27 Aug Analyzing Fire Resistance Test Results of Magnesium Wall Boards

Table of Contents

- 1 Key Takeaways

- 2 Fire Resistance Overview

- 3 Test Analysis

- 4 Material Comparison

- 5 Practical Implications

- 6 FAQ

- 6.1 What makes magnesium oxide boards fire-resistant?

- 6.2 Can magnesium oxide boards be used outdoors?

- 6.3 How do magnesium oxide boards compare to gypsum boards for fire safety?

- 6.4 Are magnesium oxide boards safe for people and the environment?

- 6.5 What building types benefit most from magnesium oxide boards?

Magnesium oxide boards do very well in fire tests. The table below shows their fire resistance. Mgo board stays strong and stable at over 1000°C. Builders and owners like fireproof wall boards. These boards help protect people and buildings. Fireproof material like mgo board does not burn. It does not give off dangerous gases. This helps keep buildings safe from fire. Non-combustible, fire-resistant materials make buildings safer. Magnesium oxide boards are a great choice for fireproof use.

Test or Property | Result or Value | Significance or Rating |

|---|---|---|

Fire Rating | Highest non-combustible classification | |

Fire Resistance Duration | 30 minutes or more; 12mm board > 1 hour | Prolonged fire protection |

Temperature Resistance | Over 1000°C | High thermal stability |

ASTM E84 Flame Spread | 0 to 25 | Class A rating |

ASTM E84 Smoke Developed | Under 450 | Low smoke emission |

Structural Integrity | Maintains strength under fire | Ensures safety and stability |

Key Takeaways

Magnesium oxide boards can handle fire really well. They stay strong even when it gets hotter than 1000°C. These boards do not catch fire or let out dangerous gases. This makes buildings safer if there is a fire. Magnesium oxide boards are better than gypsum and fiber cement boards. They last longer and resist fire more. They follow tough fire safety rules. People use them in schools, hospitals, hotels, and other big buildings. Using magnesium oxide boards helps keep people safe. It also lowers fire damage and is good for the environment.

Fire Resistance Overview

Magnesium Oxide Boards Properties

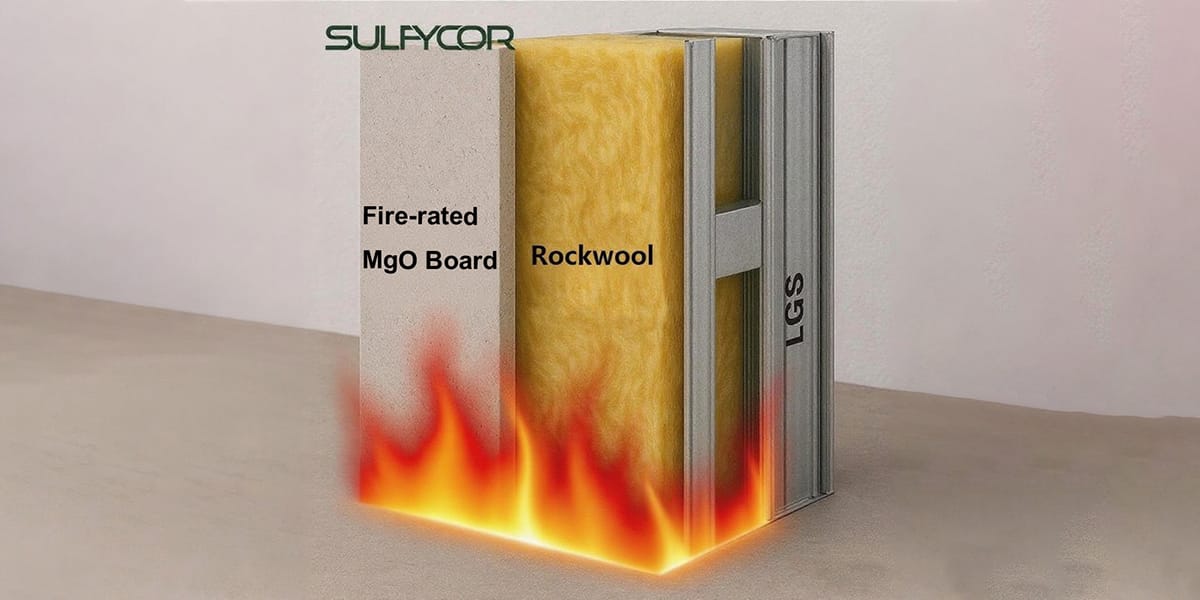

Magnesium oxide boards are very good at stopping fire. They are tested in many buildings. The boards have a binder that turns into magnesium oxide when heated. Magnesium oxide melts at about 2800°C. This makes the boards strong against heat. The minerals inside hold water. When the boards get hot, the water turns into steam. The steam helps slow down the fire. It also makes less smoke. Builders like to use magnesium oxide boards for fireproof walls and insulation. These boards keep their shape and strength during long fires. Mgo board does not bend or fall apart easily. Fire-resistant mgo boards help keep people and buildings safe. Fireproof wall boards made from non-combustible mgo give extra safety at home and work.

Note: Magnesium oxide boards are both fireproof and heat-resistant. They help stop fire from spreading and keep buildings safe.

Non-Combustible Features

Non-combustible mgo is a great choice for fire safety. Lab tests show mgo board gets Class A ratings under UL 055 and ASTM rules. These fireproof insulation boards can take heat up to 1472°F (800°C). Non-combustible wall panels made from magnesium oxide do not burn or make bad gases. Fire-resistant mgo boards stay strong in wet and changing weather. Their fire resistance does not go away over time. Builders use non-combustible wall panels and heat-resistant wall panels where fire safety is important. Fire-resistant mgo and fireproof material help meet tough fire codes. Heat-resistant wall panels and fireproof insulation boards give more protection. Mgo board and non-combustible mgo work together to make buildings safer from fire.

Property | Test/Standard | Result/Rating |

|---|---|---|

Fire Resistance | UL 055, ASTM | Class A rating; withstands up to 1472°F (800°C) |

Fire-resistant mgo and non-combustible mgo help builders feel sure. These fire-resistant materials help make buildings safer and stronger.

Test Analysis

Fire Test Methods

Magnesium oxide boards go through tough fire tests. Labs use rules like ASTM E84-24, EN 13501-1+A1:2010, and NFPA 285. These tests check how the boards handle flames, smoke, and heat. ASTM E84-24 looks at how fast flames spread and how much smoke comes out. EN 13501-1+A1:2010 gives ratings for fire resistance in building materials. NFPA 285 checks how wall assemblies perform in fire.

Test Standard | Purpose | What It Measures |

|---|---|---|

ASTM E84-24 | Surface burning characteristics | Flame spread, smoke developed |

EN 13501-1+A1:2010 | European fire classification | |

NFPA 285 | Wall assembly fire performance | Fire-resistance rated assemblies |

Magnesium oxide boards need to pass these tests to be used for fire safety. Non-combustible mgo and fire-resistant mgo do well in all these tests. Fireproof wall boards made from mgo board help builders make walls that resist fire. These tests show that magnesium oxide boards are good for fire-resistant wall assemblies.

Tip: Builders should always make sure materials pass fire safety tests before using them in fire-rated walls.

Performance Results

Magnesium oxide boards do very well in fire tests. The boards keep their shape and strength when exposed to fire. Fireproof mgo board does not burn or melt. Non-combustible mgo lets out water vapor when heated, which helps slow the fire. This also makes less smoke and keeps the air safer. Fire-resistant mgo does not bend or change color easily. The boards stay strong even when it gets very hot.

Fireproof mgo board stays strong during fire.

Non-combustible mgo does not make bad gases.

Fire-resistant mgo does not bend or crack.

Mgo board keeps its fire-resistant features for a long time.

Magnesium oxide boards help builders follow fire safety rules. Walls made with mgo board last longer in fire tests. Fire-rated walls built with non-combustible mgo protect people and property. The boards also work well in heat-resistant wall panels. Fire test results show magnesium oxide boards are good for fire-resistant buildings.

Performance Aspect | Observed Result |

|---|---|

Structural Integrity | Maintains strength under fire |

Water Vapor Emission | Releases steam, slows fire |

Warping/Discoloration | Minimal change, stays stable |

Smoke Production | Low, safer for occupants |

Note: Fire-resistant mgo and non-combustible mgo help builders make buildings safer with strong fire protection.

Failure Modes

Magnesium oxide boards almost never fail in fire tests. Most boards last more than one hour in fire-rated walls. The main problem is surface charring after being in high heat for a long time. Sometimes, the boards may crack if the fire lasts many hours. Non-combustible mgo does not burn, but very high heat can change the surface a little. Fire-resistant mgo keeps its shape and does not fall apart. Mgo board does not lose its fire-resistant features quickly.

Surface charring can happen after long fire exposure.

Cracking may occur if heat stays high for many hours.

Magnesium oxide boards do not melt or burn.

Fireproof mgo board stays strong in fire-rated walls.

Fire-resistance ratings show magnesium oxide boards protect buildings for a long time. Fire test results prove non-combustible mgo and fire-resistant mgo are safe for fire-resistant walls. Builders trust mgo board for fireproof buildings because it meets fire safety needs.

Callout: Magnesium oxide boards give strong fire resistance and help stop big damage during fires.

Material Comparison

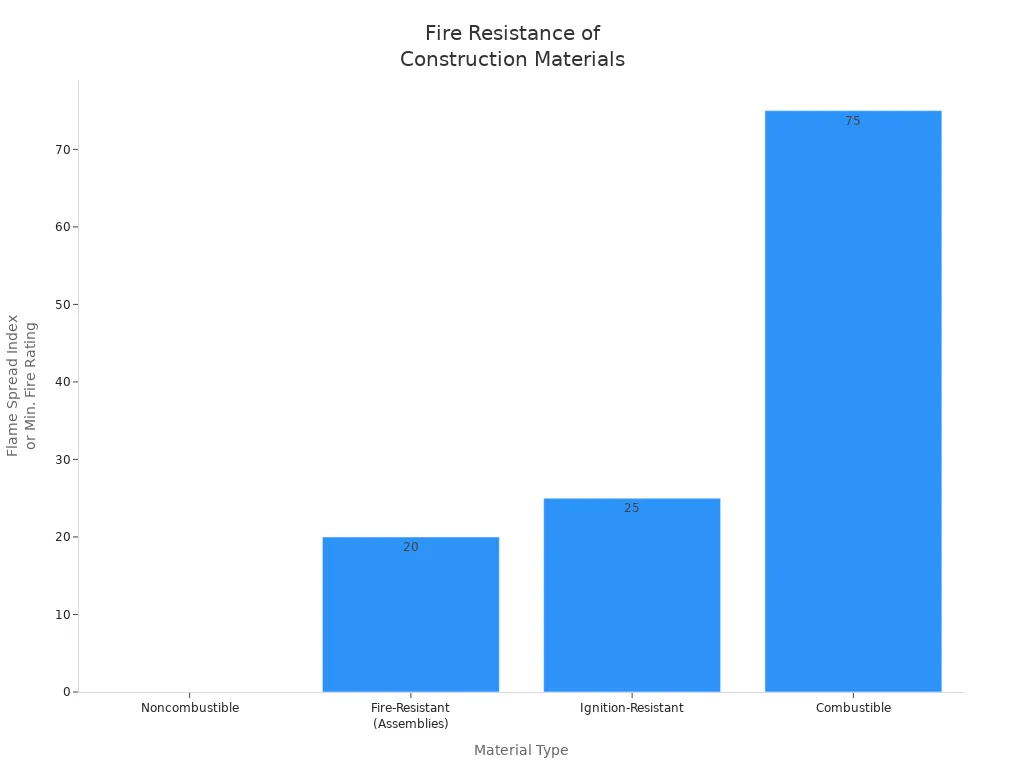

Fire-Resistant Construction Materials

Fire-Resistant Construction Materials

Builders use different materials to keep buildings safe from fire. Some of these are magnesium oxide boards, gypsum board, fiber cement board, and OSB. Each one has its own fire resistance rating. Magnesium oxide boards are special because they are fireproof and noncombustible. Gypsum board and fiber cement board can resist fire, but not as well as magnesium oxide boards. OSB is not good for fire safety and burns fast.

Material | Fire Resistance Rating | Notes on Fire Resistance |

|---|---|---|

Magnesium Oxide (MgO) Board | Up to 1-2 hours; rated noncombustible (ASTM E136 & E84) | Highly fire-resistant, superior to gypsum and fiber cement boards |

Gypsum Board | Fire-resistant but requires multiple layers or treatments | Less fire resistance unless enhanced |

Fiber Cement Board | Fire-resistant but generally less than MgO boards | Moderate fire resistance |

OSB | Not fire-resistant; ignites easily under high temperatures | Poor fire resistance |

Tip: Magnesium oxide boards give the best fireproof safety for fire-rated walls and outside sheathing.

Magnesium Oxide vs. Gypsum

Magnesium oxide boards and gypsum board are both used for fire safety. Magnesium oxide boards have better fire resistance and do not burn. They are used as fireproof wall board and fire-resistant sheathing in many places. Gypsum board can stop fire, but it often needs more layers or special help to work as well. Magnesium oxide boards make less smoke and stay strong during a fire. Builders pick magnesium oxide boards for fire-rated outside sheathing and panels where fire safety is very important.

Magnesium Oxide vs. Cement Board

Magnesium oxide boards and fiber cement boards both help protect against fire. Magnesium oxide boards are better at stopping fire and are good for outside sheathing. They stay strong and waterproof, even in wet or fire-prone places. Fiber cement boards can resist fire, but not as well as magnesium oxide boards. Magnesium oxide boards are lighter and easier to put up. Fiber cement boards are heavier and take more work. The table below shows how these two materials compare:

Feature | Magnesium Oxide Boards (MgO) | Fiber Cement Boards |

|---|---|---|

Fire Resistance | Superior fire resistance; ideal for fire-prone areas | Good fire resistance; suitable for fire protection |

Durability | Excellent longevity, even in high humidity | Reliable in harsh weather |

Water Resistance | Fully waterproof | Moisture-resistant |

Weight & Installation | Lightweight; easy to install | Heavier; more labor needed |

Callout: Magnesium oxide boards are the top choice for fire-resistant building materials. Builders use them for fire-rated outside sheathing and wall board lining in homes and businesses.

Practical Implications

Building Codes and Compliance

Magnesium oxide boards follow strict fire safety rules in many places. Builders use these boards to pass fire resistance tests. These tests are needed by codes like ASTM E84 and EN 13501-1. Non-combustible mgo helps buildings get top fireproof ratings. Fire-resistant mgo does not burn or make harmful gases. This helps buildings meet safety rules. Inspectors often suggest mgo board for fire-rated walls in schools, hospitals, and hotels. These boards keep working well even after being hot for a long time. Fireproof materials like magnesium oxide boards help owners avoid big repairs and insurance problems.

Note: Non-combustible mgo and fire-resistant mgo go beyond many code needs for fire-resistant materials. Builders trust these boards for good fire safety.

Building Type | Code Requirement Met | Benefit of MgO Board |

|---|---|---|

Commercial | ASTM E84, EN 13501-1 | High fireproof rating |

Multifamily | NFPA 285 | Strong fire performance |

Healthcare | Local fire codes | Non-combustible, safe air |

Applications in Fire-Resistant Construction

Magnesium oxide boards are used in many fire-resistant building projects. Builders use non-combustible mgo for walls, ceilings, and outside parts in schools and offices. Fireproof panels protect hospital rooms and factories. Fire-resistant mgo helps schools lower fire risks and keep students and staff safe. Big hotel groups use mgo board to make guests feel safe from fire. Car factories use fire-resistant materials to cut risks and insurance costs.

Walls and ceilings in schools and hospitals

Outside walls and coverings in offices

Fireproof panels in factories

Fire-rated walls in hotels and apartments

Non-combustible mgo gives great fire protection and stands up to heat. These boards also resist water, so mold and mildew do not grow. Builders pick magnesium oxide boards for green projects because they are better for the environment than cement or fiberboard. Mgo board can be recycled and does not make toxic fumes during a fire. Fireproof building with magnesium oxide boards helps make safer and greener places.

Callout: Magnesium oxide boards give fireproof safety, design choices, and help the environment. Builders use them to reach fire safety goals in many types of buildings.

Magnesium oxide boards are special because they do not burn. They are non-combustible and fireproof. Builders like mgo board since it stays strong in a fire. It does not make dangerous smoke.

These boards do not catch fire or grow mold. They stay strong even when wet.

They last longer in a fire, so people have more time to leave. This also means less money spent fixing damage.

Fireproof panels are used in places like airports, tunnels, and hospitals. These places need good fire safety.

Criteria | MgO Board Characteristics |

|---|---|

Fire Resistance Rating | |

Smoke and Toxic Gas Emissions | Minimal smoke, no toxic gases emitted |

Applications | Residential, commercial, wildfire-prone areas, hospitals |

Environmental Impact | Eco-friendly, recyclable, supports green building |

Using magnesium oxide boards helps make buildings safer and better for the planet. Fire safety experts say these boards are a smart choice for new fireproof buildings.

FAQ

What makes magnesium oxide boards fire-resistant?

Magnesium oxide boards contain minerals that do not burn. These minerals release water vapor when heated. The vapor helps slow down fire. The boards stay strong and do not melt or give off harmful smoke.

Can magnesium oxide boards be used outdoors?

Yes, builders use magnesium oxide boards for outdoor walls and sheathing. The boards resist water and weather. They do not rot or grow mold. This makes them a good choice for many building projects.

How do magnesium oxide boards compare to gypsum boards for fire safety?

Magnesium oxide boards offer better fire resistance than gypsum boards. They do not burn or break down in high heat. Gypsum boards may need extra layers for the same level of fire protection.

Are magnesium oxide boards safe for people and the environment?

Yes, magnesium oxide boards do not release toxic gases during a fire. They are safe for indoor air. The boards can be recycled. Builders choose them for green and healthy buildings.

What building types benefit most from magnesium oxide boards?

Schools, hospitals, hotels, and apartments benefit from magnesium oxide boards. These places need strong fire protection. The boards help keep people safe and reduce fire damage.

Fire-Resistant Construction Materials

Fire-Resistant Construction Materials