18 Sep MgO Board Use for Modular Wall Panels

Table of Contents

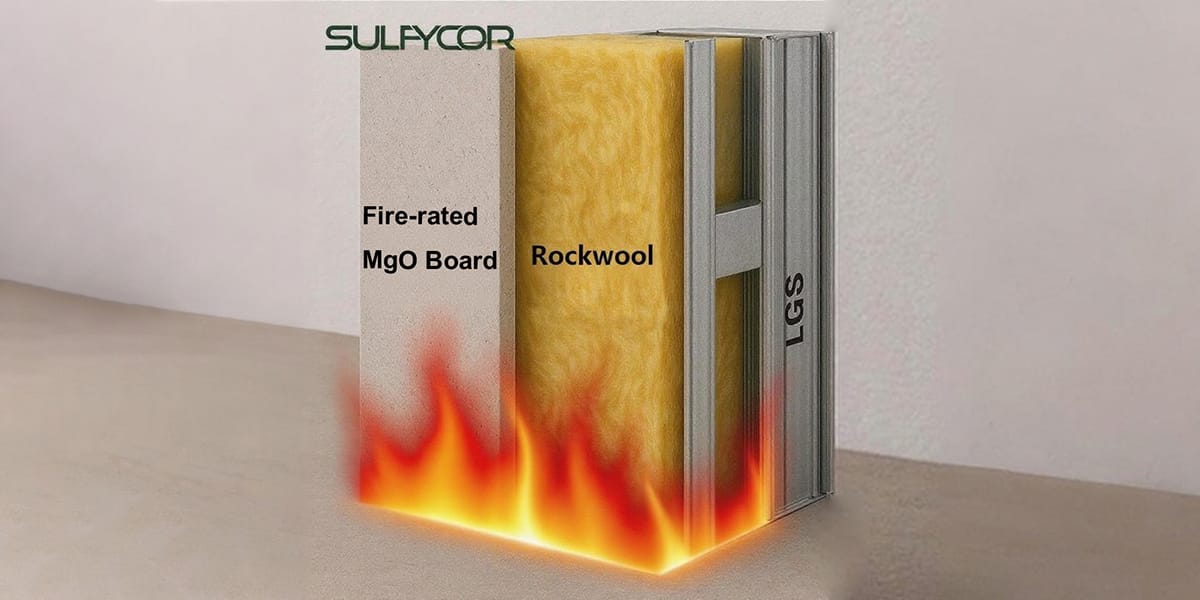

When you pick MgO Board for modular wall panels, you get strong fire protection, water safety, and a green choice. Many experts like it because it can handle high heat, stops mold, and makes walls tough but not heavy. The table below shows how well it works against fire compared to other materials:

Feature | MgO Panels | Traditional Materials |

|---|---|---|

Fire Resistance Rating | Up to 4 hours | Not much; needs more help |

Combustibility | Non-combustible | Burns fast (like wood) |

Smoke and Fume Emission | Very low | High; bad fumes from wood |

You can count on MgO Board to pass hard tests like EN 13501-1 and CAN/ULC S114 for fire safety. This helps you build homes that are safer and last longer.

Key Takeaways

MgO Board does not burn easily. It has an A1 non-combustible rating. This makes it a safe choice for wall panels.

The board does not soak up water. It does not swell or bend in wet places. You can use it in bathrooms and kitchens.

MgO Board stops mold from growing. Its surface does not let water in. This helps keep the air inside healthy.

This material is good for the earth. It makes less pollution and you can recycle it. This makes it a smart building choice.

You can install it with simple tools. If you take care of it, it will last a long time.

MgO Board Overview

Composition

You may ask why MgO Board is good for modular wall panels. The answer is in what it is made of. Here are the main parts:

Component | Percentage | Description |

|---|---|---|

Magnesium Oxide | ~50% | Main structural component providing strength. |

Magnesium Sulfate | ~40% | Prevents moisture issues, eco-friendly. |

Other Fillers | ~10% | Includes perlite, wood fiber, and fiberglass mesh for stability. |

Each part is important. Magnesium oxide makes the board strong. Magnesium sulfate helps keep water out and is good for nature. The fillers, like perlite and fiberglass mesh, help the board stay stable and last longer.

Tip: If you pick MgO Board, you get strength and water safety.

Properties

MgO Board is special because of its great features. It can stop fire, water, and mold. The mix of magnesium oxide and magnesium sulfate keeps water and rust away. This means your wall panels stay strong, even in wet rooms.

MgO Board does not burn at all. It has a zero flame spread rating, so it is safe for walls and ceilings. The board is light but strong. You can use it in busy places without worry. You can cut, snap, or screw it with normal tools, so it is easy to install.

MgO Board does not have formaldehyde or bad chemicals. It is safe for people and the earth. You can recycle it. This makes it a good choice if you want to build green.

MgO Board Benefits

Fire Resistance

Fire Resistance

You want your modular wall panels to protect you from fire. MgO Board gives you strong fire resistance. It does not burn or spread flames. You can trust it to keep your home safe. Scientific studies show that MgO Board lined walls can last up to 30 minutes in full-scale fire tests. The fire resistance depends on how you space the studs and seal the joints.

Study Focus | Key Findings |

|---|---|

Fire tests of MgO board lined light gauge steel frame wall systems | – Full-scale fire tests show strong performance. |

Integrity depends on board cracking and joint sealing.

Achieves fire resistance level (FRL) of 30.

FRL affected by mass loss, joint details, and stud spacing. |

MgO Board stands out when compared to other materials. It is rated A1, which means it is non-combustible. Gypsum board and fiber cement are also fire-resistant, but MgO Board has lower flame spread and smoke emissions.

Criteria | MgO Board | Gypsum Board | Cement Board | Fiber Cement Board |

|---|---|---|---|---|

Fire Resistance Rating | A1 Non-Combustible | Fire-Resistant | Highly Fire-Resistant | Fire-Resistant |

Thermal Combustibility | Non-Combustible | Combustible | Non-Combustible | Non-Combustible |

Flame Spread | Low | Moderate | Low | Moderate |

Smoke and Toxic Gas Emissions | Low | Moderate | Low | Moderate |

Note: MgO Board can achieve up to 1-2 hours of fire resistance, which is better than gypsum board and fiber cement.

Moisture Protection

You need wall panels that can handle wet conditions. MgO Board does not absorb water. It keeps its shape and strength even in bathrooms and kitchens. You do not have to worry about swelling or warping. The board blocks water from getting inside, so your walls stay dry.

MgO Board does not soak up water like drywall or plywood.

It keeps its structure in humid places.

You can use it in areas with lots of moisture.

Tip: Use MgO Board in places where water is a problem. It will protect your walls and keep them strong.

Mold Prevention

Mold can damage your home and make you sick. You want a wall panel that stops mold from growing. MgO Board has a non-porous surface. Water cannot get through, so mold cannot grow behind your walls or under your floors. The board does not swell or break down in wet areas.

MgO Board blocks water, so mold cannot hide.

It stays strong in bathrooms and kitchens.

The board is inorganic, so mold and mildew cannot grow on it.

Alert: If you use MgO Board, you lower the risk of hidden mold and keep your home healthy.

Sound Insulation

You want peace and quiet in your home or office. MgO Board helps block noise. It works well in schools, offices, and homes. The board has good sound insulation, so you hear less noise from outside or other rooms.

MgO Board is known for sound insulation.

It is good for quiet spaces like offices and schools.

Regular gypsum panels have an STC rating of 30. Special soundproof boards can reach STC ratings of 40-42.

Note: If you want a quiet space, MgO Board is a smart choice for your walls.

Eco-Friendly

You care about the environment. MgO Board is a green building material. Chloride-free MgO Board is better for nature than older types. The board uses less energy to make and captures CO2 during curing. This lowers greenhouse gas emissions. You can recycle MgO Board, so it does not add to landfill waste.

MgO Board has a lower carbon footprint than gypsum board and fiber cement.

Production uses less energy and captures CO2.

Gypsum and fiber cement need more energy and release more CO2.

MgO Board is recyclable and has a small impact on the environment.

Local sourcing and manufacturing make MgO Board even greener.

Tip: Choose MgO Board if you want to build sustainably and help the planet.

Material Comparison

Gypsum Board

Gypsum Board

Gypsum board is used a lot in modular wall panels. It costs less and is simple to put up. You can cut it with basic tools. It is fast to finish. Gypsum board is good for inside walls. It does not protect well from water or fire. You might need to fix it more in wet places. It is cheap at first, but repairs can add up later.

Board Type | Cost per Square Foot | Long-term Value |

|---|---|---|

MgO Board | Strong, fireproof, and water-resistant, saving money in the long run. | |

Gypsum Board | $0.50 – $1.00 | Cheaper upfront but may need more repairs, costing more over time. |

Tip: Gypsum board saves money now. For fewer repairs, try other materials.

Fiber Cement

Fiber cement boards make strong walls that resist fire and hits. You can use them inside or outside. These boards are heavy and may need extra help. If you do not seal them, they can soak up water. Mold can grow if water stays on them too long. They stop fire well, but coatings help them work best.

Feature | MgO Boards | Fiber Cement Boards |

|---|---|---|

Non-organic core prevents water absorption | Susceptible to moisture without sealing | |

Mold & Mildew Protection | No cellulose, does not support mold growth | Can allow mildew with prolonged water exposure |

Fire Resistance | Naturally non-combustible | Non-combustible but relies on coatings |

Structural Strength | Impact-resistant and dimensionally stable | Heavier, may need additional support |

Note: Fiber cement is tough, but you must seal it and watch for mold.

Plywood

Plywood is light and easy to move. It is good for quick builds and short-term walls. Plywood does not stop fire or water well. It can swell or bend if it gets wet. Mold can show up in damp spots. Plywood is cheaper, but it does not last as long as other boards.

Criteria | Plywood | |

|---|---|---|

Moisture Resistance | Highly resistant to moisture. Does not swell or warp. | Swells or warps if exposed to excessive moisture. |

Fire Resistance | Excellent fire resistance (non-combustible). | Limited fire resistance and can catch fire in high temperatures. |

Durability | Very durable. | Durable but less resistant to impact and moisture. |

Weight | Heavier than plywood. | Lighter and easier to handle. |

Cost | More expensive. | More affordable. |

Environmental Impact | Eco-friendly due to non-toxic materials. | Not a sustainable option. |

Sound Insulation | Provides better sound insulation properties. | Less effective at sound insulation than MGO. |

Lifespan | Longer lifespan due to superior resistance to environmental factors. | Shorter lifespan, especially in high moisture areas. |

If you want a panel that lasts and protects from fire and water, look at other choices.

Installation

Steps

You can install modular wall panels with confidence when you follow the right steps. Start by preparing your workspace. Make sure the area is clean and dry. Gather your tools, including a circular saw with a thin carbide blade, a level, rust-resistant screws, and safety gear.

Here is a step-by-step guide to help you:

Place the first board at one corner of the wall. Align it with the edges.

Use a level to check that the board sits straight. Adjust if needed.

Lay each MgO Board row by row. Keep seams tight but leave a small gap (about 1/8 inch) between boards for expansion.

Drill pilot holes before fastening. This helps prevent cracking.

Use rust-resistant screws, such as 316-stainless steel. Space screws about 12 inches apart along the edges and 16 inches apart in the center.

After cutting, lightly sand the edges for a smooth finish.

Apply construction adhesive to corners after cutting. This reduces micro-cracking.

Tip: Always wear safety glasses and a respirator when cutting. Good ventilation or a dust collection system keeps the air clean.

Method | Description |

|---|---|

Power Cutting | Use a circular saw with a thin carbide blade for clean cuts and blade life. |

Dust Control | Wear a respirator and ventilate or use a dust collection system. |

Scoring and Snapping | Score deeply with a utility knife and snap for small cuts. Edges may be rough. |

Secure the Board | Support the board firmly on a stable surface while cutting. |

Eye Protection | Always wear safety glasses. |

Edge Finishing | Sand cut edges for a smoother finish. |

Glue Corners | Use construction adhesive on corners to reduce micro-cracking. |

MgO boards expand and contract with temperature changes. Leave a small gap between each board to prevent buckling. This keeps your panels secure over time.

Handling

You protect your panels when you handle them with care. Store boards inside in a cool, dry place. Carry boards on their side to protect edges and corners. Stack boards flat on dunnage, not directly on the ground. Do not allow boards to bow. Avoid stacking other materials on top of the boards.

Precaution | Description |

|---|---|

Storage | Store inside in a cool, dry place. |

Carrying | Carry boards on their side. |

Stacking | Stack flat on dunnage, not on the ground. |

Bowing | Do not allow boards to bow. |

Stacking Materials | Do not stack other materials on top. |

Use gloves and eyewear when cutting. This prevents cuts and irritation from dust.

Imported panels may have inconsistent quality. Check for defects before installation.

MgO panels absorb more moisture than cement boards. This can cause corrosion of metal parts. Use rust-resistant fasteners and keep panels dry before installation.

⚠️ Alert: Unreacted magnesium chloride in some panels can corrode fasteners and steel studs. Always use high-quality, tested panels.

Maintenance

You keep your modular wall panels strong when you maintain them regularly. Inspect panels for signs of moisture or damage. Clean surfaces with a damp cloth. Avoid harsh chemicals. Check fasteners for corrosion, especially in humid areas. Replace any damaged panels or fasteners right away.

Wipe panels with a soft, damp cloth.

Check for swelling, warping, or mold.

Inspect screws and joints for rust.

Repair or replace damaged sections quickly.

Note: Regular checks help you catch problems early and extend the life of your wall panels.

Applications

Interior Use

Interior Use

You can use MgO Board for many interior applications in modular wall panels. Its strength and moisture resistance make it a top choice for different rooms and needs.

Wall and ceiling panels in living spaces and hallways stay strong and look good for years.

Wet area lining in bathrooms, kitchens, laundry rooms, and basements keeps water out and prevents damage.

Soundproof buildings, such as offices, recording studios, hospitals, and schools, benefit from its noise-blocking properties.

Tip: You can install MgO Board in places where you need both durability and quiet, like classrooms or home theaters.

Exterior Use

You can trust MgO Board for exterior modular wall panels, even in tough climates.

It resists fire naturally and does not burn, so your building stays safer.

The board offers high flexural strength and stays stable in heat, cold, or wet weather.

It does not absorb water, so it works well in humid areas and does not swell or rot.

Mold and mildew cannot grow on it, even after heavy rain or snow.

Test Type | Description |

|---|---|

Flexural Strength | Stronger than wood and gypsum, stays solid in wet conditions. |

Weatherability | Works well in wet/dry cycles and extreme heat or cold. |

Dimensional Stability | Doesn’t swell or warp when wet, stays steady during building. |

You can use MgO Board for exterior walls in both hot and cold regions without worry.

Case Studies

Many builders and homeowners have seen the benefits of MgO Board in real projects.

Modular homes with MgO panels have survived wildfires with little repair needed.

In cold climates, these panels last longer than gypsum boards, which can crack in freezing weather.

Studies show that MgO panels keep their shape and strength under stress, making them a smart choice for many locations.

People report fewer problems with fire and mold, leading to safer and stronger homes.

“I chose mgo boards for my house because they are strong and good for building. They also help keep my family safe from fire and mold.”

You get good safety, strength, and eco-friendliness with MgO Board for modular wall panels. Here is how it is different:

Description | |

|---|---|

Fire Resistance | Rated A1 non-combustible, does not burn or give off bad gases, great for fire safety. |

Water Resistance | Keeps water out, does not bend, swell, or fall apart in wet places. |

Mold and Mildew Control | Stops mold and mildew from growing, helps air stay clean, and lowers breathing problems. |

Durability | Tougher than drywall, stands up to bumps, good for busy spots. |

Pick these boards for fire and water safety, strength, and being green.

Buy from good sellers and use workers who know what they are doing.

You only need simple tools and can finish with paint or tile.

As time goes on, you will see more smart and green panels. MgO Board will help you make safer and better places.

FAQ

What tools do you need to cut MgO Board?

You can use a circular saw with a carbide blade or a utility knife for small cuts. Always wear safety glasses and a dust mask. These tools help you get clean edges and keep you safe.

Can you paint or tile over MgO Board?

Yes, you can paint or tile over MgO Board. Make sure the surface is clean and dry before you start. Use primers or adhesives made for cement-based boards for the best results.

Is MgO Board safe for people with allergies?

MgO Board does not contain formaldehyde or harmful chemicals. It resists mold and mildew, so it helps keep indoor air clean. You can use it in homes where people have allergies or asthma.

How long does MgO Board last in modular wall panels?

MgO Board lasts many years because it resists water, fire, and mold. You do not need to replace it often. Regular checks and simple cleaning help you keep it in good shape.

Can you use MgO Board in cold or wet climates?

You can use MgO Board in both cold and wet climates. It does not swell, crack, or rot when exposed to moisture or freezing temperatures. This makes it a strong choice for many locations.

Fire Resistance

Fire Resistance Gypsum Board

Gypsum Board Interior Use

Interior Use