01 Sep Analyzing Market Demand for Magnesium Wall Boards in 2025

Table of Contents

- 1 Key Takeaways

- 2 Market Demand 2025

- 3 Global Market Size

- 4 Demand Drivers

- 5 Market Segmentation

- 6 Regional Trends

- 7 Challenges

- 8 Opportunities

- 9 Competitive Landscape

- 10 FAQ

- 10.1 What makes magnesium wall boards different from gypsum boards?

- 10.2 Are magnesium wall boards safe for indoor air quality?

- 10.3 How do magnesium wall boards support green building certifications?

- 10.4 Where are magnesium wall boards most commonly used?

- 10.5 What challenges do manufacturers face in 2025?

The expected worldwide market demand for magnesium wall boards in 2025 will be about USD 1.81 to 1.96 billion. This is supported by a CAGR of around 5.6%. People in the industry watch this market demand trend carefully. The demand shows that more money goes into eco-friendly building and fire-resistant options. Builders like magnesium wall boards because they are good for the environment. They also help keep buildings safe from fire. These boards work well with new building styles. Fast city growth and better technology also change the market.

Key Takeaways

The global market for magnesium wall boards is growing quickly. It may reach about $1.8 to $2.1 billion by 2025. This is because people want eco-friendly and fire-resistant building materials. Builders pick magnesium wall boards to help the environment. These boards also follow strict fire safety rules. They fit well with new building styles and technology. Asia-Pacific is growing the fastest because cities are growing quickly there. North America and Europe are also growing, but more slowly. This is because of green building rules and more renovations. There are some problems like higher costs, trade tariffs, and supply chain delays. But companies use new ideas and work together to solve these problems. New products are stronger, lighter, and resist fire and water better. These products help green building goals. They also create chances in new markets around the world.

Market Demand 2025

Global Market Size

The world market for magnesium wall boards could be $1.8 to $2.1 billion in 2025. This is because more people want green building materials and fire-resistant products. Asia Pacific is growing fast because cities are getting bigger and new buildings are being built. Builders in Europe and North America also need these boards. They follow strict rules for building and care about the environment.

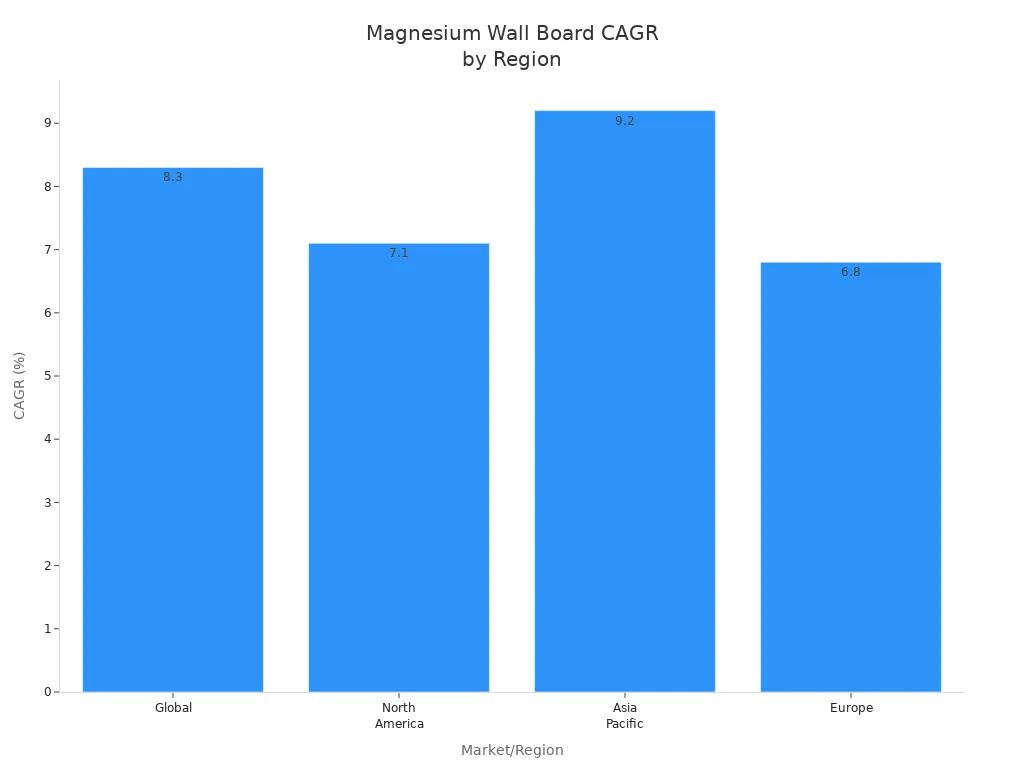

Market/Region | CAGR (%) | Forecast Period | Notes |

|---|---|---|---|

Global | 8.3 | 2023 to 2032 | Projected growth of MgO wallboard market globally. |

North America | 7.1 | Not explicitly ending in 2025 | Regional growth driven by building codes and sustainability focus. |

Asia Pacific | 9.2 | Not explicitly ending in 2025 | Fastest growing region due to urbanization and infrastructure. |

Europe | 6.8 | Not explicitly ending in 2025 | Growth driven by sustainability and energy efficiency regulations. |

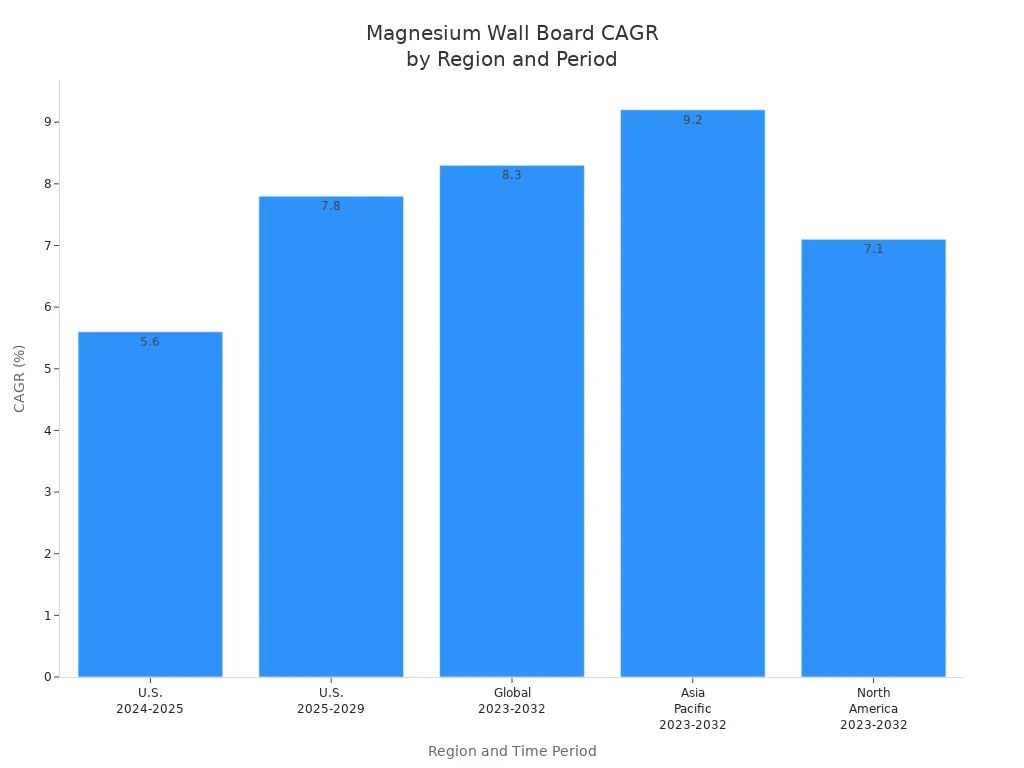

U.S. Market Size

In the United States, the market for magnesium wall boards may reach $2.15 billion in 2025. Builders pick these boards because they do not burn easily and are good for the planet. The construction industry is getting bigger, but some problems slow it down. Trade tariffs and supply chain issues make growth a bit slower. The market grew from $1.86 billion in 2024 to $1.96 billion in 2025. This shows steady growth.

Market/Region | Year(s) | Market Size (USD Billion) | CAGR (%) | Notes on Growth Trend and Drivers |

|---|---|---|---|---|

U.S. Market | 2024 – 2025 | 1.86 → 1.96 | 5.6 | Growth driven by construction activity, fire resistance, sustainability; slight moderation due to trade tariffs. |

U.S. Market | 2025 – 2029 | 1.96 → 2.65 (forecast) | 7.8 (forecast) | Forecast growth slightly reduced by 0.1% from previous projections due to tariffs impacting supply chains. |

Growth Rate Trends

The need for magnesium wall boards keeps going up. The global CAGR is 8.3% from 2023 to 2032. North America has a 7.1% CAGR. Asia Pacific grows fastest at 9.2%. Europe grows at 6.8%. These numbers show people want safer and greener building materials.

In 2025, more homes are being built, which increases demand. Builders use these boards to meet fire safety rules and use green materials. Businesses and factories also use them because they last long and resist fire. New rules and green certifications like LEED and BEAM Plus help the market grow. Better moisture resistance and lighter boards make more people interested. Government spending on new buildings helps too. But high costs and not enough knowledge among small builders make things harder.

Note: People in the industry should work on new ideas, follow rules, and teach others to make the magnesium wall board market grow.

Demand Drivers

Sustainability

Sustainability is very important for magnesium wall boards. Builders pick magnesium oxide boards to help the planet. These boards lower carbon emissions and make indoor air better. They do not have harmful stuff inside. They also give off very few bad gases. You can recycle these boards, and they last a long time. This helps green building. Many places now want new buildings to use green materials. In the United States, over 40% of new buildings may be LEED-certified by 2025. Asia-Pacific countries want cities to grow in a green way. Europe’s Green Deal wants more energy-saving building fixes. The table below shows how different places care about sustainability and how it helps demand:

Region | Sustainability Drivers and Impact on Demand for Magnesium Wall Boards |

|---|---|

United States | LEED-certified buildings expected to be over 40% of new projects by 2025, driving demand for sustainable materials like magnesium nitride. |

Asia-Pacific | Rapid urbanization and government green building initiatives (e.g., China’s 14th Five-Year Plan) promote sustainable urban development, increasing demand. |

Europe | European Green Deal and Renovation Wave strategy aim to double energy renovation rates by 2030, boosting market for low-carbon, energy-efficient materials. |

Industry Trends | Shift towards circular economy principles favors recyclable materials like magnesium nitride, enhancing market share potential. |

Magnesium wall boards use less energy to make. They do not let mold or moisture grow. Builders who care about the earth like them.

Fire Resistance

Fire resistance is a big reason people use magnesium wall boards. Builders want these boards because they meet tough fire safety rules. Groups like OSHA and the EU Construction Products Regulation set these rules. In the U.S., fire-resistant materials are needed, especially in places with wildfires. Magnesium boards are used most in fire-safe walls and ceilings. Makers try to get UL and ASTM certifications to follow new safety rules. Homes, businesses, and factories all use these boards because they do not burn easily.

Fire-rated magnesium oxide boards are popular because of safety rules.

Places with wildfires need fire-resistant materials the most.

Builders like that these boards also stop moisture and mildew.

Construction Growth

When more buildings are made, more magnesium wall boards are needed. The construction business keeps growing in 2025. The market for magnesium oxide boards goes from $1.86 billion in 2024 to about $1.97 billion in 2025. Builders want strong, fire-safe, and green materials for new rules. Magnesium boards are better than wood and gypsum boards. Both homes and businesses use them more now. Stricter rules and the need for tough materials make this happen.

More building and new rules mean more magnesium wall boards are used in new projects.

Technology

New technology helps the magnesium wall board market grow. Companies like ZS2 Technologies make better magnesium cement. This makes boards stronger against fire, water, and bugs. New boards use local by-products, so they are always good quality. Special ways to turn waste into cement help the earth and make boards better. Getting certified for new building rules makes builders trust these boards more. These new ideas fix old problems like mold, water damage, and supply issues.

Gen 2 magnesium boards are tested for fire, water, and pest safety.

Some boards are made for special uses like floors and strong walls.

These new products are ready for real jobs and show that demand is strong.

Market Segmentation

By Product Type

Magnesium wall boards come in three thickness groups. Thin boards are less than 8 mm thick. Medium boards are 8 to 15 mm thick. Thick boards are more than 15 mm thick. Thin boards are the most popular. They are light and simple to put up. Builders use thin boards for quick building jobs. These panels save space and make building faster. Makers make thin boards bend easily. This helps with curved walls and prefab buildings. Boards that stop fire are used in places that need safety. Homes need thin boards the most because many are being built.

Thin (below 8 mm): Light, easy to use, wanted for inside walls and quick builds

Medium (8–15 mm): Used for regular walls, strong and bends well

Thick (above 15 mm): Best for strong walls and floors, lasts longer

By Application

Magnesium wall boards have many uses in different jobs. The table below shows where they are used and why:

Application Area | Key Demand Drivers and Benefits |

|---|---|

Construction | Used for walls, floors, fire barriers, insulation, soundproofing; liked for stopping fire and water, light weight, good for the earth |

Furniture and Interior Design | Used for tables, shelves, cabinets, wall panels, ceilings; liked for being tough, stopping fire and water, good for the earth |

Transportation | Used in buses, trains, ships; gives strength, blocks noise, keeps heat in, helps passengers feel safe |

Modular and Prefabricated Structures | Used more in prefab homes and buildings because they bend, are strong, and help the earth |

Marine Building | Used in boat buildings for being tough and lasting in hard places |

Builders pick magnesium wall boards because they do many things and help the earth.

By End-User

Most buyers are in the building business. Homes, stores, and factories buy the most boards. Some boards are used for stopping fire and blocking sound. People fixing homes or doing DIY also buy them. The market for magnesium boards may be $2.5 billion in 2025. People like them because they stop fire, are light, and help the earth. Rules and more building help the market grow.

Home Building

Store Building

Factory Building

Fixing Up Projects

By Region

Demand changes in different places because of weather, rules, and city growth. Asia-Pacific buys the most because cities are growing fast and governments help. North America and Europe buy more each year because of fixing old buildings and wanting green materials. In the U.S., states like California and Florida use more boards because of fire rules and weather. Cities in Canada want boards that save energy and help the earth. Places near water or with disasters want boards that last and stop mold and fire.

Companies change their plans to fit local rules and needs, so more people use magnesium wall boards.

Regional Trends

Image Source: pexels

Image Source: pexels

North America

North America is the top buyer of magnesium wall boards. The United States market could be worth $2.15 billion in 2025. Builders like magnesium oxide boards because they stop fire and water. These boards are also good for the planet. Homes use about 37.4% of these boards. Thin boards under 8 mm make up 42.7% of sales. Tougher fire rules and government spending help the market grow. More people fixing homes also raises demand. The U.S. market may grow by 3.9% each year from 2025 to 2032. Big cities like New York, Los Angeles, and Houston need more safe and green building materials.

Metric | Projection for 2025 |

|---|---|

U.S. Magnesium Oxide Board Market Size | $2,153.2 million |

Residential Building Segment Market Share | 37.4% |

Market Share of Thin MgO Boards (<8 mm) | 42.7% |

Projected CAGR (2025-2032) | 3.9% |

Builders in North America use magnesium wall boards to follow new safety and green rules.

Europe

Europe’s magnesium wall board market is growing fast. More people move to cities, so builders need more boards. Strict building rules make builders pick safe and green materials. France and other countries want eco-friendly and fire-safe boards. Top companies focus on safety and helping the earth. Governments support energy-saving buildings. Builders use magnesium oxide boards in homes and offices because they last long and work well. New technology makes these boards even better. Green building ideas and new inventions help the market grow.

Asia-Pacific

Asia-Pacific is seeing fast growth in using magnesium wall boards. More people move to cities and earn more money. This means more buildings go up in China, India, and Southeast Asia. Builders want boards that are safe, green, and stop water. Green building awards are now more common. New products are better and come in many sizes. Local and global companies work together to sell more boards. New markets in the region give more chances to grow. Better supply chains help lower prices. The market was $1.2 billion in 2024 and is still growing fast. From 2026 to 2033, it may grow by 8.9% each year.

More people in cities means more building.

Builders want strong and green boards.

Working together and new ideas help sell more boards.

New places to sell mean big chances to grow.

Other Regions

Other places like Latin America, the Middle East, and Africa are starting to use more magnesium wall boards. Builders there are learning about fire safety and helping the earth. New roads and homes give more chances to sell boards. Local rules and weather change what boards people pick. As more people learn about these boards, more will want to use them.

Challenges

Cost Factors

Manufacturers and builders will pay more in 2025. U.S. tariffs and trade problems make raw materials cost more. Items like steel, aluminum, and machines are now pricier. Builders spend extra on fire-resistant board parts from China and Vietnam. These higher prices make projects cost more and take longer. Manufacturers earn less money and must change their prices. Tariffs from other countries also lower demand for U.S. construction tools. Not enough key parts cause more delays and raise building costs.

Awareness

Construction workers need to know more about magnesium wall boards.

Builders who learn about benefits like being green and fire-safe use them more.

More people care about the environment and fire safety rules, so they pick these boards.

Not knowing much about these boards makes people use them less.

Teaching and advertising help builders see cost savings and follow rules.

Tougher fire codes and green building plans make people use these boards.

Different rules in each place make it harder to sell magnesium wall boards.

Competition

Many companies sell magnesium wall boards, like GemtreeBoard Ltd., Magmatrix Science & Technology Co Ltd., and Owens Corning.

The market is in North America, Asia-Pacific, Europe, South America, the Middle East, and Africa.

Companies try new ideas, like making better fire-resistant boards such as BMSC 517.

More people living in cities and more building means companies need special products.

U.S. tariffs in 2025 make things cost more and slow down projects, hurting supply chains.

Companies buy local, use modular building, and change supply chains to compete.

New ideas and special products help companies stand out, but trade problems slow growth.

Supply Chain

Problems in the supply chain make it hard to get products and raise costs.

Local rules change how easy it is to get magnesium oxide boards.

Builders must plan early so they do not run out of materials.

Following rules can slow down selling in new places.

Lower prices make it hard for companies to make money.

Companies work on stronger supply chains and partnerships to fix problems.

New ideas help with tech changes and supply chain troubles.

Opportunities

Innovation

Manufacturers keep making better magnesium wall boards. Factories now use machines to make up to 4,000 boards each shift. This helps builders finish jobs faster and waste less. Companies make new fire-resistant boards that pass tough safety tests like Class A1 and get certifications such as ASTM E119 and ANSI/UL 263. These boards help builders follow strict building rules. New sulfate-based magnesium oxide boards do not let water or mold in, so they are good for wet places. Boards that are light and strong help with modular and prefab building. This makes building faster and lowers mistakes. Product lines like EXACOR panels last longer and are better for the earth. Using machines and recycling saves money and keeps quality high. This makes magnesium wall boards a stronger choice.

Machines help make more boards and waste less.

Fire-resistant and water-resistant boards pass strict safety rules.

New products last longer and are better for the earth.

Green Building

Green building gives big chances to magnesium wall board makers. Builders pick magnesium oxide boards because they are good for the earth, do not burn easily, and can be recycled. These boards help projects get green awards like LEED and BREEAM. Magnesium oxide boards make less carbon, about 60% to 80% less CO2 than other materials. They do not give off bad gases, so indoor air stays clean. Made from natural things, these boards help green building. They are light, so putting them up is fast and easy. Government programs like the U.S. Infrastructure Investment and Jobs Act want builders to use green materials and make things locally. Makers spend money on research to make boards from plants or mix materials to work better and cost less. More people want buildings that can handle storms and disasters, so they use more magnesium wall boards.

Magnesium oxide boards help builders meet green rules and make healthier places.

Emerging Markets

New markets give magnesium wall board makers more ways to grow. Latin America and the Middle East start using magnesium oxide boards, so makers can sell more there. Asia Pacific, with China and India, is the biggest market because lots of buildings are going up. South America, the Middle East, and Africa grow slowly as more homes and offices are built. Builders in these places want boards that last, stop fire, and are good for the earth. As more people learn about these boards, more companies join and change products for local needs.

Region | Opportunity Type |

|---|---|

Asia Pacific | Biggest market, fast city growth |

Latin America | New use, more building |

Middle East/Africa | Slow growth, more demand |

Competitive Landscape

Major Players

In 2025, big and small companies make magnesium wall boards. The top five makers are Magnum Building Products, Gemtree Board, Huizhou Meisen Board, Yongjia Decorative Material, and Ruenzhong Building Material. Together, they make about 40% of all boards and over 30 million units each year. These companies lead with new ideas and steady supply. Other large companies like LafargeHolcim, USG Boral, CertainTeed, and SaintGobain are important too. Some smaller companies, such as Mago BP and Framecad, focus on special markets and new technology.

Major Players (Global) | Description |

|---|---|

LafargeHolcim, USG Boral, CertainTeed, Siniat, Nichiha Corporation, Etex Building Performance, James Hardie, Armstrong World Industries, Etex Group, SaintGobain, GeorgiaPacific, CEMEX, Gyproc, Knauf Gips KG, Knauf | These are the biggest companies making magnesium wall boards in 2025. |

Mago BP, Framecad, Magnastruct, Yunion, Beijing Hocreboard, TRUSUS, Huacheng, Evernice Building, Yulong Technological Board | These companies are important in their own regions and have special skills. |

Magnum Building Products, Gemtree Board, Huizhou Meisen Board, Yongjia Decorative Material, Ruenzhong Building Material | These five companies make over 30 million boards each year and about 40% of the market. |

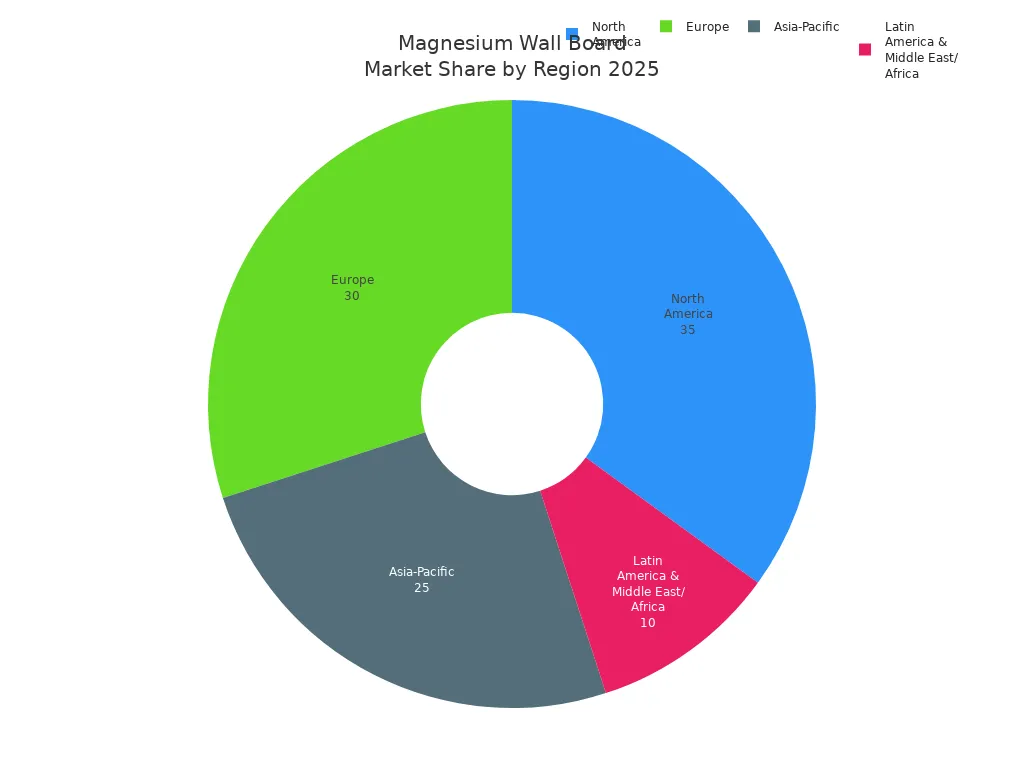

Regional Market Shares | North America has about 35%, Europe has 30%, Asia-Pacific may have 25% by 2027, and Latin America & Middle East/Africa have about 10%. |

Strategies

Top companies use many ways to stay ahead. They spend money to make better, safer, and stronger wall boards. Many companies move into fast-growing places like Asia-Pacific to find new buyers. They also care about the earth and make green products that follow rules. Some companies join together or buy others to sell more types of boards. Good customer service and fair prices help them get more builders to buy. In North America, companies work hard on new ideas. In Europe, they follow strict green rules. In Asia-Pacific, companies grow fast because cities are getting bigger.

Growing in new places, especially Asia-Pacific

Working together with other companies

Better prices and quality

Joining or buying other companies to sell more

Following rules and caring for the earth

Partnerships

Working together is very important in this market. Companies team up to make supply chains better and reach more people. Some work with local builders to make boards that fit special needs. Others join with tech companies to make new kinds of boards or improve how they are made. These teams help companies handle problems and follow new rules quickly. Partnerships also help launch new products and enter new markets.

Good partnerships help companies stay strong and give builders the boards they need everywhere.

The market for magnesium wall boards in 2025 looks strong. People want these boards because they help the planet and stop fires. More buildings are being made, so demand goes up. Companies have problems like higher prices and trouble getting supplies. They can do better by making new products and working with others. Teaching builders about the boards helps too. Top companies think new technology and green building will be important. This will give more chances for growth.

FAQ

What makes magnesium wall boards different from gypsum boards?

Magnesium wall boards stop fire, water, and mold better than gypsum boards. They last longer and help builders meet green building goals. Builders pick them for jobs that need more safety and care for the planet.

Are magnesium wall boards safe for indoor air quality?

Yes. Magnesium wall boards do not let out bad chemicals or VOCs. They help keep the air inside homes and offices clean. These boards meet tough health rules.

How do magnesium wall boards support green building certifications?

Magnesium wall boards use materials that can be recycled. They make less carbon when made. This helps builders get points for green awards like LEED and BREEAM. Builders use them to reach green goals.

Where are magnesium wall boards most commonly used?

Builders put magnesium wall boards in homes, offices, schools, and hospitals. They are also used in modular buildings and places that need strong fire safety. Their many uses make them a top pick for building projects.

What challenges do manufacturers face in 2025?

Manufacturers pay more for raw materials and wait longer for supplies. Trade tariffs and new rules make things harder. Companies work on new ideas and team up to solve these problems and meet more demand.