21 Nov Comparing Top Fire Resistant Sheathing Board Types

Table of Contents

You want your building to be safe from fire. Picking the right fire resistant sheathing board types is important. Gypsum board is the most popular choice among these types. It is used in more than half of commercial buildings in North America. Fire resistant sheathing keeps things cooler during a fire. This helps protect people and property. These boards slow down flames. They also help meet tough safety rules. Using fire resistant materials makes buildings safer. It helps keep the building strong. It lowers the risk for everyone inside.

Key Takeaways

Picking the right fire resistant sheathing board is very important for safety. It helps keep people and things safe if there is a fire.

Fire rated gypsum board is used a lot because it slows down fire. It can protect for up to 120 minutes. People use it in houses and business buildings.

MgO boards are great because they resist fire and water. They work well in places that get wet. They do not burn even when it gets very hot.

Type X and Type C gypsum boards give better fire protection. Type C is best for ceilings and important spots.

Always look at local building rules and fire ratings before you choose sheathing boards. This helps you follow the rules and stay safe.

Fire Resistant Sheathing Board Types Overview

What Is Fire Resistant Sheathing?

You want your building to stay safe in a fire. Fire resistant sheathing uses materials that do not burn fast. These boards help protect walls and ceilings from heat and flames. Noncombustible materials like MgO and cement board will not catch fire. They do not burn when there is a fire. These boards slow down flames. They keep the building cooler.

Here is a table that shows the main fire resistant sheathing board types and their features:

Type of Wallboard | Key Features | Fire Resistance Time |

|---|---|---|

Fire Rated Gypsum Board | Gypsum core, paper layers, releases water vapor to slow flames. | Up to 79 minutes (two layers) |

MGO Board | Naturally fireproof, non-combustible, eco-friendly, resists mold and water. | Up to 4 hours |

Type X Wallboard | Contains glass fibers, meets ASTM standards, used in fire-sensitive areas. | At least 1 hour |

Type C Wallboard | UL Classified, eco-friendly, strong fire resistance, low chemical emissions. | Excellent fire protection |

Each type gives different fire safety and strength. MgO and cement boards are very good at stopping fire and water damage. Plywood and OSB do not protect as well. They need extra care to stay dry.

Key Benefits and Applications

You get many good things when you use fire resistant sheathing boards:

You follow fire codes and insurance rules

Fire spreads slower and less heat moves through

People have more time to leave safely

The building parts are less likely to fall down

You have less risk and less time fixing things after a fire

MgO panels are strong and last a long time. They work well in wet places. These boards are good for the environment. They do not make toxic fumes. You can put them on walls, ceilings, and floors. They block sound and keep bugs away.

You see fire resistant sheathing in many places. Homes use it in garages, stairs, attic walls, and floors between rooms. Commercial buildings use it in halls, lobbies, and elevator areas. Factories and warehouses use these boards too. Schools and hospitals use fire resistant sheathing to help people leave safely in emergencies.

Tip: You make your building safer and protect your money when you pick the right fire resistant sheathing.

Main Fire Resistant Wallboard and Sheathing Types

Fire Rated Gypsum Board

Fire Rated Gypsum Board

Fire rated gypsum board is used in lots of buildings. It has a thick gypsum core between tough paper layers. Gypsum holds water inside. When the board gets hot, the water turns into steam. The steam stops heat from moving through the wall. This board does not burn fast, so it gives extra safety. Builders put fire rated gypsum board in walls that hold up the building. It helps protect steel studs. You see it in homes, schools, and offices. One layer protects for about 60 minutes. Two layers can last up to 120 minutes. In fire tests, this board keeps things cool and stops burn-through. Using fire rated gypsum board helps you follow safety rules.

Type X Gypsum Board

Type X wallboard protects better than regular gypsum board. It has glass fibers mixed into the gypsum core. These fibers help the board stay strong in a fire. Type X wallboard meets ASTM fire safety standards. You find it in walls and ceilings where fire safety matters. Builders use type X wallboard in stairs, hallways, and between rooms. You can pick different thicknesses, like 1/2 inch, 5/8 inch, or 1 inch. Type X wallboard gives at least one hour of fire protection. This means more time to get out and less damage.

Feature | Standard Gypsum Board | |

|---|---|---|

Fire Rating | 1-hour | Less than 1-hour |

Thickness Options | 1/2″, 5/8″, 1″ | Typically 1/2″ |

ASTM Standard | ASTM C1396 | ASTM C1396 |

Tip: Use type X wallboard where you need extra fire safety.

Type C Gypsum Board

Type C wallboard protects even better than type X wallboard. It has a special mix with more glass fibers. Type C wallboard comes in 1/2 inch or 5/8 inch thickness. It grows bigger when heated, which helps cover joints and seams. Type C wallboard does not shrink like type X wallboard. You see type C wallboard in ceilings and places where fire safety is very important. Builders use it in hospitals, schools, and tall buildings. Type C wallboard does not have a set definition, but it always protects better than type X wallboard.

Feature | Type X | Type C |

|---|---|---|

Thickness | Typically 5/8” thick | Can be ½” or 5/8” thick |

Fire Resistance Rating | Minimum 1 hour for 5/8” boards | Exceeds Type X requirements |

Composition | Standard formulation | Enhanced formulation with more glass fiber |

Performance Under Fire | Shrinks when exposed to heat | Expands, providing better joint protection |

Standard Definition | Defined by ASTM C1396 | Not currently defined by a standard |

Common Applications | General use | Often used for ceilings |

Note: Type C wallboard gives the best protection for ceilings and important areas.

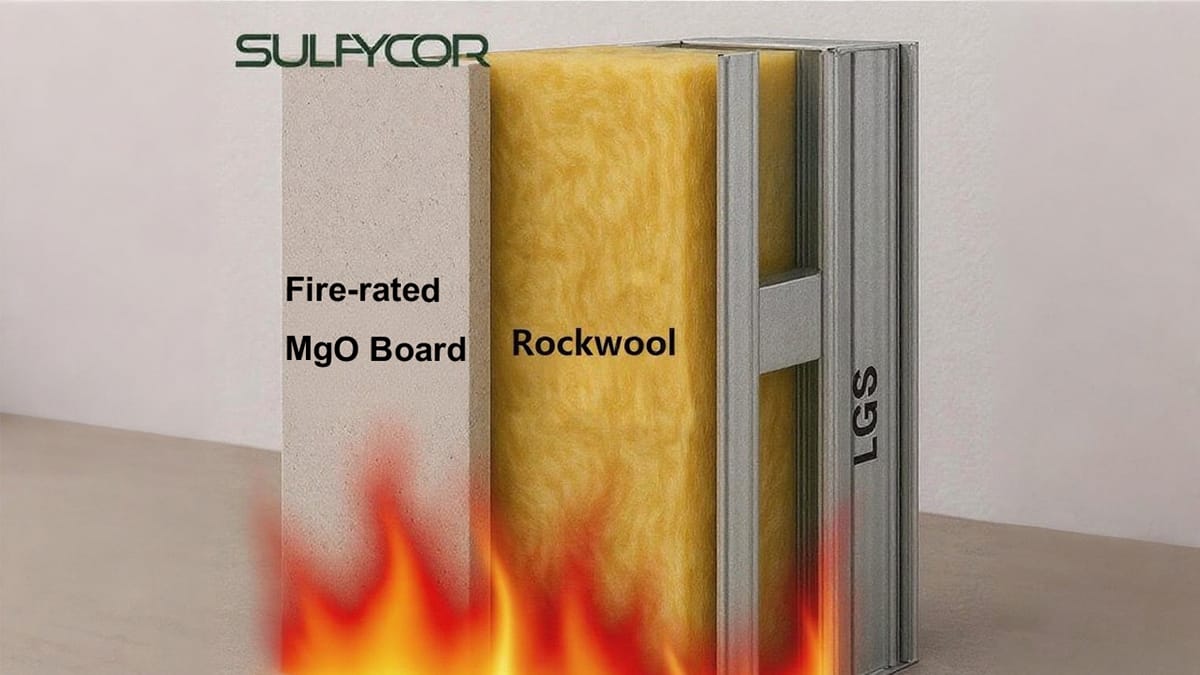

MgO Sheathing Boards

MgO board is used in many new buildings. It is made from magnesium oxide, which does not burn. MgO board can take very high heat without catching fire. It does not spread flames. This board also resists water, mold, and bugs. MgO board does not swell or bend when wet. You can use MgO board for walls, floors, ceilings, and room dividers. Builders use MgO board in homes, offices, and other buildings. MgO board can protect for up to four hours in a fire. It is good for the environment and does not make toxic fumes.

Property | Description |

|---|---|

Fire Resistance | Non-combustible; withstands high temperatures without igniting or spreading flames |

Moisture Resistance | Highly resistant to moisture, does not swell, warp, or degrade when exposed to water |

Versatile Applications | Used for walls, floors, ceilings, partitions, and fire-rated enclosures in residential and commercial settings |

Tip: Use MgO board where you need fire and water protection.

Calcium Silicate Board

Calcium silicate board gives strong fire protection. It can handle high heat and keeps its shape. Calcium silicate board has a Class A fire rating. You see it in risky places like fire barriers, walls, and ceilings. Builders use calcium silicate board in tall apartments, big office towers, and factories. You find it in fire-rated walls, ceilings, and air ducts. Calcium silicate board does not burn or break down in a fire.

Calcium silicate boards have a Class A fire rating because they can take high heat without damage.

They work well in risky places and are needed for fire safety.

You see them in walls, ceilings, and fire barriers in buildings where stopping fire is important.

Used in fire-rated walls, ceilings, and ductwork.

Needed in tall apartments, big towers, and factories where safety matters most.

Note: Pick calcium silicate board for places where stopping fire is most important.

Fiber Cement Board

Fiber cement board gives strong fire protection and lasts a long time. It does not burn, even when flames touch it. This board holds heat and slows down fire. Fiber cement board helps keep your building safe. Builders use fiber cement board in walls, floors, and dividing walls. You see it in apartments, townhouses, and mid-rise buildings. Fiber cement board can protect for one to two hours, depending on how it is used.

UL Design No. | Assembly Type | Fire-Resistance Rating | Notes/Benefits |

|---|---|---|---|

V340 | 2×4 wall construction | 1-hour both sides | No exterior gypsum required; consistent wall thickness |

U348 (stucco) | Stucco exterior | 1-hour both sides | Common in multifamily Type V construction; allows fiberglass insulation |

U350A, U350B | Townhouse dividing walls | 2-hour fire-resistance | Alternative to shaft wall; conventional framing; STC rating of 61 |

V337 | Mid-rise exterior walls | 1-hour or 2-hour | 1-hour from either side or 2-hour interior/1-hour exterior; may reduce gypsum layers |

Tip: Use fiber cement board for walls that need fire protection and strength.

Mineral Wool Board

Mineral wool board gives top fire protection. It is made from melted rocks and minerals. This board does not burn or melt, even at very high heat. Mineral wool board has a flame spread rating of zero, so fire does not move across it. It also does not make smoke. Builders use mineral wool board in wall panels, big buildings, and homes. You can put mineral wool board in walls to help stop fire and block sound.

Feature | Description |

|---|---|

Non-combustibility | Mineral wool is classified as non-combustible, ensuring it does not ignite. |

High-temperature resistance | Can withstand temperatures above 1000°C, ideal for fire protection. |

Flame spread | Has a flame spread rating of 0, indicating no flame propagation. |

Smoke developed | Also has a smoke developed rating of 0, minimizing smoke production. |

Applications | Suitable for both residential and commercial construction scenarios. |

Used in fire-resistant wall panels.

Common in big buildings for better safety.

Put in homes to help stop fire and block noise.

Note: Use mineral wool board where you need the most fire and smoke protection.

Specialty Boards (ArmorWall SP Plus, DensDeck)

Specialty boards like ArmorWall SP Plus and DensDeck give advanced fire protection. ArmorWall SP Plus has two layers of MgO board, one outside and one inside. This setup gives up to two hours of fire protection. ArmorWall SP Plus also works as a strong wall, fire barrier, and keeps out air and water. DensDeck is another specialty fire resistant wallboard. You see DensDeck in roofs, floors, and walls where you need extra strength and fire safety. Builders use these boards in big buildings, hospitals, and schools.

Tip: Pick specialty boards when you need fire, water, and strong wall protection all in one.

Comparing Fire Resistant Sheathing Board Types

Composition and Structure

Composition and Structure

Fire resistant wallboards are made in different ways. Each type uses special materials to make them safer from fire. The table below shows how the main board types are built and what they do:

Criteria | Gypsum Board | Calcium Silicate | Fiber Cement | Mineral Wool | MgO Board |

|---|---|---|---|---|---|

Fire Resistance | Moderate | High | High | Excellent | Superior |

Moisture Resistance | Low | Moderate | Moderate | Moderate | Excellent |

Durability | Low | High | High | Moderate | High |

Environmental Impact | Moderate | Moderate | High | Moderate | Low |

Cost | Low | Moderate | Moderate | High | Moderate |

Boards with strong cores and noncombustible materials work better for fire safety. MgO board is great because it protects well from fire and resists water and mold.

Fire Resistance Ratings

Fire resistance ratings show how long a wallboard can stop fire. You need to pick the right rating for your building. The table below lists common wallboard types and their ratings:

Wallboard Type | Fire Resistance | Typical Uses |

|---|---|---|

Type X | 1-4 hours | Fire-rated walls, barriers, ceilings |

Type C | Over 2 hours | Ceilings, high-demand firewalls |

Magnesium Wallboard | A1, up to 1200°F | Fire barriers, outside fire-rated walls |

Specialty Boards | Varies | Data centers, hospitals, outside walls |

Boards with higher fire resistance ratings keep buildings safer in important places.

Durability and Strength

You want wallboards that last and stay strong. Some boards can hold heavy things and handle bad weather. Fiber cement and MgO boards are very tough and strong. Fiber cement can last up to 50 years with little care. MgO board stays strong in wet or buggy places. Plywood bends but does not stop fire well. Boards that keep their shape and strength give better fire safety and value.

Moisture and Mold Resistance

Moisture and mold resistance helps keep buildings safe and healthy. MgO board blocks mold and absorbs less than 5% water. It uses SPORGARD® technology to stop mold. XP Fire-Shield Gypsum Board also fights mold and moisture with a special core. Fiber cement and mineral wool boards resist water and mold, but not as much as MgO board. Picking boards with good moisture and mold resistance protects your building and people.

MgO board stops mold and takes in little water.

XP Fire-Shield Gypsum Board fights mold and moisture.

Fiber cement and mineral wool resist water and mold a little.

Environmental Impact

Choosing wallboards with low carbon emissions helps the planet. Magnesium oxide boards release less CO2 and even capture CO2 as they cure. You can recycle MgO boards or use them as fertilizer. Gypsum boards use more energy and make more waste. They can release toxic gases in landfills. Fiber cement boards last long and help cut down waste. Picking boards with low impact helps fire safety and the environment.

Tip: You make buildings safer, save money, and help the earth when you choose the right fire resistant sheathing boards.

Cost and Installation Factors

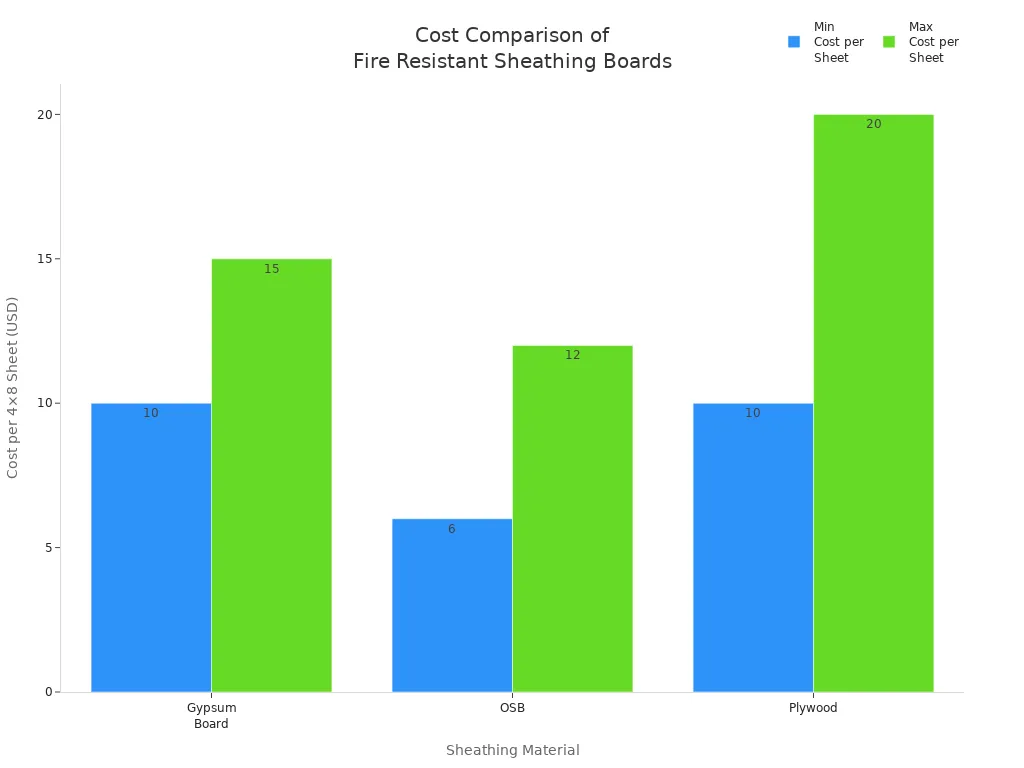

Price Comparison by Board Type

You might wonder how much these boards cost. The price depends on what the board is made of. It also depends on how much fire safety you want. The table below shows the average price for each kind of board. You can see which ones are better for fire, water, and strength.

Sheathing Material | Average Cost per 4×8 Sheet | Fire Resistance | Water Resistance | Structural Support |

|---|---|---|---|---|

Gypsum Board | $10 – $15 | Excellent | Poor | Low |

OSB | $6 – $12 | Poor | Moderate | Good |

Plywood | $10 – $20 | Poor | Good | Good |

Gypsum board is great for fire safety and costs less. OSB and plywood cost about the same as gypsum board. They do not protect well against fire. If you want more fire safety, you might pay more for boards like MgO or mineral wool. These boards help keep your building safe for a longer time.

Tip: Pick the board that fits your needs and budget. Always think about fire safety before saving money.

Installation and Maintenance Considerations

You need to put in fire resistant boards the right way. This helps you get the best fire protection. Some products, like LP® FlameBlock® Fire-Rated Sheathing, follow strict fire safety rules. You must follow all safety codes when you install boards. You should check your boards often to make sure they are still strong.

Fire-resistant boards and frames cost more at first. They give you better fire safety for many years. Checking your boards often helps them work well, especially if wildfires happen near you. Do not skip taking care of your boards. It helps keep your building and everyone inside safe.

Always follow local fire safety rules when you install boards.

Check boards often for damage or problems.

Pick boards that match your building’s fire safety needs.

Note: Good installation and care help you stay safe and worry less.

Choosing the Right Fire Resistant Sheathing

Application Scenarios (Residential, Commercial, Roof, Specialty)

You need to pick the right fire resistant wallboard for your project. Different buildings need different things. In homes, people use fire resistant wallboard in garages, stairs, and attics. These spots help keep families and things safe. In commercial buildings, fire resistant wallboard goes in halls, elevators, and lobbies. These places need strong fire safety because lots of people use them.

For roofs and special areas, you want materials that handle heat and water. MgO sheathing works well in homes and businesses. It can take heat over 1,382°F for more than 30 minutes. The color does not change. You get up to four hours of fire resistance. This is much better than plywood or regular gypsum board. MgO sheathing makes very little smoke during a fire. This helps keep everyone safer.

Common applications for mineral wool board are wall panels and sound barriers. Fiber cement board is good for outside walls and dividing rooms. Specialty boards like ArmorWall SP Plus protect roofs and important spots.

Meeting Building Codes and Safety Standards

You must follow safety rules when picking fire resistant wallboard. Building codes say what materials you need for each part. These rules help keep people safe and make sure your building passes checks.

Check the fire resistance rating for every board. Type X and Type C gypsum boards meet tough safety rules. MgO and calcium silicate boards also meet high fire safety needs. Always pick products tested and approved by trusted groups.

Tip: Ask your local building office about the newest safety rules before you start your project.

Balancing Performance and Budget

You want great fire safety, but you also need to think about price. Some boards cost more because they last longer and protect better. MgO sheathing gives strong fire safety and works in wet places, but costs more than regular gypsum board. Fiber cement and mineral wool boards give good fire safety and last long for a medium price.

Use this table to compare safety and cost:

Board Type | Fire Safety Level | Durability | Cost |

|---|---|---|---|

Gypsum Board | Good | Moderate | Low |

MgO Sheathing | Excellent | High | Moderate |

Fiber Cement Board | Very Good | High | Moderate |

Mineral Wool Board | Superior | Moderate | High |

You should balance fire safety and your budget. Pick the fire resistant wallboard that fits your project and meets all safety rules.

Note: You keep people and things safe when you choose the right fire resistant wallboard for your building.

There are big differences in fire safety, strength, and price for each board. The table below lets you see how they compare:

Siding Type | Fire Resistance | Durability | Cost Implications |

|---|---|---|---|

Fiber Cement | Very High | High | Moderate |

Brick | High | High | High |

Vinyl | Low | Low | Low |

Pick a board that works for your project. Always ask experts for advice and check local rules. Fire resistant sheathing helps save money later and keeps your building safe.

Building codes help keep people and buildings safe.

Experts help you make good choices and avoid problems.

Good boards mean fewer repairs and less spending later.

Tip: Fire safety and saving money for the future are most important when you choose your sheathing board.

FAQ

What is the best fire resistant sheathing for wet areas?

You should use MgO or fiber cement boards in wet areas. These boards resist water and mold. They keep their strength even when wet. Builders often pick them for bathrooms, basements, and exterior walls.

How do you know if a board meets fire codes?

Check the board’s label for fire ratings and certifications. Look for ASTM or UL marks. You can also ask your supplier for test reports. Always confirm with your local building office.

Can you install fire resistant sheathing by yourself?

You can install some boards yourself if you follow the instructions. Use safety gear and the right tools. For large projects or specialty boards, you should hire a professional.

Does fire resistant sheathing add much cost to a project?

Fire resistant boards cost more than regular boards. You pay more at first, but you save money later. These boards lower repair costs after a fire and help you meet insurance rules.

Fire Rated Gypsum Board

Fire Rated Gypsum Board Composition and Structure

Composition and Structure