08 Jul Emerging Trends Shaping Magnesium Oxide Sheathing Board Innovation in 2025

Table of Contents

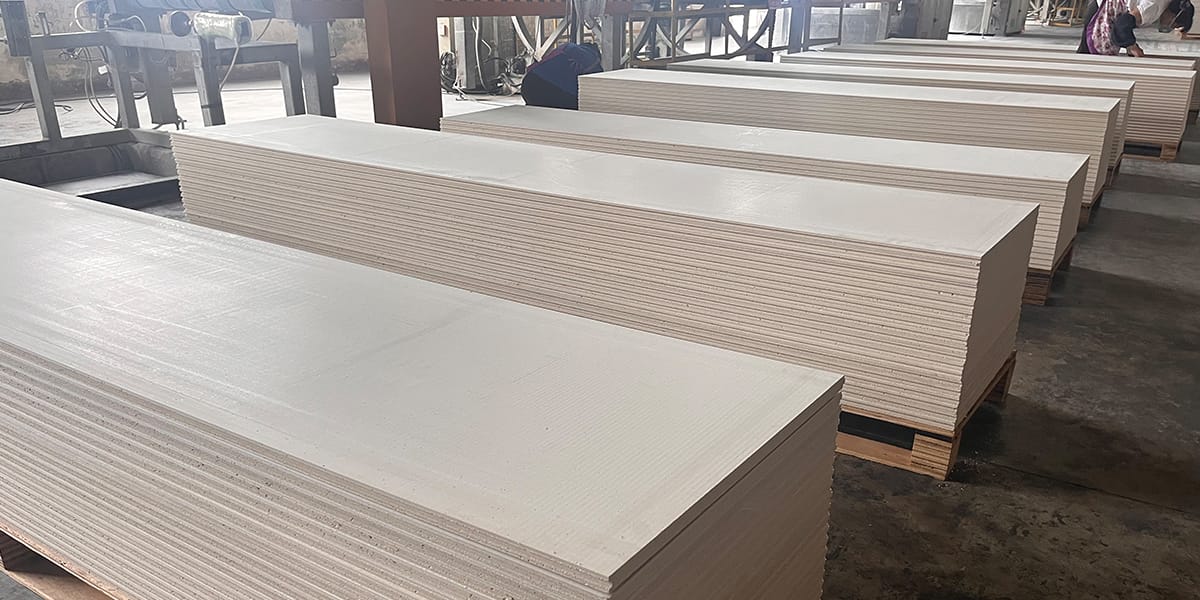

The magnesium oxide sheathing board industry is growing fast in 2025. Magnesium oxide board, also called mgo, is a green material. Architects and builders use magnesium oxide board for its strength. It is fire resistant and good for the environment. The magnesium oxide board market is getting bigger. People want more green building solutions. Market trends show magnesium oxide board is very strong. Mgo products are popular because they are eco-friendly. Magnesium oxide board helps with green building. The market is growing and mgo is a top choice. New ideas in magnesium oxide board shape the future. Magnesium oxide board works well and is good for the planet. Mgo is important in the magnesium oxide board market. Magnesium oxide board sets new rules for green building. It keeps helping the market grow. Mgo solutions fit the needs of today’s world. Magnesium oxide board helps projects get green certifications. It also helps keep places healthy. Mgo is growing fast in the market. Magnesium oxide board meets tough safety rules. The market likes green building practices. Magnesium oxide board makes construction better. Mgo makes the market stronger. Magnesium oxide board lasts a long time. It helps save energy. The market’s growth shows it matters a lot. Magnesium oxide board is key in green building. Mgo technology helps the market move forward. Magnesium oxide board helps projects succeed. It meets new needs. Mgo solutions shape the market. Magnesium oxide board helps with new designs. It makes projects better. Magnesium oxide board is good for the planet. The market will keep growing. Magnesium oxide board can handle new problems. Mgo pushes the market ahead. Magnesium oxide board is a leader in green building. It helps communities grow. Mgo makes the market stronger. Magnesium oxide board makes buildings safer. It helps reach green goals. Magnesium oxide board changes to fit new needs. The market’s growth brings new ideas. Magnesium oxide board is great for green design. It helps growth last a long time. Mgo powers the market. Magnesium oxide board can handle anything. It helps green building move forward. Magnesium oxide board stands for being green. It helps projects stay strong. Magnesium oxide board helps growth that is good for everyone. It is still very important for building today.

Key Takeaways

Magnesium oxide boards are good for the environment and help buildings get green awards. This makes them a great pick for building in a way that helps the planet. These boards are very good at stopping fires. They meet tough safety rules and keep buildings safer than many old materials. Magnesium oxide boards do not let water, mold, or mildew in. This keeps buildings healthy and means less fixing is needed. Magnesium oxide boards are light but also strong. They help builders work faster and are great for new prefab and modular buildings. New ways to make these boards and new materials make them last longer, cost less, and be used more in many places around the world.

Key Trends 2025

Sustainability Focus

In 2025, the magnesium oxide board market cares more about the environment. Builders and architects want green building materials. They look for things that help the planet. Magnesium oxide board is special because it does not harm the earth much. It is good for eco-friendly projects. More people want to use green materials, so demand is rising. Many projects want green certifications. The U.S. Green Building Council says magnesium oxide sheathing board is a top choice. This made its use in LEED-certified projects go up by 35%. Companies like GLO MgO Boards and American Magnesium Inc. made new eco-friendly boards. These are used in homes and tall buildings. The government spent US$ 2.5 billion to upgrade public buildings. They want fire-resistant and green materials. This spending made government contracts for magnesium oxide board go up by 80%.

Note: The magnesium oxide board market keeps growing. Experts think it will grow at 3.9% each year from 2025 to 2032. The market could be worth US$ 2,153.2 million in 2025. By 2032, it might reach US$ 3,975.9 million.

Market Aspect | Data / Insight |

|---|---|

Healthcare Construction Growth (2023) | 6% more spending on clinics, hospitals, and research places |

Education Construction Growth (2023) | 5% more because of new and better schools |

Prefab Construction Growth (2024) | 70% more MgO board used in prefab buildings |

Healthcare Construction Segment Growth | 45% more growth because of antimicrobial properties |

Federal Infrastructure Spending | US$ 2.5 billion for public buildings using fire-resistant materials |

Government Contracts Increase | 80% more contracts for magnesium oxide boards |

Historical CAGR (2019-2023) | 3% steady growth in the U.S. market |

Projected CAGR (2025-2032) | |

Market Size (2025E) | US$ 2,153.2 million |

Market Size (2032F) | US$ 3,975.9 million |

Residential Market Share (2025) | 37.4% because of fire resistance and people caring about the earth |

Increase in Home Remodeling (2023) | 8% more because people want safe and green materials |

LEED-certified Project Usage Increase | 35% more MgO board used in green projects |

Sales Growth in DIY Retailers | 55% more magnesium oxide board sold |

Thin MgO Panels Market Share (2025) | 42.7% because they are light and fire-resistant |

Regional Growth (Southeast U.S.) | 2.3% growth each year until 2032, 39.7% market share in 2025 |

Magnesium oxide board helps make buildings greener. It cuts down on waste and supports eco-friendly building. The market for magnesium oxide board matches the world’s push for green materials. That is why mgo is a top pick for projects that want to be sustainable.

Fire Resistance

Fire resistance is a big trend for magnesium oxide board. This board is better at stopping fires than OSB or plywood. Mgo board wall sheathing does not burn or help fire spread. It meets tough fire safety rules, like China’s GB50016-2014. This rule says it must last at least one hour in a fire. Some uses last up to two hours. Magnesium oxide board has a Class A1 fire rating. It passes hard tests like ASTM E119 and ANSI/UL 263. Mgo panels also got ESL-1290 certification for 1-hour and 2-hour fire resistance.

- Mgo stays strong even in high heat.

- Magnesium oxide board is tough and can hold heavy things.

- Fire resistance gets 47% better when mgo is used with steel sheathing.

Laws and rules help the market by asking for fire-resistant green materials. More homes and businesses use mgo board wall sheathing. They choose it for its fire safety and because it is good for the earth.

Water & Mold Protection

Water and mold protection are important for magnesium oxide board. This board does not let mold, mildew, or fungus grow. It also keeps out water, so it works well in wet places. Mgo board wall sheathing does not let things grow on it, even when it is humid. Builders use weather barriers or house wraps with magnesium oxide sheathing board. This stops water from getting in and keeps the building safe. If builders finish it right and follow the rules, mgo protects against mold and water damage.

Sulfate-based magnesium oxide board, like MagMatrix BMSC 517, does not get hurt by water. It also does not rust metal fasteners. This makes it last a long time and need little care. That means less material is used and buildings stay green. Magnesium oxide board gives good water and mold protection for inside and outside uses.

Lightweight Design

Lightweight design is now a big trend for magnesium oxide board. Thin mgo panels make up 42.7% of the market in 2025. Makers have made boards that are easy to move and put in place. This saves money and time when building. Mgo board wall sheathing is strong but not heavy. It is great for modular and prefab buildings. In 2024, prefab construction is expected to use 70% more mgo.

Light magnesium oxide board helps the planet by cutting down on truck trips. It is easy to install. These green materials help projects meet their green goals. They still work well and last long. The magnesium oxide board market keeps coming up with new ideas. It offers boards that are light, fire-resistant, and good for the earth for today’s buildings.

Magnesium Oxide Sheathing Board Innovations

Advanced Formulations

In 2025, magnesium oxide board is getting better fast. Companies use new additives and better ways to make the boards. These changes help magnesium oxide board work better than old materials. The new mgo board is lighter and stronger. It can be used for many building jobs.

- Expanded polystyrene (EPS) makes the board lighter by half. This helps people install it and gives some insulation.

- Fiberglass mesh makes the board stronger. It stops cracks and spreads weight, like steel in concrete.

- Different types of burnt mgo, like light burnt, make the board strong but not heavy. They also help the earth by lowering carbon use.

- Perlite and other fillers make the board easier to use. They help screws stay in place.

- Multi-layer sandwich boards use mesh and fillers. This makes them tough and able to take hits.

The middle of each board uses magnesium oxide as glue. Magnesium sulfate helps it set. This mix makes the board strong and long-lasting. The outside has fiberglass mesh for more support. These new boards meet tough building rules and help green building grow.

Surveys in North America show people like these new boards. They want boards that work well and are good for the planet. Many buyers want boards that stop fire and water. Companies make special boards for homes, stores, and factories. More modular and prefab buildings need these new boards.

Note: The magnesium oxide sheathing board industry keeps making new things. New mixes and layers make boards stronger, safer, and better for the earth.

Sound & Thermal Insulation

New mgo board technology helps with sound and heat. Magnesium oxide board now keeps heat in better than many cement boards. It is not the main insulation, but it helps keep buildings comfy. It works best with other insulation.

MagPanel boards use magnesium sulfate and keep their insulation even when wet. This helps save energy for a long time. Chinsun magnesium oxide board blocks over 45 dB of noise. This makes it great for stopping sound. The thick mgo board soaks up sound better than gypsum board. This is good for walls, floors, and rooms where quiet is needed.

Magnesium oxide board can take high heat. It can last up to three hours in fire and up to 1200ºC. The strong design with fiberglass mesh helps with sound and heat. Builders use magnesium oxide board for walls, floors, and more because it does many jobs.

Durability Improvements

Magnesium oxide board is very tough and lasts a long time. Reports and studies show boards with magnesium oxysulfate cement stay strong for years. In tests, over 1,000 boards faced wet and hot air for 840 days. The boards stayed good and did not have the “crying” problem of old boards.

MOS-based magnesium oxide board takes in 37% less water than MOC boards. It also fights rust and mold. Even after hard tests, MOS boards stay strong. This means magnesium oxide board can last at least 33 years in normal use. It is a good pick for new buildings.

The market likes these better boards. Builders and designers trust magnesium oxide board for jobs that need strong, easy-care materials. MOS-based boards do not have bad chlorides, so they do not rust or break. These features help magnesium oxide board meet tough rules and what people want for safety and long life.

Tip: Pick MOS-based magnesium oxide board for wet or damp places. It saves money on repairs and helps buildings last longer.

Manufacturing Advances

Automation & Efficiency

Automation & Efficiency

Factories use new machines to make mgo boards. These machines mix and check the boards by themselves. Workers do not have to do every step by hand. Now, factories can make up to 4,000 mgo boards in one shift. Before, they could only make 1,000 to 1,500 each day. Automation makes the work faster and helps avoid mistakes. Workers can spend more time checking if the boards are good. This helps companies keep up with more people wanting mgo for green buildings. The new machines also use less energy and make less waste. Builders get mgo boards quicker, so their projects stay on track.

Quality Control

Strict checks keep mgo boards safe and strong. Factories follow ISO 9000 or even better rules. Every mgo board gets tested for fire, water, and strength. Sensors look for cracks, warping, or other problems. Boards must not swell, crack, or grow mold. They stay strong after 60 weeks in very wet air. Tests show mgo boards can hold heavy things and take hard hits. Factories also test boards in tough weather. The table below shows how mgo boards compare to other boards:

Criteria | MgO Board | Gypsum Board | Cement Board | Fiber Cement Board |

|---|---|---|---|---|

Fire Resistance Rating | Non-combustible (A1) | Fire-resistant (limited) | Highly fire-resistant | Fire-resistant |

Thermal Combustibility | Non-combustible | Combustible | Non-combustible | Non-combustible |

Flame Spread | Low | Moderate | Low | Moderate |

Heat Resistance | High | Medium | High | Medium |

Smoke and Toxic Gas Emissions | Low | Moderate | Low | Moderate |

Fire Endurance | Up to 4 hours | 30-60 minutes | Up to 2 hours | 60-90 minutes |

Note: Mgo boards are better at stopping fire and water than most other boards.

Cost Optimization

Cost optimization makes mgo boards cost less. Machines help lower labor costs and waste. Factories plan well to buy materials at good prices. They recycle leftover mgo and other things. These steps help keep prices steady for builders and homeowners. Companies can sell mgo boards for less without losing quality. Fast work and fewer mistakes save money on repairs or returns. Builders trust mgo boards because they save money over time.

- Machines help cut waste and use less energy.

- Buying in bulk and recycling keeps costs down.

- Good quality means fewer boards need to be replaced.

Mgo boards are now used in more projects because of these smart changes in factories.

Regulatory & Market Drivers

Building Codes

Stricter building rules change the magnesium oxide board market in 2025. Many places now want materials that stop fire, water, and mold. Europe and North America are leading this change. Germany, the UK, and the Netherlands have tough rules for fire safety and green building. These countries want materials that last long and can be recycled. Magnesium oxide board fits these needs. North America also cares about fire safety and clean air inside. Builders use mgo instead of gypsum and cement boards. Green building awards, like LEED, make people pick magnesium oxide board. New rules say buildings must be safe and strong. More places use these rules, so the mgo boards market gets bigger. Mgo boards get more popular because they pass hard tests and help projects win green awards.

Note: The need for safer and greener buildings helps the magnesium oxide board market grow. Mgo boards meet new rules for safety and the environment.

Regional Growth

Different places help the magnesium oxide board market grow. Asia-Pacific is growing the fastest. Cities in China, India, and Southeast Asia are getting bigger. Builders in these places use magnesium oxide board for new buildings. North America has the biggest mgo boards market. New products, like EXACOR panels, help North America stay ahead. The Middle East and Africa are growing quickly too. Changes in GCC countries help this growth. Online stores make it easier to buy magnesium oxide board. Fire-rated mgo boards are used more in big buildings. The whole world market grows because of these changes. Market trends show that where you live will keep changing the industry.

- Asia-Pacific: Grows fastest because of new cities and building projects.

- North America: Biggest market with new products.

- Middle East & Africa: Grow fast because of new money and projects.

Price Trends

Price changes in the magnesium oxide board market bring both problems and chances. The world mgo boards market could grow from $1.65 billion in 2022 to $2.28 billion by 2027. This shows the market keeps getting bigger. Problems with shipping from the Russia-Ukraine war and COVID-19 made prices go up. But new machines and better ways to make boards help keep costs down. Builders like mgo because it lasts long and does not need much fixing. As more people want mgo, making lots at once helps keep prices steady. The market for magnesium oxide board keeps growing strong. Mgo boards get more popular as more places use these new materials.

Tip: Builders can save money by picking magnesium oxide board because it lasts long and is easy to care for.

Construction Impact

Adoption in Modern Projects

Adoption in Modern Projects

Magnesium oxide board is changing how people build today. More builders use it because it is safe and strong. Teams pick magnesium oxide board for schools, hospitals, and offices. They want buildings to last and keep people safe. Rusthi et al. (2017) tested walls with magnesium oxide board. Their tests showed it can stop fire for a long time. This helps builders trust magnesium oxide board in new buildings. The market grows as more people see it work well. Builders say it is quick and clean to put in. They use it where safety is very important. More green buildings now use magnesium oxide board. Many projects use it to follow strict rules. This shows magnesium oxide board is a smart choice for today.

- Rusthi et al. (2017) found that walls with magnesium oxide board stop fire better than old materials.

- Builders use magnesium oxide board in schools, hospitals, and offices because it is safe and easy to install.

- The market grows as more teams see it work well in real buildings.

Modular & Prefab Use

Modular and prefab buildings use magnesium oxide board for strength and speed. The market sees 70% more prefab projects using this board. Builders like that it is light and easy to move. They can finish jobs faster than with other boards. Prefab walls with magnesium oxide board come ready to use. This saves time at the building site. The market grows as more companies use prefab ways to build. Teams say there are fewer mistakes when they install it. They also see less waste. Magnesium oxide board helps prefab builders reach green goals. The market supports this with new products for modular use. Builders trust it for fire and water safety. They see it work well in hotels, apartments, and offices.

Comparison to Traditional Materials

Magnesium oxide board works better than many old boards. The market grows as builders compare it to gypsum and fiber cement boards. Magnesium oxide board stops fire, water, and mold better than gypsum. It also holds screws tight and bends without breaking. The market likes its strength and light weight. Builders find it easier and faster to put in. The table below shows how magnesium oxide board compares to other boards:

Property | Magnesium Oxide Board | Gypsum Board | Fiber Cement Board |

|---|---|---|---|

Fire Resistance | Up to 1200°F | Lower | Moderate |

Impact Resistance | 4.5+ kJ | 1 kJ | Good, more brittle |

Bending Strength | 18-27 MPa | 5.6 MPa or less | Variable |

Weight-to-Strength | Excellent | Poor | Heavy, good strength |

Fastener Holding | 200 lbs per screw | Limited | Good |

Moisture Resistance | High | Low | Moderate |

Mold Resistance | High | Low | Moderate |

Thermal Insulation | Excellent | Lower | Moderate |

Acoustic Insulation | Superior | Lower | Moderate |

Environmental Impact | Low carbon, recyclable | High carbon | Moderate |

Magnesium oxide board is good for green building. It takes in CO₂ when it dries and can be recycled. The market grows as more builders see these good things. It is faster to install and buildings last longer. Magnesium oxide board is a top pick for safety, strength, and easy use in new buildings.

Addressing Misconceptions

Performance Myths

Some people think magnesium oxide board does not work well with water or fire. But tests show it is better than OSB and plywood for water and fire. Sulfycor’s research says magnesium oxide board stays strong in wet places. It keeps its shape in basements and bathrooms. It does not swell or bend, even when the air is wet. A few reports from Denmark talk about problems in very wet weather. But good magnesium oxide board still works well for most jobs. New magnesium oxide board stops mold, bugs, and water damage better than plywood or drywall. A lab tested over 1,000 boards for two years. The tests showed magnesium oxide board stays strong and does not have the “crying” problem. The study says it should last at least 33 years in normal UK weather. These facts show the myths about bad fire or water performance are not true.

Longevity & Maintenance

Magnesium oxide board lasts longer than many old building boards. It stands up to fire, water, mold, bugs, and bad weather. The table below shows how it compares to other boards:

Aspect / Metric | Magnesium Oxide Board | Traditional Materials (plywood, drywall, gypsum) |

|---|---|---|

Lifespan | Longer-lasting; resists fire, water, mold, pests, weather | Shorter lifespan; more damage and decay |

Maintenance Requirements | Fewer repairs; lower upkeep costs | More repairs; higher maintenance costs |

Fire Resistance | Withstands up to 4 hours in fire; low smoke | Burns quickly; more smoke and fumes |

Water and Mold Resistance | Highly resistant; stops mold and mildew | Prone to water damage and mold |

Installation | Lightweight; easy to install | Heavier; more labor needed |

Environmental Impact | Eco-friendly, recyclable, low carbon | Higher carbon; less recyclable |

Real-World Applications | Used in wildfire zones, schools, hospitals | Limited use in tough environments |

Cost Over Time | Higher initial cost, lower total cost | Lower initial cost, higher total cost |

Magnesium oxide board needs less fixing and care as time goes on. It stays strong in hard places and helps buildings last longer.

Cost vs. Value

Some builders worry because magnesium oxide board costs more at first. But it saves money over time. A study found that using magnesium oxide board makes building faster. The panels help builders finish jobs quickly and safely. They also make buildings safer from fire and give a strong base for screws. Research shows magnesium oxide board costs more at first but less over its life. It needs fewer repairs and lasts longer. Studies say magnesium oxide board SIPs use more energy to make but cost less to run. In Canada, the energy payback is about 2.7 years. In the U.S., it is about 5.1 years. SIPs also lower greenhouse gases and yearly costs compared to other houses. Making boards close to where they are used can save even more money. Magnesium oxide board is a smart pick for saving money and making better buildings.

The magnesium oxide board market is changing how people build. It is known for being green, stopping fires, and being light. Reports show the market is growing fast, mostly in Asia-Pacific and North America.

Metric/Aspect | Details/Values |

|---|---|

Global Market Size (2024) | |

Global CAGR (2025-2032) | 5.4% |

Leading Application Segment | Residential |

Experts think the magnesium oxide board market will get much bigger by 2034. Builders who use new magnesium oxide board ideas get better safety, stronger buildings, and help the planet.

FAQ

What makes magnesium oxide sheathing board eco-friendly?

Magnesium oxide sheathing board is made from natural minerals. It creates less carbon when it is made. Many boards can be recycled after use. Builders pick it for green projects and to get green awards.

Can magnesium oxide board be used outdoors?

Yes, magnesium oxide board works outside. It stands up to water, mold, and bad weather. Builders use it for outside walls, soffits, and facades. If you install it right, it lasts a long time outdoors.

How does magnesium oxide board compare to gypsum board?

Feature | MgO Board | Gypsum Board |

|---|---|---|

Fire Resistance | Excellent | Moderate |

Water Resistance | High | Low |

Durability | Superior | Lower |

Magnesium oxide board is better than gypsum board. It is stronger and handles fire and water better.

Is magnesium oxide board safe for indoor air quality?

Magnesium oxide board does not let out bad chemicals or VOCs. It helps keep the air inside healthy. That is why hospitals and schools often use it.

Automation & Efficiency

Automation & Efficiency Adoption in Modern Projects

Adoption in Modern Projects