17 Feb The Different Types of SIP Panels for Modern Construction

Table of Contents

Structural Insulated Panels (SIPs) are prefabricated components designed for walls, floors, roofs, and even foundations. These panels combine a rigid foam core with durable outer layers, creating a lightweight yet strong building material. SIP panel construction has gained traction due to its ability to deliver energy-efficient and sustainable results.

SIPs excel in minimizing heat loss through their high R-values and airtight construction, reducing heating and cooling needs by up to 50%. This makes them an ideal building solution for those seeking environmental sustainability. Additionally, the growing demand for energy-efficient homes and commercial spaces has driven the adoption of SIP panels options in modern construction.

SIPs offer enhanced energy efficiency, reduced thermal bridging, and improved occupant comfort, while also meeting updated code compliance and providing cost-effective solutions for both new builds and retrofits.

With their adaptability, SIP panels can meet diverse construction needs, from residential homes to modular buildings. Their superior insulation and structural performance make them a smart choice for anyone looking to build sustainably and efficiently.

What Are SIP Panels?

Definition and Composition

Structural insulated panels, or SIPs, are high-performance building materials designed to simplify construction while improving energy efficiency. Each panel consists of two outer layers, known as structural facings, and a rigid insulating core sandwiched between them. The facings are typically made from materials like oriented strand board (OSB), fiber cement, or magnesium oxide. The core is often composed of expanded polystyrene (EPS), extruded polystyrene (XPS), or polyurethane foam.

Here’s a breakdown of common materials used in SIP panel construction:

| Material Type | Description |

|---|---|

| Sheathing Materials | OSB, plywood, aluminum, steel, stainless steel, magnesium oxide, fiber-cement, fiber-reinforced plastic. |

| Insulated Core | EPS, XPS, polyurethane (PU), polyisocyanurate (PIR). |

This combination of materials creates a lightweight yet durable panel that offers excellent thermal and structural performance.

How Structural Insulated Panels (SIPs) Work

SIPs function by combining insulation and structural support into a single unit. The rigid foam core provides high thermal resistance, while the outer facings add strength and durability. This design eliminates the need for traditional framing and insulation, reducing thermal bridging and creating an airtight envelope.

For example, a 4-inch SIP wall has a Whole Wall R-Value of 14, which is significantly higher than traditional 2×4 walls. This superior insulation minimizes heat loss, reducing the need for heating and cooling systems. Additionally, SIP panel construction allows for faster assembly since the panels are prefabricated and ready to install on-site.

Why SIPs Are Gaining Popularity in Modern Construction

SIPs are becoming a preferred choice in construction for several reasons:

- They provide superior insulation, reducing energy consumption and lowering utility bills.

- SIP homes can be built faster due to off-site manufacturing and quick on-site assembly.

- The continuous load-bearing structure of SIPs withstands extreme weather conditions better than traditional methods.

- SIP panel construction uses fewer raw materials, reducing waste and environmental impact.

- Their adaptability allows for creative architectural designs, making them suitable for various projects.

By choosing SIPs, you not only save time and energy but also contribute to a more sustainable future.

Types of SIP Panels

OSB (Oriented Strand Board) SIP Panels

Composition and Features

OSB SIP panels are among the most popular types of structural insulated panels. These panels feature oriented strand board as the outer facing material, paired with a rigid foam core such as expanded polystyrene (EPS). OSB provides excellent structural strength and durability, making it ideal for load-bearing applications. The foam core ensures superior insulation, with high R-values that help reduce energy consumption.

One of the standout features of OSB SIP panels is their airtightness. This minimizes air leakage, enhancing energy efficiency and maintaining indoor comfort. Additionally, OSB SIP panels are designed for long-term durability and require minimal maintenance.

| Feature | OSB SIP Panels | Other Types |

|---|---|---|

| Insulation | Superior insulation with high R-values | Varies, often lower R-values |

| Airtightness | Minimizes air leakage, enhancing energy efficiency | Often less airtight |

| Load-Bearing Capacity | High load-bearing capacity | Generally lower |

| Impact Resistance | Enhanced protection against severe weather | Varies, often less resilient |

| Longevity and Durability | Designed for long lifespan and low maintenance | Varies significantly |

| Speed of Construction | Rapid assembly due to pre-fabrication | Typically slower |

| Customizable Designs | Flexible design options | Limited customization |

| Energy Efficiency | Reduces energy bills significantly | Often less efficient |

| Sustainability | Eco-friendly with lower emissions | Varies, often less sustainable |

| Project Timelines | Shortened timelines for construction | Usually longer |

Common Applications

You can use OSB SIP panels in a variety of construction projects. They are commonly found in residential homes, including single-family and multi-family housing. These panels also work well for commercial buildings like offices and retail spaces. Their high load-bearing capacity makes them suitable for roofs, walls, and floors.

Fiber Cement SIP Panels

Composition and Features

Fiber cement SIP panels combine a fiber cement outer layer with an insulating foam core. The fiber cement provides exceptional durability and resistance to fire, moisture, and pests. This makes these panels an excellent choice for areas prone to extreme weather conditions. The foam core, often made of EPS or polyurethane, ensures high thermal performance and energy efficiency.

Fiber cement SIP panels are also sustainable. They are made from renewable materials and minimize construction waste. Their airtight construction reduces allergens, mold, and insects, creating a healthier indoor environment.

Common Applications

Fiber cement SIP panels are ideal for projects requiring enhanced durability and weather resistance. You can use them in hurricane-prone regions or areas with high humidity. These panels are often used in residential construction, particularly for exterior walls. They are also suitable for commercial buildings and modular construction projects.

Magnesium Oxide (MgO) SIP Panels

Composition and Features

Magnesium oxide SIP panels feature MgO board as the outer facing material. This material is known for its fire resistance, mold resistance, and durability. The core, typically made of EPS or polyurethane, provides excellent insulation. MgO SIP panels are lightweight yet strong, making them easy to handle during construction.

These panels are also eco-friendly. Magnesium oxide is a sustainable material that reduces the environmental impact of construction. The panels offer superior soundproofing and thermal performance, ensuring comfort and energy savings.

Common Applications

MgO SIP panels are versatile and can be used in various applications. They are particularly useful in fire-rated construction projects, such as schools, hospitals, and commercial buildings. You can also use them in residential homes, especially in areas with high fire risk. Their lightweight nature makes them suitable for modular and prefabricated buildings.

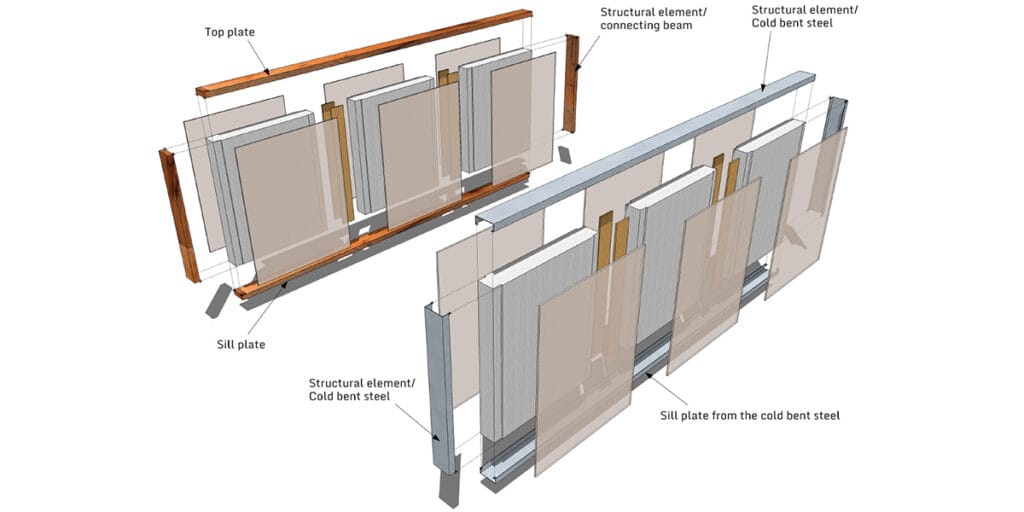

Metal SIP Panels

Composition and Features

Metal SIP panels use metal, such as steel or aluminum, as the outer facing material. These panels feature a rigid foam core, often made of expanded polystyrene (EPS) or polyurethane, which provides excellent insulation. The metal facings add strength and durability, making these panels suitable for demanding environments.

You’ll find that metal SIPs offer several advantages. They are highly resistant to fire, pests, and moisture, ensuring long-term performance. Their airtight construction reduces energy waste, helping you save on heating and cooling costs. Additionally, metal SIPs require less maintenance over time, thanks to their robust design.

Metal SIPs are ideal for projects aiming for certifications like LEED, passive house, or Net Zero Energy. They also improve indoor air quality by minimizing air leakage and ensuring controlled ventilation.

Common Applications

Metal SIP panels are versatile and work well in various construction projects. You can use them in industrial buildings, warehouses, and cold storage facilities due to their durability and insulation properties. They are also suitable for residential and commercial projects where fire resistance and structural strength are priorities.

Their architectural flexibility allows you to create unique designs without significant cost increases. Metal SIPs also speed up construction, saving 55% to 66% in labor hours compared to traditional methods. This makes them an excellent choice for large-scale or time-sensitive projects.

Specialized SIP Panels

Expanded Polystyrene (EPS) SIP Panels

EPS SIP panels feature a core made of expanded polystyrene, a lightweight and cost-effective material. These panels provide good insulation with an R-value of 3.85 per inch. EPS panels are easy to modify on-site, making them a practical choice for projects requiring flexibility. However, they offer lower fire resistance compared to other options.

Extruded Polystyrene (XPS) SIP Panels

XPS SIP panels use extruded polystyrene as the core material. These panels deliver a higher R-value of 5 per inch, offering better insulation than EPS. XPS panels are also stronger and more durable, making them suitable for heavy-duty applications. However, their availability is limited, and they tend to be more expensive.

Polyurethane SIP Panels

Polyurethane SIP panels provide the highest insulation performance, with an R-value of 7 per inch. These panels are thinner yet more efficient, making them ideal for projects where space is limited. While polyurethane panels are more expensive, their superior thermal performance and durability justify the cost for high-performance buildings.

| Panel Type | R-Value per Inch | Cost Comparison | Availability | Pros/Cons Summary |

|---|---|---|---|---|

| Expanded Polystyrene (EPS) | 3.85 | Least expensive | Most readily available | Pros: Easy modifications, low cost; Cons: Lowest R-value, poor fire resistance. |

| Polyurethane/Polyisocyanurate | 7 | More expensive than EPS | Moderate availability | Pros: Highest R-value, thin walls; Cons: Expensive, limited availability. |

| Extruded Polystyrene (XPS) | 5 | Similar to polyurethane | Very low availability | Pros: Stronger, high R-value; Cons: Very low availability, high cost. |

Choosing the right specialized SIP panel depends on your project’s insulation needs, budget, and design requirements.

Applications for SIPs in Construction

Residential Construction

Single-family Homes

SIPs are an excellent choice for single-family homes due to their energy efficiency and quick installation. You can use them for walls, roofs, and even floors to create a well-insulated and airtight structure. These panels help maintain comfortable indoor temperatures year-round by minimizing air leakage and thermal bridging. Homes built with SIPs can achieve R-values up to R-50, reducing heating and cooling needs by up to 50%. This translates to lower energy bills and a smaller carbon footprint.

SIP panel construction also speeds up the building process. Prefabricated panels arrive ready to assemble, allowing you to complete your project faster than traditional methods. Whether you’re building a cozy cottage or a modern home, SIPs provide a sustainable and cost-effective solution.

Multi-family Housing

Energy-efficient multi-family housing projects benefit significantly from SIPs. These panels enhance insulation and reduce energy consumption, making them ideal for apartment complexes and townhouses. For example, the Aeon Alliance Apartment Expansion in Minneapolis utilized SIPs to cut heating and cooling costs by 50-60%. SIPs also create quieter living spaces by reducing noise transfer between units.

You’ll find that SIPs align well with the fast-paced nature of multi-family housing construction. Their prefabricated design minimizes on-site labor and shortens project timelines, helping developers meet deadlines without compromising quality.

Commercial Construction

Office Buildings

SIPs offer numerous advantages for office buildings. They provide superior insulation, reducing energy costs by up to 50% compared to traditional construction. The airtight design minimizes HVAC requirements, leading to smaller systems and lower operational expenses. SIPs also speed up construction, allowing businesses to open sooner.

Their durability makes them suitable for long-term use, withstanding extreme weather conditions and reducing maintenance needs. Whether you’re constructing a small office or a large corporate building, SIPs deliver energy efficiency and structural reliability.

Retail Spaces

Retail spaces benefit from the quick installation and energy savings that SIPs provide. These panels create a comfortable indoor environment by maintaining consistent temperatures and reducing drafts. Faster construction times mean you can open your store sooner, maximizing revenue potential.

SIPs also support creative architectural designs, allowing you to build unique and visually appealing retail spaces. Their ability to reduce energy consumption aligns with the growing demand for sustainable commercial buildings.

Specialized Applications

Cold Storage Facilities

Cold storage facilities require high-performance insulation, and SIPs excel in this area. Their airtight construction minimizes temperature fluctuations, ensuring optimal conditions for perishable goods. You can rely on SIPs to reduce energy costs while maintaining consistent temperatures.

These panels also resist moisture and pests, making them a durable choice for food storage and processing facilities. Their quick installation helps you complete projects on time, meeting industry demands efficiently.

Modular and Prefabricated Buildings

SIPs are a natural fit for modular and prefabricated buildings. Their lightweight yet strong design simplifies transportation and assembly. You can use them to create energy-efficient structures with minimal waste.

For example, SIPs were used in a LEED Gold-certified fish hatchery in Minnesota, achieving a nearly impermeable building envelope. This project demonstrated how SIPs can enhance energy efficiency and sustainability in specialized construction applications.

SIP panels options like these showcase their versatility across residential and commercial construction, as well as specialized uses. Their adaptability and efficiency make them a valuable choice for modern building projects.

Benefits and Limitations of SIP Panels

Benefits

Energy Efficiency

SIPs excel in creating energy-efficient walls by reducing thermal bridging and air leakage. The continuous insulation provided by structural insulated panels enhances energy efficiency by up to 50% compared to traditional timber framing. SIPs with EPS cores offer high R-values, improving temperature control and contributing to improved indoor air quality. This makes your home or building more comfortable while lowering heating and cooling costs.

Did you know? Up to 40% of heat loss in homes occurs due to air leakage. SIPs mitigate this by creating a superior building envelope with excellent thermal resistance and minimal air infiltration.

The growing demand for energy-efficient construction and rising energy costs make SIPs a smart choice for sustainable building projects.

Faster Construction Times

SIP panel construction significantly reduces project timelines. These panels are prefabricated in factories, ensuring precise dimensions and quality. This eliminates the need for on-site adjustments, allowing for quicker assembly. With fewer components required, you can save up to 66% in labor hours compared to traditional methods.

| Aspect | Explanation |

|---|---|

| Pre-Fabrication | SIP panels are made in a factory, ensuring precise dimensions and quality for quick assembly. |

| Simplified Construction | Fewer components and labor are needed, allowing for faster assembly than traditional methods. |

| Shortened Project Timelines | Projects can be completed weeks or months sooner, reducing disruption and enabling quicker occupancy. |

Structural Durability

SIPs are designed to be strong and durable. Their construction mimics steel I-beams, allowing them to resist bending and absorb shear forces effectively. SIPs can support compressive loads of around two tons and withstand flex loads of 5,000 pounds per square foot. This makes them ideal for earthquake zones and areas prone to high winds, such as Florida’s High-Velocity Hurricane Zone (HVHZ).

SIPs are not just durable; they also reduce the need for multiple building components, simplifying construction while maintaining safety and reliability.

Limitations

Higher Upfront Costs

SIPs often come with higher initial costs compared to traditional materials. However, their long-term benefits outweigh these expenses. The superior insulation of SIPs reduces heating and cooling costs, while their prefabricated nature lowers labor expenses. Over time, you’ll save money through reduced energy bills and maintenance requirements.

| Aspect | Initial Cost | Long-Term Benefit |

|---|---|---|

| Construction Speed | Higher | Reduced labor costs |

| Energy Efficiency | Higher | Significant savings on heating/cooling |

| Maintenance Requirements | Higher | Lower maintenance expenses over time |

Susceptibility to Moisture and Water Damage

While SIPs are durable, they can be vulnerable to moisture if not properly sealed. Prolonged exposure to water may compromise their structural integrity. To avoid this, you should ensure proper installation and use moisture-resistant materials where necessary.

Limited Design Flexibility in Some Cases

SIPs may limit design flexibility, especially for projects requiring intricate or unique architectural features. This perception can discourage architects from using them. However, advancements in SIP technology are gradually addressing these concerns, offering more customization options.

Note: Compliance with local building codes can also pose challenges, so consulting with experts is essential when planning your project.

Choosing the Right SIP Panel for Your Project

Factors to Consider

Climate and Environmental Conditions

When selecting the right SIP for your project, you should evaluate the climate and environmental conditions of your location. SIPs are highly durable, making them ideal for cold or harsh climates. Their foam core provides excellent insulation and pest resistance, which is especially beneficial in regions with freezing winters. In areas with high humidity, SIPs resist moisture, reducing the risk of mold or water damage. Their weather resilience ensures they won’t warp or crack during extreme conditions like blizzards or freezing temperatures. This reliability makes SIPs a long-lasting and low-maintenance choice for various environments.

Budget and Cost Analysis

Budget plays a critical role in your decision-making process. While SIP panel construction may have higher upfront costs, the long-term savings on energy bills and maintenance often outweigh the initial investment. You should also consider factors like labor costs and project timelines. SIPs reduce construction time significantly, which can lower labor expenses. By analyzing your budget and weighing these benefits, you can determine if SIPs align with your financial goals.

Project Type and Scale

The type and scale of your project influence the SIP panel you choose. For example, residential homes may require panels with high insulation for energy efficiency, while industrial buildings might prioritize fire resistance and structural strength. You should also assess specific factors like wall height, shear loads, and the available staging area. Additionally, consider the SIP attachment method and air or moisture management requirements to ensure the panels meet your project’s unique needs.

Consulting with Experts

Importance of Professional Guidance

Consulting with experts ensures you make informed decisions about SIPs. Professionals can help you evaluate your project’s requirements, including fire performance, insulation needs, and design considerations. They can also guide you through local building codes and recommend the best SIP options for your specific goals. Expert advice minimizes errors during installation and ensures your project achieves optimal performance.

Resources for Further Information

You can access a variety of resources to learn more about SIPs and their applications. Explore the Construction Details Library or the ACME Installation Manual for technical insights. For hands-on learning, check out the YouTube Library or the Comprehensive Builders Guide. If you’re a builder or designer, consider the SIPA Training Units & Certification Online Builders Modules or the AIA Continuing Education courses. These resources provide valuable knowledge to help you make the most of SIP panel construction.

Structural insulated panels (SIPs) have revolutionized modern construction by offering energy efficiency, sustainability, and faster building times. Their airtight design reduces energy waste, making them ideal for projects focused on minimizing heating and cooling loads. Prefabrication ensures quicker assembly, saving significant labor hours and accelerating project timelines.

SIPs are more airtight than traditional structures, leading to improved occupant comfort and reduced energy consumption.

Choosing the right SIP panel type depends on your project’s specific needs. Factors like load capacities, panel specifications, and environmental conditions play a crucial role. Pre-planning electrical and equipment requirements ensures smooth installation and avoids costly modifications.

SIPs stand out as a sustainable building solution. They lower greenhouse gas emissions, maintain comfortable indoor temperatures, and use resources efficiently. Their durability and compatibility with renewable energy systems make them a resilient choice for eco-conscious builders.

Explore SIP panel construction for your next project to achieve a balance of efficiency, sustainability, and performance. Consult experts to ensure proper installation and maximize the benefits of this innovative building solution.

FAQ

What are the main benefits of using SIP panels?

SIP panels improve energy efficiency, reduce construction time, and enhance structural durability. They create airtight envelopes, lowering heating and cooling costs. Their prefabricated design speeds up assembly, saving labor hours. You also benefit from reduced waste and a more sustainable building process.

Are SIP panels suitable for all climates?

Yes, SIP panels perform well in all climates. Their insulation resists extreme cold and heat, maintaining comfortable indoor temperatures. In humid areas, proper sealing prevents moisture issues. Always choose SIPs with materials suited to your region’s environmental conditions for optimal performance.

How do SIP panels compare to traditional construction methods?

SIPs outperform traditional methods in energy efficiency, speed, and durability. They reduce thermal bridging and air leakage, cutting energy costs. Prefabrication shortens timelines, while their strength withstands extreme weather. However, SIPs may cost more upfront but save money long-term.

Can SIP panels support heavy loads?

Yes, SIP panels handle heavy loads effectively. Their design mimics steel I-beams, providing excellent structural strength. They can support compressive loads of up to two tons and resist flex loads of 5,000 pounds per square foot, making them ideal for roofs, walls, and floors.

Do SIP panels require special maintenance?

SIP panels need minimal maintenance. Proper installation and sealing protect them from moisture and pests. Regular inspections ensure long-term performance. Using moisture-resistant materials in high-humidity areas further extends their lifespan, keeping your structure durable and efficient.