps you save money and stay on budget.

Ideal Applications

You can use fiberboard in many places.

It works for outside walls in energy-saving homes to help lower heating and cooling bills.

Apartment buildings use it to keep sound from going between rooms.

Eco-friendly buildings pick fiberboard because it uses recycled wood.

Roofs can use fiberboard as a light layer for insulation.

Temporary buildings, like event booths or barriers, use fiberboard because it is cheap and easy to put up.

You can also use fiberboard around doors, windows, and attics for extra insulation.

Tip: Pick fiberboard for outside walls if you want better insulation, a lower price, and do not need a super strong board.

Rigid Foam Insulation

Overview

Rigid foam insulation is a good choice if you want your house to save energy. It comes in big panels made from polyiso, XPS, or EPS. These panels go on the outside of your walls. Sometimes, they go over wood sheathing. Other times, they are the main sheathing. Rigid foam helps keep heat inside in winter. It also keeps heat out in summer.

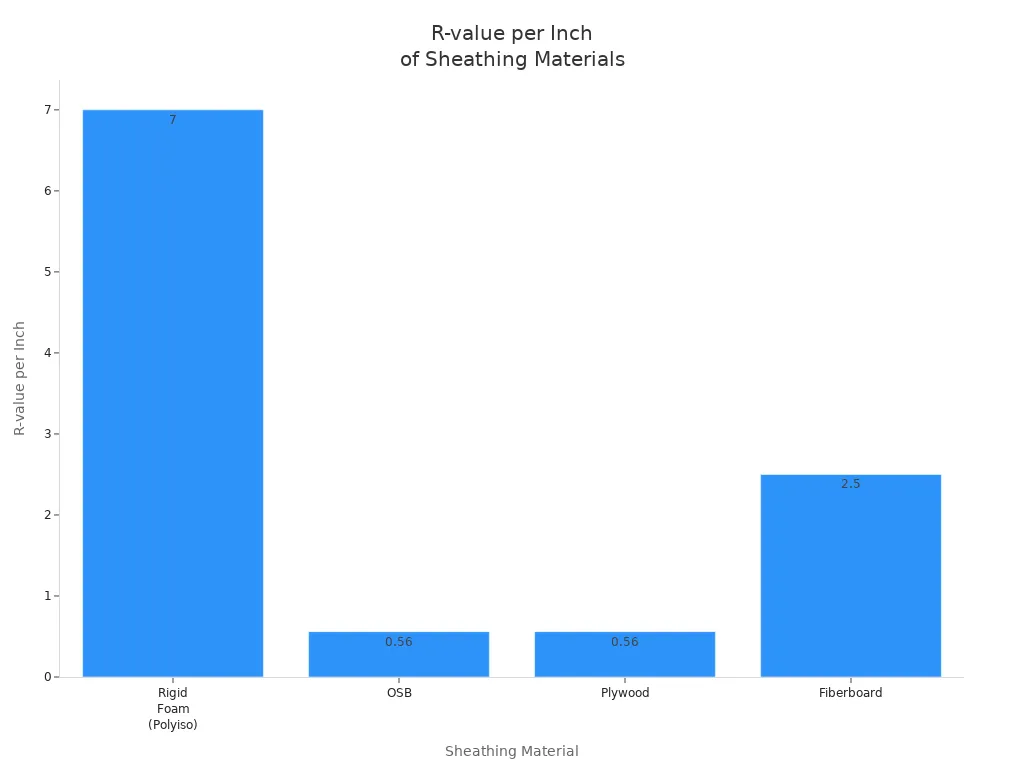

Benefits

Rigid foam insulation gives you some great benefits. It has a much higher R-value per inch than plywood or OSB. This means your house stays warmer in winter and cooler in summer. You might pay less for heating and cooling. Look at this table to see how rigid foam compares to other boards:

Sheathing Material | R-Value per Inch | Thermal Bridging Reduction | Key Benefits and Notes |

|---|---|---|---|

Rigid Foam (Polyiso) | R-6 to R-8 | High | Superior insulation, reduces heat loss by up to 40%, ideal for energy-efficient and eco-friendly buildings |

OSB | R-0.5 to 0.62 | Low | Lower insulation value, prone to swelling and warping when wet, commonly used but less effective thermally |

Plywood | R-0.5 to 0.62 | Low | Similar to OSB in R-value, stronger but more expensive, may have weak spots |

Fiberboard | R-2.5 | Moderate | Better insulation than OSB/plywood, but less than rigid foam |

Gypsum | N/A | N/A | Fire resistant, no warping, but low insulation value |

Magnesium Oxide (MgO) | N/A | N/A | Fire and moisture resistant, lower insulation than foam boards |

Rigid foam also helps stop heat from escaping through wall studs. This can make your house up to 40% more energy efficient.

Drawbacks

There are some things to think about before picking rigid foam insulation. It is not as strong as plywood or OSB. You may need extra bracing or use it with wood sheathing. If you do not seal it well, air and water can get in. This makes it work less well. Sunlight can damage rigid foam if you leave it outside too long. It costs more at first than other boards. But you might save money on energy bills later.

Tip: Keep rigid foam panels out of the sun and put them up quickly so they do not get damaged.

Cost Factors

The price of rigid foam insulation depends on the type, thickness, and brand. Polyiso costs more than XPS or EPS, but it gives the best R-value per inch. You pay more at first than for OSB or plywood. The price goes up if you need extra bracing or special fasteners. Even though it costs more at first, you can save money later because your house uses less energy.

Use Cases

You can use rigid foam insulation in many ways. It works well as extra insulation over wood sheathing. Sometimes, it is the main sheathing in some homes. Here are some ways to use it:

Put it on the outside of wood-framed walls to make your house warmer and stop heat loss.

Use it in places with strong wind or lots of rain by putting it over housewrap and plywood or OSB.

In places with mild weather, put rigid foam over housewrap and studs.

In dry areas, you can use rigid foam as the drainage layer, but seal all seams and joints.

If you use rigid foam instead of structural sheathing, add metal bracing or shear panels to meet building rules.

Note: Always follow local building codes and use the right way to install for your area.

Gypsum Board

Overview

You might know gypsum board as drywall, but it also works as a sheathing board. Builders use it for exterior wall sheathing when they want fire protection. Gypsum board has a core made from noncombustible gypsum. This makes it different from wood-based panels. You often see it in commercial buildings or high-rise apartments. It comes in large sheets, so you can cover big areas quickly.

Benefits

Gypsum board gives you some strong benefits, especially for fire safety.

The gypsum core does not burn, so it helps slow down fires.

You can use it in places where you need fire-rated walls, like stairwells or between apartments.

It is easy to cut and install, which saves you time on the job.

Gypsum board also helps block sound, making rooms quieter.

You get a smooth surface for finishing, so painting or adding siding is simple.

If you want exterior wall sheathing that protects against fire, gypsum board stands out. It is also a good choice when you want a clean, flat wall.

Drawbacks

You should know the drawbacks before you pick gypsum board.

It does not give much structural support, so you need to use it with other framing materials.

The board is brittle and can break if you drop it or hit it hard.

Gypsum board does not handle water well. If it gets wet, it can soak up moisture and grow mold.

You should avoid using it in wet or humid climates for exterior wall sheathing.

It is not as strong as plywood or OSB, so it is not the best for places with heavy wind or impact.

Cost Comparison

Gypsum board usually costs less than plywood or magnesium board. You can save money on big projects, especially if you need fire-rated exterior wall sheathing. The cost per sheet is low, but you may need extra framing or sealing to keep out water. This can add to the total cost. If you use gypsum board in the right place, you get good value for your money.

Sheathing Material | Average Cost per 4×8 Sheet | Fire Resistance | Water Resistance | Structural Support |

|---|---|---|---|---|

Gypsum Board | $10 – $15 | Excellent | Poor | Low |

OSB | $6 – $12 | Poor | Moderate | Good |

Plywood | $10 – $20 | Poor | Good | Good |

Tip: Always seal the edges and joints of gypsum board to keep out moisture and get the most out of your investment.

Applications

You can use gypsum board for many types of exterior wall sheathing, but it works best in dry climates.

It is a top pick for commercial buildings, schools, and apartments where fire safety matters.

Builders use it in stairwells, elevator shafts, and between units for fire-rated walls.

In places with little rain or humidity, gypsum board lasts a long time.

You should not use it in wet or coastal areas, since water can damage the board.

For projects that need both fire protection and a smooth finish, gypsum board is a smart choice.

If you want to save on cost and need fire-resistant exterior wall sheathing, gypsum board can be a great fit—just make sure you use it in the right climate and with proper installation.

Structural Insulated Panels (SIPs)

Overview

Overview

You might have heard about structural insulated panels, or SIPs, as a modern way to build strong and energy-efficient walls. SIPs are large panels made by sandwiching a thick foam core between two layers of structural exterior wall sheathing, usually oriented strand board. These panels can form your entire building envelope, including the foundation, walls, roof, and floor. You get panels in sizes from 4 to 24 feet, so you can use them for almost any project.

Benefits

SIPs offer some impressive benefits for exterior wall sheathing. First, you get amazing strength. SIPs can be up to seven times stronger than regular wood framing. This means your walls can handle heavy snow, wind, or even earthquakes. The panels also give you high insulation, so your home stays warm in winter and cool in summer. You save money on energy bills because SIPs stop drafts and heat loss. Another big plus is speed. Since SIPs are made in a factory, you can put up walls much faster and with less waste. You also need fewer hold-downs and less hardware, which cuts down on cost. SIPs help you qualify for energy tax incentives, making them a smart choice for your wallet and the planet.

Drawbacks

Even with all these benefits, SIPs have some drawbacks you should know. The panels are heavy and large, so you might need a crane or forklift to move them. If you want a custom design, SIPs can be tricky and may cost more. The airtightness of SIPs means you must plan for good ventilation, or you could have problems with humidity and air quality. If the panels get wet, the OSB facing can rot or grow mold, which hurts the strength of your structural exterior wall sheathing. Pests like termites or rodents can also burrow into the foam core. Fire safety is another concern, since SIPs need extra coverings to meet fire codes.

Drawback | What It Means for You |

|---|---|

Heavy panels | Need special equipment for handling |

Custom designs | Can increase cost and waste |

Moisture issues | Risk of rot and mold in OSB sheathing |

Pest problems | Foam core attracts insects and rodents |

Ventilation needed | Must plan for air flow to avoid humidity build-up |

Fire safety | Needs extra layers for fire protection |

Cost Considerations

When you look at cost, SIPs are more expensive up front than regular stick framing with OSB. You might pay $10 to $18 per square foot for SIPs, while OSB alone costs much less. But SIPs save you money in other ways. You spend less on labor because the panels go up fast. You also save on hardware and waste disposal. SIPs can lower your heating and cooling bills, and you may get tax breaks for energy efficiency. Over time, the total cost can be less than traditional building, especially for structural exterior wall sheathing that needs both strength and insulation.

SIPs cost $7 to $12 per square foot for materials, depending on the type.

You save up to 55% on labor compared to stick framing.

SIPs help you downsize HVAC equipment, saving even more money.

OSB is the most cost-effective sheathing for SIPs, giving you strength without raising the price too much.

Ideal Uses

You can use SIPs for almost any building that needs strong structural exterior wall sheathing. They work great for homes, schools, offices, and even barns. SIPs are perfect for places with heavy snow, strong winds, or earthquakes. You get the best results when you want energy efficiency, fast construction, and long-lasting strength. SIPs are also a top pick for projects that need airtight walls and good indoor air quality. If you want to build with fewer seams and less waste, SIPs make your job easier.

Tip: If you want structural exterior wall sheathing that gives you strength, energy savings, and fast installation, SIPs are a smart choice for your next project.

Diagonal Tongue and Groove Board

Overview

If you want a classic sheathing board for your subfloor, diagonal tongue and groove board is worth a look. This method uses solid wood boards, usually spruce, fir, or pine, cut into 1×6 or 1×8 sizes. You nail these boards diagonally across the studs or joists. This style was the standard before oriented strand board and OSB took over. You still see it in rural areas or where builders want a traditional touch. Diagonal tongue and groove boards tie the whole frame together, giving your subfloor extra strength.

Benefits

You get some real benefits with diagonal tongue and groove boards for your subfloor. First, these boards offer excellent structural support. They tie the headers, footers, and studs together, making your subfloor strong and stable. You also get a solid fastening surface, which helps when you install flooring or siding. Many builders say these boards last longer than OSB because they resist rot and swelling. In storm-prone areas, diagonal tongue and groove boards help your subfloor stand up to strong winds. If you want a subfloor that feels solid and holds up for years, this method delivers.

Drawbacks

There are some things you need to watch out for with diagonal tongue and groove boards on your subfloor:

Installation takes more time and skill than OSB or oriented strand board.

You need a contractor who knows how to fit and nail the boards just right.

Water can leak in around windows, doors, or joints, which may cause mold or moisture problems in your subfloor.

You have to cut more boards for diagonal placement, so you end up with more waste.

Not all wood types work well for this method.

This option is less sustainable because it uses more material and creates more waste.

The cost is higher, both for materials and labor.

Note: Always check your local building codes before choosing diagonal tongue and groove boards for your subfloor.

Cost vs. OSB

When you compare costs, diagonal tongue and groove boards for your subfloor usually cost more than OSB or oriented strand board. The material itself can be affordable, but the labor is much higher because installation takes longer and needs skilled workers. Here’s a quick look at how the costs stack up:

Sheathing Type | Material Cost (per 500 sq.ft.) | Installation Cost (per 500 sq.ft.) | Total Installed Cost (per 500 sq.ft.) | Notes on Cost and Installation |

|---|---|---|---|---|

Oriented Strand Board (OSB) | $100 | $490 | $590 | Material cost roughly $6 per 4×8 sheet; installation by skilled contractor; well-quantified costs |

Diagonal Tongue and Groove | Relatively low per sq.ft. (varies by wood type) | Higher due to labor-intensive fitting and nailing; scarcity of skilled installers | N/A | Installation more time-consuming; materials less common; no exact average cost provided |

You might pay less for the wood, but you’ll pay more for the work. OSB and oriented strand board remain the cheaper and faster options for most subfloor projects.

Best Applications

Diagonal tongue and groove boards shine in certain subfloor jobs. You often see them in new homes in rural areas, especially where local sawmills supply the wood. Builders who love traditional methods or want extra wall bracing pick this style. These boards work well for subfloors in storm-prone regions because they add strength. You can use them for solid wood sheathing on walls, too. Just remember, you need a skilled installer and approval from your local building code office. If you want a subfloor that lasts and feels sturdy, and you don’t mind the extra work, diagonal tongue and groove boards are a great choice.

Sheathing Board Options Comparison

When you pick a sheathing board, you want to know how each one compares to oriented strand board. You may ask which board fits your budget, lasts the longest, and handles water best. The table below shows how osb alternatives work for cost, strength, and wet areas. Use this guide to help you choose the right board for your subfloor or wall.

When you pick a sheathing board, you want to know how each one compares to oriented strand board. You may ask which board fits your budget, lasts the longest, and handles water best. The table below shows how osb alternatives work for cost, strength, and wet areas. Use this guide to help you choose the right board for your subfloor or wall.

Material | Cost vs. OSB | Durability | Moisture Resistance | Best Use Cases |

|---|---|---|---|---|

plywood | Higher | High | Good | subfloor, roofs, walls |

fiberboard | Lower | Moderate | Fair | subfloor, insulation, walls |

advantech | Highest | Very High | Excellent | subfloor, wet areas |

Higher | High | Excellent | subfloor, fire zones | |

Similar | Moderate | Poor | subfloor, fire-rated walls | |

rigid foam insulation | Higher | Moderate | Excellent | subfloor, energy homes |

diagonal tongue & groove | Higher | High | Good | subfloor, traditional builds |

Plywood is strong and lasts a long time for subfloors. Advantech works best in wet places, but it costs more. Fiberboard saves money and is good for insulation, but it is not as strong as plywood or oriented strand board. Mgo board and rigid foam insulation are great for wet areas, so they are smart for damp places. Gypsum board is good for fire safety, but it does not do well with water. Diagonal tongue and groove boards are strong for subfloors, but you pay more for work.

To pick the right board, think about your money, how strong you need it, and the weather. Oriented strand board is still the cheapest for most subfloors, but these other boards give you more choices for strength and how they work. Always look at the price and what you get before you pick. This table helps you find the best sheathing board for your next job.

Tip: Ask your supplier about the newest prices and what is in stock. Your budget and project needs will help you pick the right sheathing board for your subfloor or wall.

You have many choices when you look for sheathing board options besides oriented strand board. Each one has its own strengths. Some cost less than oriented strand board. Others last longer or work better in wet places. Oriented strand board stays popular because it is cheap and easy to find. You should match your board to your project, climate, and budget. Ask your supplier about the latest prices for oriented strand board and other boards. Try to get samples before you decide. Oriented strand board may fit your needs, but you might find a better option. Always compare oriented strand board with other boards for the best results.

FAQ

What is the best sheathing board for wet climates?

If you build in a wet area, try MgO board, Advantech, or rigid foam insulation. These boards resist water and mold. You get better results than with regular OSB. Always check your local building codes before you choose.

Can I use fiberboard for exterior walls?

You can use fiberboard for exterior walls if you want better insulation and a lower price. It works best in dry climates. Fiberboard does not hold up well in very wet or windy places.

Is plywood stronger than OSB?

Yes, plywood is stronger and stiffer than OSB. Floors feel more solid with plywood. You also get less swelling if the board gets wet. Plywood costs more, but you gain extra strength.

Are SIPs worth the higher cost?

SIPs cost more at first, but you save money on labor and energy bills. You finish your project faster. If you want strong, energy-efficient walls, SIPs are a smart choice.

How do I pick the right sheathing board for my project?

Think about your budget, climate, and how strong you need the board to be. Ask your supplier for samples. You can also talk to a builder for advice. The right choice depends on your needs.

Overview

Overview Overview

Overview