25 Aug Improving Industrial Workshop Safety with Magnesium Wall Boards in 2025

Table of Contents

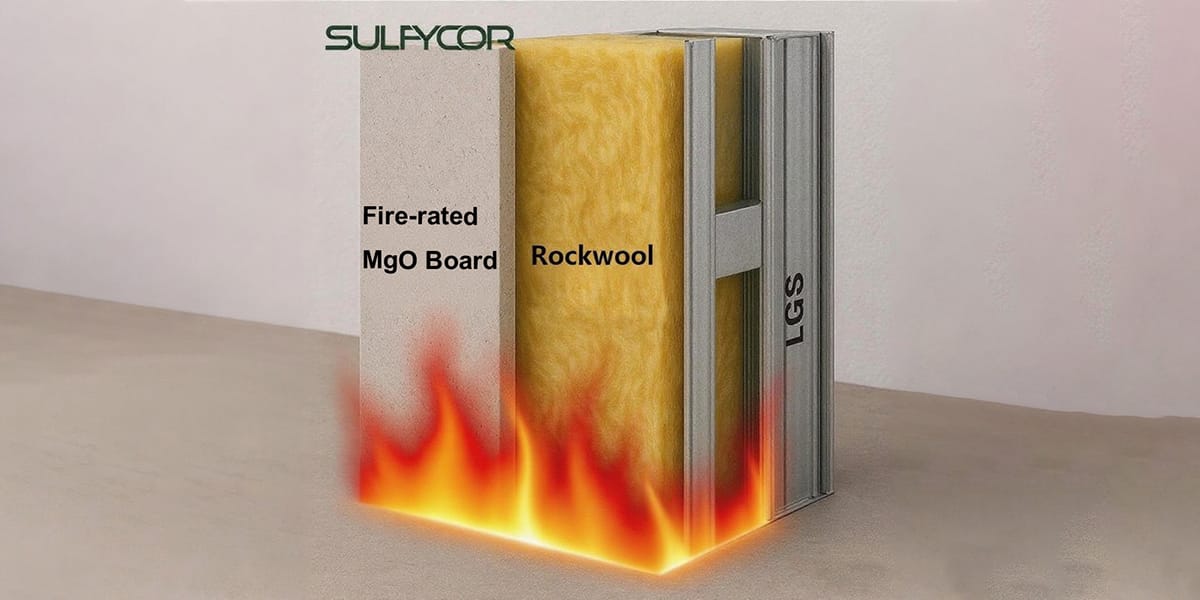

Fire safety is very important in every industrial workshop. New rules and city growth make safety harder. Buildings must be safer and better for the environment. Magnesium wall board is a new solution. It does not burn easily and is good for the planet. This is why more factories and plants use it each year.

Region | Installed Area (2024) |

|---|---|

North America | |

Europe | 67 million sqm |

Asia-Pacific | 175 million sqm |

You need better materials now to follow safety rules. These materials help keep your workplace safe.

Key Takeaways

Magnesium wall boards can stop fire for a long time. They last up to two hours in high heat. They make very little smoke. This helps keep workers safe.

These boards are strong and do not break easily. They resist water and mold. They do not get damaged fast. This makes them good for busy and wet workshops.

Magnesium wall boards follow strict fire safety rules. They help workshops avoid fines. They help keep the workplace safe.

Using magnesium wall boards helps the environment. They lower carbon emissions. They do not use harmful chemicals. This makes indoor air better.

Installing magnesium wall boards saves time and money. They are easy to use. They last longer than drywall. They need fewer repairs.

Fire Safety

Fire Resistance

Industrial workshops have many fire dangers. Wires, dust, and liquids can start fires. Tools like welders make things riskier. Checking equipment and teaching workers helps. But you also need strong materials to stop fire from spreading.

Magnesium wall board is great at stopping fire. It stays strong at over 1,000°F for two hours. Tests show 12mm boards last up to 120 minutes in fire. These boards do not melt or fall apart, even at 2,192°F. The melting point is about 2,800°C, which is higher than most fires.

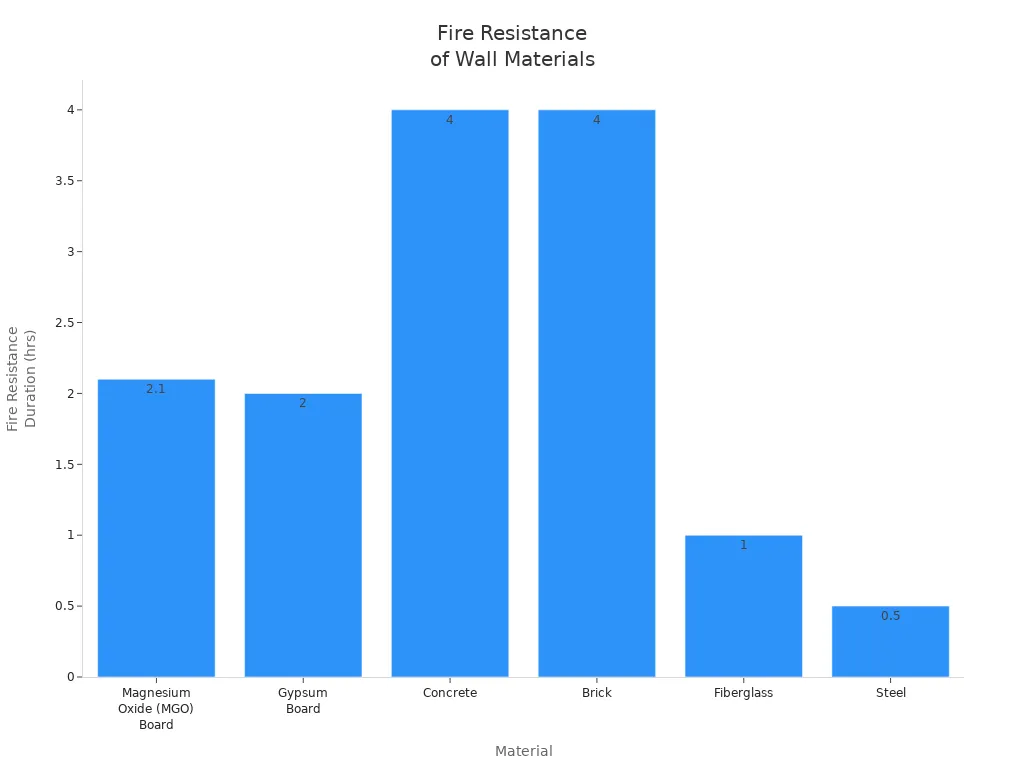

Look at this chart to see how magnesium wall board does against other materials:

Magnesium wall board is better at stopping fire than gypsum board and fiberglass. It is also lighter and easier to put up than concrete or brick.

Non-Combustibility

You want walls that do not burn or help a fire grow. Magnesium wall board is made from a mineral cement called magnesium oxide. This mineral does not burn because it does not react with oxygen. The board also has magnesium chloride, which keeps it strong and does not add anything that burns.

When there is a fire, magnesium wall board makes very little smoke. It does not let out harmful gases. This helps people get out safely during a fire. The board stays strong and keeps its shape for a long time, even in high heat.

Component | Role/Property Description |

|---|---|

Magnesium Oxide (MgO) | Main part. Makes strong bonds. Does not burn or break down in fire. |

Magnesium Chloride | Binder. Holds the board together. Adds nothing that burns. |

Tip: Using non-combustible materials like magnesium wall board means less smoke and fewer toxic fumes, so it is safer to leave the building.

Standards Compliance

You must follow strict fire safety rules in factories. Magnesium wall board meets many tough standards. It passes ASTM E119 tests, which check if a wall can stay strong and stop fire from spreading. These tests use fires hotter than 1,600°F and see how long the wall lasts. Magnesium wall board can get 1-hour and 2-hour fire-resistance ratings.

The boards also pass ASTM E84 tests for burning on the surface. They often get a Class A rating, which means they do not spread flames or make much smoke. ICC-ES Evaluation Service Reports show these boards meet national and state building codes, even in Florida and California.

Here are some main certifications for magnesium wall board:

Certification/Standard | Description |

|---|---|

Top fire resistance; does not burn and makes little smoke or fumes | |

ASTM E136 | Shows the material does not burn |

ASTM E84 Class A | Very good at stopping fire from spreading on the surface |

ASTM E119 | Test shows boards can stop fire for up to four hours |

ICC-ES ESR Reports | Third-party reports show the boards meet fire, corrosion, and strength rules |

NFPA 285 | Test for fire spreading in tall buildings |

INTERTEK, ILAC-MRA | International lab checks make sure test results are trusted everywhere |

You can count on magnesium wall board to help your workshop follow fire safety rules and keep your team safe.

Magnesium Wall Board Features

Composition

Composition

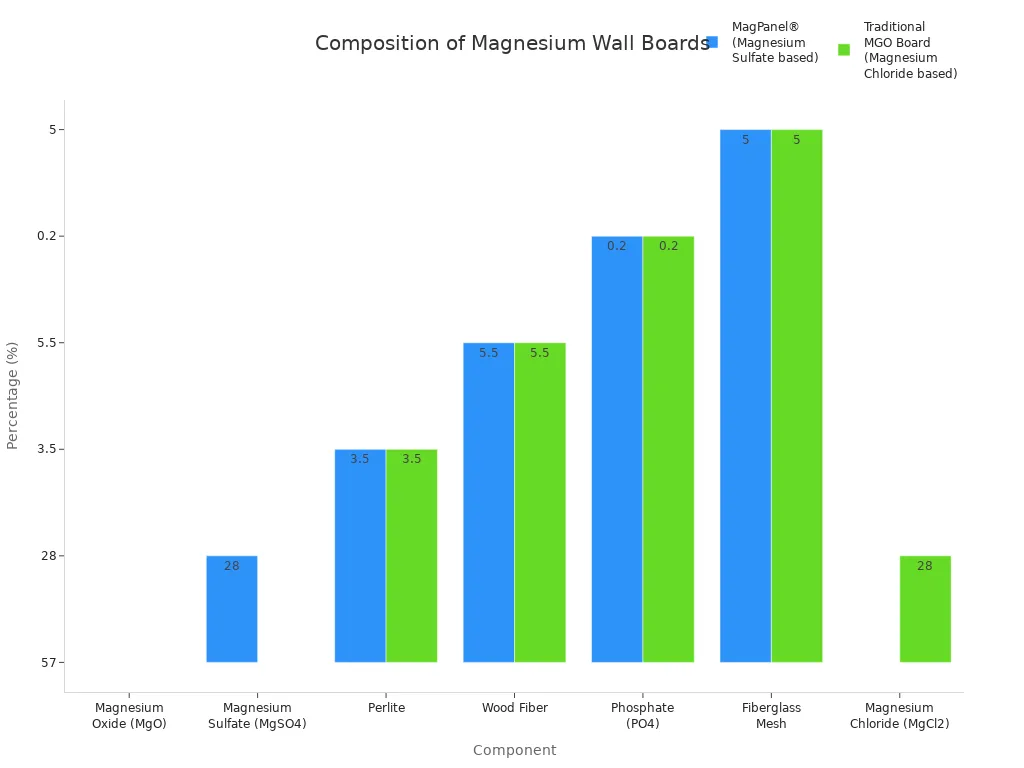

There are two main types of magnesium wall board. Both use magnesium oxide as the main part. Some boards have magnesium sulfate. Others have magnesium chloride. These boards also have perlite, wood fiber, phosphate, and fiberglass mesh. Each part helps the board stay strong. The board can resist fire, mold, and bugs.

Component | MagPanel® (Magnesium Sulfate based) | Traditional MGO Board (Magnesium Chloride based) |

|---|---|---|

Magnesium Oxide (MgO) | 56-58% | |

Magnesium Sulfate (MgSO4) | 27-29% | N/A |

Magnesium Chloride (MgCl2) | N/A | 27-29% |

Perlite | 3-4% | 3-4% |

Wood Fiber | 5-6% | 5-6% |

Phosphate (PO4) | 0.1-0.3% | 0.1-0.3% |

Fiberglass Mesh | 4-6% | 4-6% |

Factories use green ways to make these boards. They mix magnesium oxide with other minerals. Fireproof additives like dolomite are added. This makes the board strong and helps it fight fire.

Structural Strength

Busy workshops need strong walls. Magnesium wall board is tougher than gypsum and fiber cement boards. You can use it for walls, floors, and ceilings that hold weight. It does not crack or split easily. Heavy loads do not break it.

Board Type | Structural Strength Description | Typical Use Cases |

|---|---|---|

Magnesium Oxide | High structural strength; suitable for load-bearing applications such as sheathing and subflooring | Load-bearing walls, structural insulated panels (SIPs) |

Gypsum | Not structurally strong; mainly for non-load-bearing interior walls and ceilings | Interior walls and ceilings (non-load-bearing) |

Fiber Cement | Moderate structural strength; suitable for cladding but not load-bearing | Cladding and siding |

OSB | Strong; widely used in structural applications like sheathing and subflooring | Sheathing and subflooring |

Magnesium wall boards can take hits and bend without breaking.

You can use them in busy places and not worry about damage.

These boards keep their shape in wet and tough chemical areas.

Tip: Pick magnesium wall board for places that need extra strength.

Durability

You want walls that last in wet or rough places. Magnesium wall boards fight mold, mildew, and bugs. Studies show boards with magnesium sulfate take in less water. They stay drier than boards with magnesium chloride. This means less chance of rust and fungus.

Boards with magnesium chloride can leak salty water and rust in wet air.

Boards with magnesium sulfate stay dry and do not rust as much.

Both types lose some strength in very wet places, but magnesium sulfate boards lose less.

To help your boards last longer, do these things:

Let boards get used to the workshop before putting them up.

Use joint compounds and sealants made for magnesium boards.

Use screws and anchors that do not rust.

Leave a small gap between the board and the floor.

Check for damage or wet spots often.

Note: Using stainless steel parts and sealing joints stops rust and keeps your magnesium wall boards strong for many years.

Industrial Benefits

Fire Containment

It is important to stop fire from spreading at work. Magnesium wall board helps make strong fire barriers. You can use these boards for walls, ceilings, and barriers in risky places. They slow down fire and give people more time to escape. Tests show that coatings with magnesium hydroxide help even more. But there is not enough proof about how well magnesium wall board alone stops fire in big factories. Still, you can use these boards with other fire safety tools to make your workshop safer. They help keep fire in one place, lower smoke, and protect machines.

Workshop Applications

You can use magnesium wall board in many workshop areas. Here is a table that shows where you can use it:

Application Category | Specific Uses in Industrial Workshops and Related Settings |

|---|---|

Fire Resistance | Fire walls, ceilings, fire-rated assemblies |

Moisture and Mold Resistance | Walls in bathrooms, saunas, pool areas, basements |

Durability and Impact Resistance | High-traffic areas, impact-resistant walls |

Interior Applications | Wall panels, ceiling boards, tile backer, drop ceiling tiles |

Specialty Applications | Office cubicles, room dividers, Structural Insulated Panels (SIPS) |

Exterior Applications | Wall sheathing, fascia, soffit, trim, lap siding |

Industrial and Commercial Settings | Warehouses, control rooms, datacenters, equipment shelters |

Eco-friendly Construction | LEED-certified buildings, eco-conscious projects |

Magnesium wall board works for many jobs in factories. You can use it for fire walls, ceilings, and wet or busy places.

Regulatory Compliance

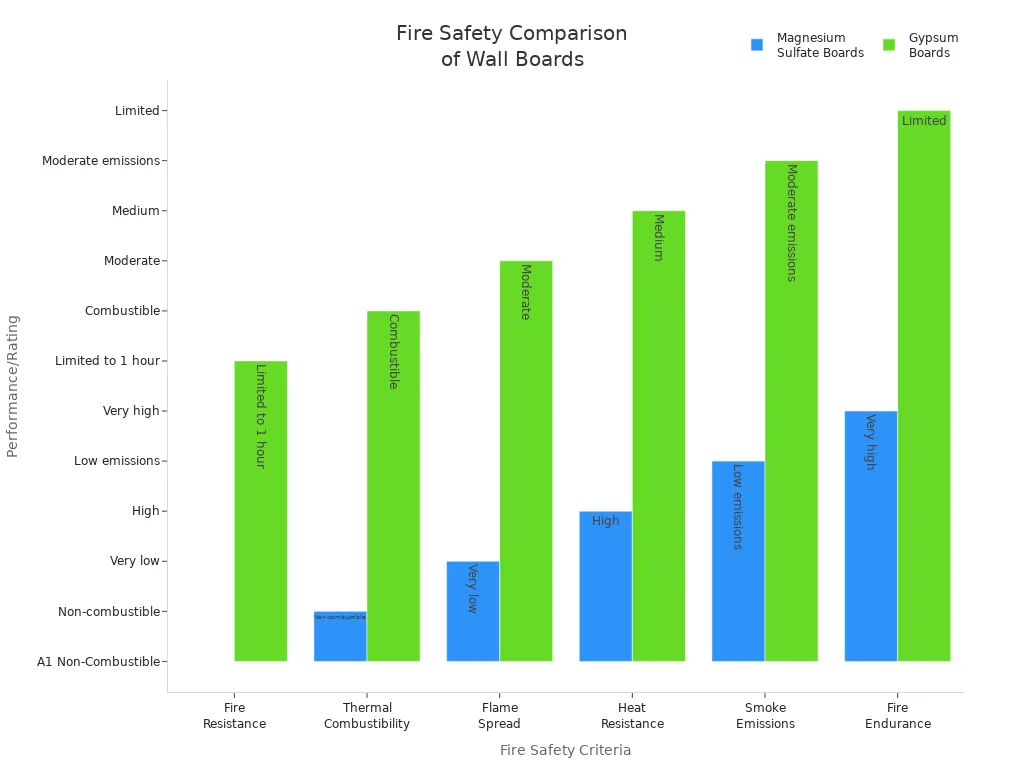

You must follow fire safety rules in 2025. Magnesium wall board helps you meet these rules. It has a high fire resistance rating and does not burn or make toxic gases. Look at this chart to see how it compares:

Magnesium wall board is better at stopping fire and makes less smoke than gypsum boards. It meets rules like EN 13501-1, ASTM E136, and the International Building Code. If you do not follow these rules, you could get fines, lawsuits, higher insurance, or have to close your business. Using magnesium wall board helps you avoid these problems and keeps your workshop safe.

Additional Advantages

Environmental Impact

When you pick magnesium oxide boards, you help the earth. These boards are made from minerals found in nature. Factories use less energy to make them than other materials. Over many years, the boards take in carbon dioxide from the air. This can lower their carbon footprint by up to 40% in 15 years. These boards do not have formaldehyde or VOCs. You do not have to worry about breathing in bad chemicals. The air inside your workshop stays cleaner.

Here is a table that shows how magnesium oxide boards compare with drywall and plywood:

Feature | Magnesium Oxide (MgO) Board | Drywall (Gypsum Board) | Plywood |

|---|---|---|---|

Resource Origin | Natural minerals | Gypsum, paper from wood pulp | Wood |

Manufacturing Energy | Low | Moderate to high | Moderate |

CO2 Emissions | Low | Moderate | Varies |

Recyclability | Recyclable | Hard to recycle | Can be repurposed |

Harmful Chemicals | None | Sometimes present | Sometimes present |

Indoor Air Quality | Healthy | Can off-gas VOCs | Can off-gas VOCs |

Waste Generation | Low | High | Moderate |

You can recycle magnesium oxide boards when you are done with them. Recycling uses less energy and keeps trash out of landfills. Using these boards helps the planet and supports green building.

Tip: Always look for water problems before you put up the boards. This helps stop mold and rust.

Health and Safety

Magnesium oxide boards help keep your team safe. They do not burn or let fire spread. The boards stay strong even in very hot fires. They do not make dangerous smoke if there is a fire. This means workers breathe cleaner air and stay healthier. The boards do not let out harmful chemicals.

Here are some health and safety benefits:

Fire resistance makes your workshop safer.

Boards do not let mold grow because they resist water.

They are tough and do not break easily.

The boards are light, so you can move and install them easily.

No toxic chemicals means the air is better to breathe.

Longevity

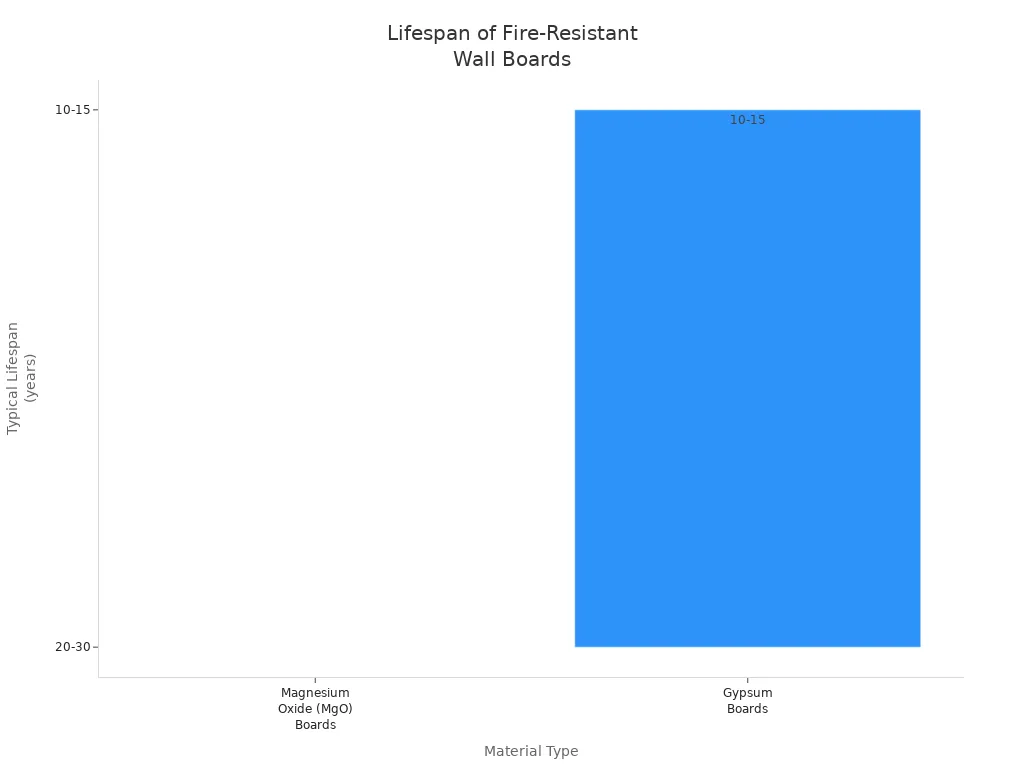

You want walls that last a long time. Magnesium oxide boards can last 20 to 30 years in busy workshops. They do not get damaged by bumps, water, or mold. You will not need to fix or replace them often. Gypsum boards usually last only 10 to 15 years and need more repairs.

You save money because these boards last longer and work well in tough places.

Magnesium wall board helps make workshops safer. It stops fire, mold, and damage from hits. Many experts say it is good for walls in busy places. You get fresh air and strong walls.

Pick the thickness that fits your job.

Use expert tips to install it well.

Get help and guides from US MgO Company and MagPanel®.

Feature | Benefit |

|---|---|

Fire Resistance | Work areas are safer |

Durability | You fix walls less |

Easy Install | You save time and work |

FAQ

What makes magnesium wall boards safer than regular drywall?

Magnesium wall boards do not burn. They do not make toxic smoke. You get more time to escape during a fire. These boards also last longer in tough places.

Can you install magnesium wall boards in wet areas?

Yes, you can use them in bathrooms, basements, and kitchens. They resist water, mold, and mildew. Always seal the joints and use rust-proof screws for best results.

Do magnesium wall boards need special tools for cutting?

You can cut magnesium wall boards with standard tools. Use a utility knife, saw, or shears. Wear a mask to avoid breathing in dust.

Are magnesium wall boards eco-friendly?

Yes! These boards use natural minerals. Factories use less energy to make them. They do not have harmful chemicals. You help the planet when you choose them.

How do you keep magnesium wall boards strong for many years?

Tip: Store boards in a dry place. Seal all edges and joints. Use stainless steel fasteners. Check for leaks or damage often. This keeps your walls strong and safe.

Composition

Composition