16 Sep Types Of Non Combustible Wall Panels

Table of Contents

You need good fire protection in every building. Non combustible wall panels help keep you safe. They do not burn or make a fire worse. These panels help you follow fire safety rules. They also protect people from harm. Some common types are fiber cement, magnesium oxide wallboard, calcium silicate boards, metal, concrete, and glass reinforced gypsum. You may also see systems like StoTherm® ci Mineral and mineral wool insulation. These help meet today’s safety standards. Each type works best for certain homes, businesses, or building upgrades.

Key Takeaways

Non-combustible wall panels help stop fires from spreading. They keep buildings and people safe. – Pick wall panels with a non-combustible core for better fire safety. This choice helps you worry less. – It is important to know about fire ratings. Look for Class A ratings and NFPA-285 standards. – Materials like fiber cement, magnesium oxide, and metal have special benefits. Choose the right one for your building. – Install panels the right way and follow local building codes. This keeps everyone safe and follows fire rules.

Fire Safety Basics

Non-Combustible Materials

It is important to know what makes wall panels safe from fire. Non-combustible materials do not burn or help a fire get bigger. Picking non combustible wall panels helps protect your building and the people inside. Solid aluminum panels like Alfrex Plate are trusted by many. These panels follow strict fire safety rules and work for inside and outside walls. Aluminum honeycomb panels also resist fire very well. They are light and do not let mold or bacteria grow, so they are good for cleanrooms.

EVOLV Fiber Cement panels are another option. These panels last a long time and do not burn. They fit many kinds of buildings. Magnesium oxide (MgO) wall panels are also a safe choice. They do not burn, even when it gets very hot, and they meet tough fire safety rules.

Tip: Always make sure your wall panels have a non-combustible core. This helps give you better fire protection and peace of mind.

Fire Ratings and Standards

You need to know about fire ratings when picking wall panels. Fire ratings show how well a material can stop fire and smoke. Here is a table that explains the main fire rating types you will see:

Fire Rating Type | Description |

|---|---|

Class A Rating | Materials that do not keep a flame, with a flame spread index of 0-25 and smoke developed index ≤ 450. |

Non-Combustible | Materials that will not add to a flame and give more fire resistance than Class A. |

1 Hour Fire Rated | Assemblies that can handle fire for up to one hour before being tested with water. |

Think about important fire safety ideas when choosing wall panels:

Fire containment: Walls should hold back fire for at least two hours to stop it from spreading.

Fire control: Good panels help you manage a fire and keep it from starting again.

Smoke control: Panels should block smoke, which is very dangerous during a fire.

If you follow these rules and use the right materials, you help keep your building safe and meet safety codes.

Types of Non Combustible Wall Panels

Fiber Cement Panels

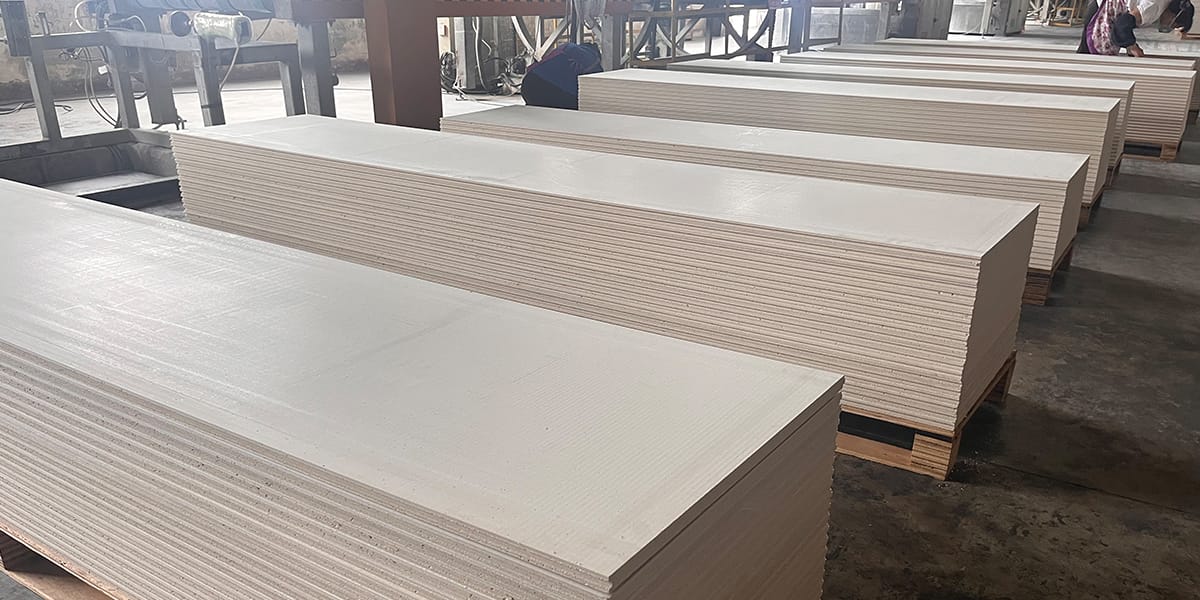

Fiber Cement Panels

Fiber cement panels give strong fire protection. They are made with cement and cellulose fibers. These panels do not burn. They stop flames from spreading. Builders use fiber cement in schools, hospitals, and homes. Most fiber cement panels have a Class A fire safety rating. Here is a table that shows how fiber cement panels do in fire tests:

Fire Test Standard | Flame Spread Index | Smoke-Developed Index | Vertical Flame Propagation | Lateral Flame Propagation | Maximum Temperature (F) |

|---|---|---|---|---|---|

ASTM E-84 | 0 | 5 | N/A | N/A | N/A |

NFPA 285 | N/A | N/A | No to 10 feet | No to 5 feet | 1000 |

CAN/ULC S134-13 | N/A | N/A | No to 5 meters | N/A | 35 kW/m2 |

Tip: Fiber cement panels work for inside and outside walls. They last long and need little care.

Magnesium Oxide Wallboard

Magnesium oxide wallboard gives great fire resistance. This panel does not burn, even when very hot. You can use it in stairwells or exit routes for extra safety. Magnesium oxide wallboard also stops mold and mildew. It works well in wet places. Here are some good points and some limits:

Advantages | Limitations |

|---|---|

Excellent fireproof qualities | Higher cost compared to gypsum boards |

Energy efficient to produce | Unique installation needs |

Reduces waste and captures carbon dioxide | Quality varies among manufacturers |

Fungus resistance, impervious to mold | May not perform well in humid climates |

Lightweight, easy to use |

|

Non-combustible, handles high heat

Stops mold and mildew

Stronger than gypsum drywall

Can be recycled

Calcium Silicate Boards

Calcium silicate boards give strong fire protection. They use silica and calcium oxide. These boards do not burn or melt in fire. Calcium silicate boards last more than two hours in fire tests. They have a Class A rating for high heat. But they may crack if the temperature gets above 450°C. You can use these boards where you need to keep fire out for a long time.

Note: Calcium silicate boards do not make toxic fumes in a fire. They help keep the air safe for people.

Metal Panels

Metal panels make walls tough and safe. You can pick steel, aluminum, or mineral wool panels. Steel panels pass hard fire tests and get a Class 1 Fire Rated label. Aluminum panels are light and work well with fire-resistant insulation. Mineral wool gives extra fire protection. Here is a table with common metals and their fire safety features:

Metal Type | Fire Safety Characteristics |

|---|---|

Steel | Passes fire resistance testing for several standards, certified as Class 1 Fire Rated (Class A fire-resistant rating). |

Aluminum | Lightweight, used in composite panels with fire-resistant properties when combined with appropriate insulating materials. |

Mineral Wool | Non-flammable and non-combustible, provides extra fire protection in insulated metal panels. |

Tip: Metal panels also stop mold and weather damage. You can use them inside or outside.

Concrete Panels

Concrete panels give strong fire protection and last a long time. Precast concrete does not burn and stops fire from spreading. You see concrete panels in apartments, hospitals, and schools. These panels last for decades and meet strict insurance rules. Concrete masonry stays strong in a fire and does not make toxic gases. Fire resistance depends on wall thickness. Some panels are rated for up to four hours.

Precast concrete protects property.

Concrete masonry does not burn and stays strong in fire.

Great for earthquakes.

Note: Concrete panels help lower fire protection costs and insurance rates.

Glass Reinforced Gypsum Panels

Glass reinforced gypsum (GFRG) panels protect better than regular gypsum board. These panels use glass fibers to stay strong in fire. GFRG panels protect their core up to 800°C. Regular gypsum board loses strength at 250°C. GFRG panels can give up to four hours of fire protection. Builders use these panels in stairwells and fire exits for extra safety.

Tip: GFRG panels keep their shape in fire. This helps protect the building.

Fire-Resistant Sheathing

Fire-resistant sheathing adds another safety layer to walls. Non-paper-faced exterior gypsum and fire-retardant-treated plywood are common choices. These materials slow fire and help meet building codes.

Type of Sheathing | Description |

|---|---|

Non-paper-faced exterior gypsum | A type of sheathing that is fire-resistant. |

Fire-retardant-treated plywood | Plywood that has been treated to resist fire. |

Note: Fire-resistant sheathing works with other non combustible wall panels for safer buildings.

Non-Combustible Claddings

Non-combustible claddings help stop fire from spreading outside buildings. You can pick brick, stone, stucco, drywall, or mineral wool. These claddings meet strict fire ratings and help keep people safe. Here is a table with common claddings and their fire ratings:

Material Type | Fire Rating | Contribution to Fire |

|---|---|---|

Aluminum Composite Panels | A2-s1,d0 | Minimal |

Pre-formed Steel Panels | A1 | None |

Fibre Cement | A1 | None |

Natural Stone Composites | A2-s1,d0 | Minimal |

Non-combustible cladding stops fire spread.

It gives people more time to leave safely.

Tip: Always check your cladding meets Class A1 or A2-s1,d0 standards for best fire safety.

Comparing Non Combustible Wall Panels

Material Composition

Material Composition

Non combustible wall panels use many materials. Fiber cement panels mix cement and cellulose fibers. Magnesium oxide panels use magnesium, oxygen, and minerals. Metal panels use steel or aluminum. Some metal panels have mineral wool for safety. Concrete panels use cement, sand, and gravel. Glass reinforced gypsum panels have gypsum and glass fibers. Each material gives the panel special strengths. Metal panels do not rust and handle bad weather. Fiber cement and magnesium oxide panels do not burn. They stay strong in high heat.

Fire Performance

Fire performance is very important to check. You want panels that stop fire and smoke. Here is a table that shows fire ratings for popular panels:

Criteria | Magnesium Oxide (MgO) Panels | Cement Boards |

|---|---|---|

Fire Resistance Duration | Up to 2 hours | |

Combustibility | Non-combustible | Fire-resistant |

Smoke Emission | Minimal | Low |

Magnesium oxide panels last longer in fire tests than cement boards. Both types do not burn and make little smoke. Metal panels also do not burn. Their fire rating depends on the insulation used. Always check the fire rating before you pick a panel.

Tip: Use panels with high fire resistance in stairwells, exits, and places where safety matters most.

Durability and Maintenance

You want wall panels that last and need little care. Insulated metal panels are strong and need almost no upkeep. They have coatings that stop rust and sun damage. Fiber cement panels can last up to 50 years with no maintenance. This makes them a smart choice, even if they cost more at first. If you pick strong panels, you can save up to 35% over time. You will not need many repairs or replacements.

Pick panels that stop moss or algae in wet areas.

Metal panels use good materials and advanced methods for extra strength.

Maintenance needs change by material. Vinyl panels need little care. Wood panels need staining or sealing.

Note: Picking the right non combustible wall panels helps you save money and keeps your building safe for years.

Applications

Residential Use

Non combustible wall panels help make homes safer. They protect families from fire. Builders put them in kitchens, garages, and laundry rooms. Fiber cement panels are used on house exteriors. These panels stop fire and bad weather. Homeowners like them because they last long and need little care. Magnesium oxide boards work well in basements and attics. These boards stop mold and mildew. You can pick panels that look nice and keep your home safe.

Tip: Talk to your builder about panels that follow local fire codes. This can help keep your home safe and may lower insurance bills.

Commercial and Industrial

Non combustible wall panels are used in many big buildings. These panels use steel, mineral wool, gypsum, and cement. They do not burn, even when it gets very hot. You can find them in factories, warehouses, schools, and hospitals. These panels make strong walls. They slow down fire and give people more time to leave. They also help keep buildings from falling down. Many companies use these panels to follow fire safety rules.

Steel panels make walls stronger.

Mineral wool panels block heat and noise.

Gypsum and cement panels are good for offices and public places.

Building Type | Common Panel Material | Main Benefit |

|---|---|---|

Factory | Steel, mineral wool | Fire and heat barrier |

School | Gypsum, cement | Safe evacuation |

Warehouse | Steel, cement | Structural stability |

Retrofit Projects

Non combustible wall panels can upgrade old buildings. These panels go over old walls to make them safer. Many people pick fiber cement or glass reinforced gypsum panels for upgrades. You can put them up fast without big changes. This helps you follow new fire codes and protect your building. Retrofit projects often use panels that stop mold and water. These upgrades make buildings safer and last longer.

Note: Retrofit panels help save money on repairs and insurance. They also make buildings safer for everyone.

Building Code Compliance

Codes and Standards

You have to follow rules when using non combustible wall panels. These rules help keep buildings safe from fire. The International Building Code (IBC) and National Fire Protection Association (NFPA) make the main rules. The NFPA-285 test checks how walls do in a fire. The IBC says you must use NFPA-285 for some buildings and heights. Here is a table that shows the main codes and what they ask for:

Standard | Description | Requirement |

|---|---|---|

NFPA-285 | A fire test method for checking how exterior wall assemblies perform in fire | Needed for Type I, II, III, and IV buildings with outside walls over 40 feet using combustible cladding or water-resistive barriers. |

IBC | International Building Code for building safety and construction | You must follow NFPA-285 under IBC for certain buildings and situations. |

Tip: Always look at your local building codes before starting your project.

Certification and Testing

You need to make sure your wall panels pass fire tests. Testing proves panels can resist fire and meet safety rules. Labs use different standards to test panels. These tests check how long panels last in fire and if they burn. Here is a table with common testing standards:

Standard | Description |

|---|---|

Test methods for fire tests of building construction and materials | |

ASTM E136 | Test method for checking if materials burn using a vertical tube furnace at 750°C |

ASTM E1725 | Test methods for fire tests of fire-resistive barrier systems for electrical system parts |

EN 1364-1 | Fire resistance tests for non-loadbearing walls |

NFPA 251 | Test methods for fire resistance of building construction and materials |

You must keep records of these tests. Construction papers should show your panels passed the right tests or have accepted engineering judgments. Your team needs to keep all test data and reports.

Construction papers must show compliance with NFPA 285 using tested assemblies or accepted engineering judgments.

The building team must keep records with test data or engineering judgments.

Some wall assemblies may need tested assemblies or new tests made for the project.

Installation Guidelines

You must install non combustible wall panels the right way to meet code rules. The NFPA-285 test checks the whole wall assembly, not just the panels. You need to follow the manufacturer’s instructions and use skilled professionals for engineering judgments. Here is a table with key installation items:

Key Items | Description |

|---|---|

Needed for non-combustible wall panels to meet code rules. | |

Testing Criteria | Checks the whole wall assembly, not just one part. |

Engineering Judgements | Can be used but must come from skilled professionals. |

Note: Careful installation helps you pass inspections and keeps your building safe.

You have lots of choices for non combustible wall panels. Some types are fiber cement, magnesium oxide, calcium silicate, metal, concrete, and glass reinforced gypsum. These panels help stop fire from spreading. They keep walls strong and lower smoke. This can help you pay less for insurance. Pick panels that fit your building and fire safety needs. Make sure they follow local rules. Do not forget to prepare the walls before you start. Use the right tools for the job. Ask experts for help if you need it. Use wall systems that meet NFPA 285 standards for best safety.

FAQ

What makes a wall panel non-combustible?

You choose panels made from materials that do not burn, like cement, metal, or gypsum. These panels stop fire from spreading and help keep buildings safe.

Can you use non-combustible panels outside?

Yes, you can use them outside. Fiber cement, metal, and concrete panels work well for exterior walls. They resist fire, weather, and damage.

How do you know if a panel meets fire safety codes?

You check the label or ask for test reports. Look for ratings like Class A or NFPA-285 compliance. These show the panel passed fire safety tests.

Do non-combustible panels cost more than regular panels?

Non-combustible panels often cost more at first. You save money over time because they last longer and need less maintenance. You may also pay less for insurance.

Fiber Cement Panels

Fiber Cement Panels Material Composition

Material Composition