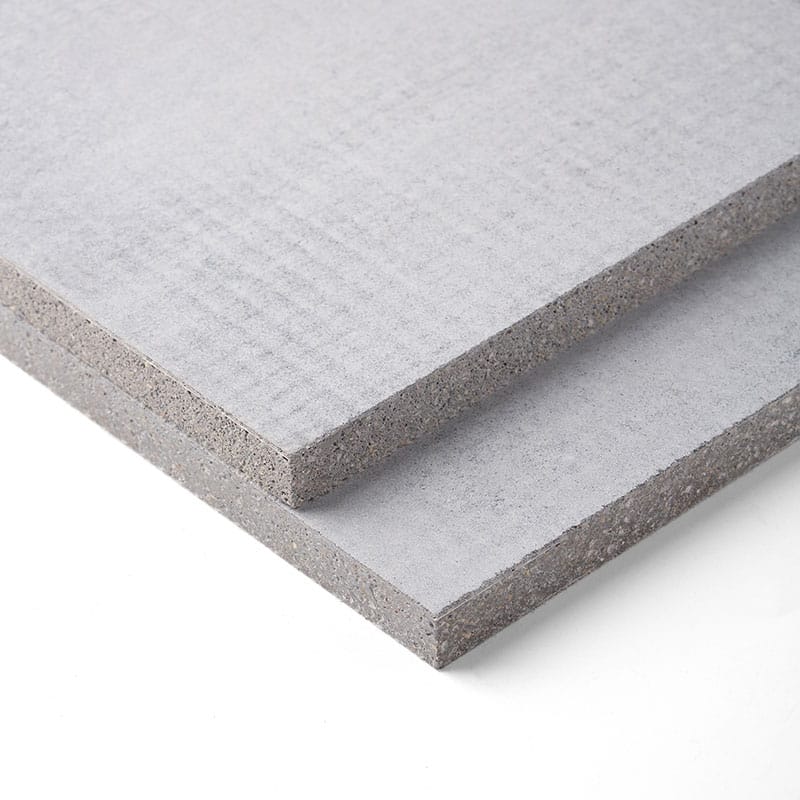

Magnesium Oxide board also known as Mgo Board, is a building material made from magnesium oxide and other additives, offering superior strength, fire resistance, and moisture resistance compared to drywall or gypsum board. It’s used in various construction applications like sheathing, walls, ceilings, and flooring

At Sulfycor! We specialize in the research, development, production, and sales of high-quality magnesium oxide boards (magnesium sulfate boards), committed to providing global customers with safe, eco-friendly, and durable MGO board solutions.

Magnesium Oxide Board Applications

- *Residential Buildings*: Partition walls, ceilings, floor underlayment, bathrooms, kitchens, etc.

- *Commercial Buildings*: Offices, hotels, shopping malls, hospitals, schools, etc.

- *Industrial Buildings*: Factories, warehouses, workshops, etc.

- *Others*: Furniture, billboards, sound barriers, etc.

Technical Specifications

- Thickness: 3-20mm

- Size: 1220x2440mm, 1220x2740mm

- Surface: standard or sanded

- Fireproof Grade: A1

- Moisture Movement: 0.1%-0.12%

- Density: 1000-1100kg/m3

- Flexural strength: 10-16MPA

Magnesium Oxide Board Product Series:

- MGO Sheathing Series: Ideal for wall sheathing applications.

- MGO Subfloor Series: Designed for durable and stable subflooring.

- MGO Wallboard Series: Perfect for interior and exterior wall decoration.

- MGO SIP (Structural Insulated Panel) Series: Combines strength and insulation for energy-efficient structures.

- MGO Ceiling Series: Suitable for stylish and functional ceiling solutions.

- Custom MGO Boards: Tailored to your specific requirements in terms of specifications and performance.

Custom Solutions

We understand that every project is unique. That’s why we offer customized Magnesium Oxide Board Solutions to meet your specific needs:

- Custom sizes and thicknesses.

- Special surface treatments for enhanced moisture resistance or acoustic performance.

- Pre-finished options for painting or decorative coatings.

Frequently Asked Questions About MgO Boards

We have shared some of our most frequently asked questions about magnesium oxide board to hep you out!

what is mgo board ?

An MGO board, also known as Magnesium Oxide Board, is a robust building material crafted from a blend of magnesium oxide, magnesium chloride or magnesium sulfate, and a selection of additives. It is celebrated for its outstanding strength, longevity, and impressive resistance to fire and moisture. With a variety of thicknesses and dimensions available, MgO board is a versatile option for numerous applications in both domestic and industrial construction projects.

what is Mgo Board Used for ?

MgO boards also know as magnesium oxide boards, It is a highly versatile material suitable for a wide range of interior and exterior applications.

| Exterior Applications | Interior Applications | Specialty Applications |

| Wall sheathing Subfloor Fascia Lap Siding | Wall panels Ceiling board Tile backer Drop ceiling tiles Fire wall system | Office cubicles Room dividers Structural Insulated Panels (SIPS) |

Check details about magnesium oxide board use for: <What is Magnesium Oxide Board Used For?>

Do Mgo Boards Offer Fire Resistance ?

Yes, MgO (Magnesium Oxide) board is classified as Class A1 fire-rated, the highest level of fire resistance.

Additionally, MgO boards produce no toxic smoke when exposed to fire, enhancing safety in emergencies.

MgO boards are renowned for their exceptional fireproof performance, capable of withstanding high temperatures without igniting. They are commonly used in fire-rated walls and ceilings, making them an integral part of fire containment systems to prevent the spread of flames.

MgO Boards Are Fire-Resistant

MgO boards are constructed from magnesium oxide, an inorganic substance that is inherently fire-resistant. Unlike drywalls, which are typically made from wood and other flammable materials, MgO boards do not contain any combustible substances. This inherent fire resistance significantly reduces the risk of the boards catching fire and contributing to the spread of flames.

MgO Boards Withstand High Heat

In the face of a fire, MgO boards prove to be a resilient choice in the construction industry. While standard drywalls and other materials quickly succumb to heat and collapse, MgO boards remain unaffected. Their composition and exceptional endurance ensure they do not melt, burn, or lose structural integrity. These boards are particularly suitable for protecting buildings from extreme heat, with the ability to withstand temperatures as high as 1,472°F (800°C). When used in pre-built walls or panels, MgO boards can even withstand an open flame for an impressive 4 hours.

MgO Boards Are Non-Toxic

One of the key advantages of MgO boards is their lack of toxicity when exposed to high heat. Unlike organic materials that can ignite and release harmful fumes, MgO boards are devoid of such components. This means that in the event of a fire, they do not produce smoke or fumes that can be hazardous to health. The absence of fumes reduces the risk of smoke inhalation, which is crucial for maintaining consciousness and safety during a fire emergency. Choosing materials like MgO boards helps protect individuals from the severe consequences of smoke inhalation.

View More: < Is MgO Board Fire Resistant? >

Is MgO Board Water Resistant?

Yes, MgO (Magnesium Oxide) board is highly water-resistant, making it an excellent choice for humid or wet environments where traditional materials (like drywall or plywood) would fail.

Key Water-Resistant Properties:

- Low Water Absorption

Unlike gypsum or wood, MgO board does not easily absorb moisture, preventing swelling, warping, or structural damage.

Ideal for bathrooms, kitchens, basements, and exterior cladding.

- Mold & Mildew Resistance

Its inorganic composition prevents organic growth, even in damp conditions.

- No Delamination

Unlike plywood or OSB, MgO boards won’t peel or separate when exposed to water.

- Compatible with Wet Areas

Often used as a tile backer board (alternative to cement board) in showers and pools.

Limitations:

While water-resistant, it is not fully waterproof unless sealed with a membrane or coating.

Prolonged submersion or standing water may require additional protection.

Is MgO Board Breathable?

Yes, MgO board is breathable—it allows some air and moisture vapor to pass through, similar to traditional lime-based or mineral-based building materials. This makes it useful for applications where moisture regulation is important, such as in passive-house designs or historic renovations.

Key Benefits of Breathability:

Prevents Condensation & Trapped Moisture

Unlike non-breathable materials (e.g., plastic foam insulation or vinyl), MgO board helps reduce the risk of interstitial condensation (moisture buildup inside walls).

Is MgO Board Sustainable?

Yes, MgO (Magnesium Oxide) board is considered a sustainable building material, but its eco-friendliness depends on sourcing, manufacturing processes, and lifecycle impact. Here’s a detailed breakdown:

- Sustainable Attributes Natural Raw Materials

Primarily made from magnesium oxide (from seawater or mined magnesite) and mineral fillers (e.g., perlite, sawdust), reducing reliance on synthetic or toxic components.

- Low Carbon Footprint

Production emits less CO₂ compared to cement-based boards or gypsum. And we use renewable energy in production.

- Durability & Long Lifespan

Resists moisture, mold, and pests, reducing replacement frequency (unlike drywall or plywood).

- Recyclable & Non-Toxic

Can be crushed and reused as filler material.

No off-gassing of VOCs or formaldehyde (unlike some engineered woods).

- Energy-Efficient Performance

Provides thermal insulation, potentially lowering building energy use.

What is MgO Material?

MgO (Magnesium Oxide) is a mineral compound derived from magnesium-rich sources like seawater, magnesite ore, or brine. When processed into boards or panels, it becomes a versatile, eco-friendly building material with exceptional fireproof, moisture-resistant, and durable properties.

Key Properties of MgO Material

- Chemical Composition:

Primarily magnesium oxide (MgO) + reinforcing fibers (e.g., glass fiber, wood pulp) + binders (e.g., magnesium chloride).

- Natural & Non-Toxic:

Free of asbestos, formaldehyde, and VOCs (unlike plywood or some drywall).

- High Alkalinity (pH ~10.5):

Naturally resists mold, pests, and corrosion.

Why Use MgO Material?

- Fireproof: Class A1 fire-rated (withstands >1,200°C / 2,192°F).

- Water-Resistant: Won’t warp or mold in humid areas (e.g., bathrooms).

- Structural Strength: Harder than drywall, lighter than cement board.

- Sustainable: Recyclable, low-VOC, and energy-efficient.

Common Uses: Wall panels, flooring underlayment, fireproofing, exterior cladding.

Is Mgo Board Safe Product?

Yes, MgO (Magnesium Oxide) board is generally considered a safe, non-toxic, and eco-friendly building material when manufactured to high-quality standards. Here’s why:

Non-Toxic & No Harmful Emissions

Unlike some traditional materials (e.g., asbestos or formaldehyde-based products), MgO boards are free of carcinogens and VOCs (Volatile Organic Compounds).

They do not release toxic fumes, even when exposed to fire (*Class A1 fire-rated*).

Mold & Moisture Resistant

Resists mold growth, making it safer for humid environments (e.g., bathrooms, basements).

No Asbestos or Hazardous Fibers

High-quality MgO boards comply with international safety standards (e.g., EU REACH, US EPA).

Alkaline & Pest-Resistant

Naturally repels insects and rodents due to its inorganic composition.

What Is The Difference Between Magnesium Oxide Board And Gypsum Board ?

Gypsum board is softer and more easily cut due to its lower hardness and bending strength, and it is also typically more affordable in price. MgO board, also known as magnesium oxide board, offers superior performance in terms of fire resistance, waterproofing, and bending strength, but it is more expensive.

Moisture Resistance

Magnesium oxide boards exhibit a remarkable surface moisture absorption rate of 0.34%, starkly contrasting the 3% absorption rate of gypsum boards. This significant difference highlights the magnesium boards’ superior resistance to water and moisture. Gypsum boards, conversely, are highly vulnerable to water damage due to their high water absorption capacity, which can lead to board deterioration even from minimal water exposure.

Fire Resistance

Magnesium Oxide and Gypsum boards are both non-combustible, but magnesium oxide boards hold a distinct advantage. With a thickness of over 3 mm, magnesium oxide boards meet fire safety standards, whereas gypsum boards require a thickness of up to 12 mm to meet the same standards. The fire resistance of magnesium oxide boards is exemplified by their exceptional performance in rigorous tests, such as the ASTM E136-16A test, where they remained unaltered at 750°C.

Density

Magnesium oxide boards boast a low density of 0.85–1.2 g/cm3, contributing to their lightweight nature. The inclusion of glass fiber in these boards provides them with both strength and reduced weight. In comparison, gypsum boards have a density range of 1.2-1.3 g/cm3, necessitating higher density to match the strength of magnesium oxide boards at a lower density.

Impact Strength

MgO boards exhibit a high impact strength of 4.5 kilo Joules or greater, thanks to their fiberglass mesh composition. This attribute is crucial for withstanding sudden and intense impacts without compromising their form. Gypsum boards, containing paper fibers, have an impact strength of only 1 kilo Joule, making them more susceptible to cracks, breaks, and deformation.

Bending Strength

Bending strength, also known as flexural strength, refers to a material’s ability to withstand loads without bending or deforming. Magnesium oxide boards offer an impressive bending strength of 18-27 MPa, which is a result of their fibrous structure and fiberglass content. Gypsum boards, however, have a lower bending strength of 5.6 MPa or less, primarily due to their paper fiber composition.

Environmental Impact

Both magnesium oxide and gypsum boards are environmentally friendly, as they do not emit toxic chemicals. The manufacturing process of magnesium oxide boards, however, consumes less fuel than that of gypsum boards, making them not only cost-effective but also more environmentally friendly.

View More: < What Is The Difference Between Magnesium Oxide Board And Gypsum Board?>

Difference Between Magnesium Oxide Board And Calcium Silicate Board ?

MgO board is stiff, which means it’s strong and supports structures. But the Calcium Silicate board is different—it’s more flexible, so it can bend and fit into different shapes without breaking.

Density:

Magnesium Oxide Board: It has a low density of 0.85–1.2 g/cm3, making it lightweight and easy to handle.

Calcium Silicate Board: It has a higher density range of 1.2-1.3 g/cm3, which provides it with greater strength and durability.

Water Resistance:

Magnesium Oxide Board: It exhibits a surface moisture absorption rate of 0.34%, showcasing excellent water resistance.

Calcium Silicate Board: It has a higher water absorption capacity, with a rate of almost 3%, making it less resistant to water compared to magnesium oxide board.

Fire Resistance:

Magnesium Oxide Board: It is non-combustible and can withstand high heat, melting, or burning. It remains stable and maintains its structural integrity even in extreme temperatures.

Calcium Silicate Board: It is also non-combustible and fire-resistant, but it may have a slightly lower fire resistance rating compared to magnesium oxide board.

Impact Strength:

Magnesium Oxide Board: It has a high impact strength of 4.5 kilo Joules or more, thanks to its fiberglass mesh composition.

Calcium Silicate Board: It has a lower impact strength of 1 Kilo Joule, primarily due to its composition of paper fibers.

Bending Strength:

Magnesium Oxide Board: It offers an impressive bending strength of 18-27 MegaPascals (MPa), attributed to its fibrous structure and fiberglass content.

Calcium Silicate Board: It has a lower bending strength of 5.6 MPa or less, which is mainly influenced by its paper fiber composition.

Environmental Impact:

Magnesium Oxide Board: It is environmentally friendly and does not release toxic chemicals. Its manufacturing process conserves more fuel, making it a sustainable choice.

Calcium Silicate Board: It is also environmentally friendly and does not emit toxic fumes. However, its manufacturing process may consume more fuel compared to magnesium oxide board.

Conclusion:

In summary, magnesium oxide board and calcium silicate board are two distinct construction materials, each with its own set of properties. Magnesium oxide board is known for its low density, excellent water resistance, high fire resistance, high impact strength, and bending strength. On the other hand, calcium silicate board has a higher density, lower water resistance, slightly lower fire resistance, lower impact strength, and bending strength. Understanding these differences can help professionals make informed decisions when it comes to selecting the right material for their construction projects.

View More: < Difference Between Magnesium Oxide Board and Calcium Silicate Board>

Request a Free Sample Or Get a Customized Quote Now!

Let us help you find the perfect solution for your project.