08 Sep Advantages Of Magnesium Oxide Board As Building Partition Walls

Table of Contents

- 1 Key Takeaways

- 2 What is Magnesium Oxide Board

- 3 Fire Resistance of MgO Boards

- 4 Durability Benefits

- 5 Moisture and Mold Resistance

- 6 Sound and Thermal Insulation

- 7 Eco and Health Benefits

- 8 Installation and Efficiency

- 9 FAQ

- 9.1 What makes magnesium oxide board a good choice for fire safety?

- 9.2 Can magnesium oxide board improve indoor safety?

- 9.3 How does magnesium oxide board compare to gypsum board for fire safety?

- 9.4 Is magnesium oxide board easy to install?

- 9.5 Where can builders use magnesium oxide board for best safety?

Magnesium oxide board gives builders many good things when used for partition walls. This board comes from natural minerals. It is a strong and light panel for building. Builders pick magnesium oxide board because it makes buildings safer. It also makes them last longer and helps the environment. It protects better than regular boards. It also makes walls last longer.

The boards do not burn, get wet, or get bugs.

They stay strong and last long in tough places.

The good things are easy to put in and help green building projects.

Key Takeaways

Magnesium oxide boards stop fire, water, mold, and bugs. This makes walls safer and helps them last longer.

These boards are light, strong, and simple to put up. Builders can finish their work faster with them.

MgO boards help keep indoor air clean. They do not let out bad gases and stop mold from growing.

They block noise and keep heat in or out. This makes buildings quieter and saves energy.

Using magnesium oxide boards is good for the environment. They help cut down pollution and save energy.

What is Magnesium Oxide Board

Basic Features

Magnesium oxide board is a new option for partition walls. Makers use natural minerals and strong materials to make mgo boards. They follow several steps to create these boards:

They get magnesium oxide powder, magnesium salts, perlite, wood fiber, and water ready.

They mix everything together until it is smooth.

The mix goes onto lines with non-woven fabric and fiberglass mesh for strength.

The boards dry in special rooms to keep their shape and bond the parts.

Workers remove the boards from molds and let them dry again to get stronger.

Mgo boards have magnesium oxide, magnesium chloride or sulfate, perlite, wood fiber, fiberglass mesh, and non-woven fabric. These things help the boards stop fire, block water, and last a long time. Mgo boards do not crack or bend easily. This makes them good for many building jobs. Builders like that these boards are light, simple to move, and good for the earth. The boards do not let out bad gases, so indoor air stays safe.

Tip: Mgo boards have a flat surface. You can paint, tile, or put wallpaper on them. This makes finishing work easier for builders.

Comparison to Traditional Materials

Mgo boards are not the same as fiberboard, gypsum board, or cement board. The table below shows how magnesium oxide board is different from fiberboard and gypsum board:

Attribute | Magnesium Oxide Board | Fiberboard | Gypsum Board |

|---|---|---|---|

Composition | Mineral-based | Wood fibers, resins | Gypsum, paper |

Fire Resistance | Non-combustible | Moderate | Moderate |

Moisture Resistance | Excellent | Poor | Poor |

Durability | High | Low | Moderate |

Weight | Lightweight | Heavy | Moderate |

Thermal Insulation | Excellent | Decent | Decent |

Environmental Impact | Low | High | Moderate |

Health Safety | Non-toxic | May emit gases | May emit gases |

Mgo boards can stop fire even when they are thin. For example, a 3 mm magnesium oxide board meets fire rules. Gypsum board must be 12 mm thick to do the same. Magnesium oxide board costs more at first. But it saves money later because it lasts longer and needs less fixing. Builders also put up mgo boards faster, so they spend less on work. These good points make mgo boards a smart pick for walls in new buildings.

Fire Resistance of MgO Boards

Noncombustible Properties

Noncombustible Properties

Mgo boards are great at stopping fire. They do not burn, even in very hot places. Their special mix lets them handle heat up to 3000°F. They keep their shape and strength when it gets hot. Builders use mgo boards for walls that need to stop fire. These boards help keep fire from moving to other rooms. Gypsum boards get weak when they get hot. Mgo boards stay strong and block flames. They do not need extra chemicals to work. The boards naturally stop fire and smoke from passing through. Mgo boards also lower the amount of bad fumes in a fire. This helps keep people safe inside buildings.

Note: Mgo boards protect people and things from fire. Their ability to not burn makes them a good pick for schools, hospitals, and homes.

Safety Ratings

Groups that test building materials give mgo boards high fire ratings. These boards pass tough fire safety rules in many places. The EN13501-1:2009 test gives mgo boards an A1 rating. This means they do not burn. The BS 476: Part 4:1970 test also shows mgo boards do not catch fire. Builders trust these ratings when picking wall materials. Mgo boards keep heat out and stay strong for up to four hours in a fire. This helps keep buildings safer. The table below shows how mgo boards rate for fire resistance:

Fire Resistance Aspect | Rating/Certification |

|---|---|

EN13501-1:2009 Classification | A1 (highest non-combustible rating) |

BS 476: Part 4:1970 Classification | Non-combustible |

Wall/Ceiling Fire Resistance | Thermal insulation & integrity: 1, 2, and 4 hours |

Mgo boards are better at stopping fire than gypsum boards. They can handle heat and flames well. Builders use mgo boards to make buildings safer and follow rules. These boards help stop fire from spreading and keep people safe.

Durability Benefits

Impact and Crack Resistance

Mgo boards are very tough for partition walls. Builders pick these boards because they do not crack or break easily. They are stronger than many old wall materials. Tests show mgo boards bend well and stay strong. They do not lose strength when wet or frozen. This means the boards do not break in bad weather. Researchers learned that mgo boards help walls stay stiff and hold weight. When builders use these boards with other wall parts, the walls get even stronger and can take more hits.

Note: Big fire tests show mgo boards keep their shape under stress. They do not crack or split at the joints like gypsum boards. This makes mgo boards a good choice for places where walls might get bumped or hit.

Mgo boards work well in wet or changing weather. They keep their strength and last a long time. Builders think these boards are a smart way to make strong partition walls.

Longevity

Mgo boards last longer than most wall boards. These boards can stay strong for many years. They do not lose their main strength or resistance. The table below shows how long mgo boards last compared to other boards:

Metric | Magnesium Oxide (MgO) Boards | Conventional Alternatives |

|---|---|---|

Average Lifespan | Typically shorter |

Mgo boards fight fire, water, mold, bugs, and bad weather. This helps them keep their shape and look good for a long time. Even if the surface gets old, the boards stay strong. They do not lose their toughness over time. Builders use mgo boards in big projects to show they last long. If you install and finish them right, they last even longer. Mgo boards are strong, last many years, and need fewer repairs.

Moisture and Mold Resistance

Water Resistance

Water Resistance

Mgo boards do not let water in easily. This makes them good for wet places. They do not swell or bend when wet. Builders use mgo boards in bathrooms and kitchens. They also use them in basements. These boards help walls last longer and need fewer fixes.

Some rules check how well mgo boards stop water:

ICC-ES AC386 Acceptance Criteria for Fiber-Reinforced Magnesium-Oxide-Based Sheets

ICC-ES AC378 Acceptance Criteria for Reinforced Cementitious Interior Substrate Sheets Used in Wet and Dry Areas

ASTM C666 Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing

ASTM D1037 Standard Test Methods for Evaluating Properties of Wood-base Fiber and Particle Panel Materials

These rules test how much water the boards take in. Mgo boards have ILAC-MRA certification. This means people trust their test results everywhere. Sulfycor mgo boards stay strong after getting wet. They meet ISO 9001, CE, and ASTM rules. This shows they are tough and stop water well.

Tip: Mgo boards help stop water damage in buildings. Their water resistance keeps walls safe in homes and stores.

Mold and Mildew Protection

Mgo boards stop mold and mildew from growing. Their special mix does not let mold live on them. Gypsum boards can soak up water and grow mold. Mgo boards do not take in much water. This keeps mold from spreading. This helps the air inside stay healthy. It also means less cleaning and fixing.

The table below shows how mgo boards and gypsum boards handle mold:

Property | MgO Board | Gypsum Board |

|---|---|---|

ASTM G21 Fungus Test Score | 0/0/0 (no fungal growth) | Prone to mold |

Moisture Absorption | Nearly 3% | |

Resistance to Water Damage | Excellent (no swelling/warping) | Poor (swelling, warping common) |

Mold Resistance | High (inorganic, no nutrients) | Low (organic, mold grows) |

Mgo boards stay strong and keep their shape in wet places. Builders trust these boards to last a long time. Using mgo boards helps keep buildings clean and safe. They work well where water is a problem.

Sound and Thermal Insulation

Acoustic Performance

Mgo boards help make buildings quieter. These boards block sound from moving between rooms. Builders use mgo boards in schools, offices, and homes to keep noise low. The boards work well in walls and floors. They stop loud sounds and help people focus or rest. Mgo boards have high sound transmission class (STC) ratings. This means they block more noise than many other wall materials.

The table below shows how mgo boards perform in different wall and floor setups:

Assembly Type | STC Rating | Additional Acoustic Info |

|---|---|---|

MgO floor assemblies with sheathing | 53 | IIC rating of 72 |

MgO wall assemblies (UL-rated systems) | 53 – 54 | Exceeds typical building codes |

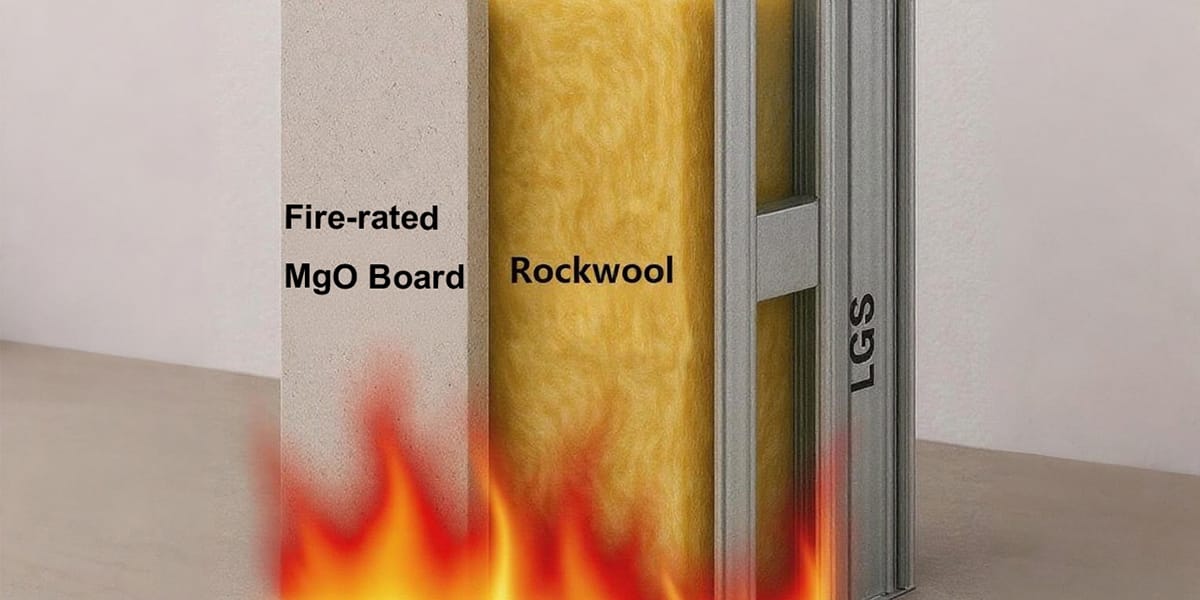

Partition with double-sided 9mm MgO boards + 75mm keel + 50mm rock wool | Noise reduction > 42 dB | – |

Note: Mgo boards can help meet or exceed building code rules for sound control. These boards make rooms more private and comfortable.

Energy Efficiency

Mgo boards also help keep buildings warm in winter and cool in summer. These boards have better thermal insulation than limesand brick block. The thermal conductivity of mgo boards is 0.216 W/cm·K. Limesand brick block has a higher value of 1.1 W/cm·K. This means mgo boards slow down heat movement better. Builders use these boards to lower energy use and save money on heating and cooling.

Calcium silicate boards have even better thermal insulation than mgo boards. Builders pick calcium silicate boards for places that need extra heat protection. Still, mgo boards give a good balance of fire resistance, moisture resistance, and durability. These boards help keep indoor spaces comfortable all year.

Mgo boards work well in many climates. They help builders create energy-efficient buildings. The boards also support green building goals by lowering energy waste.

Eco and Health Benefits

Eco-Friendly Materials

Magnesium oxide board is good for the environment. It uses minerals and natural things to make the boards. This helps builders use less energy and protect nature. Making magnesium oxide boards needs less power than making gypsum boards. These boards also trap carbon dioxide when they dry, so they help the air.

Making magnesium oxide board gives off about 340 kg of CO2 for each ton.

Making gypsum board gives off about 740 kg of CO2 for each ton.

Magnesium oxide boards save energy and use materials that can be replaced.

Gypsum boards use up resources that will run out and do not trap CO2.

These facts show magnesium oxide boards are better for green building. Builders who care about the earth pick these boards to cut down on pollution. The boards also last longer because they do not get damaged by water. This means less fixing and less trash.

Tip: Choosing magnesium oxide board helps keep the earth safe and makes buildings safer for people.

Indoor Air Quality

Magnesium oxide boards help keep the air inside buildings clean. Tests show these boards do not let out bad chemicals called VOCs. The amount is so small that machines cannot find it. These boards do not have formaldehyde, asbestos, or other dangerous stuff. This makes them safe for people who have asthma or are sensitive to chemicals.

MgO boards are made from safe, natural things.

They do not give off VOCs, formaldehyde, or ammonia.

They stop mold and bugs, which keeps the air fresh.

Good for homes, schools, and hospitals because they are safe.

MagPanel® MgO boards have a top fire safety rating and do not spread flames.

They pass hard fire safety tests like EN ISO 1716 and EN 13501.

These features help keep people healthy and safe inside buildings. Magnesium oxide boards do not let out harmful gases, so they are a good pick for safe places. Builders use these boards when they want to protect people’s health.

Installation and Efficiency

Easy Handling

Easy Handling

Magnesium oxide boards are different to work with. They are heavier and thicker than gypsum boards. Two people should carry each board to stop cracks. You need special tools to cut them, like saws with carbide tips or sharp knives. These tools help make smooth cuts and stop chips. It is best to drill holes before putting in screws. This keeps the board from breaking and makes it easier to attach. Workers should wear gloves, dust masks, and safety glasses to stay safe. Keep the boards flat when storing them. Carry them on their sides to protect the edges. You can score and snap the boards, but this can make rough edges. These rough edges need more work to look nice.

Tip: If boards are cut at the factory, it saves time and money on the job.

Construction Speed

Putting up magnesium oxide boards can go fast if workers have the right tools. Crews can use these boards without extra steps or waiting for them to dry. Once the boards are up, you can use them right away. This helps finish building faster. Gypsum boards need up to seven days to dry before use. Bad weather can make this take even longer. Magnesium oxide boards need more work and sometimes more people. But you do not need corner beads or backing, so some steps are easier. These boards are strong, so you fix them less and do not need much care.

Material | Installation Time | Curing Time | Ready for Use |

|---|---|---|---|

MgO Board | Fast | None | Immediate |

Gypsum Board | Fast | Up to 7 days | Delayed |

Getting the surface ready is important for a good finish. Workers clean, prime, and sand the boards so paint or plaster sticks well. Using the right primer helps the finish look better and last longer. If you get the surface ready, you do not need as many extra materials. This also stops cracks and bumpy spots.

Note: Spending time to get the surface ready makes the walls look better and last longer.

Magnesium oxide board is a safe and strong pick for walls. It does not let fire, smoke, or flames spread. The board also keeps out water, mold, and bugs. This makes it good for many places. Builders like that it is easy to put up and use. It helps them finish jobs faster. The table below shows how it fixes common building problems:

Challenge | Solution Provided by MgO Board |

|---|---|

Fire | |

Moisture | |

Durability | |

Installation |

Many experts say magnesium oxide board is safer and greener. It also helps walls last longer. Builders can get more tips and guides from trusted suppliers and industry groups.

FAQ

What makes magnesium oxide board a good choice for fire safety?

Magnesium oxide board does not burn. It blocks flames and heat. Builders use it to meet fire safety rules. The board keeps people and property safe during a fire.

Can magnesium oxide board improve indoor safety?

Magnesium oxide board does not release harmful gases. It stops mold and bugs. People feel safer in homes, schools, and hospitals when builders use this board.

How does magnesium oxide board compare to gypsum board for fire safety?

Magnesium oxide board has better fire safety than gypsum board. It stays strong in high heat. Gypsum board can weaken and break during a fire.

Is magnesium oxide board easy to install?

Workers can cut and shape magnesium oxide board with special tools. The board goes up quickly. Builders finish projects faster and spend less time on repairs.

Tip: Factory-cut boards save time and help workers avoid mistakes.

Where can builders use magnesium oxide board for best safety?

Builders use magnesium oxide board in schools, hospitals, and homes. The board works well in places that need strong fire safety and clean air.

Place | Benefit |

|---|---|

School | Fire safety, clean air |

Hospital | Fire safety, health |

Home | Fire safety, comfort |

Noncombustible Properties

Noncombustible Properties Water Resistance

Water Resistance Easy Handling

Easy Handling