19 Feb MgO Board vs Gypsum Board for Substrate Floors Which Is the Best Choice

Table of Contents

If you want the best substrate floor base, magnesium oxide board is a great pick. When you compare materials, MgO Board VS Gypsum Board Substrate Floor shows that MgO board provides strong floors. It lasts a long time and does not get damaged by water. Gypsum board costs less at first, but MgO board saves money later. Check the table below to see the good and bad points of MgO board and gypsum board for substrate floor.

Feature | MgO Board | Gypsum Board |

|---|---|---|

Moisture Resistance | Excellent | Poor |

Fire Resistance | High | Moderate |

Durability | Very strong | Less durable |

Cost | Higher upfront, long-term save | Lower upfront, more repairs |

MgO board keeps out water and fire better than gypsum board.

Gypsum board breaks more in places with lots of people.

Key Takeaways

MgO board is very good at stopping water and fire. This makes it great for wet places like bathrooms and kitchens.

You can install MgO board fast and easy. It comes dry and does not need time to cure. This helps you finish projects faster.

MgO board costs more at first. But it lasts longer and needs less fixing, so it saves money over time.

Gypsum board works well in dry places with not many people walking on it. But it can get damaged by water and needs a strong floor under it.

Pick MgO board for busy or wet places. This will make your floor last longer and be safer.

Installation Comparison

MgO Board Installation Steps

You can install mgo board quickly and easily. Most mgo board products come dry and ready to use. You do not need to wait for curing. Standard framing crews can handle the installation. Here are the basic steps:

Measure and cut the mgo board to fit the floor space.

Place the mgo board directly on the joists or structure. You do not need a subfloor.

Fasten the mgo board with screws or nails.

Check for gaps and fill them if needed.

The surface is now ready for your final floor finish.

This process saves time and avoids delays from moisture or curing.

Gypsum Board Installation Steps

Gypsum board installation takes more time and planning. You need to prepare the area and use a wet mix. Here are the main steps:

Prepare a solid subfloor before you start.

Mix the gypsum underlayment with water.

Pour the wet gypsum mix over the subfloor.

Spread and level the mix.

Wait for the gypsum to cure. This can take three to seven days.

Only after curing can you add your final floor finish.

You need special crews for this process. The extra steps can slow down your project.

Workflow and Labor Differences

The mgo board vs gypsum board substrate floor installation shows clear differences. You can see the main points in the table below:

Feature | MgO Board | Gypsum Board |

|---|---|---|

Installed dry, no curing needed | Poured wet, requires curing time | |

Structural Strength | Can be placed directly on joists | Needs a solid base, may require layers |

Moisture Sensitivity | Resistant to water and mold | Absorbs water, prone to damage |

You save time with mgo board. You do not need to wait for curing or hire special crews. Gypsum board needs more steps and more labor. Mistakes like poor priming or using low-quality boards can cause problems for both types. Always check the quality of your materials to get the best floor.

Moisture and Mold Resistance

MgO Board in Wet Areas

MgO Board in Wet Areas

You want a substrate floor that stands up to water. MgO board gives you that protection. You can use it in bathrooms, kitchens, and basements. The board absorbs very little moisture, so it does not swell or break down. Take a look at the moisture absorption rates:

Board Type | Moisture Absorption Rate |

|---|---|

Magnesium Oxide | 0.34% |

Gypsum | almost 3% |

This low rate means mgo board keeps its shape and strength, even when you have leaks or spills. You do not need to worry about freeze-thaw cycles, either. MgO board stays tough and stable when temperatures change. You get a floor that lasts longer in wet and cold places.

Gypsum Board in Dry Areas

Gypsum board works best in dry rooms. You can use it in living rooms, bedrooms, and offices. The board absorbs more water than mgo board. If you use it in wet areas, it can swell, crack, or even fall apart. Gypsum board does not handle freeze-thaw cycles well. It can break down when exposed to moisture and temperature changes. You should avoid using gypsum board in places with high humidity or water risk.

Mold and Mildew Protection

You want to keep your home safe from mold and mildew. MgO board gives you strong mold resistance because it does not hold much water. You get better protection in bathrooms, laundry rooms, and basements. Gypsum board absorbs more moisture, so it can grow mold and mildew faster. Here is how mgo board vs gypsum board substrate floor compares:

MgO board performs better in wet environments because of its low water absorption.

Gypsum board is more likely to grow mold and get damaged in high humidity.

MgO board’s moisture resistance helps it last longer and stay safe in wet spaces.

MgO board keeps its strength and shape during freeze-thaw cycles.

Gypsum board weakens and can break down with moisture and temperature changes.

You should choose mgo board if you want a floor that fights mold and mildew. It gives you peace of mind and a healthier home.

Strength and Durability

When you compare mgo board vs gypsum board substrate floor, you see big differences in strength and durability. You want a floor that stands up to daily use and lasts for years. By comparing material properties, you can make the best choice for your project.

Impact Resistance

You need a substrate floor that can handle drops, bumps, and heavy foot traffic. Mgo board gives you excellent impact resistance. Its dense and rigid structure means it does not dent or crack easily. You can move furniture or equipment without worrying about damage. Gypsum board, on the other hand, feels softer and more fragile. It dents and punctures more easily, especially during installation or when you drop something heavy.

Tip: If you want fewer repairs and a longer-lasting floor, choose mgo board for areas where things get dropped or moved often.

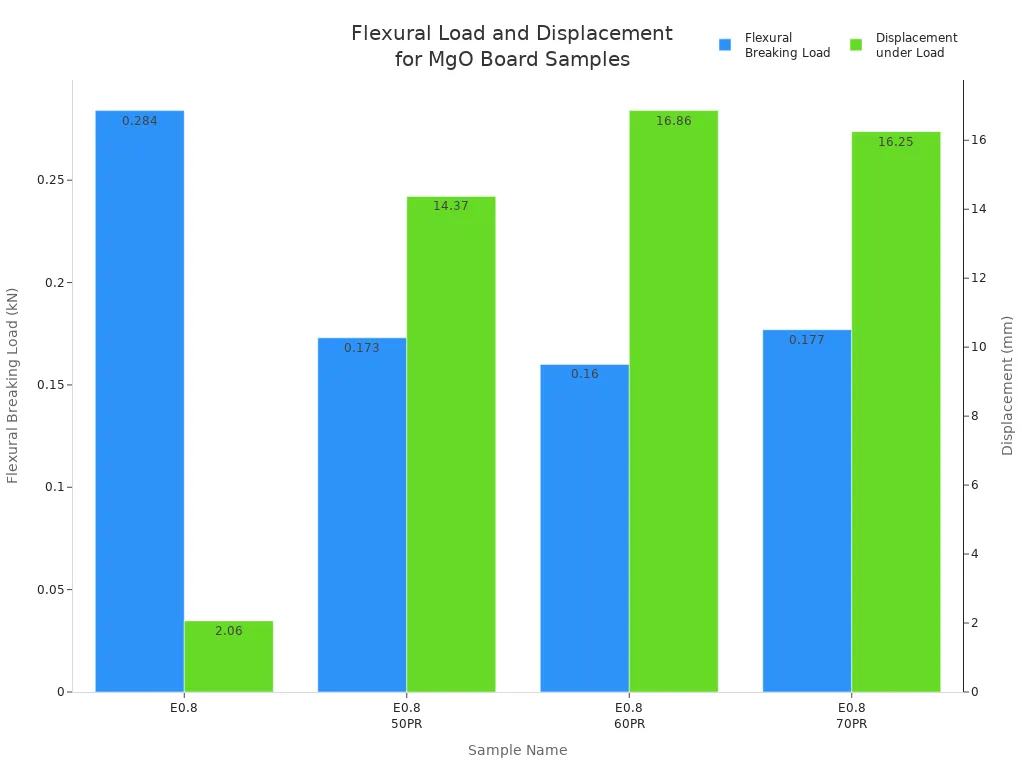

You can see the difference in flexural breaking load and displacement under load in the table below. These numbers show how much force each board can handle before breaking.

Series | Name | Flexural Breaking Load (kN) | Displacement under Load (mm) |

|---|---|---|---|

III | E0.8 | 0.284 ± 0.02 | 2.06 ± 0.49 |

E0.8 50PR | 0.173 ± 0.03 | 14.37 ± 1.22 |

|

E0.8 60PR | 0.160 ± 0.02 | 16.86 ± 0.69 |

|

E0.8 70PR | 0.177 ± 0.01 | 16.25 ± 0.79 |

|

These results show that mgo board has higher strength and lower displacement. This means it stays strong and does not bend much under pressure. Gypsum board does not perform as well in these tests. You get better structural performance with mgo board.

Longevity in High-Traffic Areas

You want your floor to last, especially in busy places like schools, hospitals, or stores. Mgo board gives you long-term durability. It can last 25 to 50 years as an underlayment. Gypsum board usually lasts only 10 to 15 years in the same conditions. That means you will need to replace gypsum board more often, which costs more over time.

Mgo panel underlayment: 25-50 year lifespan

Gypsum underlayment: 10-15 year lifespan

You also get better warranties with mgo panels. Some brands offer lifetime warranties. Mgo panels can handle exposure for up to 180 days before you finish the floor. Gypsum board only lasts about 30 days if left uncovered. This shows the pros and cons of mgo board. You get more value and peace of mind with mgo.

Note: If you want the best durability and strength for high-traffic areas, mgo board is the smart choice. It gives you better structural performance and long-term durability.

When you look at the performance of both boards, mgo board stands out for its durability and strength. You get a floor that stays strong, resists damage, and lasts for decades. Gypsum board works in low-traffic, dry areas, but it cannot match the structural performance of mgo board. Choose mgo board if you want a substrate floor that handles tough conditions and keeps your building safe.

Fire Resistance and Safety

Fire Ratings for MgO Board

You want your floors to stay safe during a fire. MgO board gives you top fire resistance. It does not burn or release smoke. You can trust it in places where safety matters most, like hospitals and schools. MgO board passes strict tests such as ASTM E119 and EN 13501-1. These tests show that the board can resist fire for a long time. You get an A1 rating, which means the board will not catch fire at all.

Here is a table that shows how mgo board compares to fire rated gypsum board:

Material | Fire Resistance Rating | Temperature Endurance | Toxicity When Burned |

|---|---|---|---|

MgO Board | A1 | Up to 1200°F | Non-toxic |

Gypsum Board | Lower than A1 | Less effective | Can release toxic fumes |

MgO board can last up to 4 hours in a fire endurance test. It keeps its shape and strength even under high heat. You may also save money on insurance because some companies offer lower rates for buildings with mgo board. This happens because the board lowers the risk of fire damage.

Tip: You can use mgo board in areas where you need the best fire performance and safety.

Fire Ratings for Gypsum Board

Fire rated gypsum board gives you some fire resistance, but not as much as mgo board. You can use it in homes and offices where fire risk is lower. Fire rated gypsum board can resist fire for 30 to 60 minutes. This gives you time to escape, but it does not protect as long as mgo board.

Here is a table that compares fire performance for mgo board vs gypsum board substrate floor:

Property | MgO Board | Gypsum Board |

|---|---|---|

Fire Resistance Rating | A1 Non-Combustible | Fire-resistant up to 1 hour |

Fire Endurance | Up to 4 hours | 30-60 minutes |

Fire rated gypsum board can release toxic fumes when it burns. You should know that insurance costs may be higher if you use gypsum board instead of mgo. You may need to replace fire rated gypsum board more often after a fire.

Fire rated gypsum board works for basic fire safety.

MgO board gives you the highest level of fire resistance.

You get better long-term value and safety with mgo board.

You should choose mgo board if you want the best fire resistance for your substrate floor.

Environmental and Health Factors

Material Safety

Material Safety

You want safe materials in your house or school. MgO board uses magnesium oxide, magnesium chloride, and strong fibers. These ingredients are not toxic and do not hurt people. You can use MgO board in many places without worry. Gypsum board safety sheets tell you what is inside. You should read these sheets to check for dangerous stuff. Some gypsum boards have extra chemicals, so always look at the safety info before picking one.

Indoor Air Quality

Clean air indoors is important for your health. MgO board helps keep the air fresh. It does not let out many bad chemicals called VOCs. The board uses natural magnesium sulfate, which is safe. You get a better place to live or work. Gypsum board has paper and glue. These can let out VOCs over time. You might smell things or feel uncomfortable in rooms with bad air. MgO board lasts longer and helps keep the air clean.

MgO board lets out very few VOCs.

Gypsum board can let out VOCs from glue and paper.

Tests show MgO board has almost no VOCs.

Sustainability

You want to help the earth when you choose building materials. MgO board is better for the planet than gypsum board. Making MgO board traps CO2, so it is good for the environment. Making gypsum board uses more energy and makes more CO2. Mining gypsum can hurt nature and animals.

Here is a table that shows how easy it is to recycle both boards:

Material | Recycling Options | End-of-Life Disposal Challenges |

|---|---|---|

MgO Board | Few problems | |

Gypsum Board | Hard to recycle | More problems, can make harmful gas |

You can recycle MgO board without trouble. Gypsum board is harder to recycle and can make bad gases when thrown away. When you think about how to use and get rid of these boards, MgO board is the better choice for the environment.

Cost and Value

Upfront Costs

When you compare the cost of mgo board vs gypsum board substrate floor, you notice a difference right away. Mgo board usually costs more at the start. You pay a higher price per square meter, especially if you choose thicker panels. Gypsum board costs less up front, which makes it popular for budget projects. Take a look at this cost comparison table for different thicknesses:

Board Type | |

|---|---|

6mm MgO Board | $8–$12 |

8mm MgO Board | $10–$15 |

12mm MgO Board | $14–$20 |

You see that mgo board costs more than gypsum board. If you want to save money at the start, gypsum board looks like a better choice. However, you should think about more than just the initial cost.

Long-Term Value and ROI

Over time, the cost comparison changes. Mgo board gives you better value because it lasts longer and needs less care. You spend less on repairs and replacements. Gypsum board needs more attention, especially in places with water or lots of people. You might have to fix or replace it if it gets wet or grows mold. Here is what you can expect over ten years:

Mgo boards need fewer repairs and replacements, so you save money.

Gypsum boards need more maintenance, especially in wet areas, which increases your cost.

Mgo board costs more at first, but you spend less over time because it stays strong and safe.

If you want a floor that saves you money in the long run, mgo board is the smart choice. You get a better return on investment because you avoid extra costs for repairs and replacements. The cost comparison shows that mgo board helps you keep your building safe and your budget under control.

Tip: Always look at both upfront and long-term costs before you choose your substrate floor. A higher initial cost can mean bigger savings later.

Overall Performance Summary

You want to pick the best floor for your project. When you compare mgo board and gypsum board, you notice big differences. The table below shows how each board does in important ways:

You want to pick the best floor for your project. When you compare mgo board and gypsum board, you notice big differences. The table below shows how each board does in important ways:

Feature | Gypsum Wallboard | MgO Board |

|---|---|---|

Fire Resistance | Good, but not as strong as MgO boards. | Excellent, rated A1 for fire safety. |

Moisture Resistance | Can break down when wet. | Very good, works in wet places. |

Strength and Durability | Weaker and easier to damage. | Strong and impact-resistant. |

Cost | Cheaper and budget-friendly. | Costs more due to better features. |

Installation Speed | Longer preparation time needed. | Quicker and easier to install. |

Mgo board gives you better fire safety and water resistance. It is also stronger than gypsum board. Gypsum board costs less and works well in dry rooms with little foot traffic. You should choose the board that fits your needs and budget.

Best Use Cases for MgO Board

Mgo board works best in tough places. Here are some common uses for mgo board:

Underlayment for tile, vinyl, or laminate floors in kitchens, bathrooms, and basements.

Substrate floors in factories and entryways where you need strength and fire safety.

The table below shows where mgo board is a good choice:

Environment | Reason for Use |

|---|---|

Kitchens | High moisture resistance prevents swelling. |

Bathrooms | Durable under wet conditions, ensuring longevity. |

Basements | Effective in moisture-prone areas, unlike plywood. |

Factories | Strong enough to withstand heavy loads and impacts. |

Entryways | Provides a robust underlayment for high traffic. |

You should use mgo board when you need a floor that is strong, safe from fire, and resists water. These are the most common ways people use mgo board in buildings today.

Best Use Cases for Gypsum Board

Gypsum board is good for dry places with little wear. Here are some common uses for gypsum board:

Substrate floors in bedrooms, living rooms, and offices.

Projects where you want to save money and do not expect much water.

You can use gypsum board for floors that do not get wet or have lots of people walking on them. These are the main ways people use gypsum board at home or work.

Tip: Pick mgo board if you want a floor that lasts longer and can handle tough spots. Choose gypsum board if you need a simple, low-cost floor for dry rooms.

Now you know the facts to help you pick the right floor for your space.

When you look at mgo board and gypsum board, mgo board is usually the better pick for most jobs. It works better, lasts longer, and keeps out water and fire. The table below shows how they compare:

Property | MgO Board | Gypsum Board |

|---|---|---|

Moisture Resistance | Very good, does not swell or mold | Gets wet fast, can swell and mold |

Durability | Can last up to 100 years, stays strong | May crack and get moldy when wet |

Strength after wet/dry cycles | Keeps almost all strength after 25 cycles | Can lose up to 52% strength |

Use mgo board in kitchens, bathrooms, or busy places. Use gypsum board in dry rooms with few people if you want to save money.

FAQ

What makes mgo board a good choice for wet areas?

You get strong moisture resistance with mgo board. It does not swell or break down when water touches it. You can use it in bathrooms, kitchens, or basements without worry.

Can you install gypsum board directly on floor joists?

You cannot install gypsum board directly on floor joists. You need a solid subfloor first. This step helps prevent cracks and damage over time.

How long does mgo last compared to gypsum board?

You can expect mgo to last 25 to 50 years as a substrate floor. Gypsum board usually lasts 10 to 15 years in the same space.

Is mgo board safe for indoor air quality?

You get clean air with mgo board. It releases very few chemicals. This helps keep your home or office healthy.

Does mgo board cost more than gypsum board?

You pay more for mgo board at first. Over time, you save money because it needs fewer repairs and lasts longer.

MgO Board in Wet Areas

MgO Board in Wet Areas Material Safety

Material Safety