23 Nov Defining Fire Resistant Sheathing and Its Building Standards

Table of Contents

You use fire resistant sheathing to slow down fire. It helps stop fire from moving through walls and floors. This material acts like a shield. It gives you more time to get out or call for help. Fire safety standards check how well these shields work. They help keep people and property safe. When you look at fire resistance ratings, you see what matters most. Timber thickness and load ratio are very important.

Fire-related things cause more fire spread and money loss.

Human-related things matter most for injury risk.

Different risks mean you need different safety plans.

Parameter | Influence on Fire Resistance Rating |

|---|---|

Timber Thickness | Main thing |

Load Ratio | Main thing |

Model Performance (R2) | 0.93 |

You learn important words and rules by seeing how these ratings make things safer.

Key Takeaways

Fire resistant sheathing helps slow down fire. This gives you more time to get out or call for help.

Knowing fire resistance ratings helps you pick safe materials. It also helps you follow the rules.

Using certified fire-resistant materials keeps your building safe. It also helps protect people inside.

Materials like gypsum board and concrete have different fire resistance. Pick what your building needs most.

Always look at local building codes and certifications. This makes sure your fire-resistant sheathing is safe and allowed.

Fire Resistant Sheathing Overview

Definition and Function

Fire resistant sheathing helps protect buildings from fire. This layer sits between rooms and floors. It slows down flames and heat. When you use these materials, you make compartments inside the building. These compartments stop fire from spreading fast. You get more time to leave or call for help.

Fire resistant sheathing does more than block flames. It protects beams and columns in the building. These boards help keep the building strong during a fire. You can put these materials in walls, ceilings, and partitions. This makes buildings safer and helps you follow rules.

Here is a table that shows what fire resistant sheathing does:

Function | Description |

|---|---|

Preventing Fire Spread | These boards act as barriers and split buildings into sections to slow fire. |

Protecting Structural Elements | Fire-resistant boards cover important parts and keep them safe during a fire. |

Enhancing Fire Safety | You can use them in many places, like walls and ceilings, to make buildings safer. |

Maintaining Structural Integrity | They keep heat and radiation out, so the other side stays cool. |

Compliance with Building Codes | You need them to meet building codes and keep buildings safe. |

Fire-resistant construction materials are important for safety plans. These materials can stand up to fire and heat for a long time. They slow fire down, give you more time to escape, and lower damage. Many buildings need special roofs and wall coverings. For example, roofs may use fire-retardant wood or gypsum board. Walls must stop flames and keep fire from moving to other buildings.

Tip: Always check if your fire-resistant construction materials follow local building codes. This keeps your property safe and legal.

Common Fire-Resistant Construction Materials

You have many choices for fire-resistant construction materials. Each one protects in different ways. Some work better in certain parts of a building. Here are the most common fire-resistant construction materials and what they do:

Material | Fire Resistance Characteristics |

|---|---|

Bricks | Bricks do not burn and are used to stop fire. |

Gypsum (Drywall) | Gypsum has water inside. When it gets hot, it makes steam and cools things down. Some types need extra treatment to resist fire. |

Steel | Steel does not burn but can get weak if it gets too hot. It is often covered or put in concrete to help. |

Stucco | Stucco is made from things that do not burn. It gives walls a one-hour fire rating if installed right. |

Fire-Resistant Cellulose Insulation | This insulation is easy to put in and saves energy while resisting fire. |

Gypsum board is often used in walls and ceilings. Type X gypsum board has glass fibers and is stronger against fire. Type X can last up to one hour in a fire. Type C gypsum board can last up to two hours. Cement board is another good choice. It is strong and heavy and does not crack easily. Cement board has a Class A fire rating and can protect for up to one hour. Mineral wool does not burn and gives great fire resistance.

You can use these fire-resistant construction materials in many buildings:

High-rise buildings use concrete and protected steel for strong fire resistance.

Newer buildings have masonry walls and metal roofs.

Ordinary buildings may have walls that do not burn but wood roofs.

Older buildings use thick wood for extra safety.

Modern homes use wood frames, so they need extra fire-resistant materials.

When you pick fire-resistant construction materials, you help keep buildings safe. You also make sure your project follows safety rules. These materials slow fire, protect important parts, and give you more time to act in an emergency.

Fire Resistance Ratings and Classifications

Fire-Resistance Rating Explained

Fire-Resistance Rating Explained

It is important to know how long materials last in fire. The fire resistance rating tells you this. You measure it in minutes or hours. It shows how long a material stops fire from spreading. Experts test these materials in labs. They use the ASTM E119 fire test. This test checks if walls, floors, or ceilings can block fire and stay strong.

Fire resistance ratings sort materials by how well they stop fire.

These ratings use time, like minutes, to show how long materials last in fire.

The ASTM E119 fire test checks if building parts can hold back fire and stay strong.

Here is a table that shows common fire resistance ratings for sheathing materials:

Fire Rating | Duration |

|---|---|

1 hour | |

2-hour | 2 hours |

Class A and Other Ratings

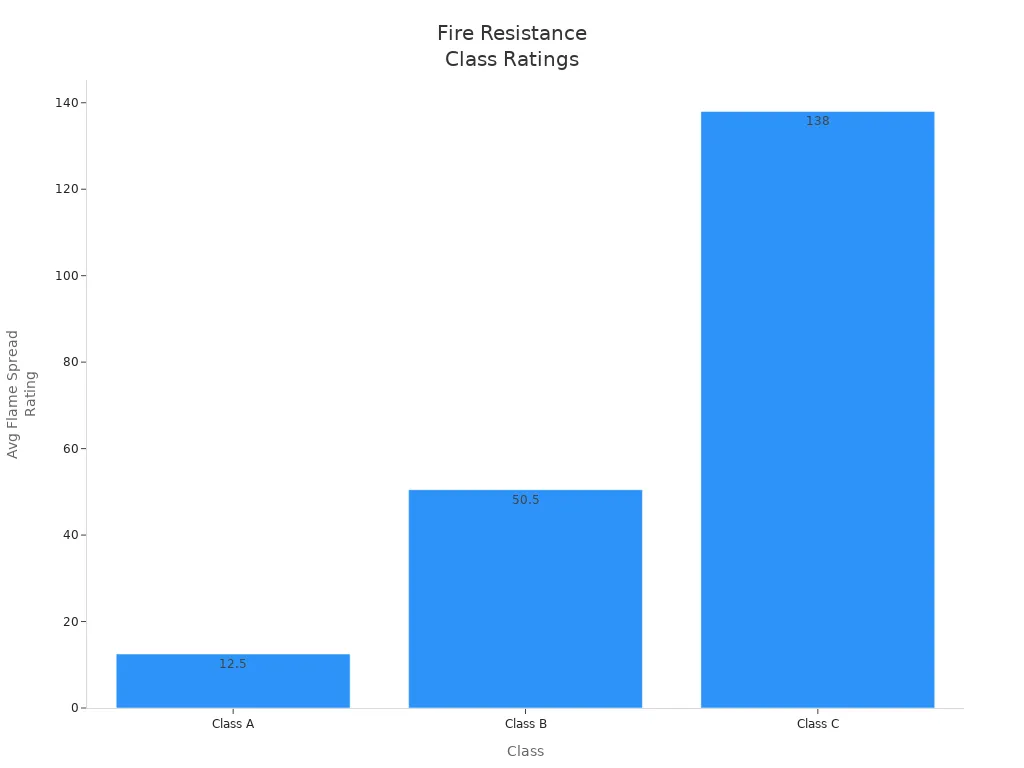

There are different classes for fire resistance. Class A gives the best protection. It stops flames from spreading and keeps buildings safer than Class B or C. Class B protects a little less. Class C gives the least protection. You can see the differences in this table:

Class | Flame Spread Rating | Fire Resistance | Performance Compared to Other Classes |

|---|---|---|---|

A | 0 – 25 | Greatest fire resistance | Better than Class B and Class C |

B | 26 – 75 | Moderate fire resistance | Less effective than Class A |

C | 76 – 200 | Limited fire resistance | Least effective among the classes |

You can also look at fire protection levels:

Class Rating | Fire Resistance Level | Description |

|---|---|---|

Class A | Highest | Can handle strong fire and does not catch fire or spread flames. |

Class B | Moderate | Can handle some fire but not as much as Class A. |

Class C | Lowest | Only handles light fire and catches fire easier than Class A and B. |

Key Terms: Noncombustible, Ignition Resistant

You will hear non-combustible and ignition resistant when talking about fire safety. Non-combustible materials do not catch fire, burn, or make flammable vapors when heated. You find these in steel, concrete, masonry, and some insulation. Non-combustible materials help stop fire from moving.

Ignition-resistant materials do not catch fire or burn quickly. These materials protect buildings during wildfires, especially in dry and windy weather. Here is a table that shows how these materials are tested:

Material Type | Test Method | Criteria for Classification |

|---|---|---|

Noncombustible | ASTM E-136, Standard Test Method for Behavior of Materials in a Vertical Tube Furnace at 750°C | 1. Weight loss ≤ 50%: Temperature ≤ 30°C above test apparatus; No flaming after 30 seconds. 2. Weight loss > 50%: Temperature ≤ test apparatus; No flaming at any time. |

Ignition-resistant | Horizontal flame spread tunnel test (30 minutes duration) | Defined by minimum flame spread rating after wetting-drying cycle; Example: pressure-impregnated lumber with fire retardant. |

Note: Non-combustible materials are very important for fire-resistant sheathing. They do not burn or make a fire worse, so they help keep buildings safe.

Standards and Codes for Fire Resistant Sheathing

Major Building Codes (NFPA, IBC, ASTM)

You need to know the main codes for fire resistant sheathing. These codes help you pick safe materials and build strong walls. The National Fire Protection Association, International Building Code, and ASTM International make the rules for fire safety. You see these codes in every building project.

The IBC puts buildings into groups based on fire resistance. Each group has its own rules for walls, floors, and roofs. You use non-combustible wall panels and fire-rated exterior sheathing to meet these rules. The table below shows how each building part must follow fire resistance ratings for every group:

Building Element | Type 1 A B | Type II A B | Type III A B | Type IV HT | Type V A B |

|---|---|---|---|---|---|

Primary structural Frame | 3 2 | 1 0 | 1 0 | HT | 1 0 |

Bearing Walls Exterior | 3 2 | 1 0 | 2 2 | 2 | 1 0 |

Bearing Walls Interior | 3 2 | 1 0 | 1 0 | 1/HT | 1 0 |

Nonbearing walls | 0 | 0 | 0 | 0 | 0 |

Floor Construction | 2 2 | 2 0 | 1 0 | HT | 1 0 |

Roof Construction | 1.5 1 | 1 0 | 1 0 | HT | 1 0 |

ASTM standards are used for every fireproofing material certification. ASTM E119 tests wall assemblies for how long they last in fire. ASTM E84 checks how fast flames move across foam plastics. NFPA 286 tests foam plastics that are thick. These codes make sure you use fireproof wall panels and fireproof insulation boards that protect your building.

Tip: Always check your local building codes before you start. These codes tell you which rules you must follow for fireproof wall boards and fire-rated exterior sheathing.

Testing and Certification Standards

You need to know how experts test and certify fire resistant sheathing. Testing uses strict rules to make sure materials work in real fires. ASTM E119 is the main test for fire resistance. You see this test in every fireproofing material certification.

ASTM E119 puts a wall or floor in fire until it fails. You measure how long the material lasts.

The Hose Stream Test checks if the wall can handle water from a fire hose. You use a copy of the wall for the standard test, or the same wall for the optional test.

ASTM E84 measures how fast flames move across foam plastics. You want a flame spread index of 75 or less.

NFPA 286 tests thick foam plastics. You make sure flames do not reach the ceiling and smoke stays low.

Thermocouples are used in these tests. They track temperature on both sides of the material. You start at 68°F and go up to 2300°F. This makes a time and temperature curve. You use this curve to see how fireproof wall panels and fireproof insulation boards work.

Here is how the test goes:

You put the material in a chamber with controlled temperature.

You connect thermocouples to both sides.

You raise the temperature over time.

You record how long the material stops fire.

You must use a thermal barrier, like half-inch gypsum drywall, to keep foam plastics away from the inside of the building. This barrier keeps the foam’s surface temperature below 250°F after 15 minutes of fire. You need this for fire-rated exterior sheathing and non-combustible wall panels.

The table below shows who certifies fireproofing material certifications:

Organization | Role in Certification | Standards Used |

|---|---|---|

ASTM | Makes standards | Fire resistance standards |

NFPA | Makes codes | Fire safety codes |

UL | Tests and certifies | Fire safety standards |

Intertek | Tests and certifies | Fire safety standards |

Factory Mutual (FM) | Tests and certifies | Fire safety standards |

You need to plan with a fire safety expert. You pick certified materials with a four-hour fire resistance rating. You build by safety plans and local codes. You ask a certified expert to check your work. You get a certificate from a trusted fire safety group.

Fire-Rated Assemblies and Applications

You use fire resistance rated assemblies to protect your building. These assemblies use fireproof wall panels, fireproof wall boards, and fireproof insulation boards. You see them in homes and businesses.

Material Type | Key Features | Common Uses |

|---|---|---|

Concrete Panels | Non-combustible, handles high heat, stops fire spread | Commercial buildings, hospitals |

Gypsum Board (Type X) | Has additives to slow fire, water turns to steam to stop fire | Interior walls |

Magnesium Oxide Panels | Handles high heat, non-combustible, eco-friendly | Places needing strong fire protection |

You use non-combustible wall panels in hospitals and schools. You put fireproof wall boards in inside walls. You pick fireproof insulation boards for ceilings and attics. You use fire-rated exterior sheathing for outside walls.

Fire rated assemblies help you split up fire. You slow down smoke and flames. You protect escape routes and stairs. You keep the building strong during a fire. You use fire-retardant and heat-resistant panels to make things safer. You help everyone get out safely.

Note: Fire resistance rated assemblies are needed to meet standards and codes. You must use certified fireproof wall panels and fireproof insulation boards to keep your building safe.

You see fire-retardant and heat-resistant panels in many places. You use them in walls, floors, and roofs. You follow local codes and standards to make sure your building passes inspection.

Compliance and Product Selection

Identifying Certified Sheathing

Identifying Certified Sheathing

You need to pick certified fire-resistant sheathing for your building. Certified products help you follow fire safety rules and keep people safe. You can find these panels by checking trusted sources. The UL Product iQ Database lets you search for fire-rated sheathing. You can see their fire-resistance ratings there. You should follow the instructions for each fire-rated assembly. This helps you use the right materials and meet safety standards.

Key Indicator | Description |

|---|---|

UL Product iQ Database | Search for UL Listed and Certified fire-resistant sheathing products. |

Fire-resistance Ratings | Look for specific fire-resistance ratings and construction requirements. |

Assembly Construction | Follow details for fire-rated assemblies, including required elements. |

You can also check your local building codes and ask the person in charge. You should read technical documents and fire test reports. Many certification marks show fireproofing and fire-resistant safety, like the UL Mark, C-UL Mark, CE Mark, and GREENGUARD Certification.

Importance of Standards Compliance

You must use fire-resistant sheathing that meets safety standards. If you use the wrong materials, fire can spread faster and make more smoke. Unsafe escape routes can put people in danger. Fire-rated assemblies help keep paths open and protect lives. You may get fines, pay for repairs, or have legal trouble if you do not follow fire safety codes.

Fire-rated sheathing helps control smoke and fire dangers.

Breaking rules can lead to fines.

You may need to fix things if you use the wrong materials.

You could be responsible if someone gets hurt or worse.

Building inspectors check fire-rated assemblies during visits. They look at fire-resistant gypsum board and shaftliner board. Inspections happen after the fire-rated sheathing is put in but before the outside layer is finished. Inspectors check shaft walls from three sides and the outside.

Step | Description |

|---|---|

1 | Inspect fire-resistance-rated assemblies, such as gypsum board or shaftliner board. |

2 | Inspect after fire-rated sheathing is in place but before taping and covering. |

3 | Inspect shaft walls from three sides and the exterior. |

Practical Selection Tips

You should pick fire-resistant sheathing that matches your building and local codes. Look for fire-rated panels that can hold weight well. Choose materials that keep flames and hot gases out. Pick insulation that keeps the other side cool. Use non-combustible materials like steel, concrete, brick, and gypsum board for fire-rated assemblies. Fire-rated roofing and siding protect against embers and flames. Insulation and barriers slow down fire and heat.

Cost, what you can buy, and local rules affect your choice.

Fiber cement and concrete work well where fire safety rules are strict.

In wildfire areas, you must use fire-rated sheathing for new buildings and repairs.

Tip: Always check fireproofing certifications and fire-resistance ratings before you buy fire-resistant sheathing. This keeps your building safe and legal.

When you pick fire resistant sheathing, you help keep people safe. This material slows down fire and protects buildings. It also helps you follow building codes. Using it can even make insurance cheaper. If you follow rules like NFPA 285 and IBC, your building stays safer for a long time.

Tip: Always pick sheathing with trusted certifications. Use gypsum board inside and fiber cement boards outside. Hire certified workers and make sure all products are tested by another company.

Common Mistakes | How to Avoid |

|---|---|

Bad firestop install | Hire certified experts |

Products not tested | Use materials tested by others |

FAQ

What does fire resistant sheathing do in a building?

You use fire resistant sheathing to slow down fire. This material helps keep flames from moving through walls and floors. You get more time to leave the building safely.

How do you know if a product meets fire safety standards?

You check for fire resistance ratings and certifications. Look for marks from trusted groups like UL or ASTM. These show the product passed strict fire tests.

Where should you install fire resistant sheathing?

You put fire resistant sheathing in walls, ceilings, and floors. You use it in places where fire could spread quickly. This helps protect escape routes and important building parts.

Can fire resistant sheathing stop all fires?

You cannot stop all fires with sheathing. It slows down fire and gives you more time to act. You still need alarms and other safety tools in your building.

Why do building codes require fire resistant sheathing?

You follow building codes to keep people safe. Fire resistant sheathing helps control fire and smoke. This lowers the risk of injury and damage in homes and businesses.

Fire-Resistance Rating Explained

Fire-Resistance Rating Explained Identifying Certified Sheathing

Identifying Certified Sheathing