03 Sep Magnesium Wall Boards and Fire Safety in Modern Construction

Table of Contents

Magnesium oxide board is a strong choice for fire safety in buildings. This board is different from other materials because it does not burn. It can handle very high heat. Studies show the board can resist fire up to 1200°C. It also lets out water that helps stop smoke. More people use these boards now because fire safety is very important. The table below shows how different wall materials resist fire:

Material Type | Fire Resistance Characteristics |

|---|---|

Magnesium oxide board | Does not burn; handles very high heat; does not melt or catch fire at 1200°C; lets out water that helps stop fire and smoke |

Cement Boards | Does not burn; great fire resistance; does not get wet easily but can grow mold |

Fiber Cement Boards | Does not burn; great fire resistance |

OSB Boards | Can burn unless treated with special fire protection |

Plywood | Burns easily; can catch fire and turn black |

Gypsum Boards | Stops fire but breaks down at very high heat |

Key Takeaways

Magnesium wall boards do not catch fire. They can handle very high heat. This makes them great for fire safety in buildings.

These boards follow strict building rules and fire tests. They help keep people and property safe in homes and businesses.

Magnesium boards last a long time. They do not get damaged by water, mold, or bugs. This lowers repair costs and helps green building plans.

You need to install them with special screws. Careful fitting is needed to keep fire safety strong.

Many real buildings use magnesium wall boards. They help meet hard fire safety rules and make buildings safer.

Fire Safety Today

Building Code Trends

Building codes have changed to solve new fire safety problems. Today, rules like the International Building Code (IBC) set tough standards for walls in big buildings. These codes sort buildings by how they are used. This sorting changes what fire resistance is needed for outside walls. Designers and engineers must think about fire ratings, how far walls are from each other, and tests for how easy things catch fire. The NFPA 285 test now checks how flames move up and across walls with burnable materials. This test acts like a big fire breaking through a window. It helps experts see how fire can move on the outside of a building.

New rules say stairs and elevators need fire-rated covers, especially in tall buildings with many homes. Codes also want strong walls to protect escape paths. Making these rules takes many people, like fire engineers, code officials, and makers. They work together to make sure walls and other parts meet fire safety rules for the whole life of a building. These changes show that stopping fires, keeping them in one place, and keeping people safe are very important.

Building codes now say outside walls must pass big fire tests. Fire safety is now a main goal for buildings with many homes or businesses.

Why Fire Resistance Matters

Fire resistance is very important for keeping people and things safe. New buildings often have lots of things that burn fast, like plastic chairs and couches. Open rooms and glass walls can make it easier for fire to move quickly. In buildings with many homes, fire-resistant walls help slow down fire. This gives people more time to get out and lets firefighters do their job.

Materials that resist fire help keep walls strong. They also help stop damage and can make insurance cheaper. Rules say fire resistance must meet the law and keep people healthy. In places with more fire danger, local rules like California’s Wildland-Urban Interface (WUI) Code ask for better fire-resistant walls. Owners who know about fire ratings can pick better upgrades and follow the rules.

Fire resistance in walls is needed to keep people safe, protect buildings, and follow rules in places with many homes or businesses.

Magnesium Wall Boards

What Are Magnesium Wall Boards

What Are Magnesium Wall Boards

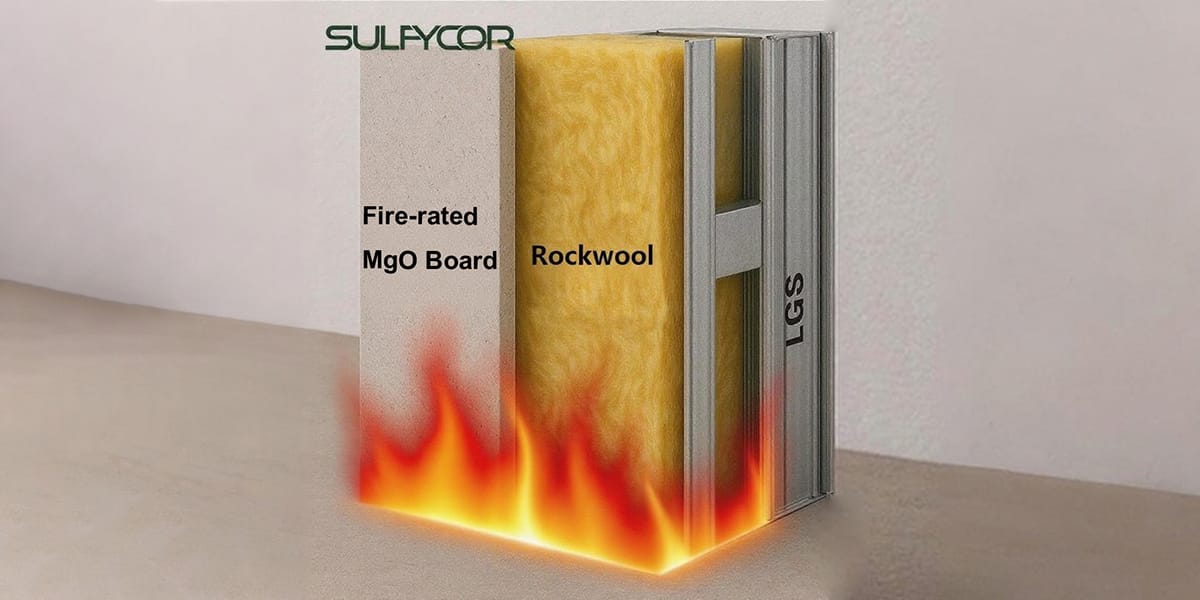

Magnesium wall boards are special panels made for fire safety and strength. Makers use magnesium oxide as the main mineral in these boards. This mineral does not burn, so the board can resist fire. Glass fibers are added to make the board stronger. Silica and clay help stop the board from catching fire or spreading flames. To make the boards, workers mix the materials, shape them, press them, and let them dry in a controlled place. This dry way of making the boards makes them thick, tough, and able to handle heat.

New ideas have made magnesium oxide boards even better. Companies now add fiberglass mesh and fillers like perlite to make the boards stronger and safer from fire. Some boards have magnesium alloy to last longer. These boards get top fire ratings, like A1 Fire Rating. They can stand heat over 750°C for more than 30 minutes. They also do not get damaged by water, mold, or mildew. This makes them good for tough places. The boards are safe, do not give off bad chemicals, and help keep the air inside clean.

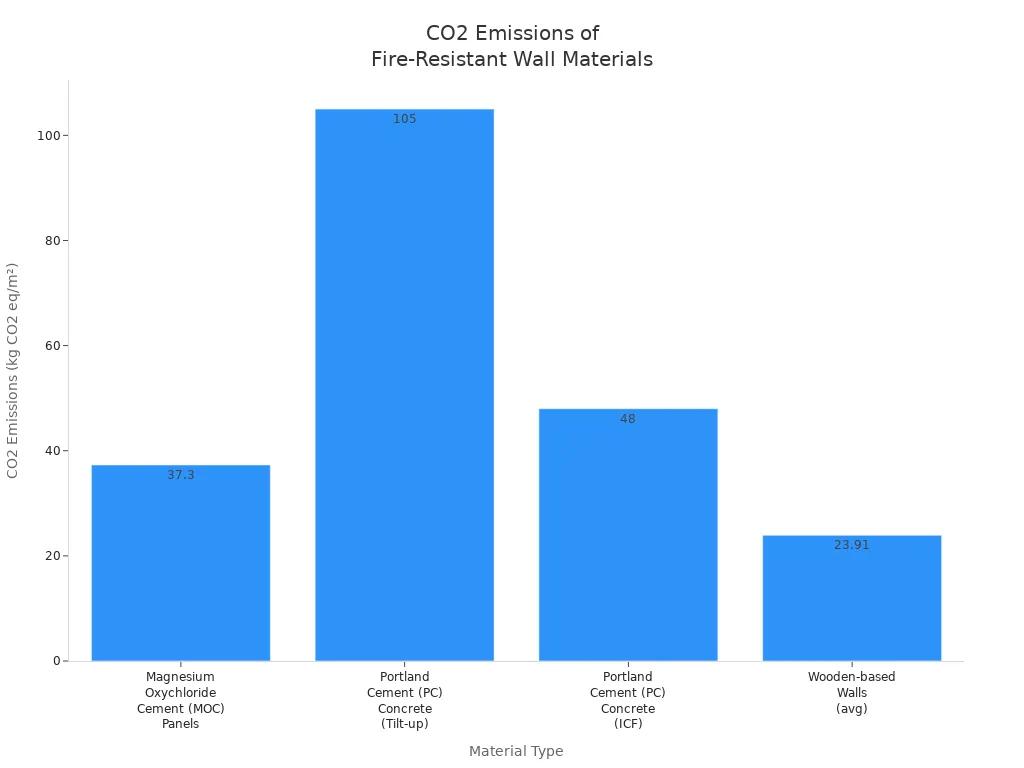

How building materials affect the environment is important today. Magnesium wall boards make less carbon dioxide than Portland cement concrete panels. Making these boards uses less energy because magnesium oxide needs a lower heat to make. The table below shows how much CO2 different materials make:

Material Type | CO2 Emissions (kg CO2 eq/m²) | Notes |

|---|---|---|

Magnesium Oxychloride Cement (MOC) Panels | At least 22% less CO2 than Portland cement concrete-based walls | |

Portland Cement (PC) Concrete (Tilt-up) | 105 | High emissions due to calcination at >1400°C |

Portland Cement (PC) Concrete (ICF) | 48 | Lower than tilt-up but still higher than MOC panels |

Wooden-based Walls | 19.12 – 28.7 | Lower CO2 emissions but limited fire resistance and durability |

Common Applications

Builders use magnesium wall boards in many building projects. These panels work as walls, ceilings, floors, and strong insulated panels. They are also used in fire doors, tunnels, and prefab buildings. Magnesium oxide board panels help keep buildings safe from fire and make them strong inside and outside.

Many apartment buildings, especially those called Type III Construction by the International Building Code, use these boards for better fire safety. The panels help meet tough fire safety rules, like ASTM E119 and NFPA 285 tests. Big buildings and important projects also use magnesium wall boards where fire safety matters most. Their strength and water resistance make them great for schools, hospitals, and other busy places.

Magnesium oxide board panels help buildings earn green building awards like LEED and BREEAM. They do not have asbestos, formaldehyde, or VOCs, so the air inside stays safe. The way they are made uses fewer natural resources and helps with recycling. These boards last a long time, so they do not need to be replaced often. This cuts down on waste and helps the planet.

Fire Resistance

Non-Combustibility

Non-combustible mgo panels are a top pick for fire safety. These panels do not catch fire, even with a direct flame. Tests show magnesium oxide board stays strong during a fire. In lab tests, non-combustible mgo panels did not burn or make smoke. Scientists compared these panels to gypsum and calcium silicate. Gypsum boards use chemicals to slow fire, but mgo panels stop fire from starting. If you add steel sheathing, the panels get even stronger in a fire.

Non-combustible mgo panels block fire from moving between rooms or floors. They do not give off bad fumes or gases, so people stay safer. These panels meet tough rules for fire-resistant walls and assemblies. Builders put non-combustible mgo panels in important places like stairs, fire exits, and escape paths. The panels do not let flames spread and make very little smoke, so they are great for both homes and businesses.

Classification | Description | Key Characteristics | Typical Applications |

|---|---|---|---|

Non-Combustible MgO | Inherently fireproof material that resists ignition and combustion without burning or off-gassing. | High melting point, resists direct flame without igniting | Fire-resistant walls, ceilings, flooring, structural components, critical areas like fire exits and stairwells |

Fire-Resistant MgO | Engineered MgO boards enhanced with additives and treatments to improve fire resistance. | Higher fire ratings than non-combustible MgO | Fire-rated walls, fire-resistant enclosures, critical infrastructure in commercial, industrial, and residential buildings |

Non-combustible mgo panels are a safe way to stop fire from spreading and help buildings pass fire safety rules.

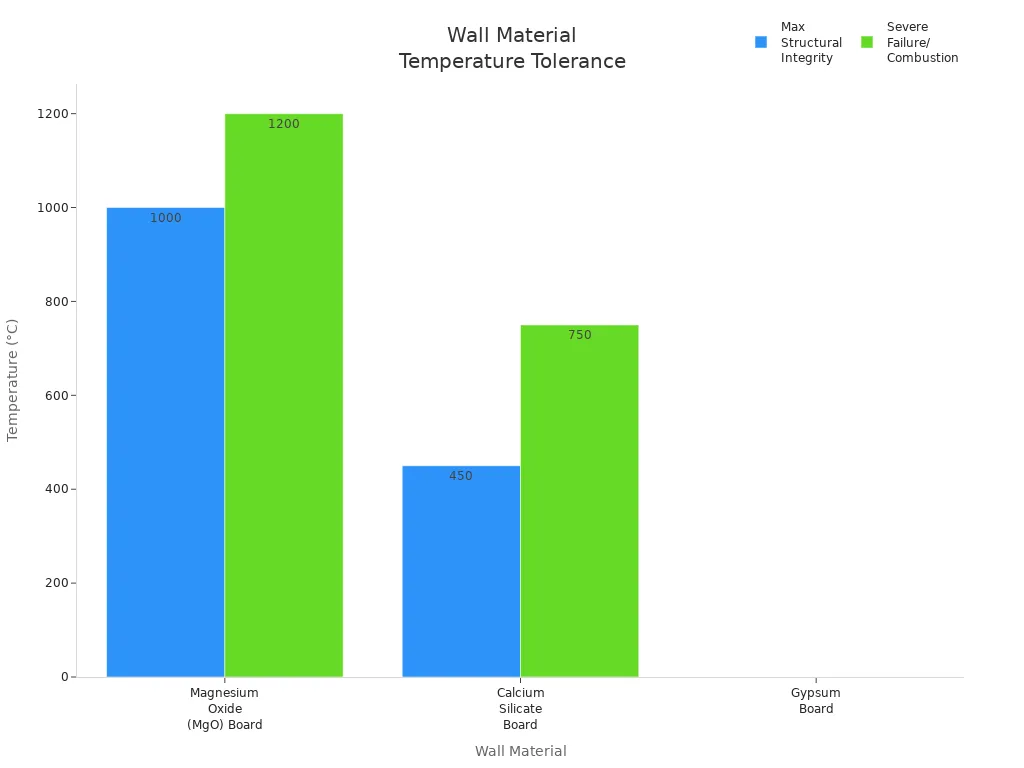

High-Temperature Performance

Non-combustible mgo panels work well in very hot fires. These panels keep their shape at up to 1000°C and do not burn at 1200°C. In tests, non-combustible mgo panels stayed strong at 750°C. This is better than gypsum and calcium silicate, which can break or fail sooner. Gypsum boards must be much thicker to be as safe, and calcium silicate boards start to crack at 450°C.

Material | Temperature Tolerance / Fire Resistance |

|---|---|

Magnesium Oxide (MgO) Board | Maintains structural integrity up to 1000°C; fire resistance up to 4 hours; flame-free even at 1200°C; no quality loss at 750°C |

Calcium Silicate Board | Begins cracking at 450°C; severe cracking and failure at 750°C; fire resistance often exceeds 2 hours but less durable at extreme heat |

Gypsum Board | Requires greater thickness (≥12mm) to meet fire safety; less resistant to high temperatures; combustible at lower thresholds |

Non-combustible mgo panels do not burn, melt, or lose shape in a fire. They do not help fire spread or make toxic smoke. This makes them good for fire-resistant walls in homes and businesses. Their strong test results show they are great for important fire safety jobs.

Fire Ratings

Non-combustible mgo panels get top marks in fire safety tests. These panels pass tests like ASTM E136, ASTM E84, EN 13501-1, and Canadian rules like CAN/ULC S114. In these tests, non-combustible mgo panels get Class A or A1, which means the best fire safety and almost no flame spread. The panels also do well in tests for how long they last in a fire, with 1 to 4 hours of protection, depending on how thick they are and how they are used.

Certification / Standard | Purpose / What It Tests | Typical Fire Rating Achieved by MgO Boards |

|---|---|---|

ASTM E136 | Determines if material is noncombustible | Classified as Noncombustible |

ASTM E84 | Measures flame spread on surfaces | Achieves Class A rating (best fire resistance) |

EN 13501-1 | European fire classification | Class A1 (noncombustible) |

CAN/ULC S114 and ULC S135 | Canadian fire safety standards | Meets noncombustible requirements |

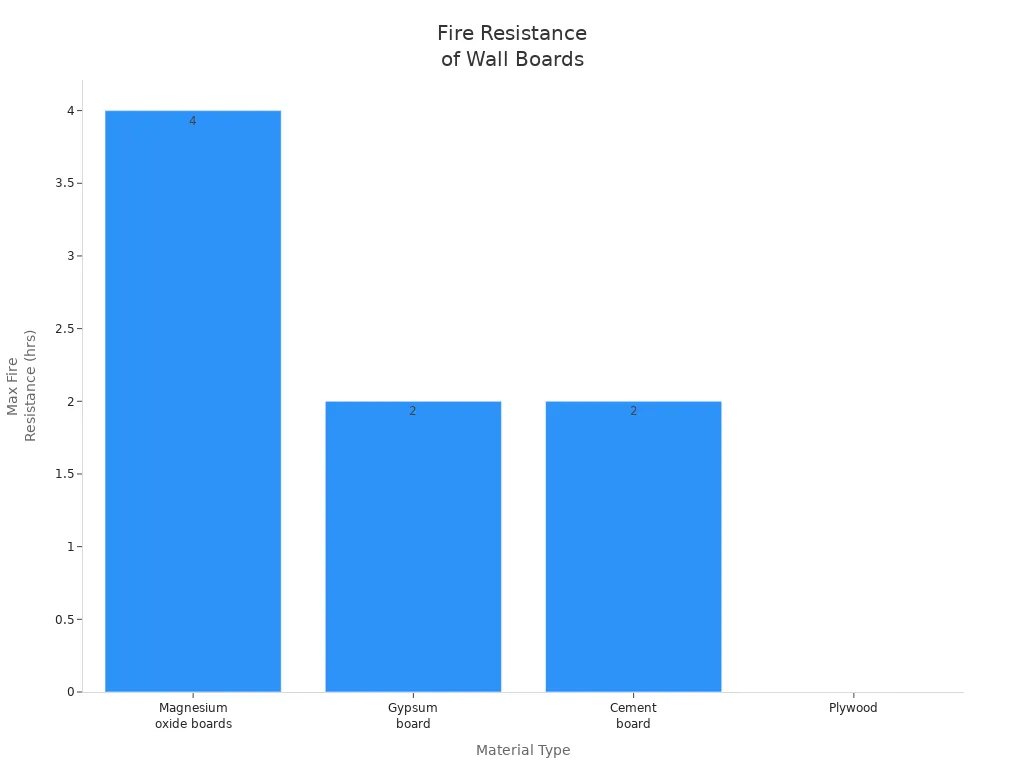

Non-combustible mgo panels also pass the NFPA 285 test, which checks how fire moves on building outsides. The panels do not burn or make toxic fumes, even in long fires. This makes them safer than plywood or gypsum. The table below shows how long different wall materials last in a fire:

Material Type | Fire Resistance Duration | Combustibility | Smoke/Toxic Fume Emission |

|---|---|---|---|

Magnesium oxide boards | 1 to 4 hours | Non-combustible | None |

Gypsum board | 0.5 to 2 hours | Combustible | Low |

Cement board | 1 to 2 hours | Non-combustible | None |

Plywood | 0 hours | Combustible | Yes |

Non-combustible mgo panels meet the hardest fire safety rules. Fire-resistant mgo panels, with special extras, can get even better fire ratings and keep heat out. Builders use these panels for walls, ceilings, and floors in schools, hospitals, and tall buildings. The panels do well in tests and real fires, so they are a top choice for fire safety.

Material Comparison

MgO vs. Gypsum

Magnesium oxide boards and gypsum boards are both used for walls. Their fire safety is very different. MgO panels do not burn and are better at stopping fire. They stay strong in tests and real fires. These panels can handle heat up to 1200°C. They keep their shape even in big fires. Gypsum boards get soft and weak when they get hot. In a fire, gypsum panels reach 95°C in three minutes. This can make it harder for people to escape and can be dangerous.

Criteria | Magnesium Sulfate Boards (MgO) | Gypsum Boards |

|---|---|---|

Fire Resistance Rating | A1 Non-Combustible (top rating, EN 13501-1) | Fire-Resistant but Limited (up to 1 hour) |

Thermal Combustibility | Non-Combustible; withstands heat up to 1200°C | Combustible; softens under high heat |

Flame Spread | Very Low (Flame Spread Index 0-25, ASTM E84) | Moderate Flame Spread |

Heat Resistance | High; remains strong in extreme heat | Medium; weakens with prolonged heat |

Smoke and Toxic Gas Emissions | Low emissions; little smoke, no toxic gases | Moderate emissions; more smoke, non-toxic gases |

Fire Endurance | Very High; protects up to 4 hours | Limited; typically 30-60 minutes |

MgO panels make less smoke and fewer bad gases. This helps keep people safer. Builders use MgO boards in places with high fire risk, like subway tunnels and parking garages. Gypsum boards are mostly used in homes and offices where fire risk is lower.

MgO vs. Plywood and Cement Board

MgO boards are safer than plywood and cement board in fires. Plywood burns fast and makes a lot of smoke. Cement board is better than plywood but not as good as MgO panels. MgO panels can stop fire for up to 4 hours at 800ºC. Their flame spread rating is 0/0. This means they do not burn or make smoke. MgO panels are great for fire-rated walls.

Material | Fire Resistance Duration | Temperature Resistance | Flame Spread Rating (ASTM E84) | Combustibility |

|---|---|---|---|---|

Magnesium Oxide (MgO) Board | Up to 4 hours | Up to 800ºC (1472ºF) | 0/0 (No flame spread, no smoke) | Non-combustible |

Drywall | About 30 minutes | Moderate | Higher than MgO (flame spreads) | Combustible |

Plywood | Low | Weak in high heat | High (burns easily) | Combustible, burns easily |

MgO panels help builders and designers in many ways. They are light and easy to put up. The panels do not get damaged by water. They do not bend or twist. MgO boards also block sound and can be used in many ways. These panels are good for the environment and safe to use. Builders use MgO panels in fire doors, ceilings, and other places that need fire protection.

MgO boards give the best fire safety. They are the top choice for new buildings where fire protection is important.

Real-World Use

Code Compliance

Code Compliance

Designers and builders must make sure magnesium oxide board follows fire safety rules. Most building codes do not list magnesium wall boards by name. They accept wall systems that pass important fire tests. These tests include ASTM E119/ANSI UL 263 and ICC-ES ESL-1290. For tall buildings, NFPA 285 is very important. This test checks how fire moves on the outside of a building. Fire-resistance ratings, like 1-hour or 2-hour, come from these tests. Designers should always check local rules and use certified wall systems to be sure they follow the law.

Key code references for MgO board assemblies:

ASTM E119/ANSI UL 263: Fire-resistance rated wall assemblies

ICC-ES ESL-1290: Third-party certification for code compliance

NFPA 285: Exterior wall assemblies for multifamily and tall buildings

Tip: Always talk to local code officials and use certified wall systems. This helps you meet fire safety rules for inside and outside walls.

Installation Tips

It is very important to install magnesium oxide board the right way. This keeps the wall safe from fire. Installers should follow these steps:

Put all wires and pipes in the right place inside the wall. Cover them with the right conduit and insulation.

Wear safety gear like goggles, dust masks, and gloves when working.

Use sharp knives or power saws with good blades to cut the board. Make sure tools work well.

Clean the area and check the wall frame for any damage.

Measure the wall and cut the board so it fits tight. Do not leave gaps or crooked edges.

Use self-drilling or rust-proof screws made for MgO board. Attach the panels tightly to keep fire resistance.

Keep the work area neat and clean to stop accidents.

Installers should always use certified outside sheathing and follow the maker’s instructions. This makes sure the wall meets fire safety ratings and code rules.

Project Examples

Many apartment and business buildings use magnesium oxide board for outside walls. In one tall apartment building, builders picked MgO panels for the outside because of strict fire rules. The panels passed all the needed tests for fire and water safety. Schools and hospitals also use these boards to protect important areas. In apartments, MgO board helps meet fire safety wall standards. This gives peace of mind to people who live and work there.

Note: Real projects show that magnesium oxide board gives strong fire safety. It meets the hardest code rules for outside walls in apartments and business buildings.

Pros and Cons

Key Benefits

Magnesium wall boards have many good points for new buildings. These boards are great at stopping fire, so they are a safe pick for places with strict rules. Non-combustible mgo panels do not burn or melt in a fire. They also do not make dangerous smoke. Fire-resistant mgo boards stay strong when it gets hot, which helps keep people and things safe. Builders see that these boards do not get ruined by water, mold, or bugs. This makes them last longer. Because non-combustible mgo is tough, you do not need to fix or change them often. These boards cost more at first than other materials. But they save money later because they last longer. Fire-resistant mgo boards help lower repair costs and give better safety. This makes them a smart buy for the whole life of a building.

Magnesium wall boards help keep buildings safe, lower insurance risks, and support green building goals.

Limitations

Magnesium wall boards work well for fire safety, but there are some problems. Workers must cut each board carefully so it fits right. They need to use special screws to hold the boards tight. Small spaces must be left between boards so they do not break when the weather changes. Boards should be put up straight and even to stop future trouble. Some brands are not the same quality, which can make putting them up harder. These problems are about how you put the boards in, not about fire safety. The fire protection stays strong because these boards pass hard fire tests.

Special screws are needed to hold boards tight.

Leave small spaces to stop damage.

Boards must be put up straight and even.

Different brands may make installation harder.

Non-combustible mgo and fire-resistant mgo boards still give strong fire safety, even if installation is tricky.

Magnesium oxide wall boards help keep buildings safe from fire. They do not burn or let out bad gases. Flames cannot move across these panels. Builders use them for outside walls in schools, hospitals, and apartments. The table below shows how MgO boards are better than old materials for outside use:

Feature | MgO Boards | Traditional Materials |

|---|---|---|

Combustibility | Non-combustible (A1 rating) | Combustible |

Fire Endurance | Up to 4 hours | Less than 1 hour |

Exterior Durability | Resists water, mold, pests | Prone to damage |

Experts say to pick certified MgO panels for outside walls. Builders should follow the right steps and use skilled workers. Groups like UL, ASTM, ICC, CCRR, and Intertek share news about fire safety rules for outside walls.

FAQ

What makes magnesium wall boards fire safe?

Magnesium wall boards do not burn. They stay strong at high temperatures. These boards do not release toxic smoke. Builders use them to slow fire and protect people.

Can magnesium wall boards be used outdoors?

Yes, magnesium wall boards work well outside. They resist water, mold, and pests. Builders use them for exterior walls, soffits, and facades in many climates.

How do magnesium wall boards compare to drywall for fire safety?

Magnesium wall boards last longer in fire than drywall. They do not melt or weaken quickly. Drywall can break down under heat. The table below shows the difference:

Feature | MgO Board | Drywall |

|---|---|---|

Fire Endurance | Up to 4h | Up to 1h |

Combustibility | No | Yes |

Are magnesium wall boards safe for indoor air quality?

Yes, these boards do not contain asbestos or formaldehyde. They do not release harmful gases. Indoor air stays clean and safe for people.

Do magnesium wall boards meet building codes?

Most magnesium wall boards pass strict fire tests like ASTM E119 and NFPA 285. Builders should check local codes and use certified products for compliance.

What Are Magnesium Wall Boards

What Are Magnesium Wall Boards Code Compliance

Code Compliance