14 Nov What Is Magnesium Oxide Wallboard and How Is It Used

Table of Contents

You might know magnesium oxide wallboard as mgo board or just mgo. This building material is very good at stopping fires. It also helps protect against mold and is better for the environment. You can use magnesium boards for walls and ceilings. They also work in other places where you want things to last longer. Many builders pick it because more people are buying magnesium oxide wallboard every year. Sales may go over $4 billion by 2032. If you want something safer and better for the planet than regular drywall, you should think about this choice.

Key Takeaways

Magnesium oxide wallboard is a tough building material. It does not burn easily. It helps stop mold and keeps out water. Using magnesium boards can help save money over time. They last longer and need less fixing than regular drywall. These boards are good for the environment. They do not let out bad chemicals. This makes them safe for the air inside. You need to prepare carefully before putting them up. You must use special steps to stop cracks and keep them strong. Think about using magnesium oxide wallboard where you need more fire safety. Good places are kitchens, bathrooms, and business buildings.

What Is Magnesium Oxide Wallboard

Definition and Composition

People sometimes call it magnesium oxide wallboard, magnesium oxide board, or just mgo. This is a kind of wall panel that builders use in many ways. You can put magnesium oxide panels on walls, ceilings, or even floors. Magnesium boards are strong, safe, and last a long time.

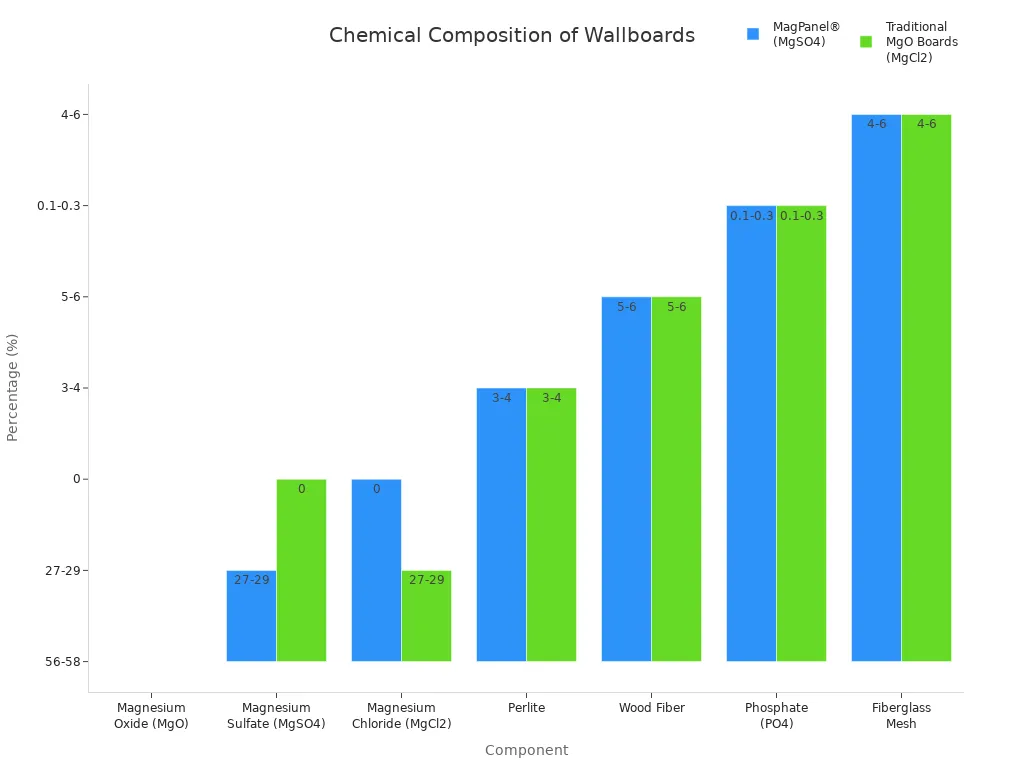

Magnesium oxide wallboard has a few main parts. The most important part is magnesium oxide. It makes the board strong and helps stop fires. Other parts are magnesium sulfate or magnesium chloride, perlite, wood fiber, phosphate, and fiberglass mesh. These parts work together to make the board tough and light.

Here is a table that shows what is in different types of magnesium oxide wallboard:

Component | MagPanel® (MgSO4) | Traditional MgO Boards (MgCl2) |

|---|---|---|

Magnesium Oxide (MgO) | 56-58% | 56-58% |

Magnesium Sulfate (MgSO4) | 27-29% | N/A |

Magnesium Chloride (MgCl2) | N/A | 27-29% |

Perlite | 3-4% | 3-4% |

Wood Fiber | 5-6% | 5-6% |

Phosphate (PO4) | 0.1-0.3% | 0.1-0.3% |

Fiberglass Mesh | 4-6% | 4-6% |

You can also see how the chemical makeup is different by looking at this chart:

Manufacturing Process

You might want to know how magnesium oxide wallboard is made. The process uses both natural and man-made things. Here are the main raw materials in magnesium oxide panels:

Magnesium oxide

Magnesium sulfate

Perlite

Wood fiber

Non-woven fabric

Fiberglass mesh

The steps to make magnesium oxide board are easy to follow. Each step helps make a strong and safe board for buildings.

Raw material preparation: Workers get magnesium oxide, magnesium chloride, wood fibers, and perlite ready.

Mixing and forming: They mix these things together and pour the mix into molds.

Pressing and curing: The mix is pressed to make it thick and strong. Then, it goes through two curing steps to get hard.

Finishing and quality control: Workers cut and sand the boards. Sometimes they add coatings. Each board is tested to make sure it is safe and good quality.

Tip: You can use magnesium boards where you need more fire safety or moisture protection. These boards are good for kitchens, bathrooms, and even outside walls.

Magnesium oxide wallboard is a modern choice for building. It uses a special mix of parts and a careful process to make panels that last and keep your space safe.

Key Features of Magnesium Oxide Board

Fire and Moisture Resistance

Fire and Moisture Resistance

You want your walls to be safe and strong. Magnesium boards are great at stopping fires. These panels can handle high heat and do not break down. They work better than gypsum board for fire safety.

Material | Fire Resistance Rating | Notes on Fire Resistance |

|---|---|---|

Magnesium Oxide Board | Up to 1-2 hours; rated non-combustible | Highly fire-resistant, better than gypsum and fiber cement |

Gypsum Board | Needs extra layers for fire resistance | Not as fire resistant unless you add more layers |

Magnesium oxide board does not burn and keeps its shape in a fire. This wallboard helps protect your home or building. Magnesium boards also do well with water. Some types work better than others, but the best ones do not fail even after being wet for a long time. You can trust these panels in kitchens, bathrooms, and basements.

Mold, Mildew, and Insect Protection

Mgo boards help stop mold, mildew, and bugs. These panels do not soak up water, so mold cannot grow. The way magnesium boards are made means mold and mildew have nothing to eat. You also get protection from bugs. Magnesium boards do not attract termites or other pests because they do not have things bugs like. Here are some good things about them:

Magnesium boards keep away termites and bugs.

You do not need to use chemicals to stop pests.

These panels are better than drywall and plywood at stopping mold and mildew.

You can use magnesium boards in places that are wet or have lots of bugs. You can feel sure about how well they work.

Environmental and Health Benefits

You want to stay healthy and help the planet. Magnesium oxide board gives you many good things for both. Many products have safety and quality certificates like CE, ISO, and INTERTEK. These panels meet strict rules for safety and quality. They do not burn and have the highest fire rating (A1) with a 90-minute fire time. Magnesium boards do not let out bad chemicals. They have almost no VOCs, and tests show no formaldehyde or asbestos. You can use these panels at home or work and breathe safely.

Tip: Magnesium wall boards are safe, last a long time, and help make indoor air better. You get all these good things and help the environment too.

Magnesium board is a smart pick if you want a safe, water-resistant, and fire-safe building material.

How It Differs from Traditional Wall Boards

Comparison with Gypsum Board

You may ask how magnesium boards are different from regular wall boards like gypsum board. Both types look almost the same, but they are made from different things. Magnesium oxide wallboard uses magnesium oxide, magnesium sulfate, perlite, and other strong stuff. Gypsum board is made from gypsum and has a paper layer on top. These materials make each board good at different things.

Here is a table that shows how magnesium boards and gypsum boards compare:

Feature | Magnesium Oxide Board (MGO Board) | Gypsum Board |

|---|---|---|

Composition | Made from magnesium oxide, magnesium sulfate, and others. | Made primarily from gypsum with paper facing. |

Fire Resistance | Excellent fire resistance, withstands high temperatures. | Some fire-resistant properties, but less than MGO. |

Water and Moisture Resistance | Highly resistant to water and mold. | Not water-resistant, can deteriorate in moisture. |

Strength and Durability | Stronger and more impact-resistant. | Less strong, more prone to damage. |

Environmental Impact | More eco-friendly, recyclable, non-toxic materials. | Natural material, but energy-intensive production. |

Cost | Typically more expensive. | Generally less expensive. |

Applications | Used in high fire and moisture resistance areas. | Commonly used for interior walls and ceilings. |

Magnesium boards do not burn and can take a lot of heat. You can use them where fire safety is important. Gypsum board slows fire down, but not as well as magnesium oxide wallboard. Magnesium boards also do better with water. They do not swell or bend when wet. Gypsum board can get ruined if it gets wet, unless you use special kinds.

Note: Magnesium boards hardly soak up water and stay strong in wet places. Gypsum boards can get soft and break when they get wet.

Performance and Cost Differences

You should think about how well the boards work and how much they cost. Magnesium boards protect well against fire, water, and mold. You can use them in bathrooms, kitchens, and other wet rooms. They do not let out bad fumes, even in a fire. Gypsum boards can burn and might give off fumes if they get too hot.

Here is a table that shows fire and moisture ratings:

Property | Magnesium Oxide Board | Gypsum Board |

|---|---|---|

Fire Rating | A1 | Fire-resistant additives |

Maximum Temperature | 1200°F | Less effective in high temperatures |

Burns | No | Yes, under certain conditions |

Fumes Released | None | Harmful fumes possible |

Magnesium boards cost more at first. The price is about $1.50 to $2.50 for each square foot. Gypsum board is cheaper, about $0.50 to $1.00 for each square foot. Even though magnesium boards cost more, you save money later. They last longer and do not need as many repairs. You do not have to replace them as often as gypsum boards.

Wallboard Type | Average Cost per Square Foot |

|---|---|

Magnesium Oxide Board | $1.50 – $2.50 |

Gypsum Board | $0.50 – $1.00 |

Magnesium boards need less fixing and replacing. They do not swell, bend, or get moldy. You do not have to spend as much money fixing them as you do with gypsum boards. This helps you save money over time.

Magnesium boards save you money on repairs.

You do not need to fix or replace them as much.

The higher price at first is balanced by savings later.

Magnesium wall boards work better in tough places. They give strong fire and water protection and are better for the planet. Magnesium boards are strong, safe, and need fewer repairs. If you want a wall board that lasts and keeps you safe, magnesium boards are a good pick.

Tip: Use magnesium boards in places that get wet or could catch fire. You get better safety and save money in the long run.

Now you know how magnesium oxide wallboard is different from regular wall boards. Magnesium boards give you more safety, last longer, and help you save money. Gypsum board is good for normal walls and ceilings, but magnesium boards are better for special needs.

Uses of Magnesium Wall Boards

Interior Walls and Ceilings

Interior Walls and Ceilings

Magnesium boards are used for many indoor jobs. They work in homes and businesses. These panels are good for strong, fire-safe walls. You can put them in offices, schools, and apartments. Builders use them for ceilings in malls and theaters. They also go in classrooms. These panels help keep places safe and clean.

Good for ceilings in malls, offices, and schools

You can put mgo backer board behind tiles. This is helpful in bathrooms and kitchens. It helps stop water damage and mold.

Sheathing and Roofing

Magnesium boards are great for sheathing. You can use mgo sheathing inside or outside. These panels give strong support to buildings. They protect from fire and water. Mgo sheathing does not change shape when wet. You do not need to worry about swelling or bending.

Property | Value/Detail |

|---|---|

Moisture Movement | 0.1% – 0.12% |

Surface Moisture Absorption | 0.34% |

Dimensional Stability | Excellent |

Resistance to Warping | Stays strong even when wet |

You can use mgo sheathing on new buildings outside. Many people use it under roofing. These panels meet top fire safety rules like EN 13501-1 Class A1 and ASTM E136. Mgo sheathing helps you feel safe in bad weather.

Other Applications

Magnesium wall boards are used in special projects too. They work for fire-safe walls in hospitals and hotels. You can use them in schools and offices. They are good for floor underlayment. They are used in structural insulated panels for energy-saving buildings. Mgo sheathing is good for soffits and ceilings that get wet. It is also used as a base for tiles in wet places.

Application Type | Description |

|---|---|

Fire-rated walls and enclosures | Used in hospitals, schools, hotels, offices, and apartments to meet fire codes. |

Floor underlayment | Used in fire-rated assemblies to help stop fire. |

Structural insulated panels (SIPs) | Used in energy-saving commercial buildings. |

You can see magnesium wall boards have many uses. They give strength, safety, and last a long time in building projects.

Drawbacks and Considerations for MgO Board

Limitations and Risks

You need to know that magnesium oxide wallboard has some downsides. Mgo boards are strong, but you might have problems in some cases. One big problem is stability. These boards can get tiny cracks if a building moves or settles. Changes in temperature or wetness can also move the frame. This can hurt how stable and strong your walls are.

Here is a table that shows some common limitations and their causes:

Limitation | Cause |

|---|---|

Micro Cracking | Movement from settling, wind, or temperature changes |

Frame Movement | Shrinking wood or expanding metal frames |

Installation Needs | Special installation steps to prevent cracking |

You might see more problems in places with lots of moisture. MgO panels can take in water from the air. This can make metal parts rust and cause water drops on the board. Some countries do not use these boards for important building parts because of these risks. In Denmark, water damage made repairs expensive. In Australia, experts say not to use these boards in some weather. Bad quality control can make these problems worse.

Note: Always check if magnesium oxide wallboard works for your weather and building needs.

Installation Tips

You can help your boards last longer by installing them the right way. Start with a site that is clean and dry. This helps keep your walls strong and stable. Always look at your boards before you start. Mark where the walls go to help with stability. Make sure the frame is tight. This gives the board the support it needs.

Here are some tips to help you with installation:

Carry boards standing up, not flat, so they do not bend or break.

Make sure the surface is clean and flat for better stability.

Use fire-safe sealants on the seams, even though the boards are fire-safe.

Follow all the steps to get the best strength and stability.

Many people think these boards are easy to put in. You can cut and move them with simple tools. If you follow these tips, your walls will stay strong and last a long time. Skipping steps can cause problems like cracks or weak walls. Good installation lets you enjoy the full strength of your walls.

Tip: If you want a wallboard that is easy to install and stays strong, always follow the right steps. This helps you avoid problems and get the most from your mgo board.

Magnesium oxide wallboard is strong and safe. It stops fire and water from causing damage. It lasts a long time and is good for the planet. You can use it in many places. Offices, factories, kitchens, and homes near the ocean are good choices. But it costs more than other wallboards. You might find it harder to install.

Drawback | Description |

|---|---|

High Cost | Costs more than regular wallboards |

Installation Challenges | Needs special tools and skills |

You should look for safety certificates before you buy. Always wear safety gear when you work with it. Think about what your project needs. This helps you choose the right wallboard for your space.

FAQ

What tools do you need to cut magnesium oxide wallboard?

You can cut thin boards with a utility knife. For thick panels, use a circular saw with a carbide blade. Always wear a dust mask and safety glasses to stay safe.

Can you paint or tile over magnesium oxide board?

Yes, you can paint or put tiles on magnesium oxide board. Make sure the board is clean and dry first. Use special primers or glue made for cement boards to get the best results.

Is magnesium oxide wallboard safe for people with allergies?

Magnesium oxide wallboard does not give off bad chemicals or dust. It does not have asbestos or formaldehyde inside. You can use it in homes where people have allergies or asthma.

How long does magnesium oxide board last?

Magnesium oxide board can last for many years. It does not rot or break down fast. It also keeps out mold, fire, and water.

Where should you avoid using magnesium oxide wallboard?

Do not use magnesium oxide wallboard in places that are always very wet or have salty air, unless the board is made for those places. Always check the manufacturer’s instructions.

Fire and Moisture Resistance

Fire and Moisture Resistance Interior Walls and Ceilings

Interior Walls and Ceilings