12 Nov Pros and Cons of Magnesium Oxide Wallboard in 2025

Table of Contents

You might see more builders using magnesium oxide wallboard in 2025. This material is very safe from fire. It does not get damaged by water or mold. It lasts longer than many other boards. People want buildings that are safer and better for the planet. So, more people are buying magnesium oxide wallboard.

The market could be worth about $2.15 billion in 2025. It is growing a little more each year.

Builders like that it is easy to take care of. They also like that it is better for the environment than old materials.

Key Takeaways

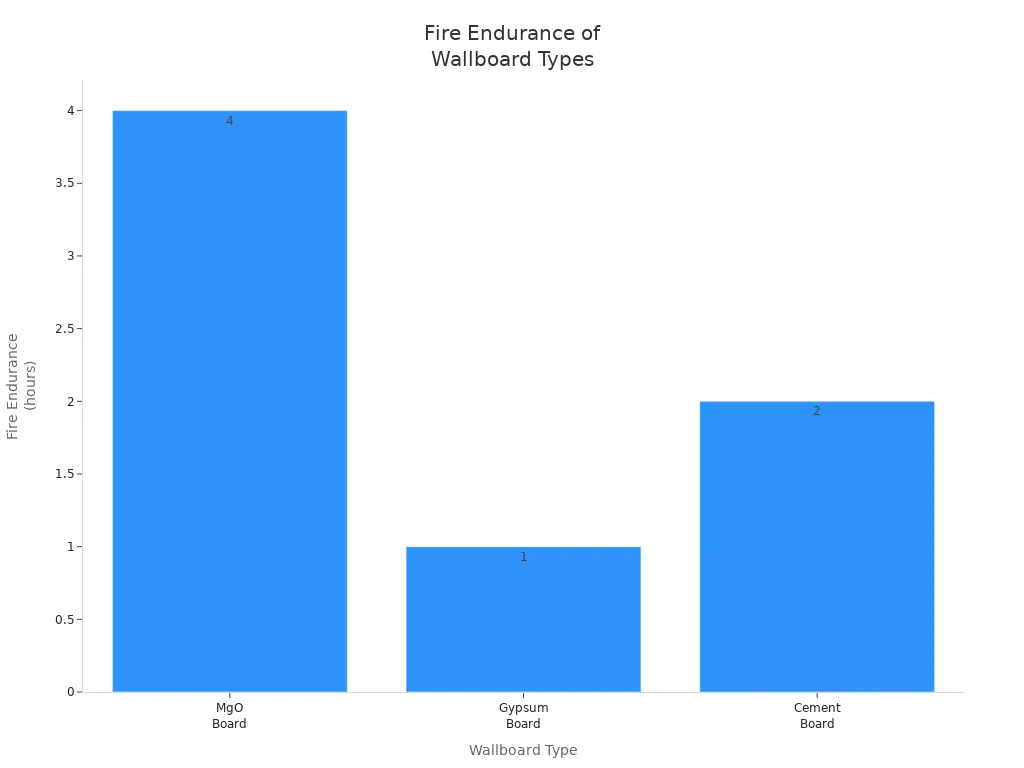

Magnesium oxide wallboard does not burn easily. It can protect for up to four hours. This makes buildings safer.

This material does not weigh much. It is simple to put in place. This can help save time. It can also lower work costs when building.

Mgo boards do not let water or mold in. They work well in wet places. You can use them in bathrooms and kitchens.

Magnesium oxide wallboard has many good points. But it can cost more than other materials. You should think about your budget.

Always look at the quality of Mgo boards before you buy. Check for certifications to make sure the product is good.

Magnesium Oxide Wallboard Advantages

When you pick new building materials, you want them to be strong and safe. You also want them to be easy to use. Magnesium oxide wallboard gives builders many good things for today’s buildings. Let’s see why so many people use mgo for their work.

Durability and Impact Resistance

Walls need to handle bumps and hits every day. Mgo is known for being tough. It keeps its shape and strength in busy places like schools or hospitals. Tests show magnesium oxide sheet panels are stronger than other boards.

Board Type | |

|---|---|

Magnesium Oxide | ≥4.5 |

Cement Board | ≥3.5 |

Gypsum Board | ≤1 |

Mgo board is good because:

It has high impact strength (up to 10 KJ/m2)

It does not dent or bend, even when wet

It works well in bad weather

You can count on mgo to last a long time. It stays strong, so it is a smart choice for building.

Fire Safety

Safety is very important in every building. Mgo boards are great at stopping fire. They do not burn or make dangerous smoke. You get more time to get out if there is a fire. The walls stay strong even when it is hot.

Property | Description | Benefits of Fire Protection |

|---|---|---|

Fire Resistance | Stops fire spread | |

Thermal Stability | Handles high heat | Slows building collapse |

Smoke and Toxicity | No harmful gas release | Safer during fires |

Structural Integrity | Stays strong in fire | More time to escape |

Moisture Resistance | Resists water and mold | Less damage after fire |

Eco-Friendliness | Made from natural materials | Green and fire-safe |

Mgo boards pass hard tests like ASTM E84. This test checks how fast fire spreads and how much smoke comes out. These boards score between 0 and 25 for flame spread. They also keep smoke low. Mgo gives you the best fire safety compared to other boards.

Property | MgO Board | Gypsum Board | Cement Board |

|---|---|---|---|

Fire Resistance Rating | Fire-resistant up to 1 hour | Fire-resistant up to 2 hours | |

Fire Endurance | Up to 4 hours | 30-60 minutes | Up to 2 hours |

Moisture and Mold Resistance

You want walls that stay dry and clean. Mgo boards do not let water or mold in as much as other boards. They work well in wet places like bathrooms, pools, or outside. Some magnesium oxide boards, like those with magnesium oxysulfate, stay strong and mold-free for years in damp air. They do not leak or fall apart.

Mgo boards made with magnesium oxysulfate:

Do not get weak or moldy in wet places

Note: Some magnesium oxide boards with lots of chloride can soak up water and may rust metal. Always check the type of mgo board before using it in very wet places.

Lightweight and Easy Installation

Heavy boards are hard to move and put up. Mgo boards are light, so you can carry and install them easily. This makes building faster and safer.

Material | Thickness | Weight (psf) |

|---|---|---|

Magnesium Oxide Board | 12mm (0.5 in) | 1.5 to 2.0 |

Traditional Drywall | 1/2 inch | 1.6 to 2.2 |

You can cut and shape mgo boards without trouble. This saves time and money when you build.

Eco-Friendly Materials

Being green is important in 2025. Mgo boards help you build in a way that is better for the earth. They use natural minerals and need less energy to make. They even take in CO2 while they dry, which helps the planet.

Mgo boards:

Have a smaller carbon footprint than gypsum or cement boards

Can be recycled or used again in building or as fertilizer

Make less waste because they last longer

Material | Recyclability |

|---|---|

Magnesium Oxide Boards | Highly recyclable – can be reused or as fertilizer |

Gypsum Boards | Limited recyclability – mostly ends up in landfills |

You can feel good about using mgo because it has many safety and air quality certificates, like CE Marking, ISO 9001, and VOC reports. These show that magnesium oxide wallboard is safe and good for indoor air.

Tip: Using mgo in your building project means you pick a material that is safe, strong, and good for the earth.

With all these good things, magnesium oxide sheet panels are a top pick for builders who want strong, fire-safe, water and mold-resistant, and green walls. Mgo board advantages help make your building safer and last longer.

Disadvantages of Magnesium Oxide Boards

Mgo has many good things, but it also has some problems. You should know about these before you pick it for your building. Learning about these issues helps you choose wisely.

Mgo has many good things, but it also has some problems. You should know about these before you pick it for your building. Learning about these issues helps you choose wisely.

Higher Cost

Mgo costs more than other wallboards. The price for each square meter is higher than drywall and cement board. This can make your project cost more money, especially if you need a lot.

Material Type | Price per m² |

|---|---|

Magnesium Oxide Board | |

Fiber Cement Board | $6–$15 |

There are several reasons why mgo is more expensive. It needs special ways to make it, which raises the price. Gypsum is easy to find and cheap to make, so it costs less. Mgo boards are not as common, so prices can go up in some places. Making mgo cleaner and able to be recycled also adds to the cost.

You should think about your budget if you want to use mgo.

Limited Availability

It can be hard to find mgo boards in some places. Problems with getting supplies and not enough factories can cause delays or higher prices. The table below shows some big challenges:

Challenge Type | Description |

|---|---|

Cost Factors | U.S. tariffs and trade issues raise costs for raw materials like steel and aluminum. |

Supply Chain Issues | Problems in the supply chain make it hard to get mgo when you need it. |

Factory Limitations | Not enough factories means you may face delays or shortages. |

Regulatory Changes | Local rules can make it harder to buy magnesium oxide sheet panels. |

Planning Requirements | You need to plan ahead to avoid running out of materials. |

Pricing Pressures | Lower prices can hurt companies, making supply less stable. |

Supply Chain Strategies | Companies work on better supply chains and partnerships to fix these problems. |

If you want mgo, talk to your supplier early and order ahead.

Moisture Absorption and Corrosion Concerns

Mgo can soak up water, especially in damp places. Some types of mgo boards take in more water than others. The table below shows how different boards do:

Board | Water Absorption Performance | Notes | |

|---|---|---|---|

A | 0.05 – 0.07 | Traces of moisture after 24h | Less susceptible to moisture |

B | 0.25 | Large droplets after 24h | Increased porosity |

C | 0.13 | No moisture after 24h | Best performance |

D | 0.05 – 0.07 | Traces of moisture after 24h | Acceptable performance |

E | 0.11 | N/A | N/A |

F | 0.05 – 0.07 | N/A | N/A |

When mgo takes in water, it can make a salty liquid called brine. This brine can make metal parts rust. You might see water drops on the board, especially when it is very humid. These drops have chloride ions, which make rust happen faster. Over time, this can hurt metal and other parts of your building.

Note: If you use mgo in wet places, put a barrier between the board and metal to stop rust.

Quality Variations

Not all mgo boards are made the same. Quality can change a lot between brands and countries. Some boards take in more water or get mold, especially from less skilled factories. How each company makes the board changes its strength and water resistance.

Quality standards are different because of changes in the mix and how boards are made.

Some new makers do not check quality well, so their boards may not be as good.

You might see problems like uneven strength, poor water resistance, or even mold.

Always check if the maker is trusted before you buy mgo.

Compatibility Issues

Mgo does not always work with every building material. Some types, especially those with magnesium chloride, can make metal parts rust if they touch. The table below shows common problems:

Material Type | Recommendation | |

|---|---|---|

Traditional MgO Boards (MgCl) | Corrosion of metal fasteners, weeping boards | Install a barrier to avoid direct contact with galvanized steel framing |

MagPanel® (MgSO4) | Better moisture resistance, less prone to weeping boards | Use with galvanized steel framing and a barrier |

You may also have other problems when putting up mgo. Mgo can soak up water, which can make paint peel, mold grow, or boards bend. Some paints and glues do not stick well to mgo, which can hurt how your walls look and last. Cracks and bending can happen if you do not handle or dry the boards right.

Tip: Always follow the maker’s instructions and use the right finishes and barriers to stop these problems.

Knowing these problems helps you decide if mgo is right for your building. Think about the good and bad sides to get the best results.

Magnesium Oxide Wallboard vs. Traditional Materials

MgO vs. Drywall

MgO vs. Drywall

When you compare mgo to drywall, you see big differences in strength and safety. Mgo stands up to bumps and hits much better than drywall. You do not have to fix dents or holes as often. In a fire, mgo gives you up to four hours of protection. Drywall lasts less than one hour. Mgo also keeps out water and mold, so your walls stay strong and clean. Drywall gets weak and soggy when it gets wet.

Material | Durability | Fire Resistance | Moisture Resistance |

|---|---|---|---|

MgO Boards | Strong, less damage | Up to 4 hours | Excellent, stays dry |

Gypsum Drywall | Easily damaged | < 1 hour | Weakens when wet |

You will find that mgo panels do not soak up water. They stop mold from growing, which helps keep your building healthy. Drywall needs repairs if it gets wet.

Tip: Use mgo in bathrooms, kitchens, or any place that gets wet often.

MgO vs. Cement Board

Mgo and cement board both work well in tough places, but mgo is lighter and easier to use. You can carry and cut mgo boards with less effort. Cement board is heavy and may need extra support. Mgo has great strength and does not break easily. Cement board is strong but can wear down in busy spots.

Attribute | Magnesium Oxide Wallboard | Cement Board |

|---|---|---|

Weight | Lighter, easy to handle | Heavier, needs more support |

Strength | Very strong, less damage | Durable, may wear over time |

Cost | Higher upfront | Lower upfront |

Mgo boards also do better in wet places. They do not soak up water or let mold grow. Cement boards can resist water, but you may need to seal them for extra safety.

Mgo boards work well in bathrooms, kitchens, and basements.

Cement boards are good under tiles but may need more care to last as long as mgo.

Cost and Performance Comparison

You might notice that mgo costs more at first. However, you save money over time. Mgo does not need as many repairs because it is strong and does not get damaged by water or fire. Drywall and cement board are cheaper to buy, but you may spend more fixing them later.

Mgo has a higher starting price but lower repair costs.

You spend less on maintenance with mgo because it lasts longer.

Mgo is a smart choice for construction in places that need strong, safe, and long-lasting walls.

If you want a wall that stays strong and safe for many years, magnesium oxide wallboard gives you the best value. You get peace of mind and save money in the long run. Builders use mgo in modern construction because it works well and lasts.

Choosing MgO Boards in 2025

Best Applications

You should use mgo when you want strong and safe walls. Magnesium oxide wallboard works in many places because it is tough, safe, and good for the earth. You can use mgo inside or outside buildings. The table below shows where experts say to use magnesium oxide boards in 2025:

Application Type | Specific Uses |

|---|---|

Indoor | Offices, Meeting Rooms, Classrooms, Building Shafts, Warehouses, Datacenters, Hospitals, Kitchens, Wet Areas, Hotel Rooms, Libraries |

Outdoor | Roof decking, Sheathing, Fascias, Soffits, Trim work, Wall sheathing, Residential roofs, Commercial roofs |

Mgo fits many jobs. You might pick magnesium oxide sheet panels for kitchens or bathrooms because they do not let water or mold in. You can also use mgo for roof decking or wall sheathing outside. These boards help keep you safe and are not harmful, so they are good for the planet and your health.

Decision Factors

Before you pick mgo for your building, you should think about a few things. Not every job needs magnesium oxide boards, so you want to make the right choice. Here are some important things to check:

Product quality and consistency

Production capacity and technology

Range of applications

Global export experience

Customer support and technical assistance

Sustainability practices

Check if the mgo you buy is made well. Look for a company with good customer service and strong ways to make the boards. You want a board that is safe and made from green materials. Make sure the supplier has worked on big projects and uses earth-friendly ways. These steps help you get the best things from mgo, like strength and being good for the earth.

Tip: Always ask for test reports and certificates before you buy magnesium oxide wallboard. This helps you make sure you get a safe, strong, and good product.

When you look at all these things, you can see why mgo is a smart pick for many building jobs in 2025. You get a material that is good for the earth, lasts a long time, and keeps your building safe.

You have learned the main pros and cons of magnesium oxide wallboard. MgO boards give you strong, safe, and eco-friendly walls for construction. You may pay more and face supply issues, but you get long-lasting results.

Think about your budget and project needs.

Ask for quality checks before you buy.

Remember: Weigh the benefits and drawbacks. Choose the best wallboard for your building.

FAQ

What makes magnesium oxide wallboard different from drywall?

You get stronger, safer walls with magnesium oxide wallboard. It resists fire, water, and mold better than drywall. You can use it in places where drywall might fail.

Can you paint or finish MgO boards like other wallboards?

Yes, you can paint or finish MgO boards. Use primers and paints made for cement or masonry. Always follow the manufacturer’s instructions for the best results.

Is magnesium oxide wallboard safe for indoor air quality?

You can trust MgO boards for healthy air. They do not release harmful gases or dust. Many brands have certifications for low VOCs and safe indoor use.

How do you cut and install MgO boards?

You can cut MgO boards with a standard utility knife or saw. Install them with screws or nails, just like drywall. Always wear safety gear when cutting.

Where should you avoid using magnesium oxide boards?

Avoid using MgO boards in places with constant water exposure unless you use a moisture barrier. Check with your supplier for the right board type for wet areas.

MgO vs. Drywall

MgO vs. Drywall