14 Aug What is a Subfloor Board and Why Does Your Home Need One

Table of Contents

A subfloor board serves as a sturdy base above the floor joists and beneath the visible flooring. This subfloor board supports the main floor and distributes weight evenly. It also helps maintain a flat and level surface. Without a subfloor board, floors can become uneven or start to sag. Moisture issues may arise, leading to mold or pest problems. Homeowners might find repairs more challenging. Floors could feel colder, and heat may escape through gaps. Using a quality subfloor board helps keep your home safe, comfortable, and stable.

Key Takeaways

A subfloor board is a tough base layer. It sits on top of floor joists. It holds up the whole floor. It keeps the floor flat, steady, and safe.

Installing the subfloor the right way stops floor problems. It helps stop sagging, squeaks, and water damage. It also helps your home stay comfy and saves energy.

Checking your subfloor often for damage and water can help. It can stop expensive repairs. It keeps your floors quiet, strong, and lasting a long time.

Subfloor Board Basics

What Is a Subfloor Board?

A subfloor board is the main structural layer that sits directly above the floor joists in a home. Builders use materials like plywood or oriented strand board (OSB) for this layer. The subfloor board creates a strong, flat surface that supports everything above it. It helps distribute weight from furniture, people, and appliances across the floor joists. This layer prevents sagging and keeps the floor stable.

Tip: Proper subfloor installation includes securing the boards tightly to the joists. Nails should go deep into the joists, and glue can add extra strength. This helps stop squeaks and keeps the floor flat.

Where It Fits in Flooring Layers

A typical floor has several layers, each with a special job. The subfloor sits between the floor joists and the finished flooring. Here is how the layers stack up in most homes:

Floor Joists: These are strong wooden beams that run underneath the floor. They carry the weight of the floor and everything on it.

Subfloor: The subfloor board is attached right on top of the joists. It acts as a bridge, spreading out the weight and making the floor solid.

Underlayment: This thin layer goes above the subfloor. It smooths out small bumps and adds comfort, sound reduction, or moisture protection.

Finished Flooring: This is the visible surface, like hardwood, carpet, tile, or laminate. People walk on this layer every day.

Note: Before laying down any types of flooring, builders check the subfloor for squeaks or loose spots. A strong subfloor installation makes the finished floor last longer and feel better underfoot.

Subfloor vs. Underlayment

Many people mix up subfloor and underlayment, but they have different jobs and materials. Here is a quick comparison:

Feature | Subfloor | Underlayment |

|---|---|---|

Main Purpose | Structural support, strength | Smoothness, comfort, sound, moisture |

Location | On top of joists | On top of subfloor |

Materials | Plywood, OSB, concrete, planks | Foam, cork, felt, rubber, fiber |

Role in Flooring | Holds up all types of flooring | Prepares surface for finished floor |

Structural? | Yes | No |

The subfloor board gives the floor its strength and keeps it from moving or sagging. It is essential for all types of flooring, from hardwood to tile.

Underlayment is a softer, thinner layer. It does not hold up the floor but makes it smoother and more comfortable. Some types of flooring, like laminate or engineered wood, need special underlayment for best results.

Remember: Subfloor installation comes first. Underlayment and finished flooring come after. Each layer plays a key part in making floors safe, quiet, and long-lasting.

Why Subfloor Boards Matter

Structural Support

Structural Support

Subfloor boards are very important for your home’s strength. They help hold up the whole floor system. Builders put subfloor panels right above the floor joists. This layer spreads out the weight from furniture, people, and appliances. It keeps the floor from sagging or bouncing. If the subfloor is weak, floors can get uneven or unsafe.

Subfloor boards do more than just sit under the finished flooring. They give a flat and steady base for carpet, hardwood, or tile. Underlayment only makes the surface smoother and softer. The subfloor is the main part that keeps the floor strong. Plywood, OSB, and particleboard are common subfloor materials. Each one has good and bad points. Plywood is strong and does not soak up water easily, but it costs more. OSB is cheaper but can swell if it gets wet.

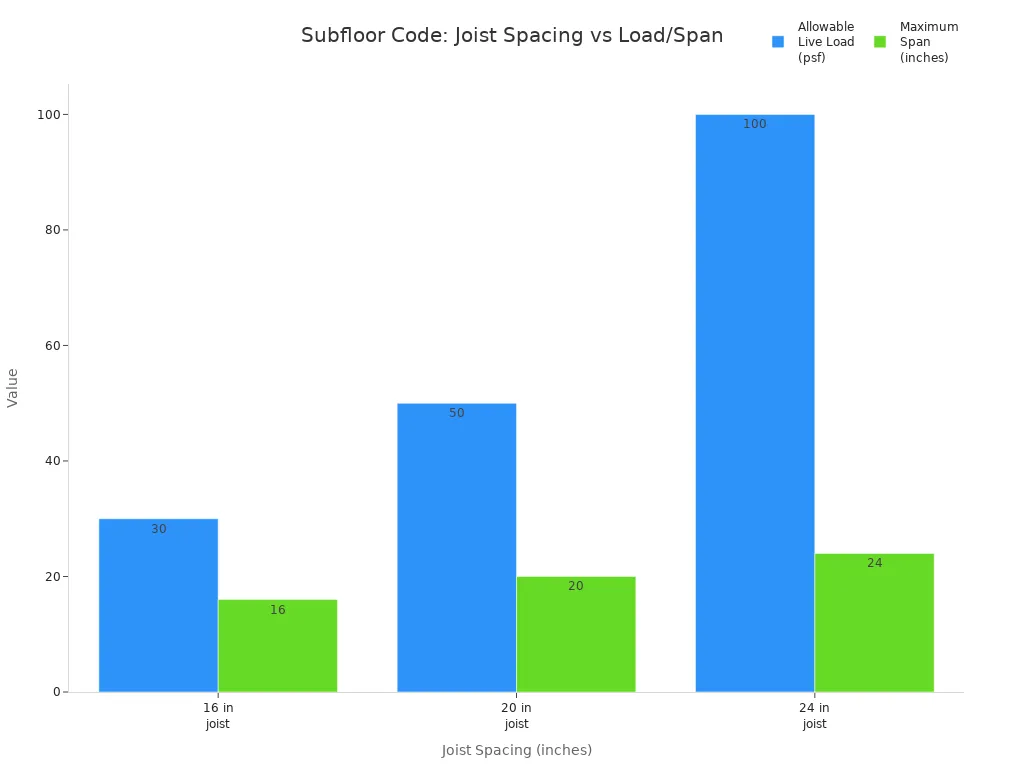

Building codes have rules for how thick and strong subfloors must be. These rules make sure the subfloor can support the house. The table below shows some basic rules:

Joist Spacing (inches) | Minimum Nominal Panel Thickness (inches) | Allowable Live Load (psf) | Maximum Span (inches) |

|---|---|---|---|

16 | 3/8 | 30 | 16 |

20 | 3/8 | 50 | 20 |

24 | 3/8 | 100 | 24 |

Tip: Using two layers of plywood with joints that do not line up can make the floor stronger and stop movement.

Moisture and Insulation

Subfloor boards help control moisture and keep homes warm or cool. The subfloor can block some water, but it works best with other barriers. Builders use things like plastic sheets or rubber layers under or over the subfloor for more protection. Good installation stops water from getting in and causing rot or mold.

Insulation under the subfloor helps keep heat in during winter and out during summer. Rigid foam boards and mineral wool are often used for this. Rigid foam has a high R-value and does not let water in, so it is good for damp places. Mineral wool is fireproof, blocks sound, and still works when wet. Sealing cracks and using vapor barriers can save energy and stop heat from escaping.

Rigid foam boards: High R-value, blocks water, good for basements.

Mineral wool: Fireproof, blocks sound, eco-friendly, works when wet.

Vapor barriers: Keep water away from the subfloor and insulation.

Checking and caring for the subfloor and insulation helps stop water damage and heat loss.

Comfort and Noise Reduction

A good subfloor makes your home feel better. It softens footsteps and heavy things, so floors feel solid and quiet. Subfloor boards add thickness, which helps block noise between rooms and floors. In homes with more than one floor, this means less sound moves from one level to another.

Adding sound-blocking materials, like rubber underlayment or joist isolators, can make things even quieter. Sealing cracks and using thicker subfloor panels also help stop noise. People notice fewer squeaks, less bouncing, and a nicer floor when the subfloor is strong.

If floors squeak or feel uneven, the subfloor might be the problem. Loose boards, bad installation, or water damage can cause these issues. Picking the right subfloor materials and putting them in the right way can stop most problems.

Note: A strong subfloor supports the floor and makes the home quieter and more comfortable for everyone.

Materials and Common Issues

Subfloor Board Materials

Homeowners have a few subfloor materials to pick from. Each one has its own good points. Plywood is the most used subfloor material. Builders have used plywood since the 1950s. It gives strong support and is easy to install. The ¾” tongue-and-groove style is very common. Oriented Strand Board (OSB) is also popular. OSB works like plywood but usually costs less money. Older homes sometimes have wood planks as subfloor. These planks can get loose and squeak as time passes. Some builders mix materials, like concrete with plywood or OSB, for special needs.

Plywood and OSB are the main choices in new homes.

OSB is getting more popular in North America. It is cheaper and better for the environment.

Material | Durability Rating and Characteristics | |

|---|---|---|

OSB | $15–$43 per sheet | Strong; low cost; can swell if wet; water-resistant types exist; eco-friendly; big panels |

Plywood | $4.50–$10 per sq ft | Strong; dries fast; does not warp much; can be used in many ways; better with water; smaller panels |

Choosing the Right Type

The best subfloor material depends on where you live and your budget. It also depends on what flooring you want. Plywood is good in wet places because it dries fast and does not bend. OSB is good for dry rooms and big jobs where saving money matters. Concrete panels work well in wet areas and hold up heavy tile floors. Builders also think about insulation, sound, and heating systems. Some green homes use eco-friendly subfloor materials like magnesium oxide boards. These are strong and block water. Good subfloor installation uses moisture barriers and underlayment that fit the flooring.

Signs of Problems

Subfloor problems can cause bigger trouble if ignored. Homeowners should look for these signs:

Floors that are uneven or sagging may mean weak panels.

Loud squeaks often happen when nails come loose.

Musty smells can mean mold or mildew from water.

Bouncy or moving floors show the subfloor is breaking down.

Cracked tiles or bent hardwood can be from bad support or water.

Soft spots, warping, or buckling mean rot or long-term damage.

Water is the main reason subfloors fail. Leaks, bad drainage, or poor air flow can all cause problems. Finding issues early and installing subfloors the right way can stop expensive repairs.

Subfloor boards keep your home safe from damage and mold. They also help you avoid expensive repairs. Cleaning often and keeping water away protects the subfloor. You should check your subfloor to catch problems early. Getting experts to look at and fix issues keeps your home safe and comfy. Knowing about this layer helps you feel calm and keeps your home strong and healthy.

FAQ

What is the most common subfloor problem in homes?

Squeaky floors are the biggest problem in most homes. This happens when nails get loose or water causes damage. Checking your floors often can stop bigger problems.

How often should someone inspect their subfloor?

Homeowners need to look at their subfloor once a year. Early checks help find water, mold, or damage before repairs cost a lot.

Can a homeowner replace a subfloor board alone?

Changing a subfloor board takes special skills and tools. Many people hire experts to make sure it is safe and done right.

Structural Support

Structural Support