07 Feb Magnesium Sulfate Board vs Magnesium Oxide Board Applications and Benefits in 2025

Table of Contents

In 2025, selecting the right board for your project is crucial. The choice between Magnesium Sulfate Board vs. magnesium oxide board hinges on your specific requirements. If you prioritize strong fire protection and durability, magnesium oxide board is ideal for fire walls and exterior wall layers. Conversely, for wet environments and modular construction, the MgSO4 board excels due to its excellent water resistance. Recent studies indicate that both boards are now suitable for roofing applications and off-site construction. The market for magnesium oxide board reached $1,722.7 million in 2024 and continues to expand, particularly in the Asia Pacific region.

Key Takeaways

Magnesium sulfate boards work well in wet places. They are good for bathrooms and kitchens. These boards do not let water or mold in. This helps them last a long time.

Magnesium oxide boards protect well against fire. They are good for fire walls. They help keep places safe from fire.

Both boards can be used in modular buildings now. They also work for off-site construction. This gives builders more choices for projects.

Think about costs over time. Magnesium sulfate boards cost more at first. But they need less fixing later. This can save money in the future.

Pick the board that fits your project best. Use magnesium sulfate for wet areas. Use magnesium oxide for places needing fire safety.

Quick Comparison

Key Differences Overview

It is important to know how magnesium sulfate board and magnesium oxide board work in different places. The table below shows their main features side by side. This makes it easier to pick the right board for your project.

Property | Magnesium Sulfate Board | Magnesium Oxide Board |

|---|---|---|

Moisture Resistance | Low water absorption; great for wet spaces | Good moisture resistance; works in most places |

Fire Resistance | 1 to 4 hours; strong fire protection | A1 rating; does not burn or make smoke |

Strength | Flexural strength: Dry 2685 psi, Wet 1496 psi | High impact resistance; supports heavy loads |

Dimensional Stability | No breaking after freeze/thaw cycles | Stays stable when temperatures change; can be recycled |

Tip: Magnesium sulfate boards pass tough tests for bending and freezing. You can trust them in damp or wet places. Magnesium oxide boards give the best fire safety and stay strong in fires.

Best Uses in 2025

You want to choose the right board for your needs. Here is a simple guide to help you decide:

Magnesium sulfate boards are best for bathrooms, kitchens, and basements. They do not soak up water or let mold grow. They work better than OSB or gypsum.

Magnesium oxide boards are best for fire walls, outside wall layers, and places that need strong fire protection. They keep your building safe.

Both boards now meet building rules for modular and off-site construction. You can use either one, but magnesium sulfate boards are better in wet weather.

Think about where you will use each board before you start your project. Picking between magnesium sulfate board and magnesium oxide board depends on your space and safety needs. This comparison helps you choose wisely for your projects in 2025.

Magnesium Sulfate Board Overview

Composition and Features

Composition and Features

Magnesium sulfate boards use magnesium sulfate as the binder. This helps the board resist water and stay stable. The binder is what makes it different from magnesium oxide board. Magnesium sulfate mixes with water and forms a strong structure. The board does not swell or shrink, even after getting wet and drying many times.

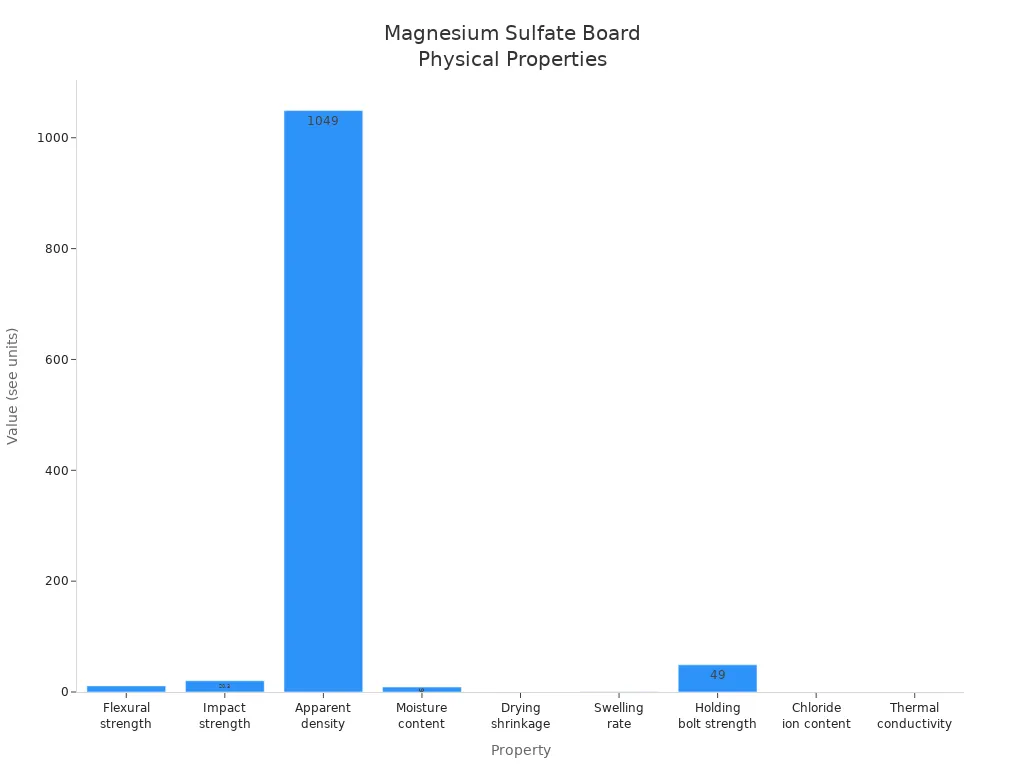

Here is a table that shows the physical properties of magnesium sulfate boards:

Property | Value |

|---|---|

Flexural strength | 11 MPa |

Impact strength | 20.3 KJ/m² |

Apparent density | 1049 kg/m³ |

Moisture content | 9% |

Drying shrinkage | 0.2% |

Swelling rate | 0.4% |

Holding the bolt strength | 49 N/mm |

Chloride ion content | 0.01% |

Thermal conductivity | 0.206 W/(m·K) |

Combustion property | A1 Grade |

You can also see these properties in the chart below:

Manufacturers add fiberglass mesh to make the board stronger and more flexible. Water-resistant agents help stop water damage and mold. Smoothening agents make the surface easier to finish.

Benefits and Limitations

Magnesium sulfate boards have many good points for your projects. These boards only take in about 0.34% water. That is much less than gypsum boards. You can use them in bathrooms, kitchens, and other wet places. They keep their shape and strength, even if they get wet for a long time.

Here are the main advantages and disadvantages:

Waterproofing: Magnesium sulfate boards do not let water in and stop mold.

Lightweight: You can carry and install them easily. This saves time and money.

Impact strength: These boards do not dent or break easily in busy areas.

Durability and longevity: The boards last for years, even in tough places.

Note: Magnesium sulfate boards resist water and stay stable better than many other boards.

There are some challenges when you install them. You must cut them carefully and use the right screws. Sometimes, delivery can be slow because of supply chain problems. The first cost is higher than plywood. But you save money later because you do not need many repairs.

When you look at the good and bad sides, magnesium sulfate boards are strong, resist water, and work well in wet places.

Magnesium Oxide Board Overview

Composition and Features

Magnesium oxide boards use magnesium oxide as the main binder. This makes the board strong and fireproof. Manufacturers mix magnesium oxide with magnesium chloride, vermiculite, and perlite. Each part helps the board work well and stay safe.

Component | |

|---|---|

Magnesium Oxide (MgO) | Needed for fire safety and strength. |

Magnesium Chloride (MgCl2) | Holds the board together and starts a chemical change. |

Vermiculite | Gets bigger when hot and helps stop fires. |

Perlite | Makes the board better at keeping heat in. |

This mix gives the board an A1 fire rating. You can use magnesium oxide boards where fire safety is important. The board stays strong even when it gets very hot. These boards also work in many climates and do not break easily in busy places.

Benefits and Limitations

Magnesium oxide boards have many good points. They are great at stopping fires, last a long time, and use earth-friendly materials. You can put them in schools, hospitals, and places with lots of people. They do not need much care, so you save money.

Great fire protection

Very strong and hard to break

Good for the environment

Magnesium oxide boards work better than other boards for fire safety. They are strong and can be used in many ways. When you compare magnesium sulfate board and magnesium oxide board, magnesium oxide boards protect against fire better and last longer.

But there are some problems too. Magnesium oxide boards can soak up water. This can make drops form on the surface. Over time, you might see stains, mold, or rust, especially if it is damp. The board is alkaline, so paint and glue do not stick well. This can cause peeling or bubbles. Water can also make joint compounds crack. You need special tools to install them. If you do not handle them right, they can break.

Tip: Always read and follow the manufacturer’s instructions when you install magnesium oxide boards. This helps you avoid problems and get the best results.

You can trust magnesium oxide boards for fireproof walls and safe buildings. They have many benefits, but you should think about the problems before you start your project.

Magnesium Sulfate Board vs. Magnesium Oxide Board: Performance Comparison

Durability and Strength

Durability and Strength

You want building materials that last a long time. Both magnesium sulfate boards and magnesium oxide boards are strong. They act differently in tough places. Magnesium sulfate boards do not bend or break easily. They stay strong after freezing and thawing. You can use them where the weather changes a lot. These boards keep their shape for many years. Magnesium oxide boards are also tough. They do not crack when hit. You can use them for walls that hold up buildings. They can carry heavy things.

Magnesium sulfate boards have a flexural strength of 11 MPa. Their impact strength is 20.3 KJ/m². You can use them in busy places like kitchens and hallways. Magnesium oxide boards are good for schools and big buildings. They can handle people walking on them every day. Both boards last a long time. Magnesium oxide boards are better for holding up buildings.

Note: Magnesium sulfate boards are light. You can put them up fast. Magnesium oxide boards are heavier. They give more strength for big projects.

Fire and Moisture Resistance

Fire safety is very important. Magnesium sulfate boards and magnesium oxide boards act differently in fire tests. Magnesium sulfate boards can stop fire for 1 to 4 hours. They meet safety rules like ICC, NFPA, UL, and ASTM E119. Magnesium oxide boards have a Class A fire rating. They do not burn or help fire spread. You can use them for walls and ceilings that need to be fireproof.

Board Type | Fire Resistance Rating | Compliance Standards |

|---|---|---|

Magnesium Sulfate Board | 1 to 4 hours | ICC, NFPA, UL, ASTM E119 |

Magnesium Oxide Board | Stronger against fire | ASTM E84 (Class A fire rating) |

How much water a board takes in is important. Magnesium sulfate boards do not soak up much water. You can use them in bathrooms, kitchens, and basements. They stop mold and keep their shape. Magnesium oxide boards can take in about 20% water in one day. You might see stains or mold if they get wet. Magnesium sulfate boards take in less water than magnesium oxychloride boards.

Tip: Use magnesium sulfate boards in wet places. They stop rust and water damage. Magnesium oxide boards are best in dry places or where fire safety is most important.

Environmental Impact

You want to help the planet. Both magnesium sulfate boards and magnesium oxide boards are good for the environment. Magnesium sulfate boards use natural materials. Making them uses less energy and makes less pollution. They do not have harmful chemicals. You can throw them away safely.

Magnesium oxide boards are also green. When they dry, they trap carbon dioxide. They do not have asbestos, formaldehyde, ammonia, silica, or benzene. Getting magnesium oxide from the ground does not use chemicals. The dust from these boards is safe for people, animals, and land.

Feature | Magnesium Sulfate Board | Magnesium Oxide Board |

|---|---|---|

Curing Process | Not specified | Captures carbon dioxide |

Toxic Materials | Not specified | Contains no asbestos, formaldehyde, ammonia, silica, or benzene |

Chloride Content | Not specified | Generally below 8 percent |

Mining Process | Not specified | Surface mining, no chemicals required |

Dust Impact | Not specified | Beneficial to land, people, or animals |

Magnesium oxide boards make 340 kg of CO2 for each ton. Gypsum boards make 740 kg for each ton. MOC panels make 22% less CO2 than concrete panels. You can pick either board for green buildings.

Cost Factors

Cost is important for every job. Magnesium sulfate boards cost more to make and buy. You pay more at first. Magnesium oxide boards cost less to make and buy. Both boards cost about the same to put in. You do not need special tools for magnesium sulfate boards. You do need the right screws. Magnesium sulfate boards cost less to take care of. You do not have to fix them as much because they stop water and mold. Magnesium oxide boards may need more fixing in wet places.

Cost Factor | Magnesium Sulfate Board | Magnesium Oxide Board |

|---|---|---|

Material Costs | Higher | Lower |

Manufacturing Costs | Higher | Lower |

Installation Costs | Similar | Similar |

Maintenance Costs | Lower | Higher |

Tip: If you want to save money later, pick magnesium sulfate boards. They cost less to fix. Magnesium oxide boards save you money at the start.

This comparison helps you pick the right board. Magnesium sulfate boards are best for wet places and where you need to stop rust. Magnesium oxide boards are best for fire safety and holding up buildings. Both boards have good points for building and fixing up places. You can choose what works best for your budget, the environment, and safety.

Best Applications 2025

Residential Uses

Magnesium sulfate boards and magnesium oxide boards are used in homes. You see them in bathrooms, kitchens, and basements. Magnesium sulfate boards stop water and last a long time. They also block sound. You do not need to replace them often. This saves you money. The table below shows why magnesium sulfate boards are good for homes:

Benefit | Description |

|---|---|

Durability | Can hold heavy things and does not break easily. |

Moisture Resistance | Stops mold and mildew, great for wet rooms. |

Eco-friendliness | You can recycle them and they have no bad chemicals. |

Sound Insulation | Keeps rooms quiet by blocking noise. |

Thermal Insulation | Helps keep rooms warm or cool and saves energy. |

You pick magnesium oxide boards for places with fire risk. They are good for strong walls. These boards keep your home safe and follow safety rules. Both boards help make homes healthy, quiet, and save energy.

Commercial and Industrial Uses

Magnesium oxide boards are used in schools, hospitals, and offices. They stop fires and are strong for busy places. Magnesium sulfate boards work well in wet places like kitchens and locker rooms. They do not rust and last a long time. Big projects need boards that fit your budget. Magnesium oxide boards are used for outside walls. Magnesium sulfate boards are best inside buildings.

Specialty and SIPs Applications

Both boards are used in special building jobs. SIPs use these boards for strength and insulation. SIPs can save lots of energy with high R-values. They meet safety and building rules. Magnesium sulfate boards and magnesium oxide boards give support for SIPs and other special uses.

Trends and Innovations

In 2025, people want green building materials. Magnesium sulfate boards and magnesium oxide boards now stop fires and water better. Lighter boards help build faster and make modular buildings. New mixes make boards stronger and cheaper. Sound and heat insulation is better now. Magnesium oxide boards help save energy. More people use magnesium oxide boards for green buildings. Governments buy more magnesium oxide boards for public buildings.

Tip: Pick the board that matches your needs. Magnesium sulfate boards are best for wet and moldy places. Magnesium oxide boards are best for fire safety and strong walls.

Choosing Between Magnesium Sulfate and Magnesium Oxide Boards

Decision Factors

Decision Factors

You need to think about a few things before you pick a board. Each board works best in different places. Make sure your choice fits your project and where you will use it.

Durability is important if you want strong walls or floors. Magnesium sulfate board, like MagPanel®, lasts longer and needs less fixing than regular magnesium oxide boards.

Moisture resistance helps in wet or salty places. Magnesium sulfate board does not rust and stays strong when wet. Magnesium oxide board can get damaged or show rust in damp spots.

Environmental impact matters if you want a green building. Magnesium sulfate board uses sulfate, not chloride, so it is better for the planet.

Fire resistance keeps your building safe. Both boards protect against fire, but MagPanel® works better.

Ease of installation saves time. Magnesium sulfate board is easier to put in, so you can use it for more jobs.

Here is a simple chart to compare how the boards work in different places:

Feature | Magnesium Sulfate Board (MagPanel®) | Traditional Magnesium Oxide Board (MgCl) |

|---|---|---|

Moisture Resistance | Handles wet places better | Can rust and get damaged in wet places |

Composition | Has magnesium sulfate | Has magnesium chloride |

Durability | Lasts longer in wet areas | Does not last as long in wet areas |

Practical Selection Tips

You want your project to look nice and last a long time. Use these easy tips to help you pick the right board:

Make sure the new board is as thick as your old walls or floors. This stops bumps or uneven spots.

Pick engineered decking if you need a strong base that fits with wood sizes.

Check that your deck joists are spaced right for the board you choose.

For wet rooms like bathrooms or kitchens, use magnesium sulfate board. It handles water better.

For places with fire risk or where you need strong walls, magnesium oxide board is a good choice.

Always read the instructions from the maker before you start putting in the boards.

Tip: Think about your money, the planet, and how much fixing you want to do. The right board makes your project safer and easier to take care of.

You know that magnesium sulfate boards work well in wet places. Magnesium oxide boards are best for stopping fires. In 2025, experts say you should pick the board that fits your project. Use the quick guide to help you choose. The table below shows which board is good for each job:

Application | Recommended Board | Main Benefit |

|---|---|---|

Bathrooms/Kitchens | Magnesium Sulfate Board | Moisture resistance |

Fire Walls | Magnesium Oxide Board | Fire safety |

Think about your space and what you want to do. Ask an expert if your project is hard. You can make buildings safer and last longer.

FAQ

What makes magnesium sulfate board better for wet areas?

Magnesium sulfate board keeps water out. It does not get bigger or let mold grow.

Tip: Put it in bathrooms, kitchens, and basements. It will last a long time.

Can you paint or finish magnesium oxide board easily?

Painting magnesium oxide board is hard. The surface is alkaline, so paint can come off.

Use a primer made for alkaline surfaces before you paint.

Is magnesium oxide board safe for the environment?

Magnesium oxide board is good for the planet. It does not have bad chemicals.

Feature | Magnesium Oxide Board |

|---|---|

Asbestos | No |

Formaldehyde | No |

Silica | No |

Which board costs less to maintain over time?

Magnesium sulfate board needs fewer repairs. It stops water and mold, so you fix it less.

Note: Magnesium oxide board might need more fixing in wet places.

Composition and Features

Composition and Features Durability and Strength

Durability and Strength Decision Factors

Decision Factors