22 Sep Understanding Fire Resistance Ratings for Wall Panels

Table of Contents

- 1 Key Takeaways

- 2 Fire Resistance Ratings Explained

- 3 Codes & Standards for Fire Rated Wall Systems

- 4 Types of Fire Resistant Wall Panels

- 5 Interpreting Fire-Rated Wall Panel Certifications

- 6 FAQ

- 6.1 What does a fire resistance rating mean for wall panels?

- 6.2 How do you check if a wall panel is fire rated?

- 6.3 Can you use any fire-rated panel anywhere in a building?

- 6.4 What is the difference between flame spread and fire resistance?

- 6.5 Why do you need independent testing for fire-rated panels?

A fire resistance rating shows how long wall panels stop fire and heat. It is important to know about fire resistance ratings. Building codes like the International Building Code and the National Building Code of Canada need fire resistant wall panels in some places. These rules help buildings meet safety standards and pass checks. For example, some tall buildings must use wall panels with a two-hour fire resistance rating. This helps keep people safe.

Key Takeaways

Fire resistance ratings show how long panels block fire and heat. You should always look at these ratings for safety.

Pick Class A panels for the best fire protection. They stop flames from spreading fast and work well in risky places.

Follow the steps to certify fire-rated wall systems. This makes sure all parts work together for safety.

Use outside testing labs to check fire resistance ratings. Good labs make sure products follow safety rules.

Check and take care of fire-rated panels often. This helps your building stay safe and follow fire codes.

Fire Resistance Ratings Explained

What Fire Resistance Ratings Mean

Fire resistance ratings show how well wall panels stop fire and heat. These ratings tell you how long a panel can keep its shape and block flames. They look at a few important things:

Criteria | Description |

|---|---|

Labs test panels with special steps to find their fire resistance ratings. | |

Building Code Requirements | Codes say what fire resistance levels you need for each building type. |

Material Thickness | Thicker panels usually get better fire ratings. |

Performance Classification | Panels get ratings like 30-minute or 1-hour after fire tests. |

UL Certification | Makers must prove their panels passed tests and got certified. |

Always check fire resistance ratings before picking wall panels. These ratings help you know if a panel will protect people and things in a fire.

Class A, B, and C Ratings

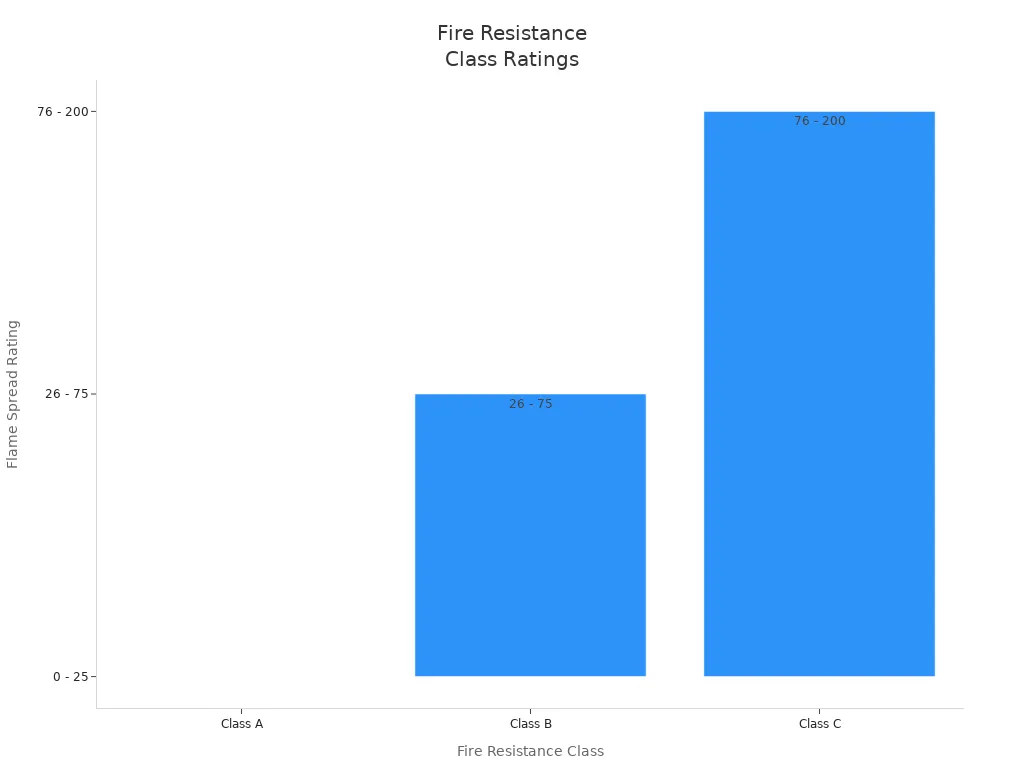

Wall panels with fire ratings come in three main classes: A, B, and C. Each class shows how well the panel stops fire and slows down flames.

Class | Flame Spread Rating | Typical Materials | Applications |

|---|---|---|---|

A | 0 – 25 | Brick, Gypsum Wallboard, Fiber Cement | Egress routes, Elevator shafts, Stairwells |

B | 26 – 75 | Slower-burning whole wood materials | Controlled access areas |

C | 76 – 200 | Plywood, Fiberboard, Hardboard | Detached structures, Lower risk areas |

Class A gives the best fire resistance. You see it in places like stairs and hallways where safety is very important. Class B panels give some protection and work in less risky spots. Class C panels have the lowest fire resistance and fit in places with less fire danger.

Tip: For the best safety, pick panels with a class A rating. These panels have a flame spread rating from 0 to 25. They use materials like brick, gypsum wallboard, and fiber cement. They help stop fire from spreading fast and make your building safer.

Duration and Performance

Fire resistance ratings also show how long a wall panel can last in a fire. You might see ratings like 20 minutes, 1 hour, 2 hours, or even 4 hours. Longer times mean better protection for your building.

One layer of plasterboard can make fire resistance go up by 170%.

Two layers make insulation fire resistance go up by 80%.

Higher fire resistance ratings mean better insulation and more time for people to get out safely.

Always match the fire resistance rating to your building’s needs. Hospitals or tall buildings may need panels with a two-hour rating. Small sheds may only need a 20-minute rating. Knowing these ratings helps you follow safety rules and keep everyone safe.

Codes & Standards for Fire Rated Wall Systems

ASTM E119 and UL 263

It is important to know the main standards for fire resistance ratings. ASTM E119 and UL 263 are the top standards. They show how long a wall can stop fire and stay strong. These standards test the whole wall system, not just the panels.

Here is a table that explains what each standard does:

Standard | Key Requirement | Purpose |

|---|---|---|

ASTM E119 | Tests fire resistance of an assembly, making sure it can hold back fire for a set time (like one hour). | To see how long a wall can block fire and stay strong. |

UL 263 | Same as ASTM E119, since UL 263 is the matching standard for fire resistance tests. | Makes sure the wall system follows fire safety rules. |

ASTM E84 | Checks how fast flames spread and how much smoke comes from materials. | To find out if materials are safe by looking at flame spread and smoke. |

ASTM E119 and UL 263 both look at how the whole wall system works in a fire. You will find these standards in building codes all over the country. They help you pick fire rated wall systems that follow safety rules.

Certification Process

There is a clear process to certify fire rated wall systems. This process checks that every part of the wall system works together to stop fire. You cannot just test one panel. You must test the whole wall system.

Here are the main steps in the certification process:

Planning: Work with an architect or engineer who knows about fire safety and what is needed for a four-hour fire rating.

Material Selection: Choose doors, walls, ceilings, and windows that have a four-hour fire resistance rating. Make sure these materials are certified by an independent testing group.

Construction: Build with the chosen fire-resistant materials. Follow the rules from the makers and local building codes.

Inspection: Have a certified expert check the building. This person makes sure you followed the fire safety plan and put everything in the right way.

Certification: Get a certificate from a trusted fire safety group. This proves your building meets the four-hour fire rating rules.

You need to do every step the right way. This process helps you make safe fire rated wall systems for your building.

Role of Independent Testing

Independent testing labs are very important for fire safety. You want to be sure your fire resistant wall panels and wall systems really work. These labs test products using strict rules.

Independent testing labs are needed to find fire resistance ratings by doing special fire tests. These tests let makers prove their products meet fire resistance rules, which is important for building code rules and public safety.

You should look for labs approved by groups like the International Accreditation Service (IAS). Approved labs help you trust that your fire rated wall systems follow all safety rules. Some well-known labs, like ICC-ES, do full fire resistance testing for many building materials.

Testing makes sure products follow the right rules and codes.

Approved labs give good results for fire resistance ratings.

When you pick fire resistant wall panels, always check that they were tested and certified by an approved, independent lab. This step keeps your building safe and helps you follow the law.

Types of Fire Resistant Wall Panels

Common Materials

Common Materials

There are many materials for fire resistant wall panels. Each one has its own fire rating and safety features. The table below lists some common choices and their fire resistance:

Material | Fire Resistance Characteristics |

|---|---|

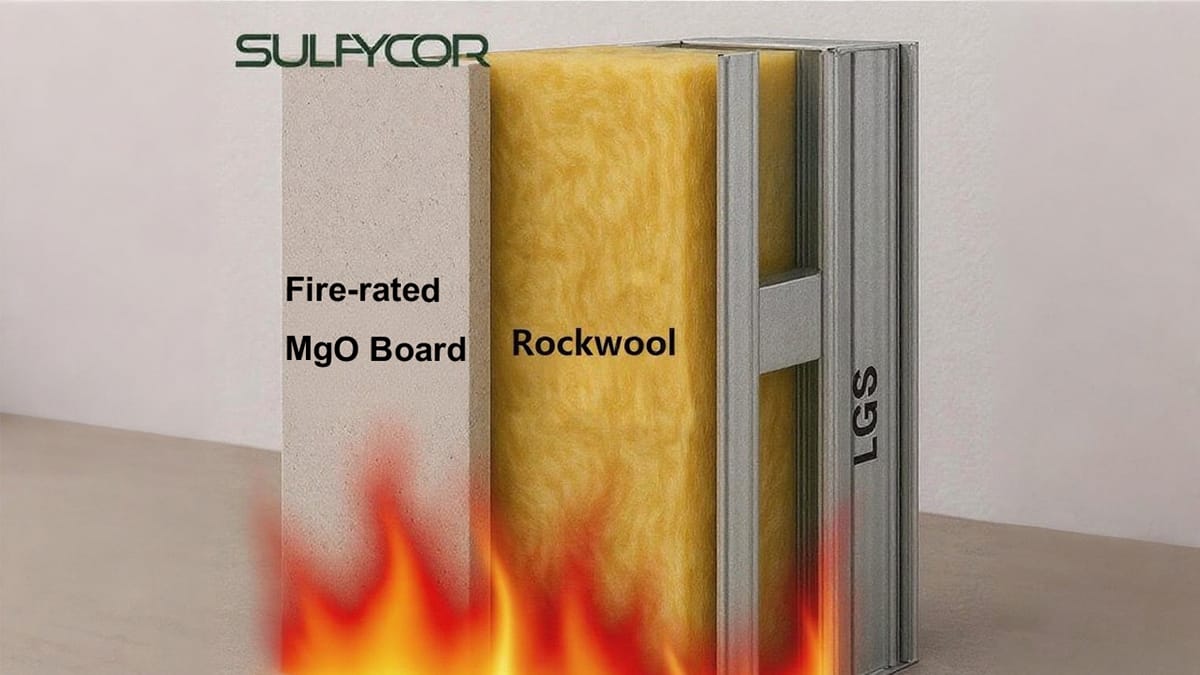

Mgo Board | Excellent Non-combustible Materials, Does not burn and gives good fire resistance |

Acoustic Panels | Fire resistance depends on the fabric and inside material; fiberglass panels do not burn. |

PVC | If not treated, it can burn; fire retardants make it safer. |

Used a lot in acoustic panels; usually resists fire. | |

Steel | Does not burn and gives good fire resistance. |

Gypsum board is used in many fire rated panels. Type X gypsum can stop fire for at least one hour. Type C gypsum has more glass fibers, so it protects better. Concrete panels give great fire protection. Metal panels give medium to high fire resistance.

Fire-Resistive Construction

Fire-resistive construction slows down fire and keeps people safe. It gives you more time to leave if there is a fire. Fire resistant wall panels keep fire in one spot and protect your things. These panels help you follow safety rules and lower repair costs.

Some building methods make fire rated panels stronger. Mineral wool insulation does not burn and can last up to four hours. Metal covers like steel or aluminum protect the inside from flames. Foam insulations like expanded polystyrene and polyurethane need fire retardants to be safer.

Tip: Always look at the fire ratings before you pick panels. Fire-resistive construction makes your building last longer and keeps it safer.

Fire Barriers and Assemblies

Fire barriers and assemblies give more safety than regular fire-rated wall panels. Fire barriers go from the floor to the roof and have higher fire resistance. They keep fire in certain places, like hallways or shafts.

Fire barriers stop fire from spreading and can last one to four hours.

They split up high-risk areas and close off exits.

Fire barriers use strong things like steel and concrete.

They work with sprinklers and alarms to keep people safe.

The table below shows the differences between fire barriers and fire rated panels:

Feature | Fire Barriers | Individual Fire-Rated Wall Panels |

|---|---|---|

Fire Resistance Level | Higher fire resistance | Lower fire resistance |

Purpose | Made to split up high-risk areas | Used for less important separations |

Material Composition | Made from steel, concrete, or fire-resistant materials | Changes, often not as strong |

Role in Fire Safety | Stops fire from spreading and keeps people safe | Only holds fire in for a short time |

Use fire barriers where you need the most protection. Fire rated panels are good for less risky places. Both help keep your building safe.

Interpreting Fire-Rated Wall Panel Certifications

Certification Labels

Always check the certification label on a fire-rated wall panel. The label gives you important facts about the panel. It lists what materials are used, like steel studs or gypsum board. The label also shows the fire resistance rating. This rating comes from tests done by trusted labs, such as those using UL 263. If the panel passes these tests, it gets a UL certification mark. This mark means the panel meets safety rules.

You can check if a label is real by doing these things:

Find a label from a trusted lab. This proves the panel passed fire tests.

Look up the product in the UL online directory.

Make sure the rating is from a third-party group.

Tip: Only use panels with clear certification labels. This helps you follow building codes and keeps your building safe.

Flame Spread and Smoke Ratings

There are two important numbers on the label. These are the flame spread rating and the smoke developed index. These numbers show how the panel acts in a fire. The flame spread rating tells how fast fire moves across the panel. The smoke developed index shows how much smoke the panel makes during a fire.

These ratings come from the ASTM E84 test, also called the Steiner tunnel test. This test checks how materials burn and how much smoke they make. Here is a table to help you understand the numbers:

Rating Class | Flame Spread Index (FSI) | Smoke Developed Index (SDI) | Implication for Safety |

|---|---|---|---|

Class A | 0-25 | Low | Highest fire safety |

Class B | 26-75 | Moderate | Moderate fire safety |

Class C | 76-200 | High | Lowest fire safety |

A Class A rating means the panel has the lowest flame spread and makes very little smoke. This is the safest choice, especially for places like hospitals. The International Building Code and National Fire Protection Agency require Class A panels in many buildings. To get this rating, panels must pass hard tests for flame spread and smoke developed index.

Recognizing Accredited Agencies

Only trust certifications from accredited agencies. These agencies must follow strict rules. They use standards from groups like ASTM or NFPA. Accredited companies, such as UL or Intertek, test products and give reports. They also list certified products in public databases.

Criteria for Accreditation | Description |

|---|---|

Standards Development | Standards come from groups like ASTM or government agencies. |

Testing | Accredited labs test products and report results. |

Certification | Agencies certify products and publish them in a database. |

When you see a certification from an accredited agency, you know the wall panel meets all safety rules. This helps you trust that the panel will protect your building in a fire.

If you know about fire resistance ratings, you can make your building safer. Always pick paneling that does not burn and check the fire ratings. This helps you follow fire safety codes. Choose panels with strong fire protection and Class A fire safety for the best safety. Use this table to help you pick panels:

Factor | Description |

|---|---|

Choose panels that last as long as you need in a fire. | |

Material Selection | Pick steel or aluminum for better fire protection. |

Building Codes and Standards | Make sure your panels meet local fire safety rules. |

Write down when you check and fix panels.

Teach workers about fire safety.

Plan regular checks to keep fire protection working.

FAQ

What does a fire resistance rating mean for wall panels?

A fire resistance rating tells you how long a wall panel can stop fire and heat. You use this rating to know if a panel will protect people and property during a fire.

How do you check if a wall panel is fire rated?

You should look for a certification label from a trusted lab, like UL or Intertek. The label shows the fire rating and test standard. You can also check the product in the lab’s online directory.

Can you use any fire-rated panel anywhere in a building?

No, you must match the panel’s fire rating to the building code for each area. High-risk places, like stairwells, need panels with higher ratings. Always check local rules before you choose.

What is the difference between flame spread and fire resistance?

Flame spread shows how fast fire moves across a panel’s surface. Fire resistance shows how long the panel can block fire and heat. Both ratings help you pick safer wall panels.

Why do you need independent testing for fire-rated panels?

Independent labs test panels using strict rules. You can trust their results. This testing proves the panel meets safety codes and gives you peace of mind.

Common Materials

Common Materials